Method for co-producing 3,5-dimethylbenzoic acid and trimesic acid

A technology of dimethylbenzoic acid and trimesic acid, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate salts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

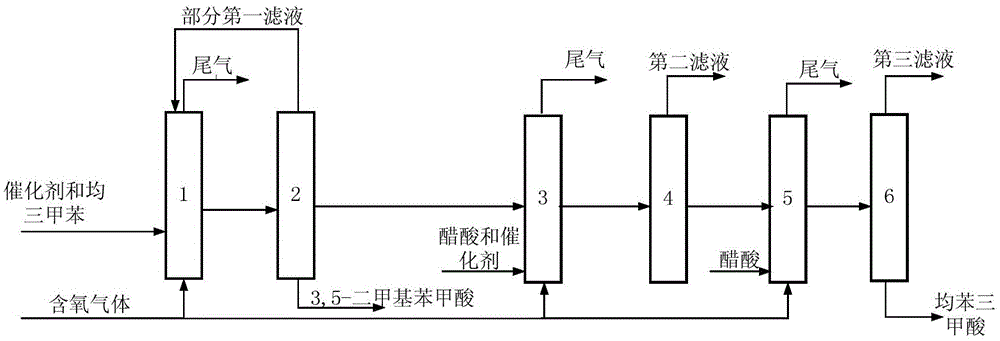

Method used

Image

Examples

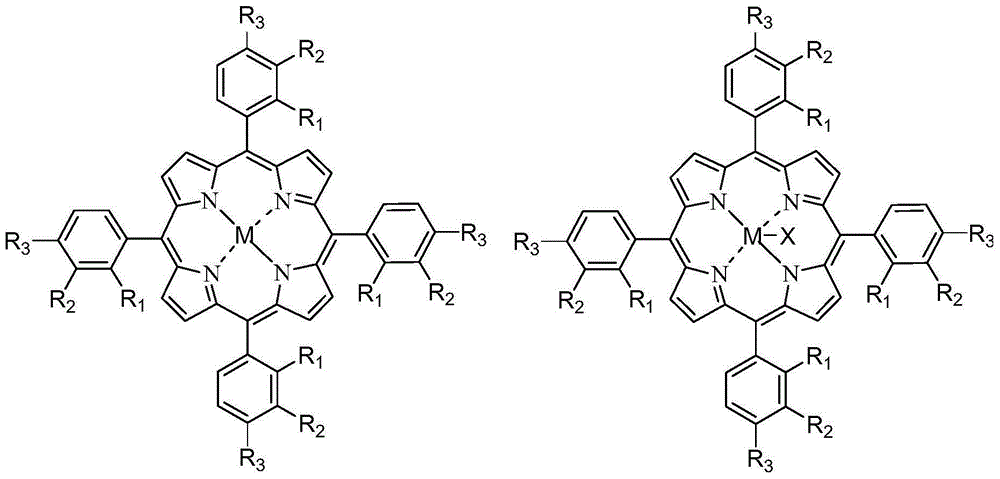

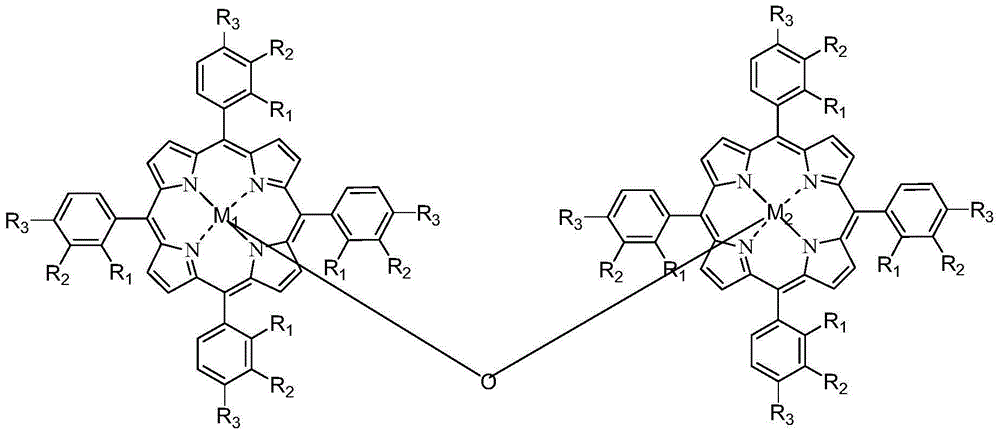

Embodiment 1

[0081] The catalyst that dissolves in the fresh mesitylene that adds system is N-hydroxyl phthalimide, the metal phthalocyanine (R with general formula (IV) structure 1 = H, R 2 =H, M=Co), Co(Ac) 2· 4H 2 O and the metalloporphyrin (R 1 = R 2 = R 3 = H, M 1 = M 2 =Mn) with a total concentration of 800 ppm. When the device is in steady state operation, the flow rate of fresh mesitylene entering the primary oxidation reactor is 55.5L / h, the flow rate of the first filtrate rich in nine-carbon oxygenate intermediates is 24.9L / h, and the total flow rate is 80.4 L / h. Now the average residence time of the primary oxidation reactor in terms of liquid phase substances is 3h, and the pressurized air with an oxygen mass percentage concentration of 21% is continuously passed into the primary oxidation reactor to maintain the system reaction temperature at 120°C. The pressure is 0.5 MPa. The primary oxidation reaction solution is continuously fed into the primary separation system...

Embodiment 2

[0083] The catalyst dissolved in the fresh mesitylene added to the primary oxidation reactor is N-hydroxyphthalimide, metal phthalocyanine (R) with general formula (IV) structure 1 =OH, R 2 =H, M=Ru), cobalt naphthenate and metalloporphyrin (R 1 = R 3 = H, R 2 =OH,M 1 = M 2 =Mn), the total concentration is 10000ppm. During the steady state operation of the device, the operating process is the same as in Example 1, the operating conditions of the primary oxidation reactor are as shown in Table 1, the operating conditions of the secondary oxidation reactor are as shown in Table 2, and the operating conditions of the aging reactor are as shown in Table 3 shown. Under these operating conditions, the quality, purity, yield, yield and conversion of mesitylene are listed in Table 4 for each product obtained.

Embodiment 3

[0085] The catalyst dissolved in fresh mesitylene added to the primary oxidation reactor is CeO 2 , cobalt acetylacetonate and metallophthalocyanine (R 1 = H, R 2 =CH 3 CH 2 , M=Mn) mixture, the total concentration is 450ppm. During the steady state operation of the device, the operating process is the same as in Example 1, the operating conditions of the primary oxidation reactor are as shown in Table 1, the operating conditions of the secondary oxidation reactor are as shown in Table 2, and the operating conditions of the aging reactor are as shown in Table 3 shown. Under these operating conditions, the quality, purity, yield, yield and conversion of mesitylene are listed in Table 4 for each product obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com