Patents

Literature

31results about How to "Reduce the chance of tearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

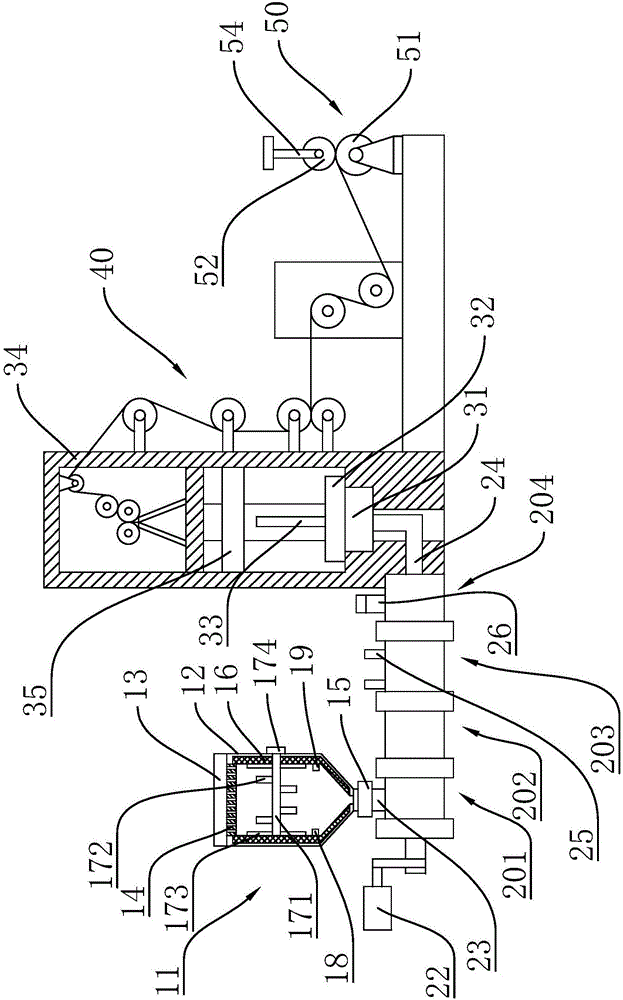

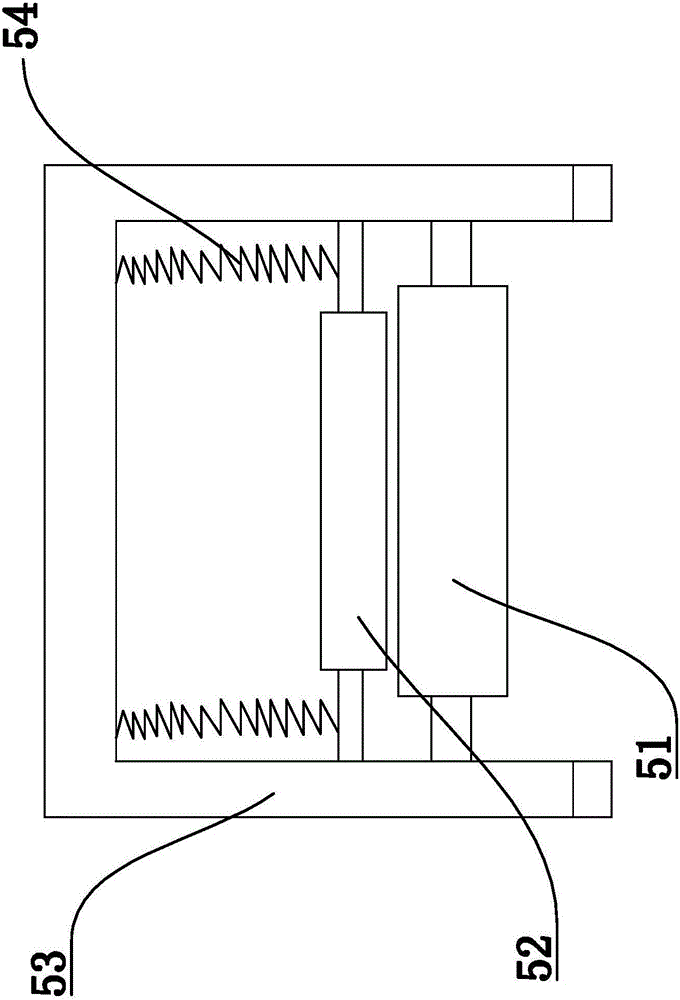

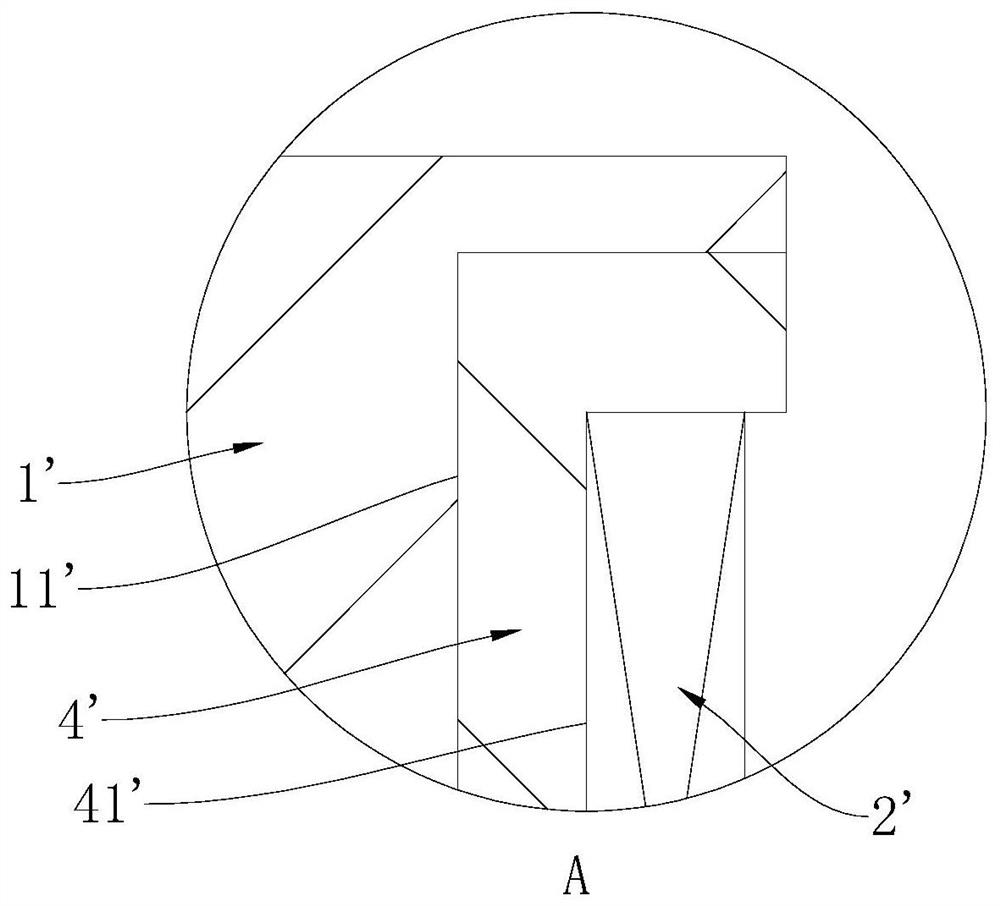

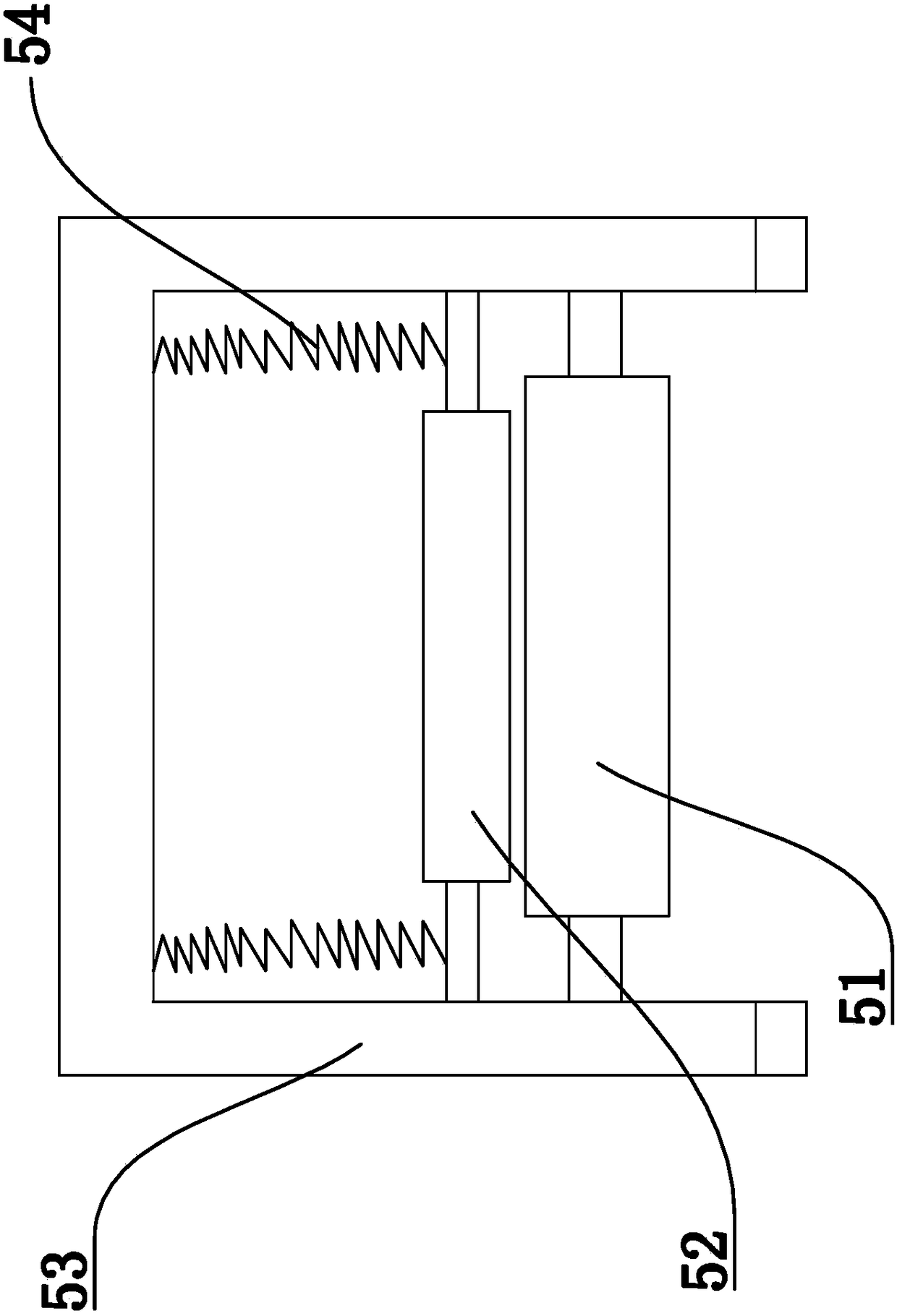

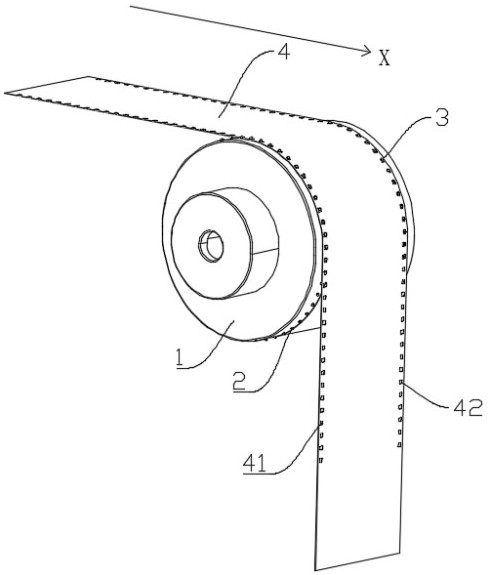

Film blowing machine with improved winding mechanism

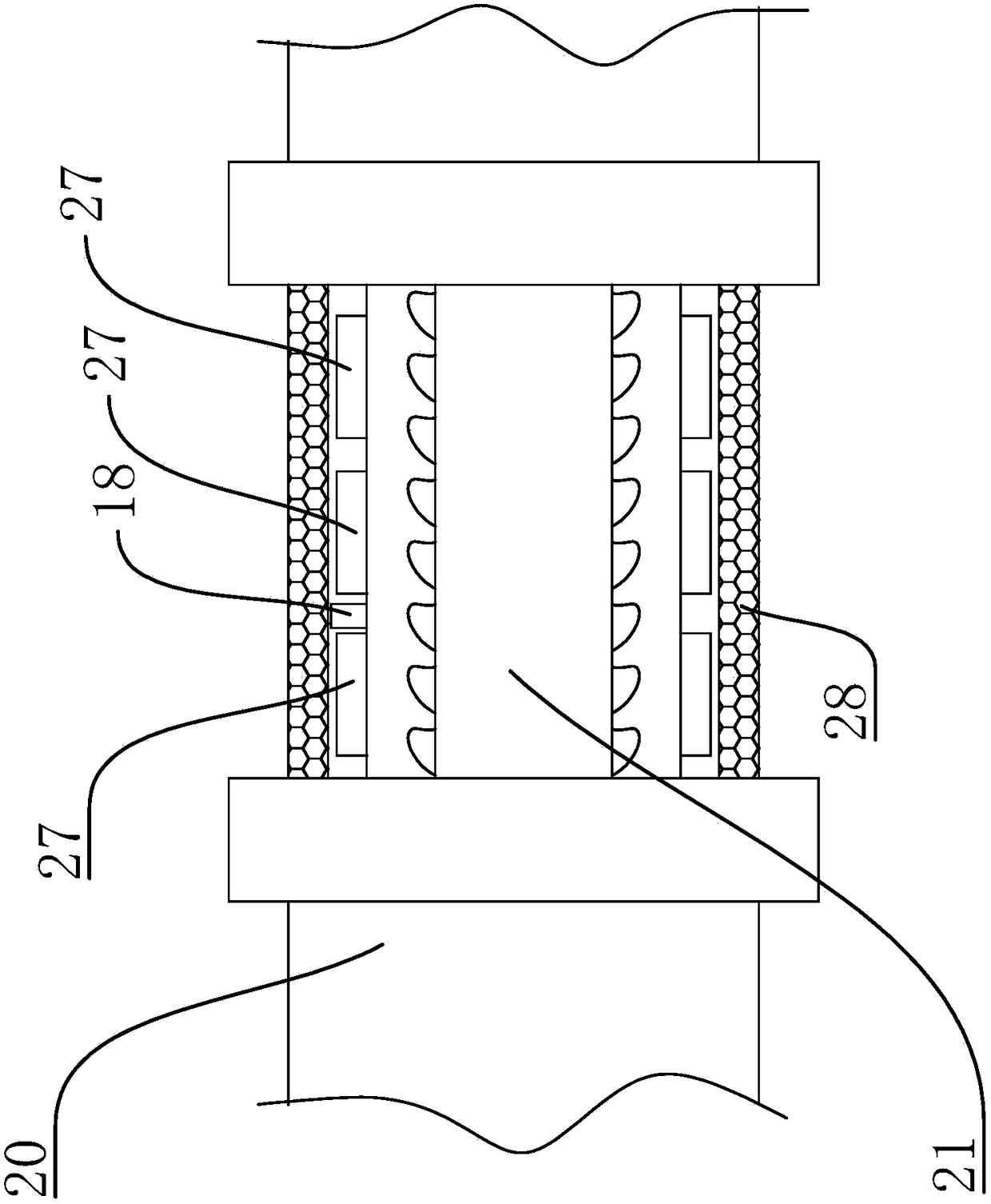

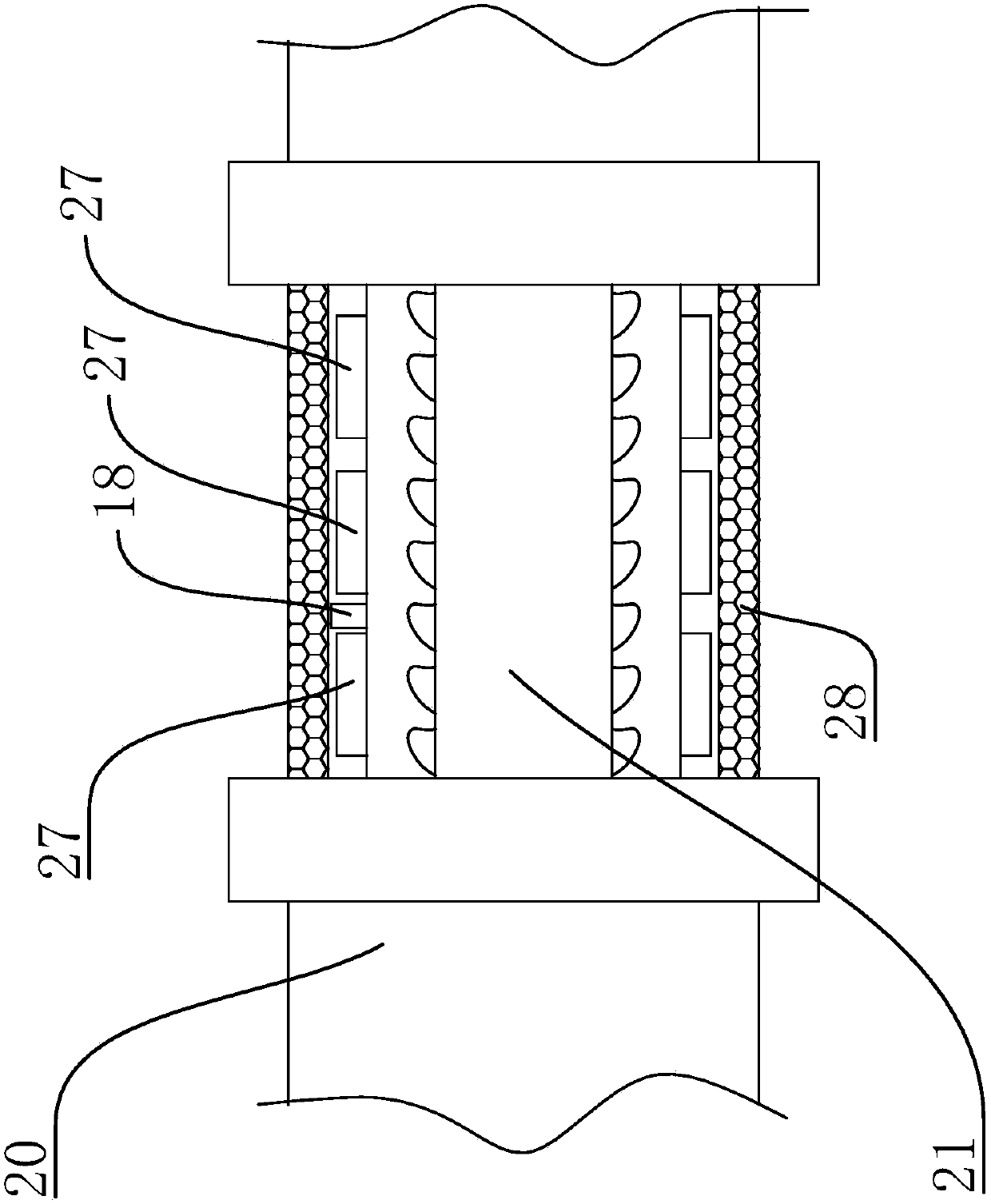

The invention provides a film blowing machine with an improved winding mechanism. Th film blowing machine comprises an extrusion mechanism, a film blowing mechanism, a traction mechanism and the winding mechanism. The film blowing mechanism comprises a die head, an air ring and a rack. The air ring is arranged on the die head. The die head and the air ring are fixedly arranged at the lower end of the rack. The traction mechanism is arranged at the upper end of the rack. The extrusion mechanism is provided with a discharge outlet connected with the die head. The winding mechanism comprises a winding shaft, a belt and a motor, wherein the winding shaft is used for winding thin films. The motor is in transmission connection with the winding shaft through the belt. The thin films blown out from the die head are conveyed to the winding shaft through the traction mechanism. A press shaft capable of pressing the thin films is arranged above the winding shaft. The winding mechanism further comprises a support frame and elastic suspended arms. The press shaft is connected to the support frame through the elastic suspended arms. According to the film blowing machine with the improved winding mechanism, deviation of the thin films in the winding process can be avoided, and dislocation of an upper layer and a lower layer of a thin film is prevented.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

