Method for purifying ursodeoxycholic acid by mixed solvent

A technology of ursodeoxycholic acid and mixed solvent, applied in the field of medicine, can solve the problems of high yield of ursodeoxycholic acid, high energy consumption of solvent recovery, small solvent consumption, etc. The effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

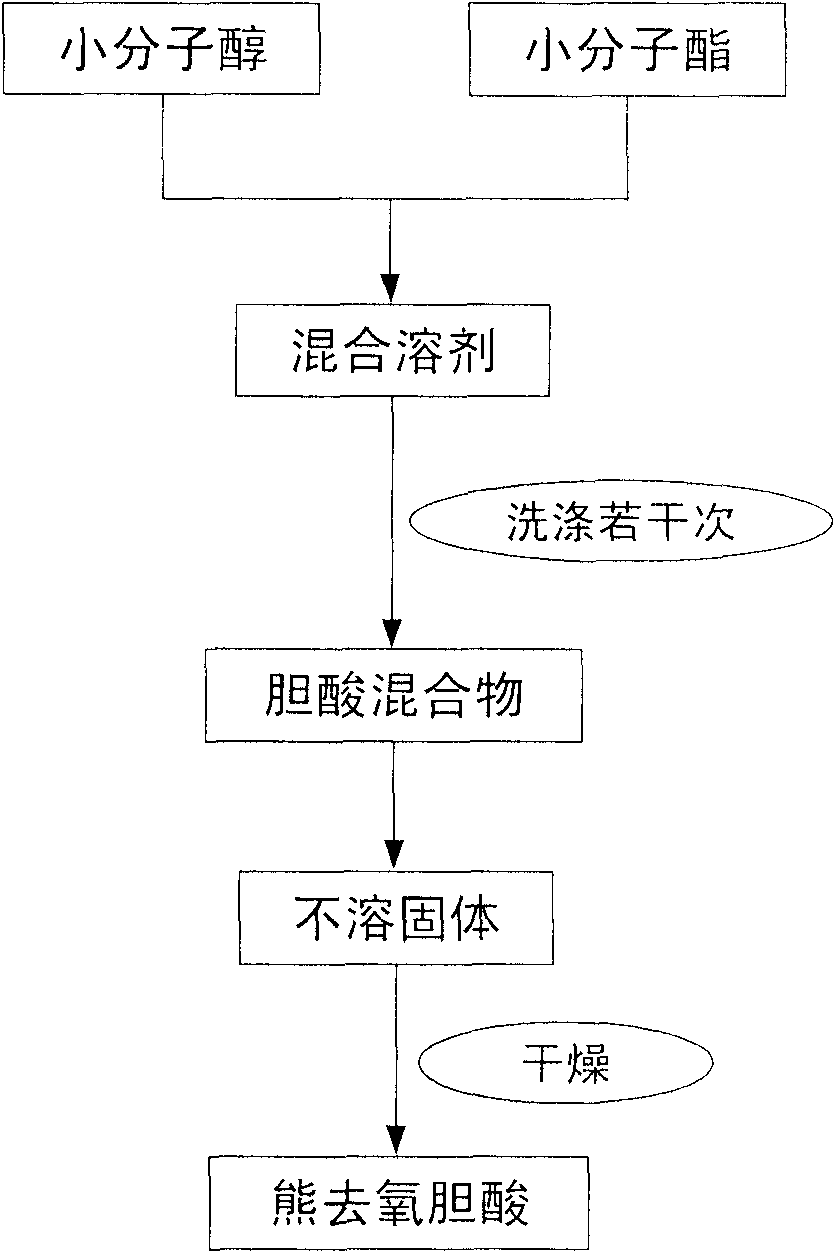

Image

Examples

Embodiment 1

[0011] Get ethanol 0.5kg, ethyl acetate 9.5kg, mix and make the mixed solvent that weight ratio is 5:95. Take 1 kg of cholic acid mixture to be purified, the purity of ursodeoxycholic acid is 60% by mass fraction, add 1.6 kg of mixed solvent at one time, stir for 1 h, and then keep it sealed for 20 h. Filtration gave an insoluble solid. The insoluble solid was dried to obtain 0.56 kg of ursodeoxycholic acid product. The purity of the ursodeoxycholic acid product was determined by high performance liquid chromatography, and it was 95.3% in terms of mass fraction.

[0012] The chromatographic condition that high performance liquid chromatography measures ursodeoxycholic acid product purity is:

[0013] The column is Dima C 18 Column (250mm×4.6mm i.d., 5μm), the mobile phase is 0.2% acetic acid acetonitrile-0.2% acetic acid water (70:30), the flow rate is 1.0mL / min, the column temperature is 30°C, and the injection volume is 10μL; : Evaporative light scattering detector (ELSD...

Embodiment 2

[0018] Get n-propanol 1kg, ethyl acetate 9kg, mix and make the mixed solvent that weight ratio is 1:9. Take 1 kg of cholic acid mixture to be purified, and its ursodeoxycholic acid purity is 70% in terms of mass fraction. Add 0.8 kg of mixed solvent for washing, stir for 1 h, then seal and let stand for 5 h, filter, and wash the insoluble solid again once more. The insoluble solid was dried to obtain 0.65 kg of ursodeoxycholic acid product, and the purity of the ursodeoxycholic acid product was determined according to the high performance liquid chromatography conditions of Example 1, and it was 96.3% in mass fraction.

Embodiment 3

[0020] Get isopropanol 2kg, isopropyl acetate 8kg, mix and make the mixed solvent that weight ratio is 2:8. Take 1 kg of the cholic acid mixture to be purified, and its ursodeoxycholic acid purity is 55% by mass fraction. Add 0.4kg of mixed solvent to dissolve, stir for 1 hour, then seal and let stand for 5 hours, then filter to obtain insoluble solid. The above washing process was repeated 4 times. The insoluble solid was dried to obtain 0.48 kg of ursodeoxycholic acid product, and the purity of the ursodeoxycholic acid product was determined according to the high performance liquid chromatography conditions of Example 1, and it was 97.6% by mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com