Tough anti-electrostatic double-network silicone hydrogel and preparation method thereof

A technology of silicon hydrogel and double network is applied in the field of toughness and antistatic double network silicon hydrogel and its preparation, which can solve the problem that the hydrogel cannot have mechanical and mechanical properties, self-healing properties, fatigue resistance and antistatic properties at the same time. performance, complex preparation method, low production efficiency and other problems, to achieve the effect of improving comprehensive mechanical and mechanical properties, simple preparation method and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

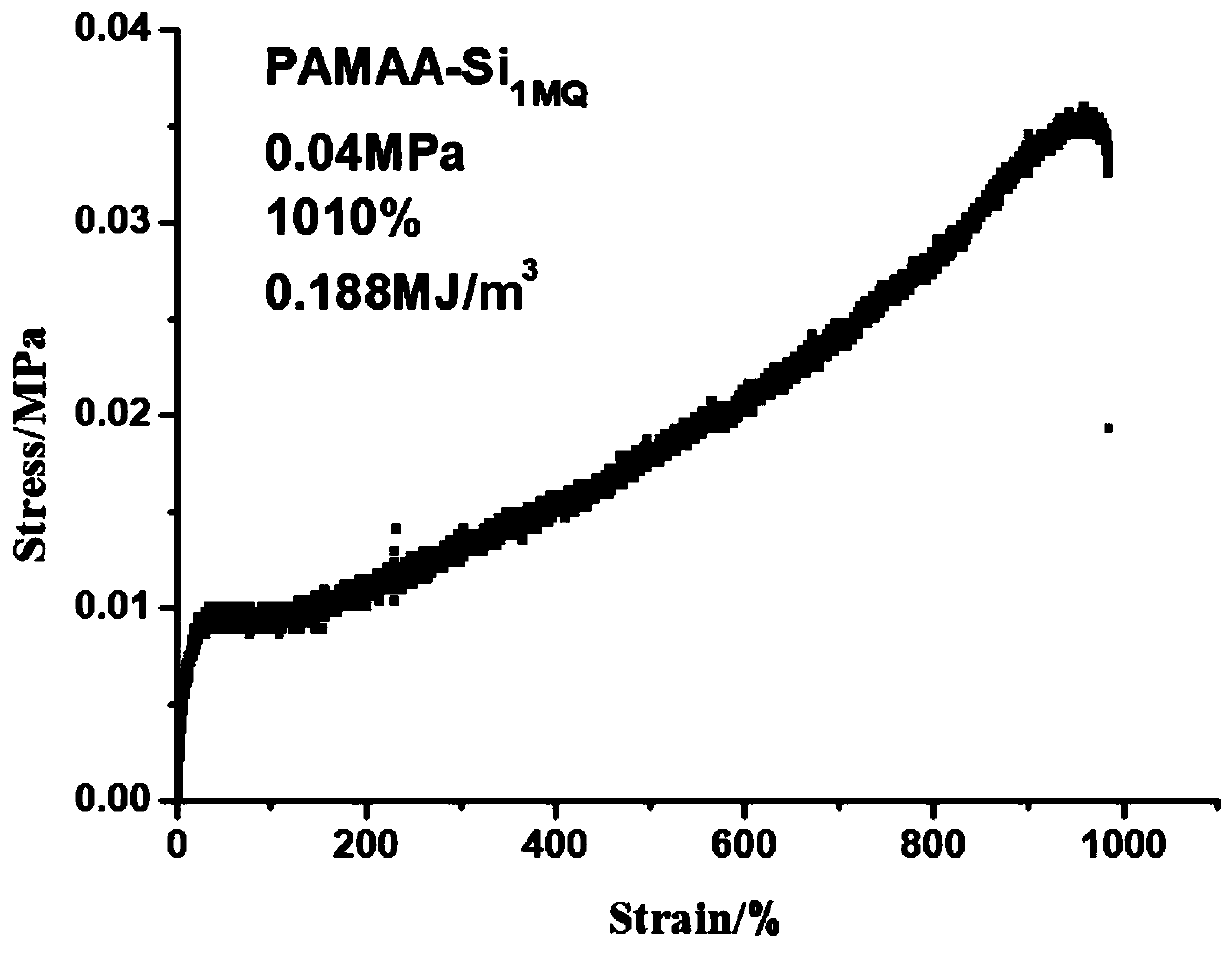

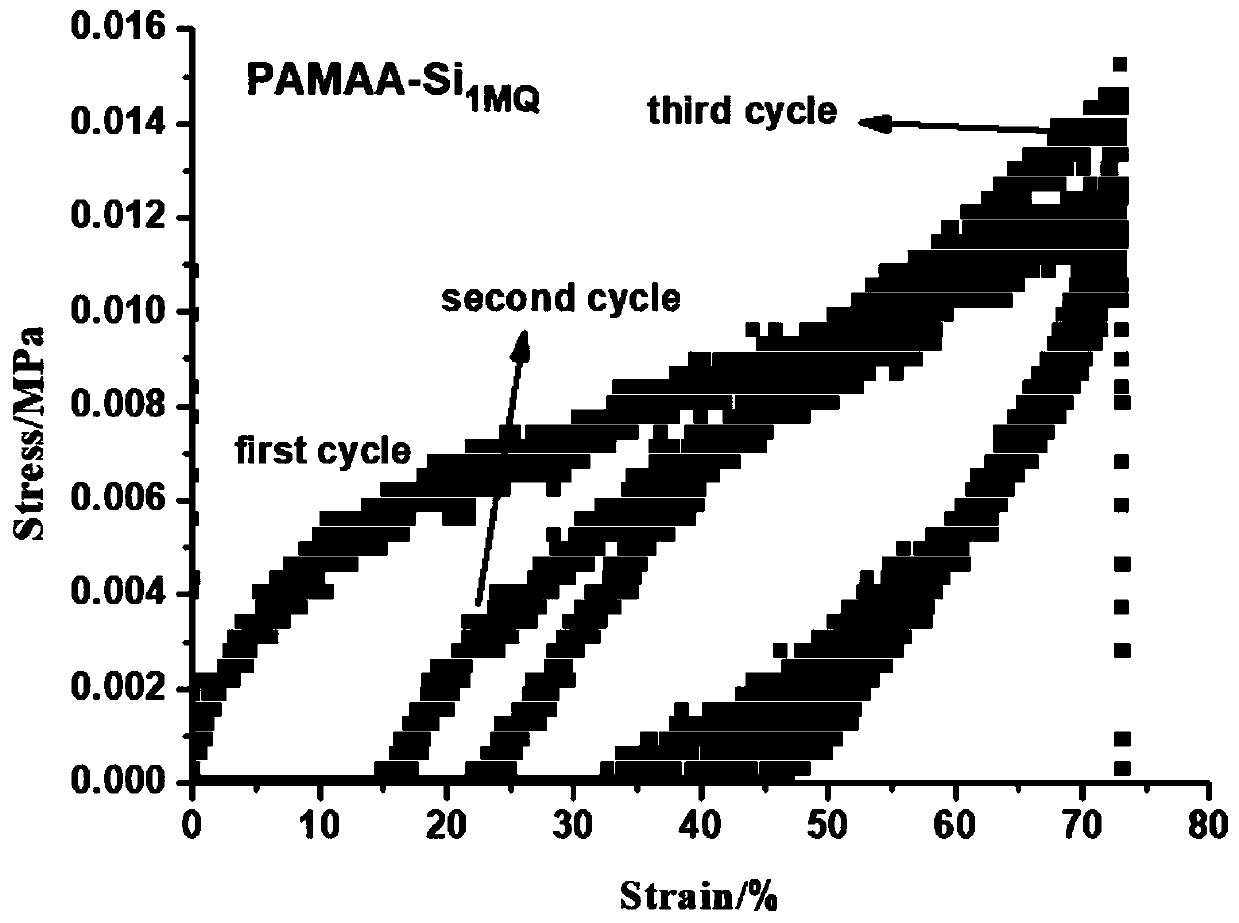

[0042] Put 24mL of deionized water into a 100mL beaker, add 3.75g of acrylamide AM, 0.47g of acrylic acid AA and 15mg of N,N-dimethylbisacrylamide dissolved in deionized water, then add 2mL of ethanol, 1g of hexamethyldisiloxane alkane, 3.25g ethyl orthosilicate, 1mL concentrated hydrochloric acid and 5mg potassium persulfate, mix well to obtain a mixed solution, then heat the mixed solution to 70°C, polymerize for 24 hours, and when the polymerization is complete, place the hydrogel in Dialyzed in deionized water to remove residual monomers and hydrochloric acid to prepare the silica hydrogel PAMAA-Si 1MQ (1 represents the volume mL of concentrated hydrochloric acid added, M and Q represent silicon monomers hexamethyldisiloxane and ethyl orthosilicate respectively).

[0043] 1, the silicon hydrogel PAMAA-Si that the present embodiment obtains 1MQ Using a surface resistivity meter to test, the result shows that the surface resistivity is 10 4 Ω, has good antistatic propertie...