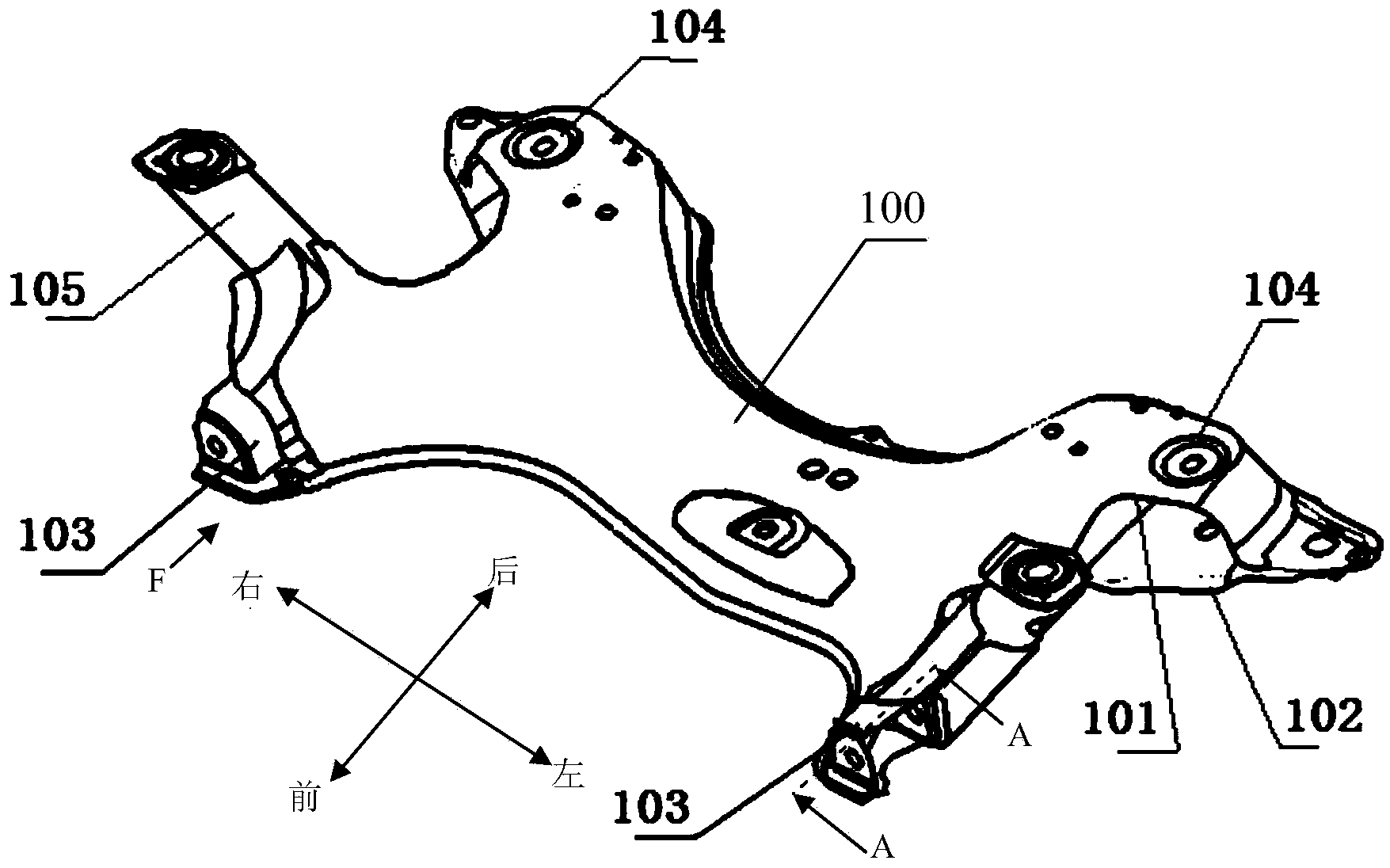

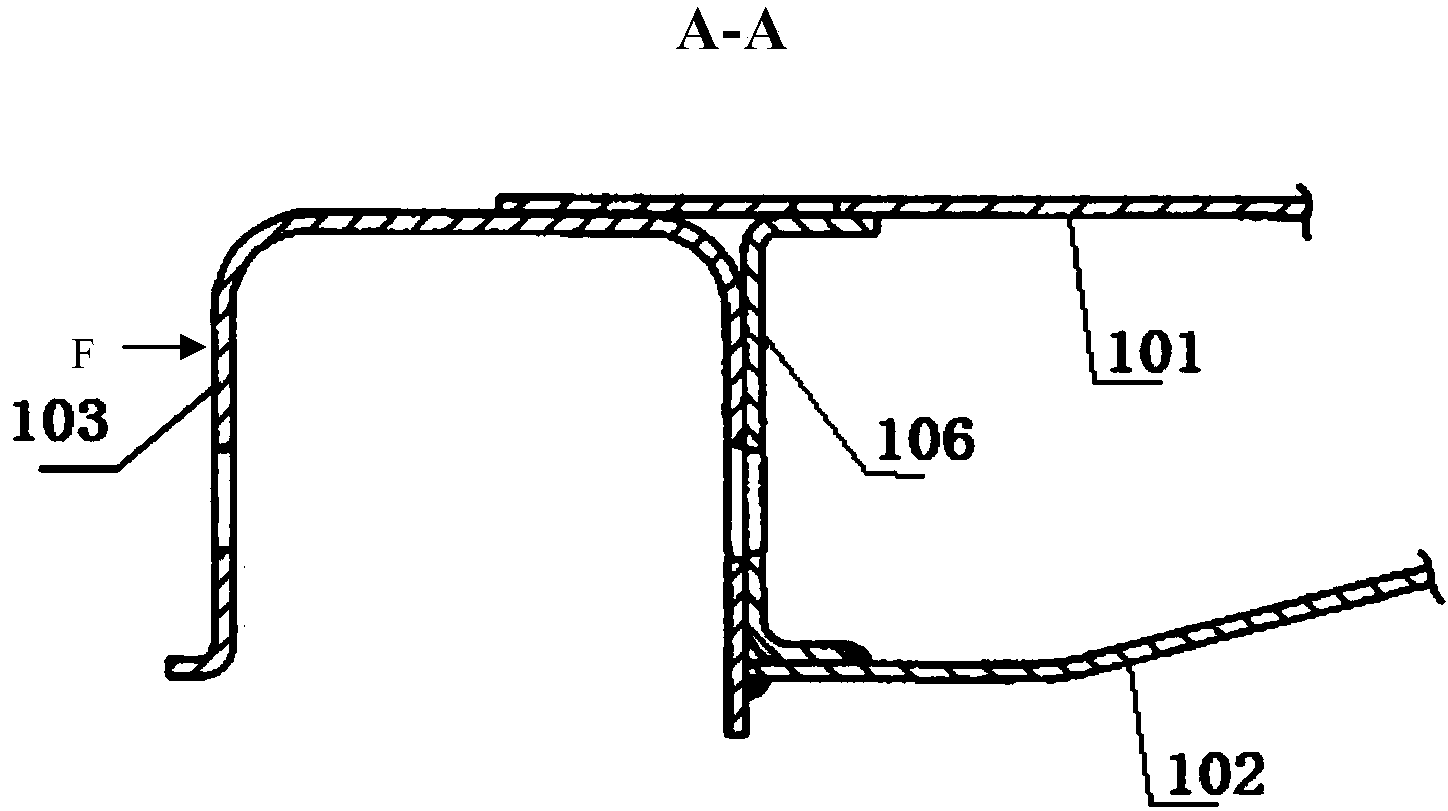

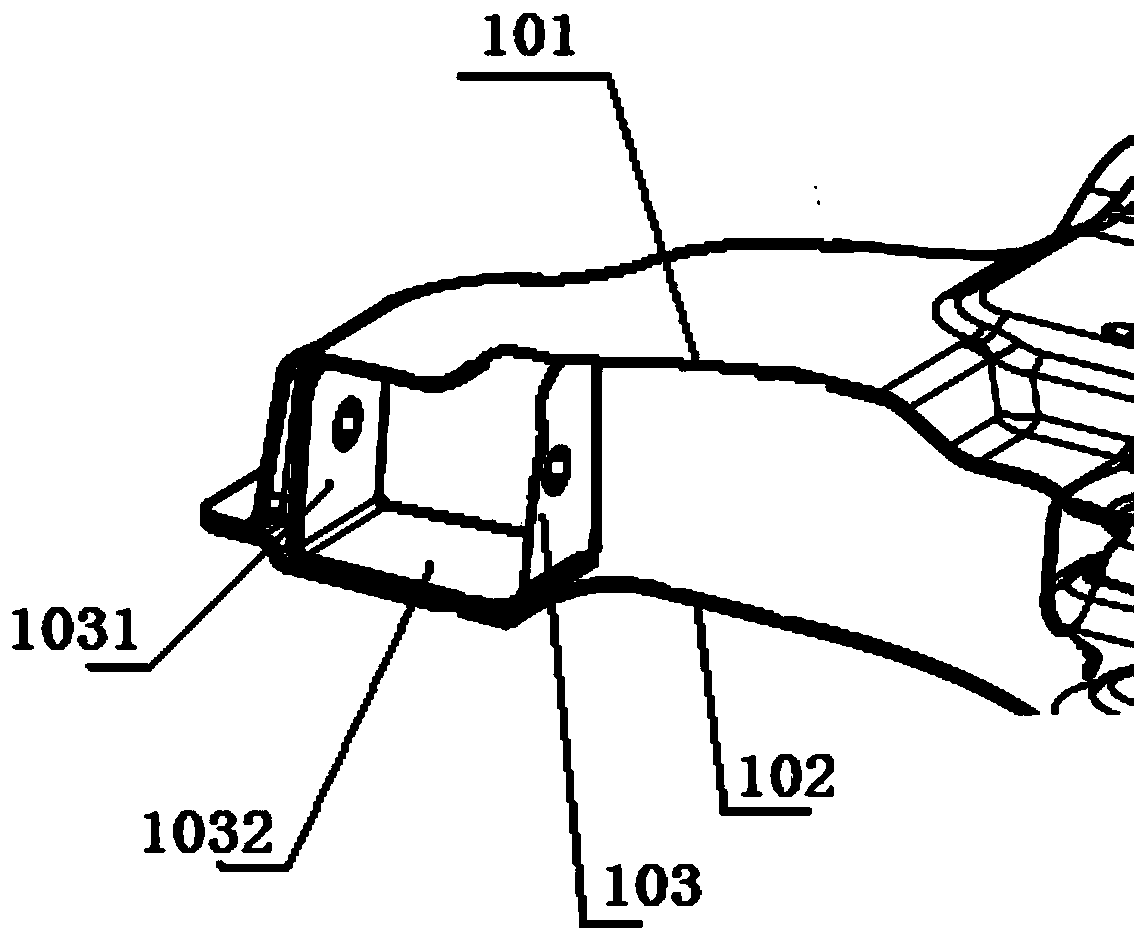

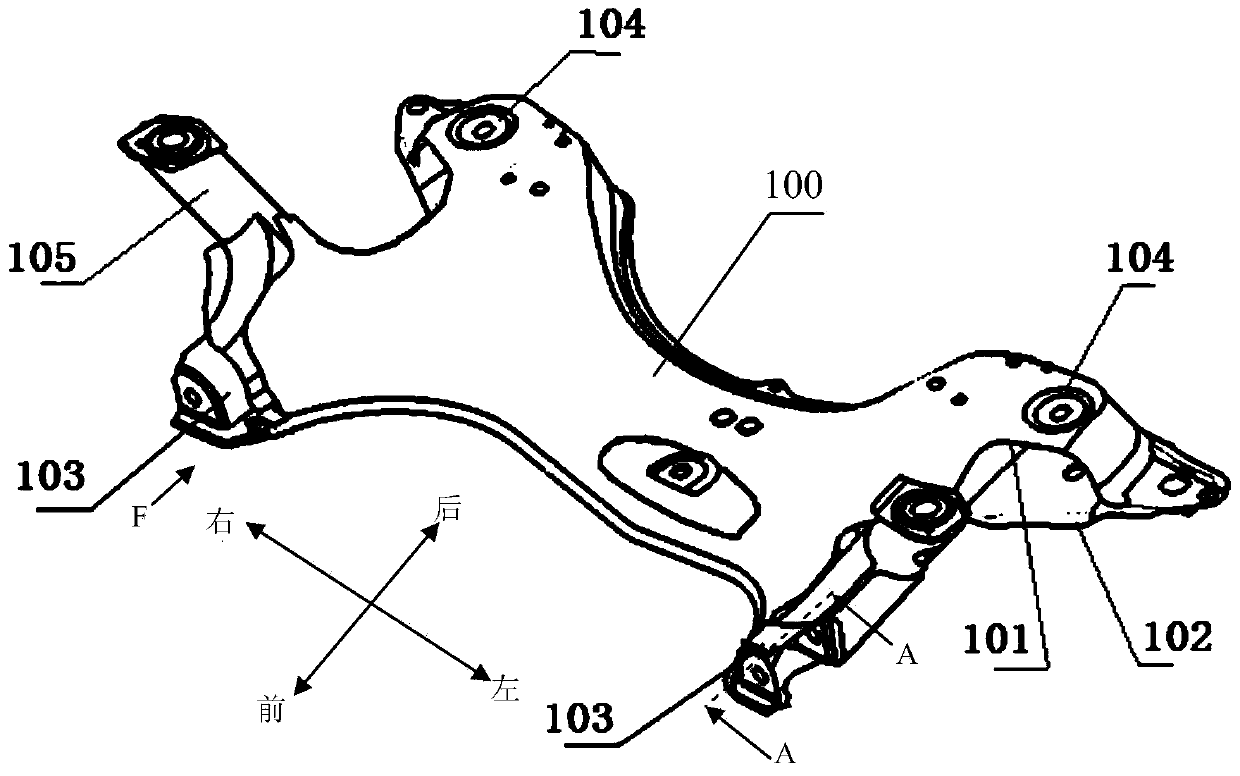

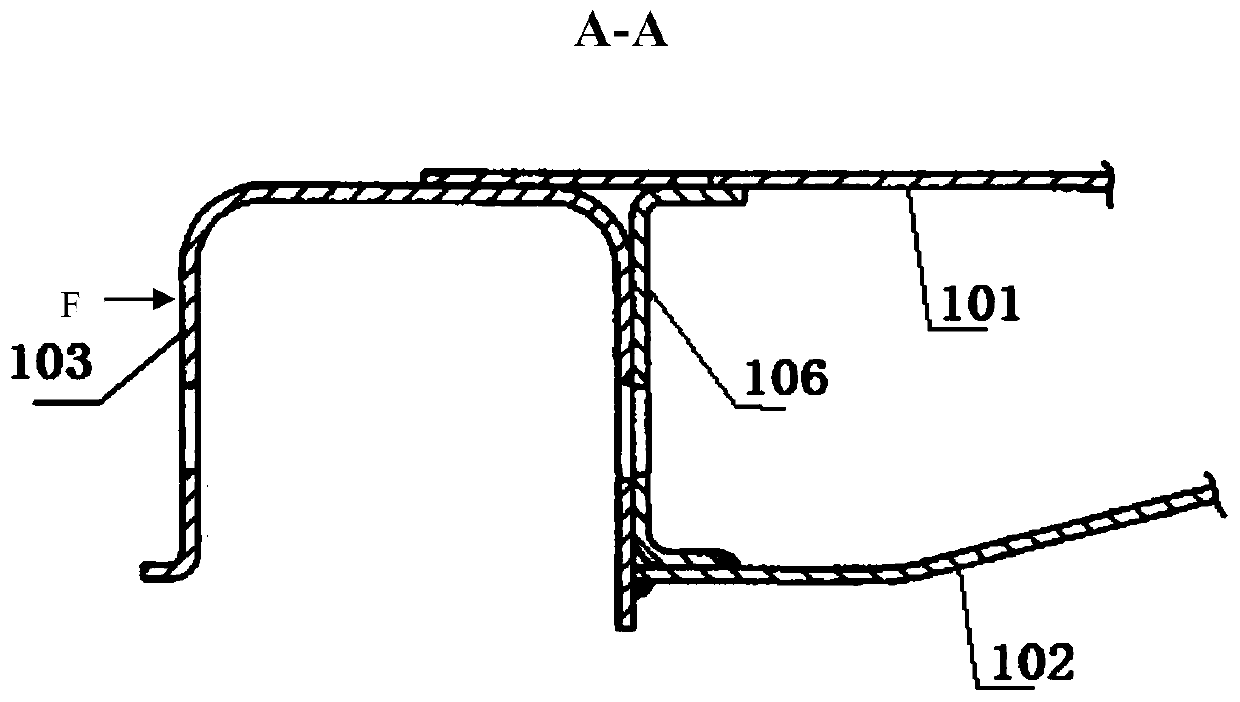

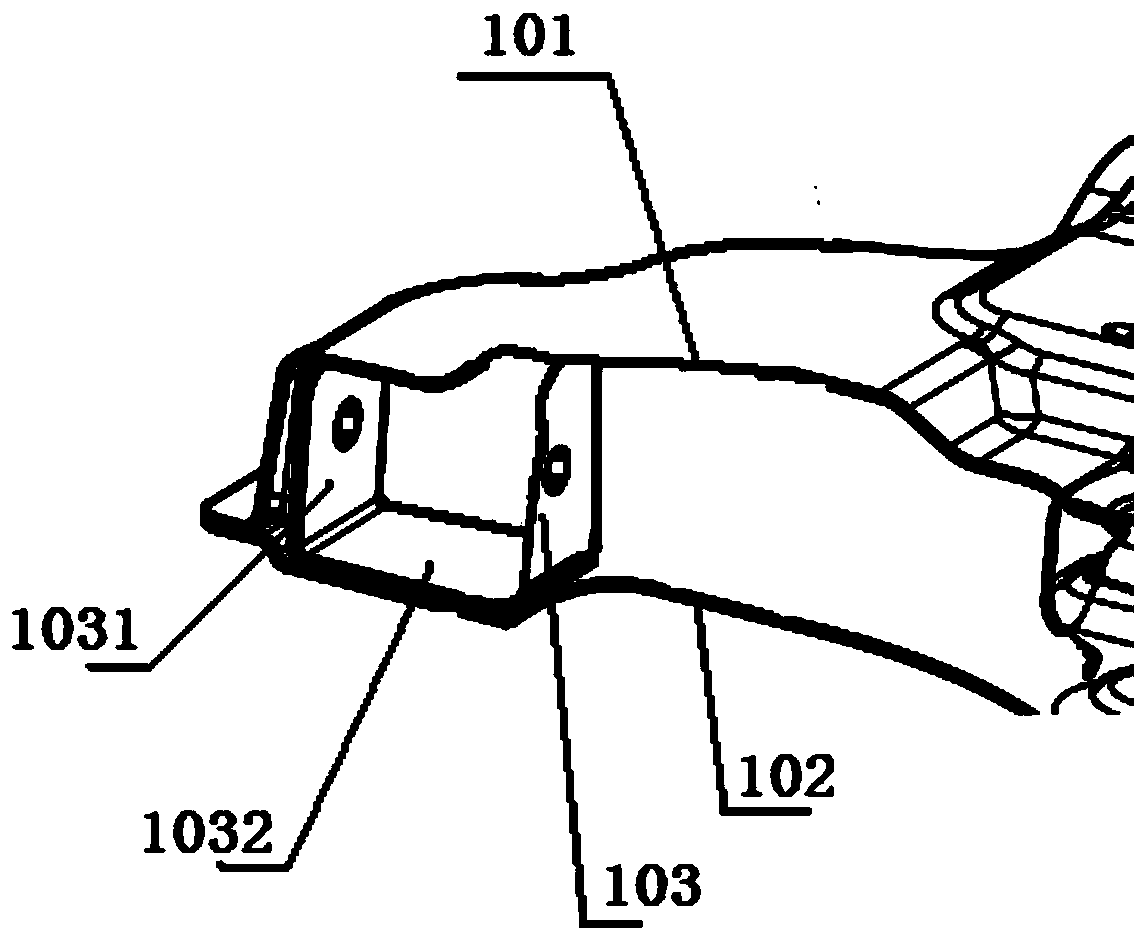

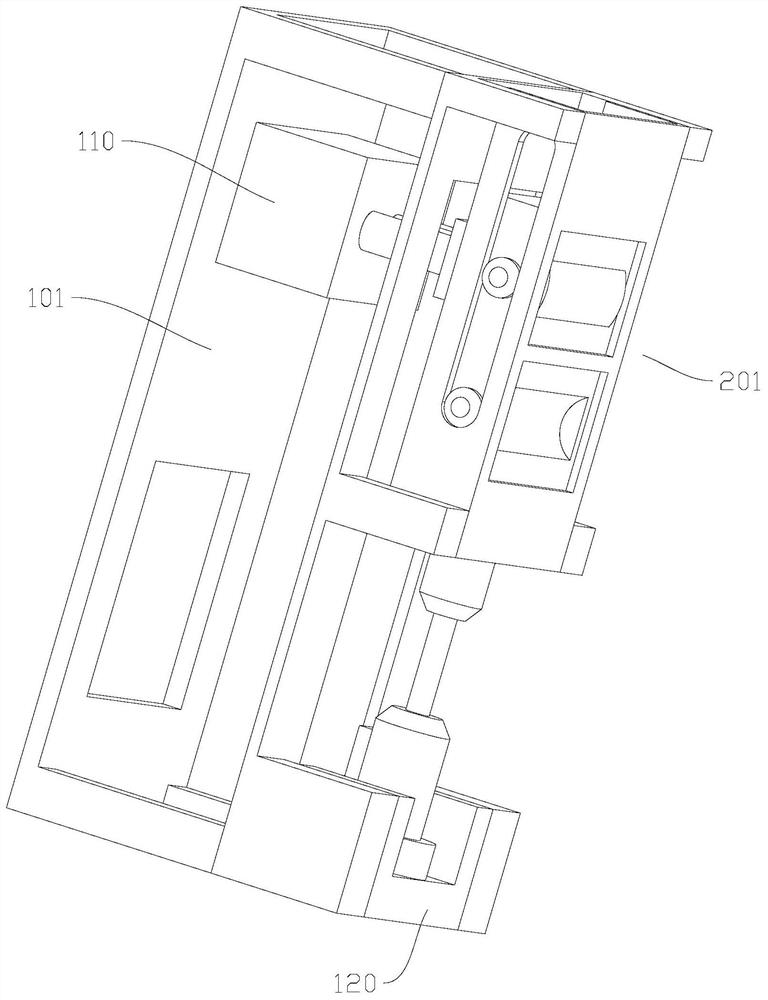

