General automatic feeding pinprick mechanism for vehicle decoration product line

A technology for auto trim and automatic feeding, which is applied in the direction of manipulators, object separation, thin material handling, etc. It can solve the problems of high labor intensity of workers, uneven product quality, and inability to meet on-site production, so as to reduce the labor intensity of workers and ensure Stability, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

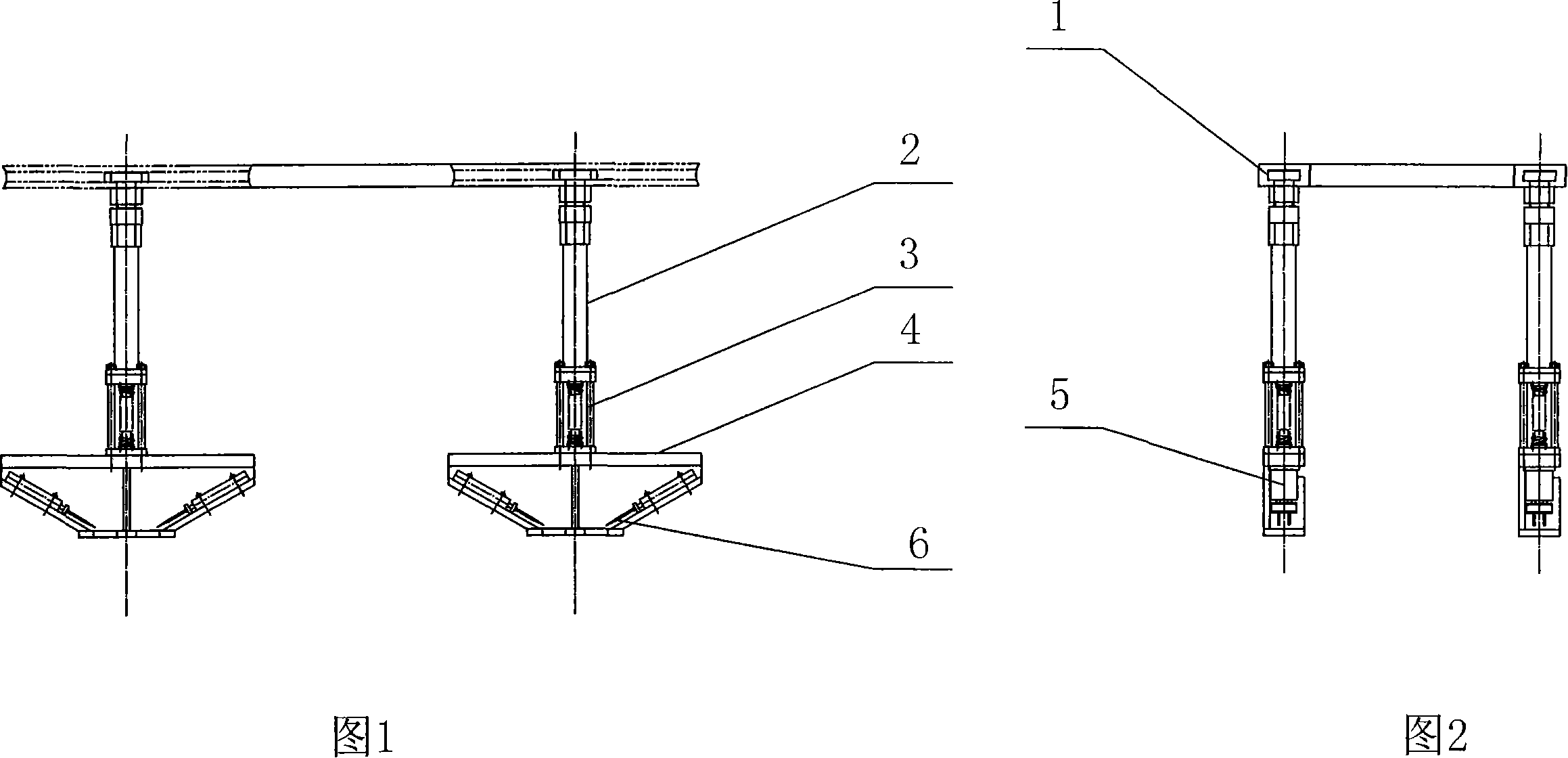

[0010] The present invention is mainly composed of a T-shaped groove 1, a supporting column 2, an elastic device 3, a slanting puncture cylinder seat 4, a sliding seat cylinder 5, a needle 6 and the like. As shown in the figure: there is a support column 2 under the support 1, a slanted cylinder block 4 is arranged at the lower end of the support column 2, and an elastic device 3 is arranged between the support column 2 and the slanted thorn cylinder block 4. Two sliding seat cylinders 5 are symmetrically installed below 4, and the lower end of each sliding seat cylinder 5 inwardly inclines to claim a cross shape, and thorns 6 are arranged on the piston rod of each sliding seat cylinder 5. The bracket 1 is composed of T-shaped groove components. Use two sliding seat cylinders 5 as the power source to carry out combined movement along the track of the fork, and then use the elastic connection between the support column 2 and the elastic device 3 and the oblique thorn cylinder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com