Lithium battery leading-out electrode with high charge-discharge rate

A charge-discharge rate and lead-out electrode technology, which is applied in the field of lithium battery lead-out electrodes, can solve problems such as difficulties in lead-out electrodes of thin-film current collectors, and achieve the effects of avoiding short-circuiting between positive and negative electrodes, small internal resistance, and large connection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

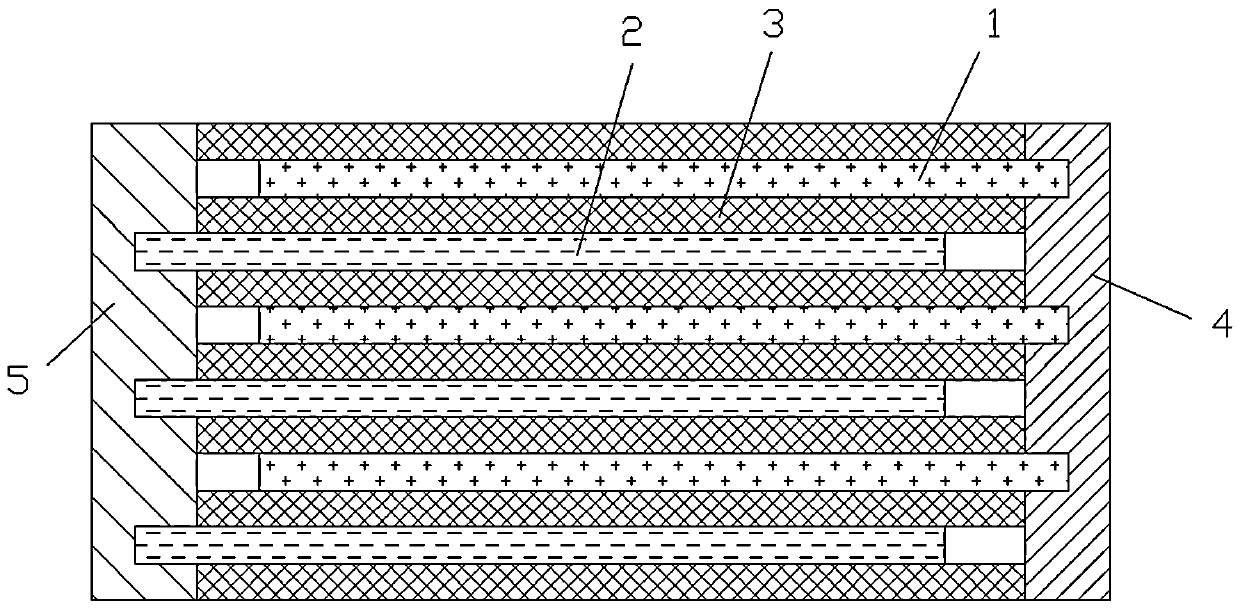

[0015] Such as figure 1 As shown, the present invention provides a lithium battery lead-out electrode with a high charge-discharge rate. The positive current collector 1, the separator 3 and the negative current collector 2 are sequentially stacked or wound; the positive current collector 1, the separator 3 and the negative current collector 2 The overlapping area is the active area of the battery chemical reaction. The protruding end of the positive electrode collector 1 is located on one side of the lithium battery, and the protruding end of the negative electrode collector 2 is located on the other side of the lithium battery; Positive gold-sprayed layer 4 is deposited on the end as an effective connection area, and the positive gold-sprayed layer 4 is electrically connected to each positive electrode collector 1, and the protruding end of the negative electrode collector 2 is deposited as an effective connection area. Layer 5 is electrically connected to each negative el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com