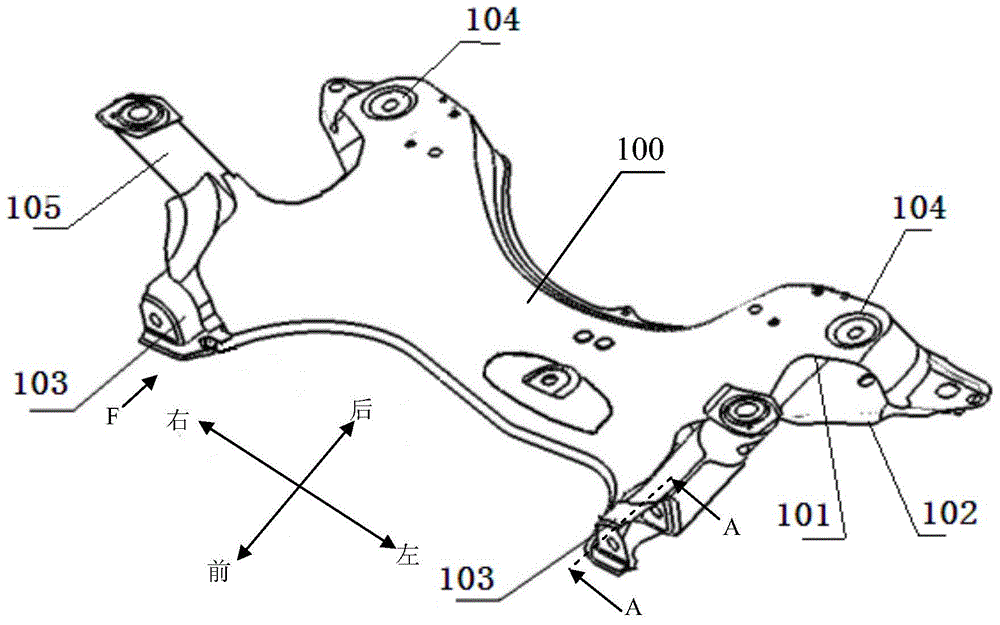

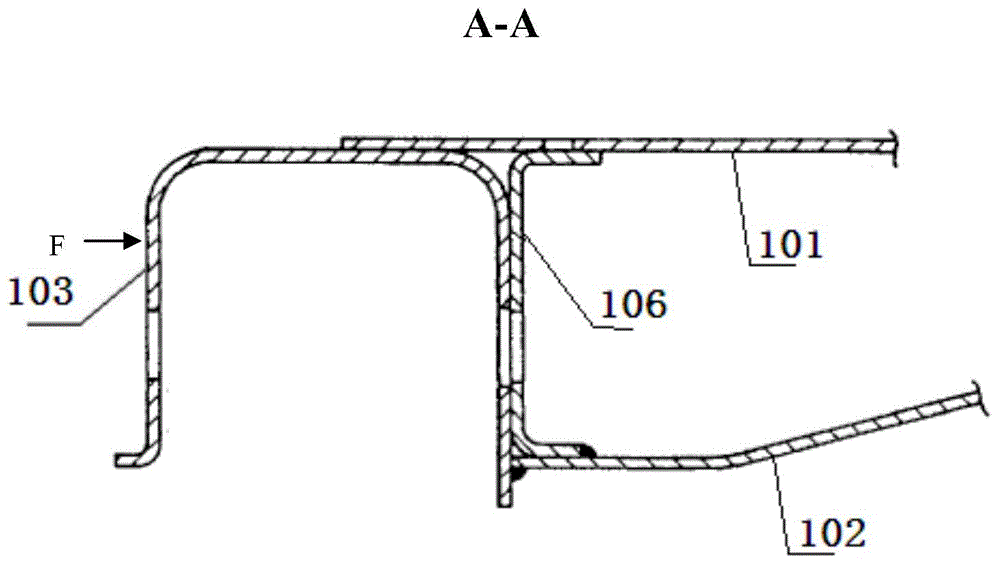

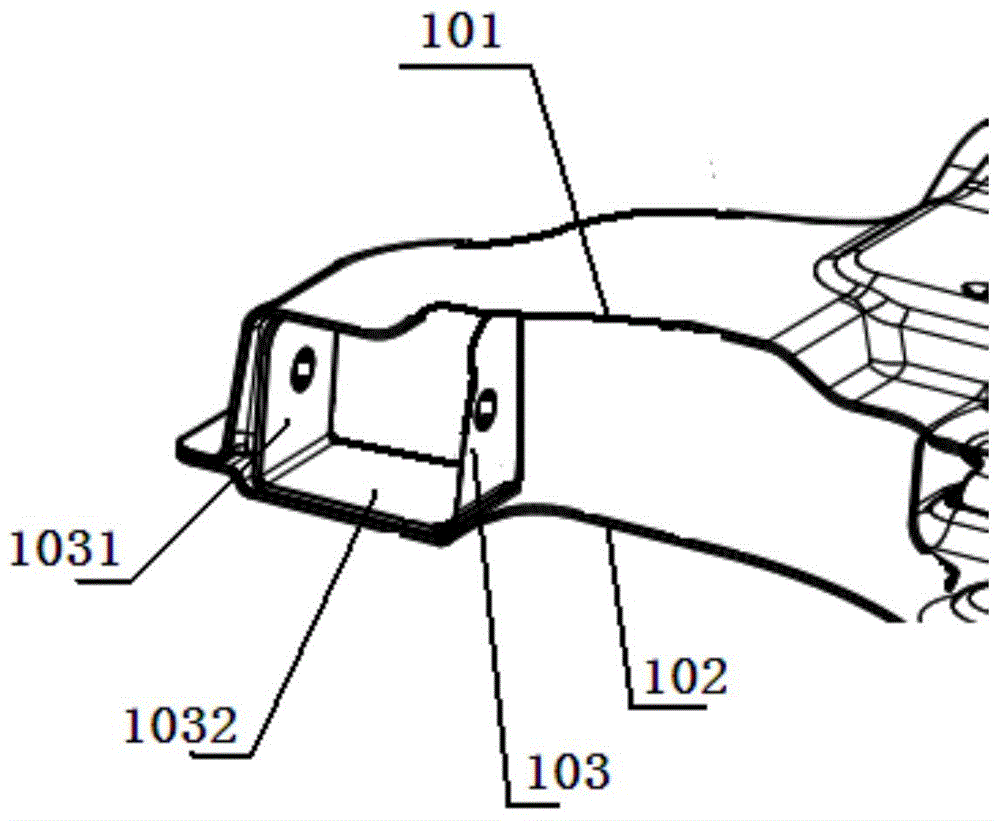

Front auxiliary frame

ActiveCN103832473ATroubleshoot Connection Strength IssuesImprove the strength of forceUnderstructuresPunchingVehicle frame