Embodiment 2

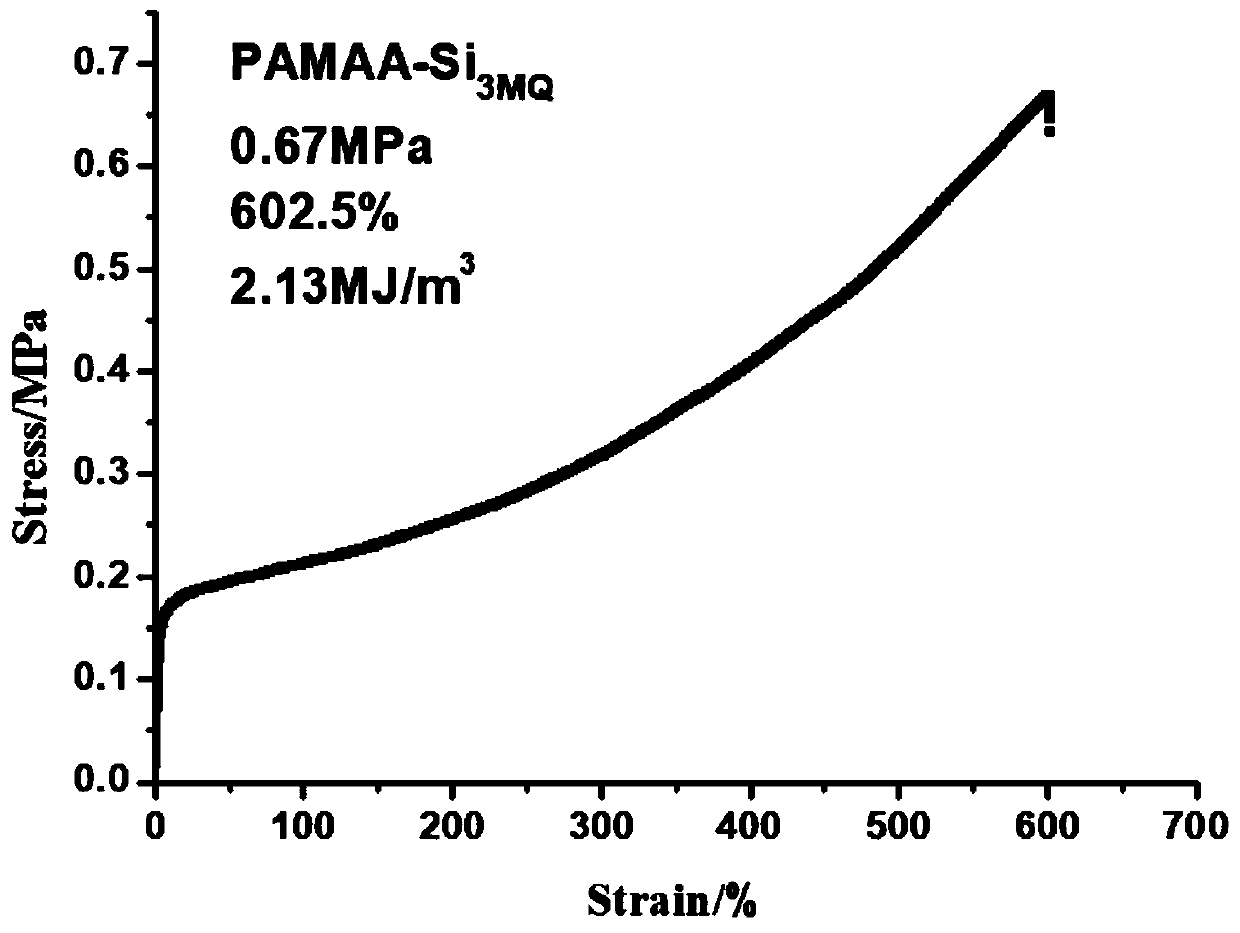

[0049] Put 24mL of deionized water into a 100mL beaker, add 3.75g of acrylamide AM, 0.47g of acrylic acid AA and 15mg of N,N-dimethylbisacrylamide dissolved in deionized water, then add 2mL of ethanol, 1g of hexamethyldisiloxane alkane, 3.25g tetraethyl orthosilicate, 3mL concentrated hydrochloric acid and 5mg potassium persulfate, mix well to obtain a mixed solution, then heat the mixed solution to 70°C, and react for 24h. Dialyze in deionized water for 24 hours to remove residual monomers and hydrochloric acid, and prepare the silicon hydrogel PAMAA-Si 3MQ (3 represents the volume mL of concentrated hydrochloric acid added, M and Q represent silicon monomers hexamethyldisiloxane and ethyl orthosilicate respectively).

[0050] 1, the silicon hydrogel PAMAA-Si that the present embodiment obtains 3MQ Using a surface resistivity tester, the result shows that the surface resistance is 10 4 Ω, indicating that it has good antistatic properties.

[0051] 2, the silicon hydrogel P...

Embodiment 3

[0056] Put 24mL of deionized water into a 100mL beaker, add 3.75g of acrylamide AM, 0.47g of acrylic acid AA and 15mg of N,N-dimethylbisacrylamide dissolved in deionized water, then add 2mL of ethanol, 3.25g of ethyl orthosilicate , 3mL of concentrated hydrochloric acid and 5mg of potassium persulfate were uniformly mixed to obtain a mixed solution, and then the mixed solution was heated to 70°C, and the polymerization reaction was carried out for 24 hours. After the polymerization reaction, the hydrogel was dialyzed in deionized water for 24 hours to remove residual monomers body and hydrochloric acid, the silicon hydrogel PAMAA-Si was prepared 3Q (3 represents the volume mL of concentrated hydrochloric acid added, and Q represents silicon monomer tetraethyl orthosilicate).

[0057] 1, the silicon hydrogel PAMAA-Si that the present embodiment obtains 3Q Using a surface resistivity tester, the result shows that the surface resistance is 10 4 Ω, has good antistatic properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fracture energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com