Method for producing liquid oxygen and liquid nitrogen through LNG cold energy and single-tower rectification technology

A technology of liquid oxygen, liquid nitrogen, and rectification, which is applied in the field of air separation-LNG utilization, can solve the problems of complex process and low utilization rate of LNG cold energy, and achieve the effect of simple circulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

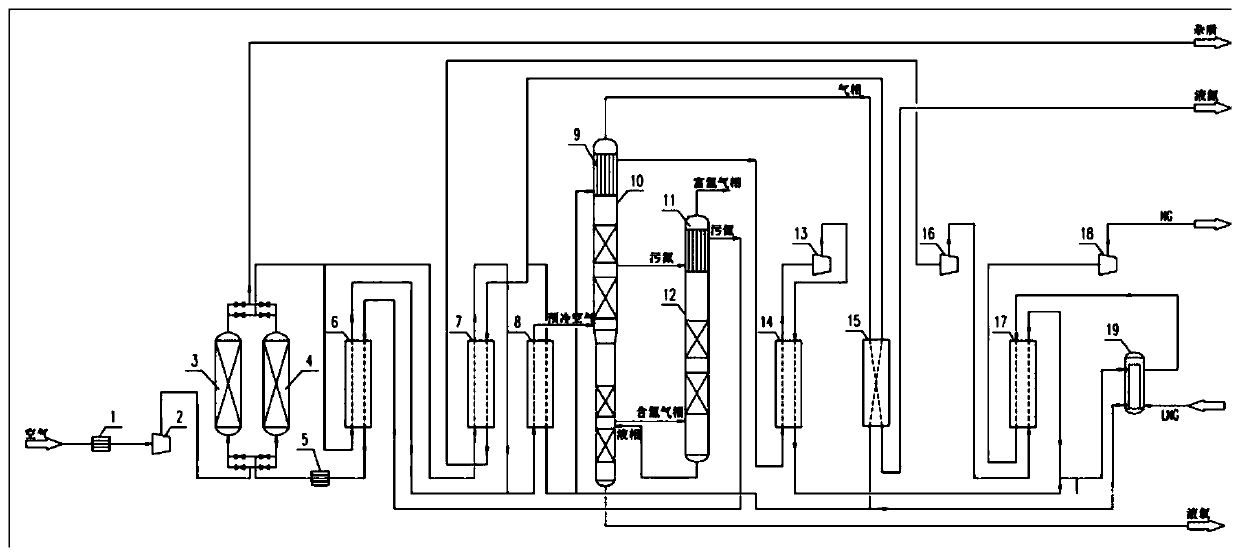

[0051] The method for producing liquid oxygen and liquid nitrogen by using LNG cold energy and single-column rectification process, the flow chart is as follows figure 1 , including the following steps:

[0052] (1) Purification step

[0053] The air at normal temperature and pressure enters the air compressor 2 after being filtered by the air filter 1 and is pressurized to 0.8MPa; the pressurized air passes through the purifier I 3 to remove impurities in the air, and the purified air reaches the standard allowed by the air separation process; at the same time, the purifier II 4 performs a regeneration operation; when the purifier I 3 is saturated with impurities in the adsorbed air, switch to the regenerated purifier II 4 to continue purifying the air, and the purifier I 3 starts a regeneration operation; the purifier I 3 and the purifier II 4 alternate Carry out purification operation and regeneration operation for air purification cycle operation;

[0054] (2) Cooling st...

Embodiment 2

[0074] The method for producing liquid oxygen and liquid nitrogen by using LNG cold energy and single-column rectification process, the flow chart is as follows figure 1 , including the following steps:

[0075] (1) Purification step

[0076] The air at normal temperature and pressure is filtered by the air filter 1 and then enters the air compressor 2 to pressurize to 500KPa; the pressurized air passes through the purifier I 3 to remove impurities in the air, and the purified air reaches the standard allowed by the air separation process; at the same time, the purifier II 4. Perform a regeneration operation; when the purifier I 3 absorbs impurities in the air and is saturated, switch to the regenerated purifier II 4 to continue purifying the air, and the purifier I 3 starts a regeneration operation; the purifier I 3 and purifier II 4 are alternately performed Purification operation and regeneration operation for air purification cycle operation;

[0077] (2) Cooling step

...

Embodiment 3

[0089]The method for producing liquid oxygen and liquid nitrogen by using LNG cold energy and single-column rectification process, the flow chart is as follows figure 1 , including the following steps:

[0090] (1) Purification step

[0091] The air at normal temperature and pressure enters the air compressor 2 and is pressurized to 1.2MPa after being filtered by the air filter 1; II 4 performs a regeneration operation; when the purifier I 3 is saturated with impurities in the adsorbed air, switch to the regenerated purifier II 4 to continue purifying the air, and the purifier I 3 starts a regeneration operation; the purifier I 3 and the purifier II 4 alternate Carry out purification operation and regeneration operation for air purification cycle operation;

[0092] (2) Cooling step

[0093] After the purified air is cooled by heat exchanger I 6 and heat exchanger II 7 arranged side by side, it enters heat exchanger III 8 again for secondary cooling to obtain pre-cooled air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com