The invention provides a front auxiliary frame. The front auxiliary frame comprises a front auxiliary frame body and a front side component. The front auxiliary frame body comprises an upper plate and a lower plate, the upper plate and the lower plate are connected together, and a front mounting support of a lower suspension arm and a rear mounting portion of the lower suspension arm are arranged between the upper plate and the lower plate. The front side component is used for connecting the front auxiliary frame body onto a vehicular body. The front side component and the front mounting support are integrally formed by punching, and the front side wall of the front mounting support is connectedly welded to the upper plate or the lower plate while the bottom wall is connectedly welded to the lower plate to form a front-rear double-layer reinforcement structure and an upper-lower double-layer reinforcement structure. A cushion plate is welded between two side walls of the front side component, and the cushion plate and an upper end cover of the front side component jointly clamp a sleeve. The front auxiliary frame has the advantages of high strength, convenience in welding and high positioning precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

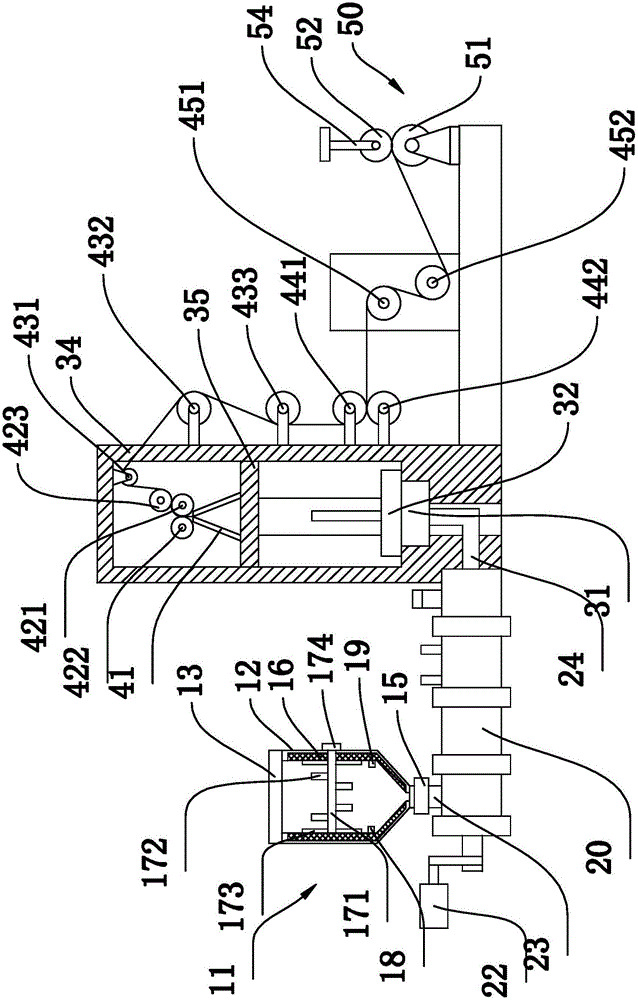

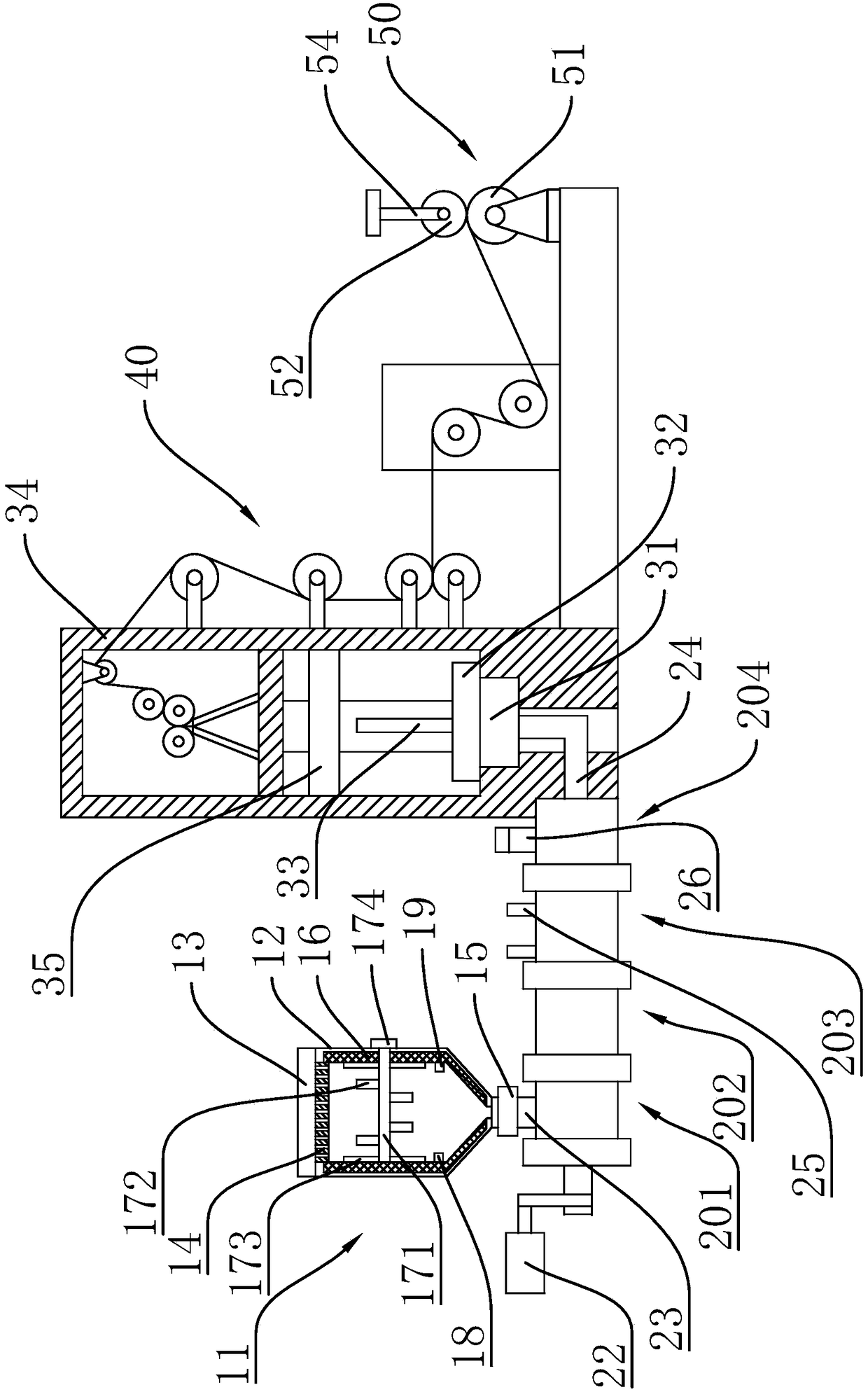

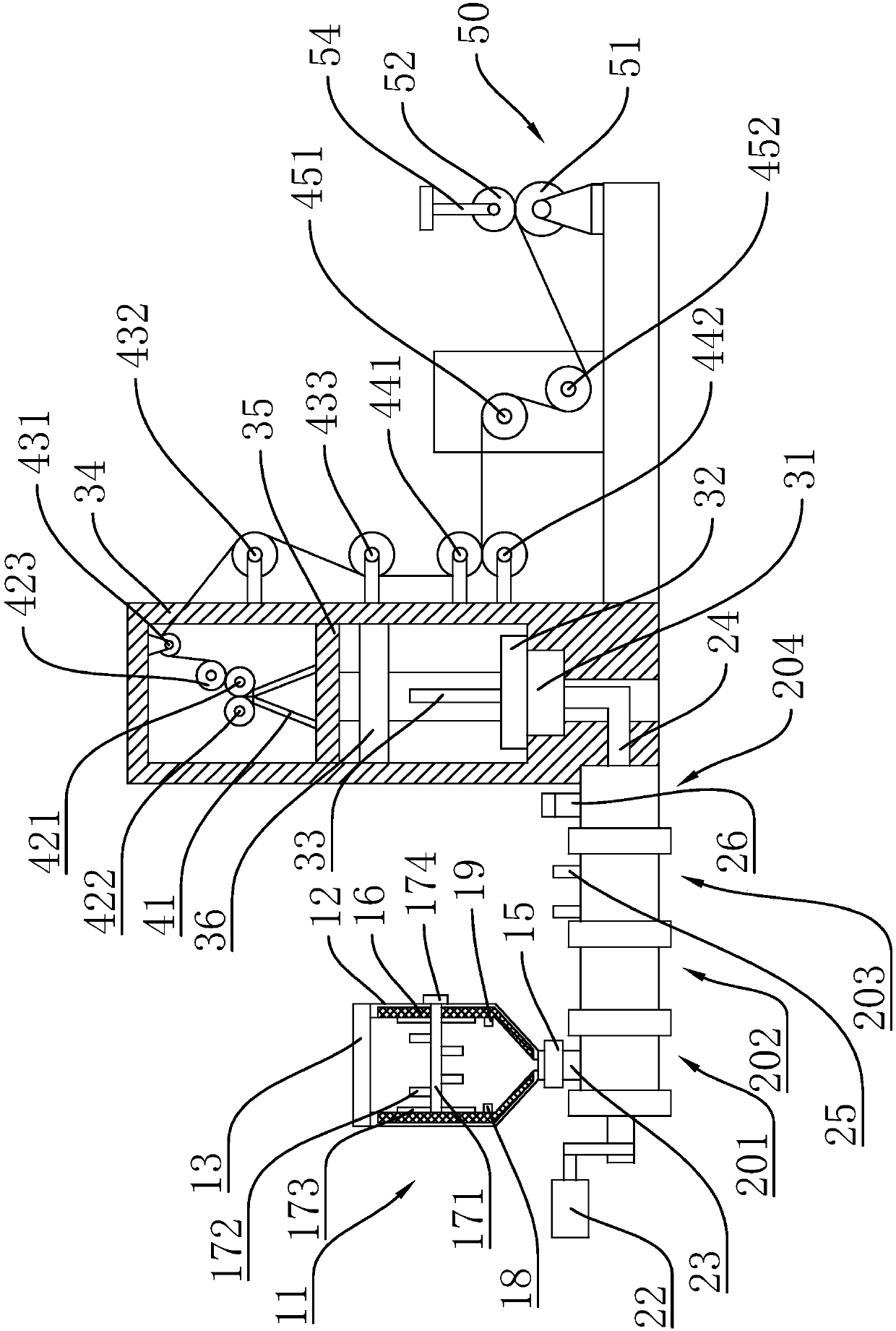

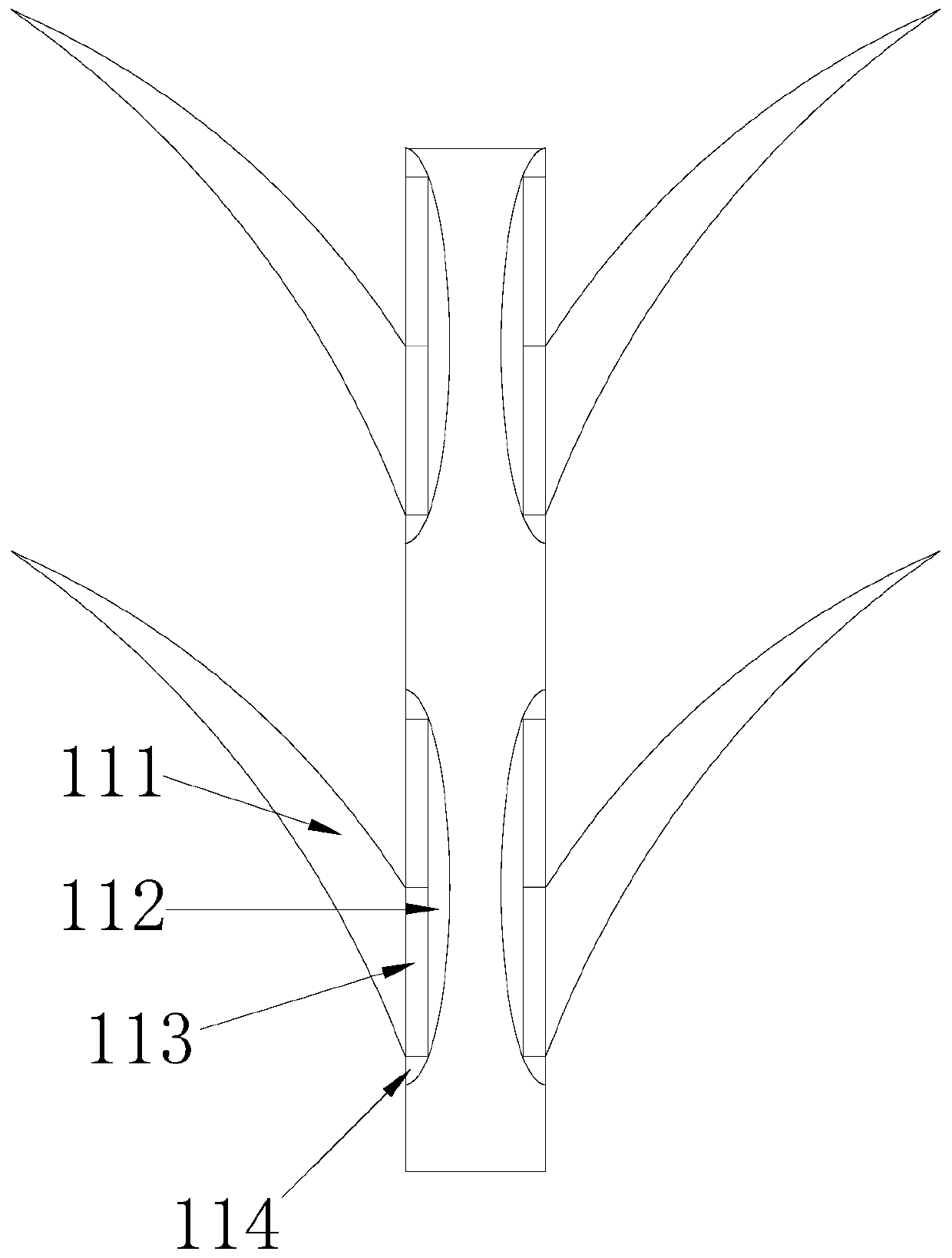

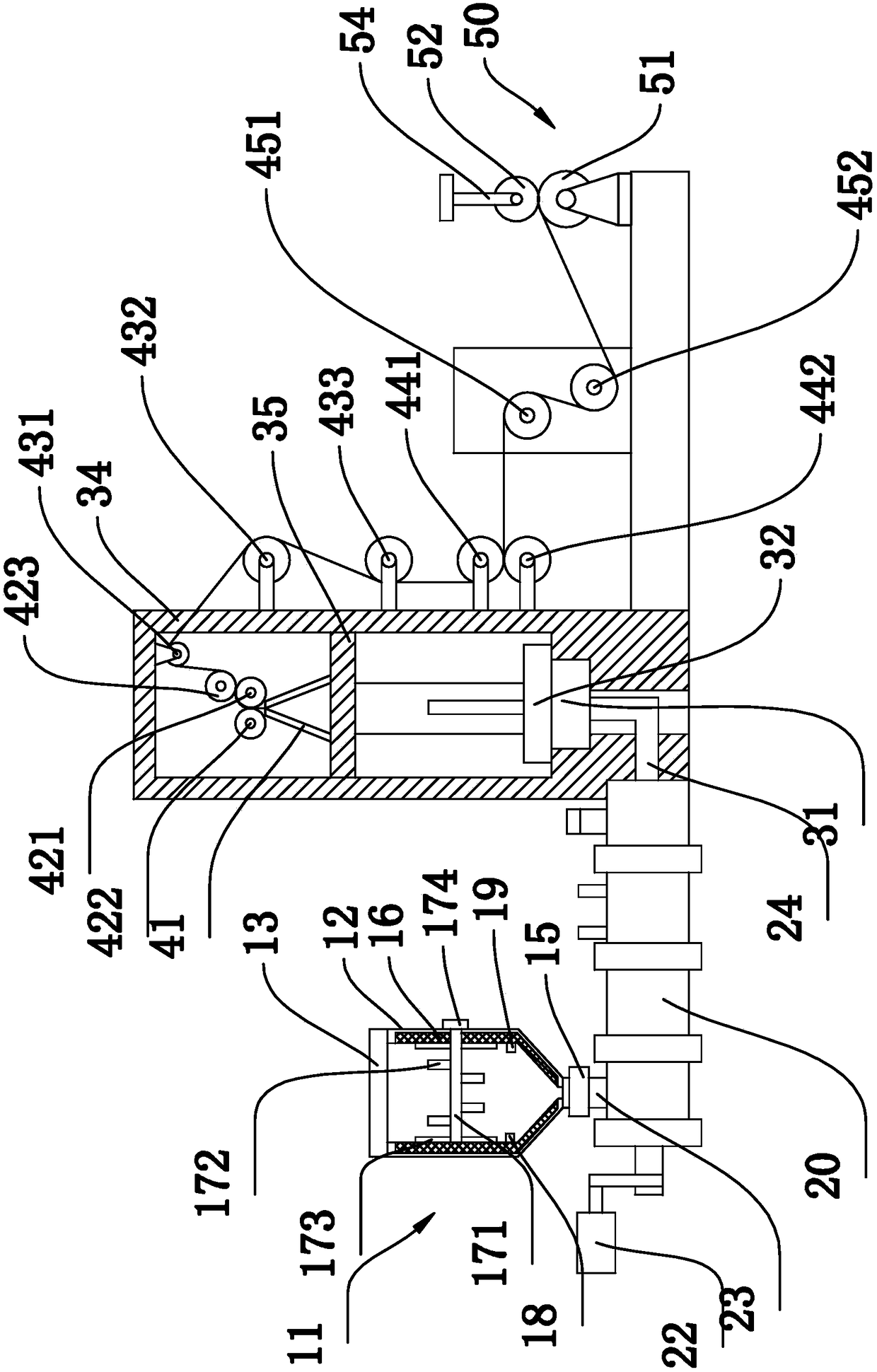

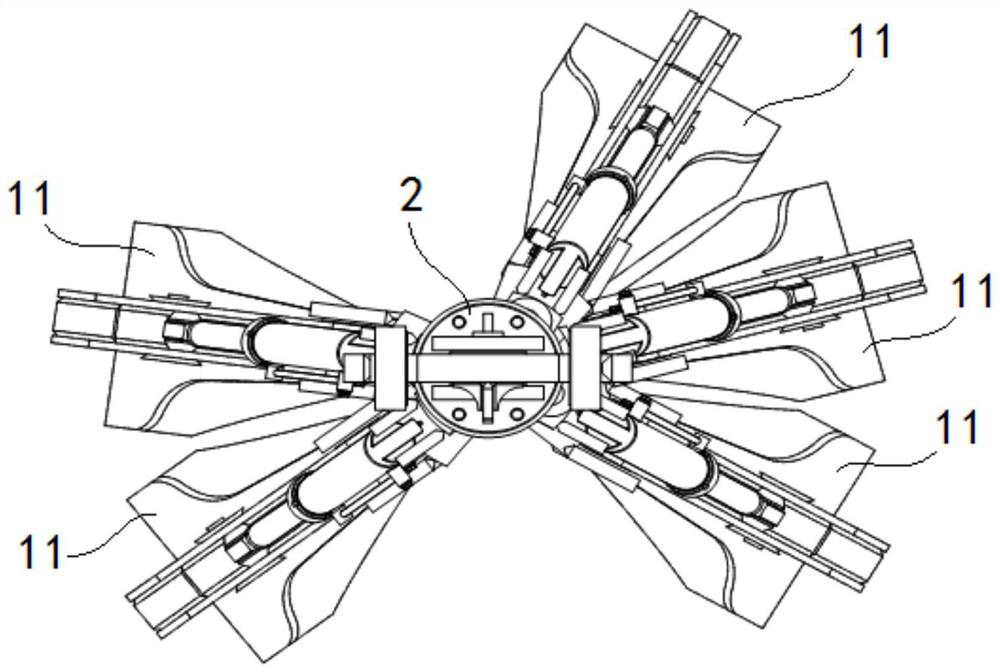

Film blowing machine provided with improved drawing mechanism

The invention provides a film blowing machine provided with an improved drawing mechanism. The film drawing machine comprises an extrusion mechanism, a film blowing mechanism, the drawing mechanism and a reeling mechanism, wherein the film blowing mechanism comprises a die head, an air ring and a rack; the air ring is arranged above the die head; the die head and the air ring are separately fixedly arranged on the lower end of the rack; the drawing mechanism is arranged on the upper end of the rack; the extrusion mechanism is provided with a material outlet which is connected with the die head; the reeling mechanism comprises a reel which is used for reeling a film; the film blown from the die head is conveyed to the reel through the drawing mechanism; the upper end of the rack is provided with a cross support base; the drawing mechanism comprises a herringbone plate; the herringbone plate is arranged on the cross support base; the upper end of the herringbone plate is provided with a first pressing roll, a second pressing roll and a third pressing roll; the second pressing roll and the third pressing roll are separately pressed against the first pressing roll; the first pressing roll is in transmission connection with a motor I; and a first drawing assembly, a second drawing assembly and a third drawing assembly are sequentially arranged along the transmission direction of the film.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

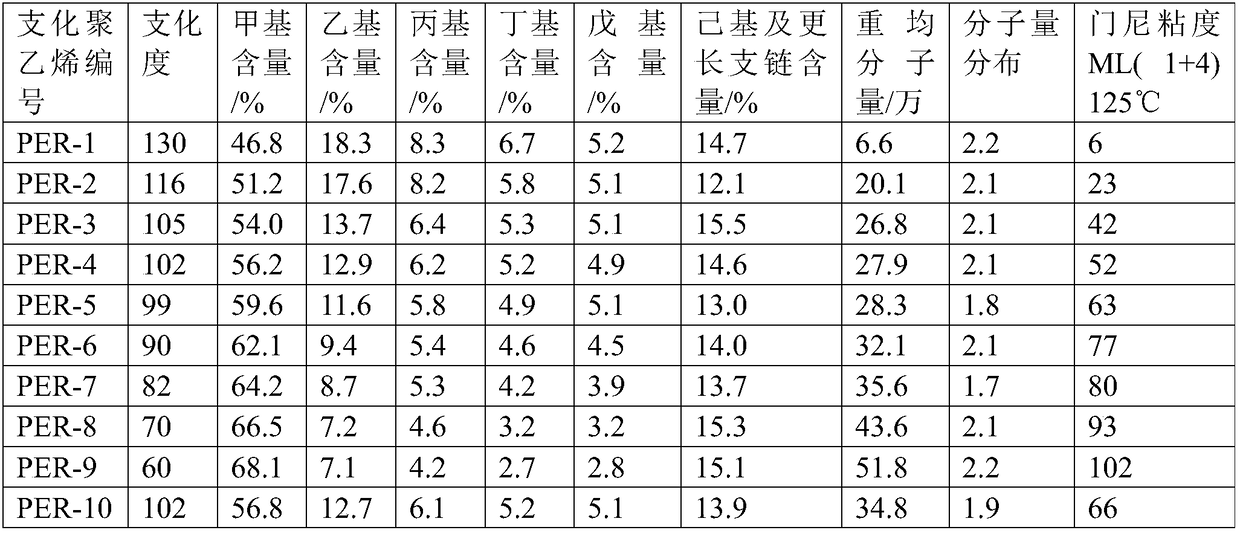

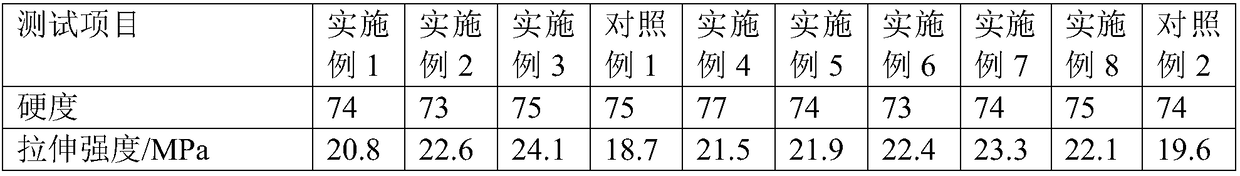

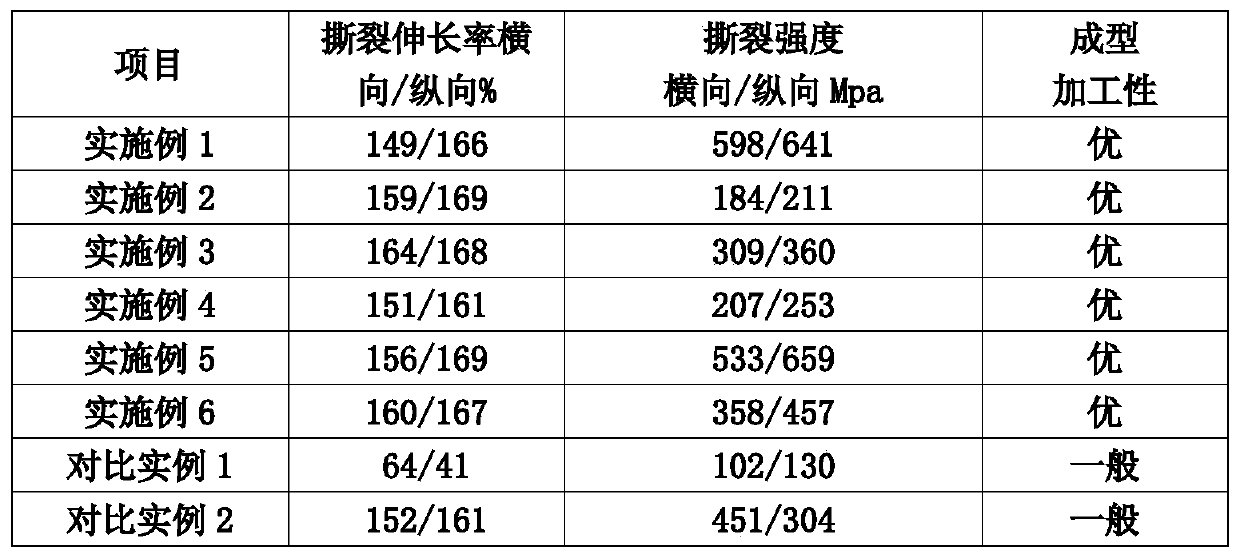

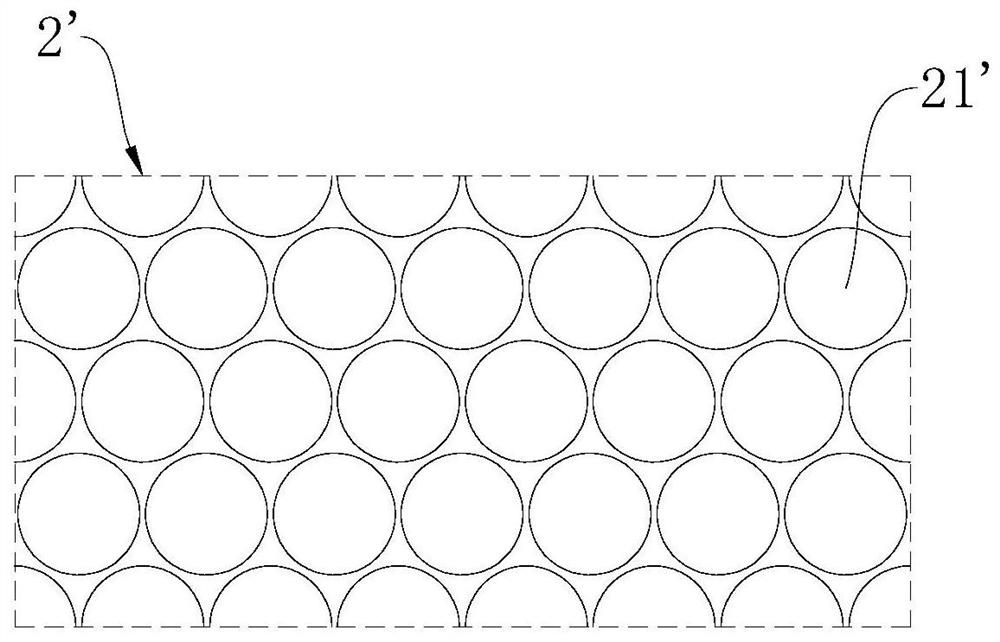

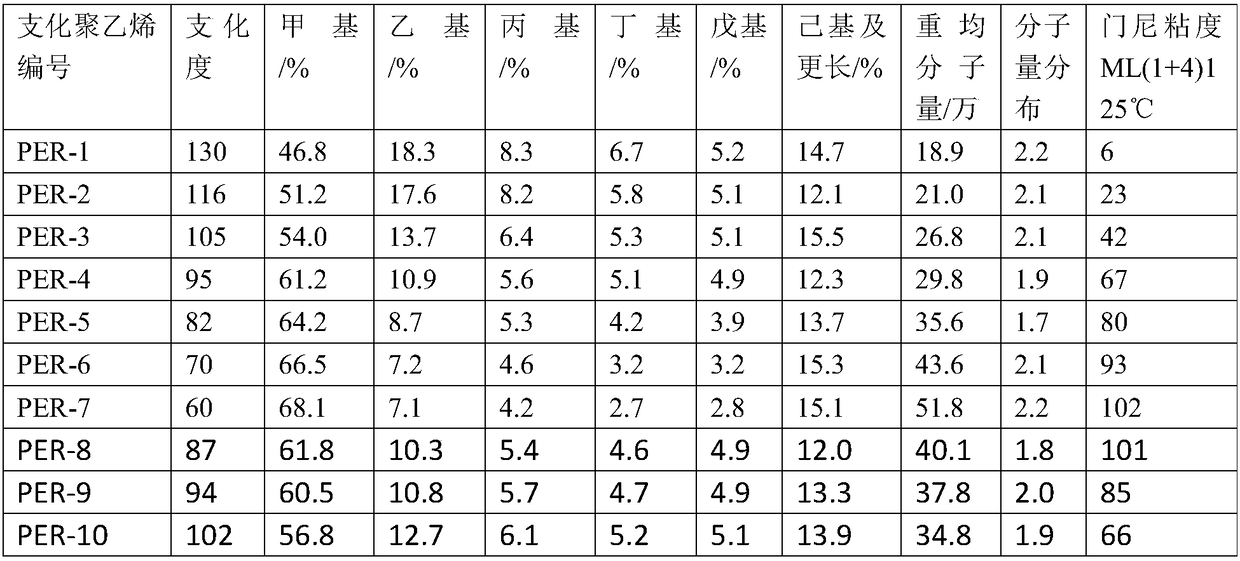

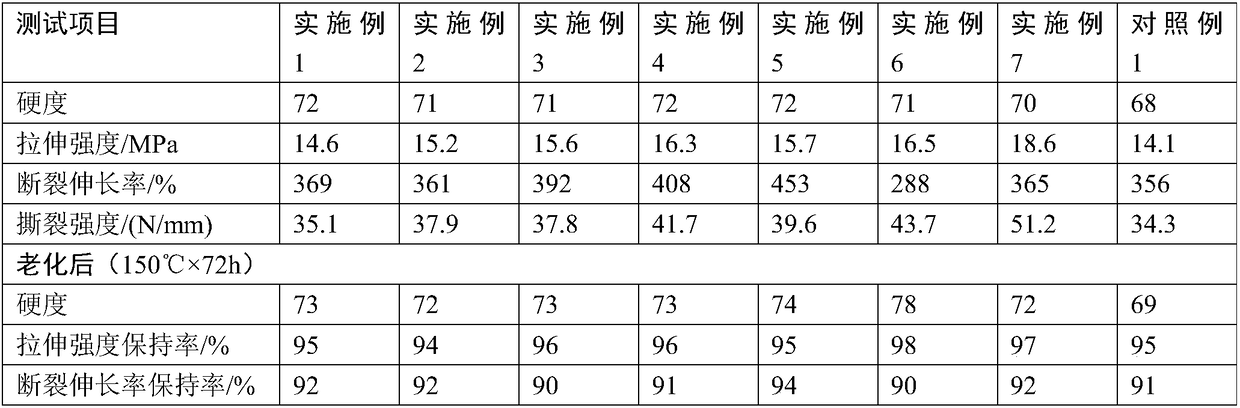

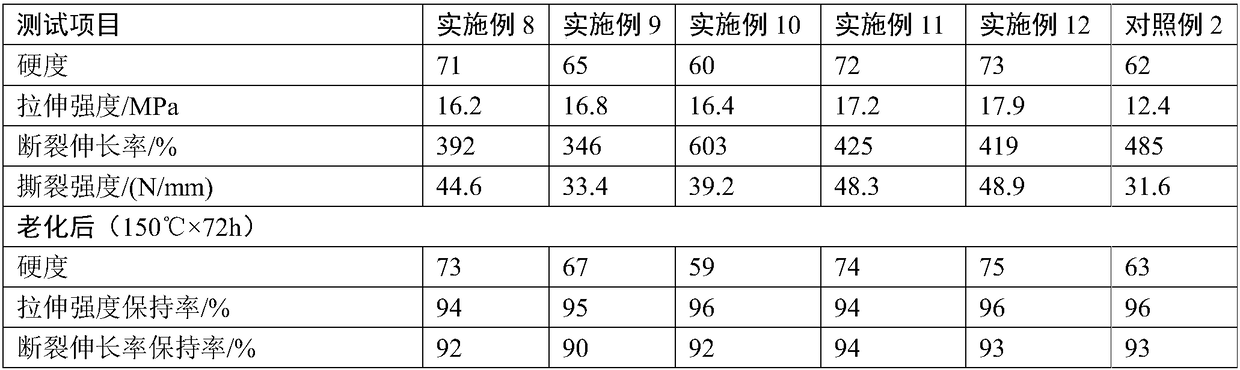

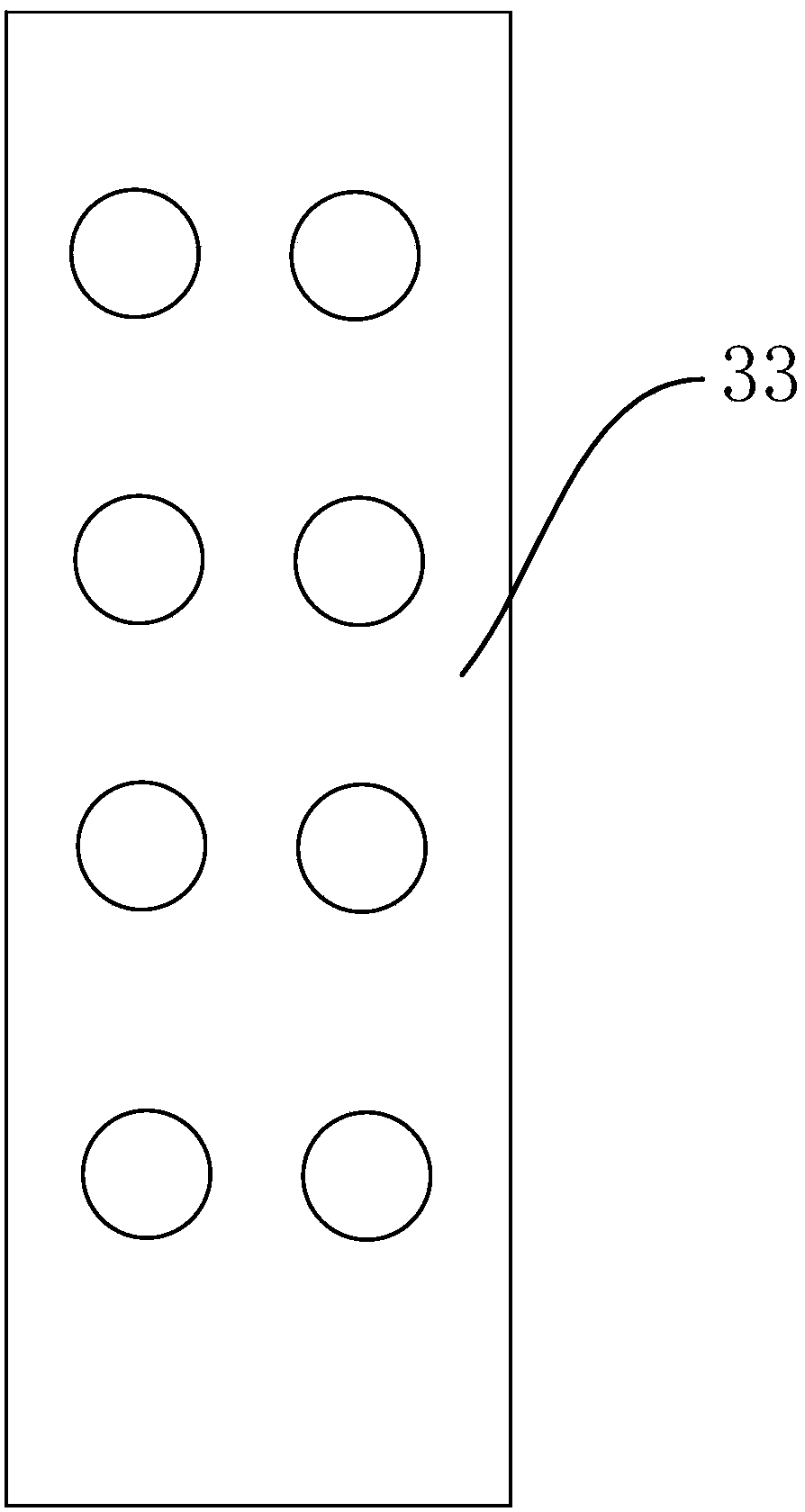

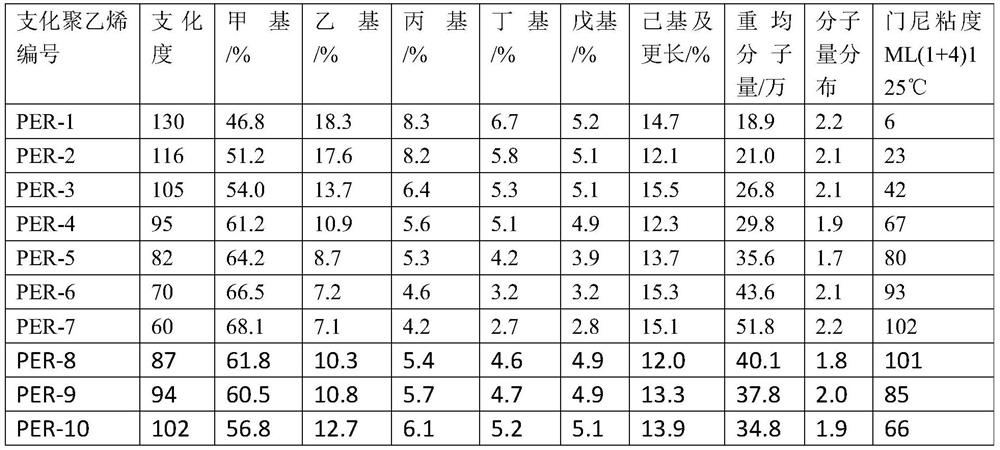

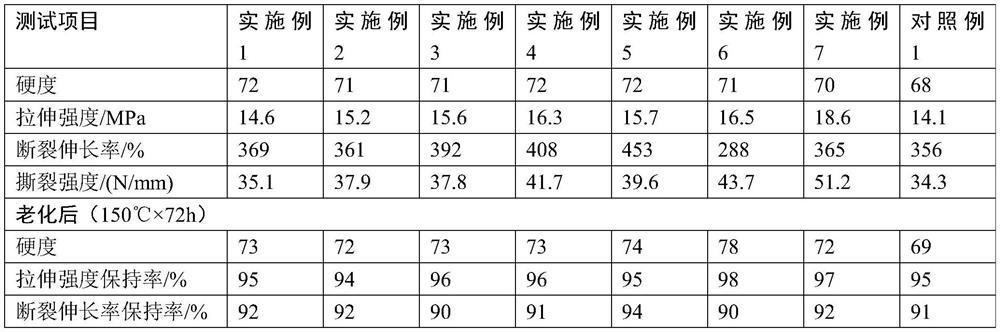

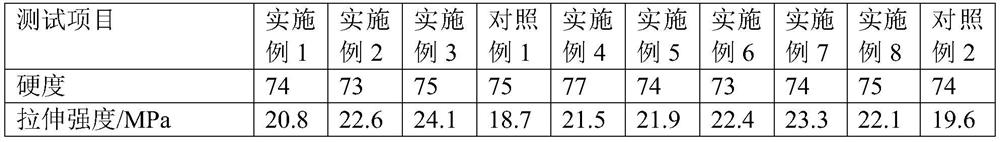

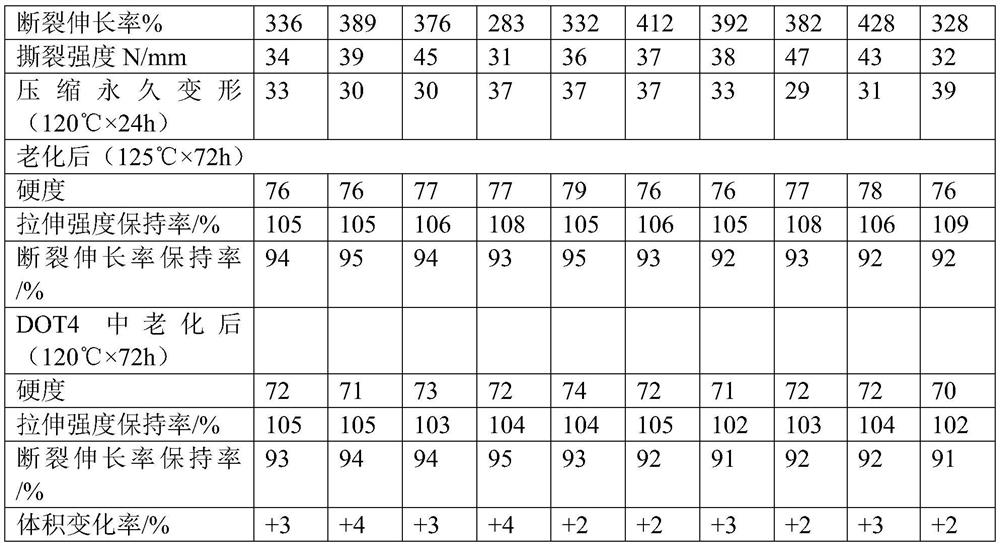

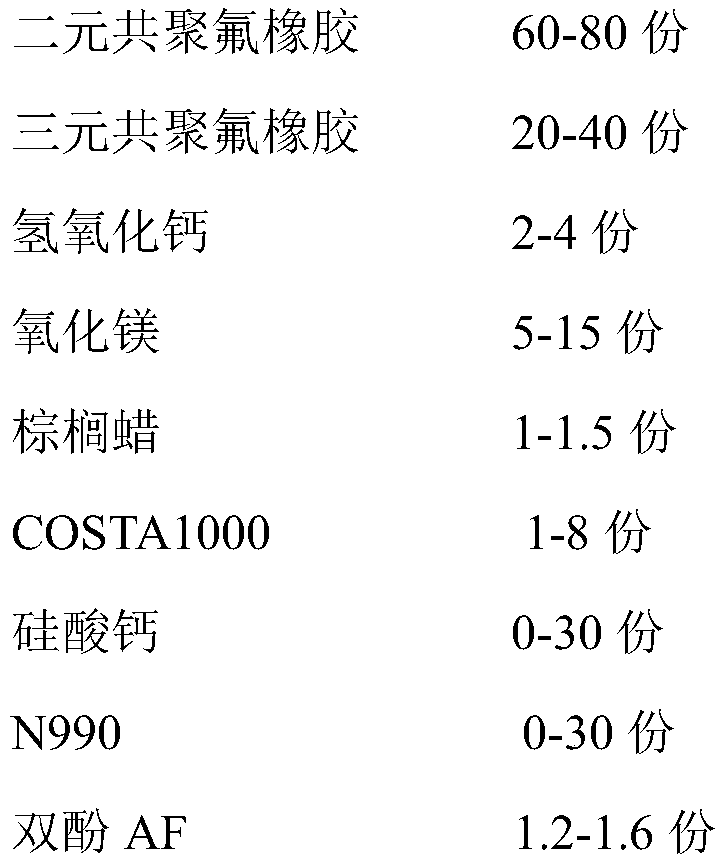

Rubber composition, processing method, brake fluid resistant product adopting rubber composition and production method

ActiveCN108314848AReduce the chance of tearingImproved compression set resistanceBraking membersFlexible pipesCross-linkPolymer science

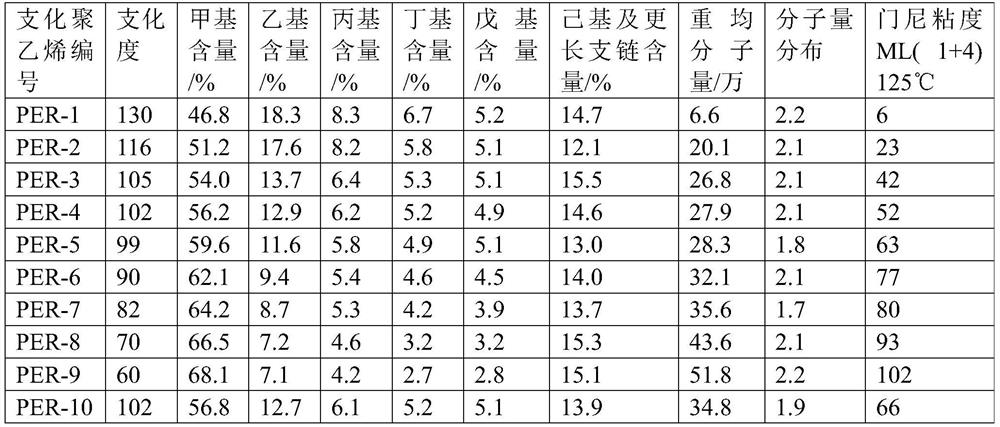

The invention discloses a rubber composition and a processing method thereof, further discloses application of the rubber composition, and a method for producing the application. The rubber composition comprises the following components in parts by weight: 100 parts of rubber matrix; 1.5 to 8 parts of a cross-linking agent; 40 to 140 parts of a reinforcing filler; 0 to 40 parts of a plasticizer; the rubber matrix comprises the following components in parts by weight: greater than 0 and smaller than or equal to 100 parts of branched polyethylene with the content, greater than or equal to 0 andsmaller than 100 parts of ethyene-propylene rubber, and greater than or equal to 0 and smaller than 100 parts of ethylene propylene terpolymer. The rubber composition is applied for the manufacture ofbrake fluid resistance brake rubber hoses and brake cups. The rubber composition has the benefits that as the rubber composition has the branched polyethylene, the tear strength of size can be improved, so that the probability of tearing of a product during production is reduced, and the overall processing performance is improved.

Owner:HANGZHOU XINGLU TECH CO LTD +1

Method for producing polyphenylene sulfide film

InactiveCN109957125ASmall polydispersity coefficientExcellent polydispersity coefficientWax coatingsChemical industryPolymer science

The invention discloses a method for producring a polyphenylene sulfide film. Sodium sulfide and p-dichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, 1,3,5-trichlorobenzene and 2,4,6-trichlorobenzene molecular weight regulators are added to control the molecular weight distribution coefficient of polycondensation synthesized polyphenylene sulfide resin, an antioxidant is added to the synthetic polyphenylene sulfide resin, all above materials are mixed according to a certain ratio to form a raw material for the polyphenylene sulfide film, the material is extruded by a twin-screw extruder, goes through a T-shaped mold, and is biaxially drawn into the polyphenylene sulfide film, and the polyphenylene sulfide film undergoes corona and anti-adhesion agent treatment, and then is wound into a polyphenylene sulfide film roll. The film obtained in the invention can be widely used in the fields of electronic appliances, military industry, aerospace, machinery, chemical industry and the like.

Owner:德阳科吉高新材料有限责任公司

Front subframe and producing method thereof

ActiveCN103738399APrecise positioningFacilitate subsequent weldingUnderstructuresVehicle frameEngineering

The invention provides a front subframe comprising an upper plate and a lower plate which are connected to form a front subframe body, and a front component used for connecting the front subframe body to a vehicle. A lower swing arm front mounting support and a lower swing arm rear mounting portion are arranged between the upper plate and the lower plate on the left and right sides of the front subframe body. The front component and a front mounting support are punched and formed integrally. The front wall of the front mounting support is welded to the upper plate or the lower plate, and the bottom wall is connected to the lower plate in welded manner so that a front-rear double-layered reinforcing structure and an upper-lower double-layered reinforcing structure are formed. The invention further provides a method for producing the front subframe. The front subframe has the advantages of high strength, convenience of welding and high positioning accuracy.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

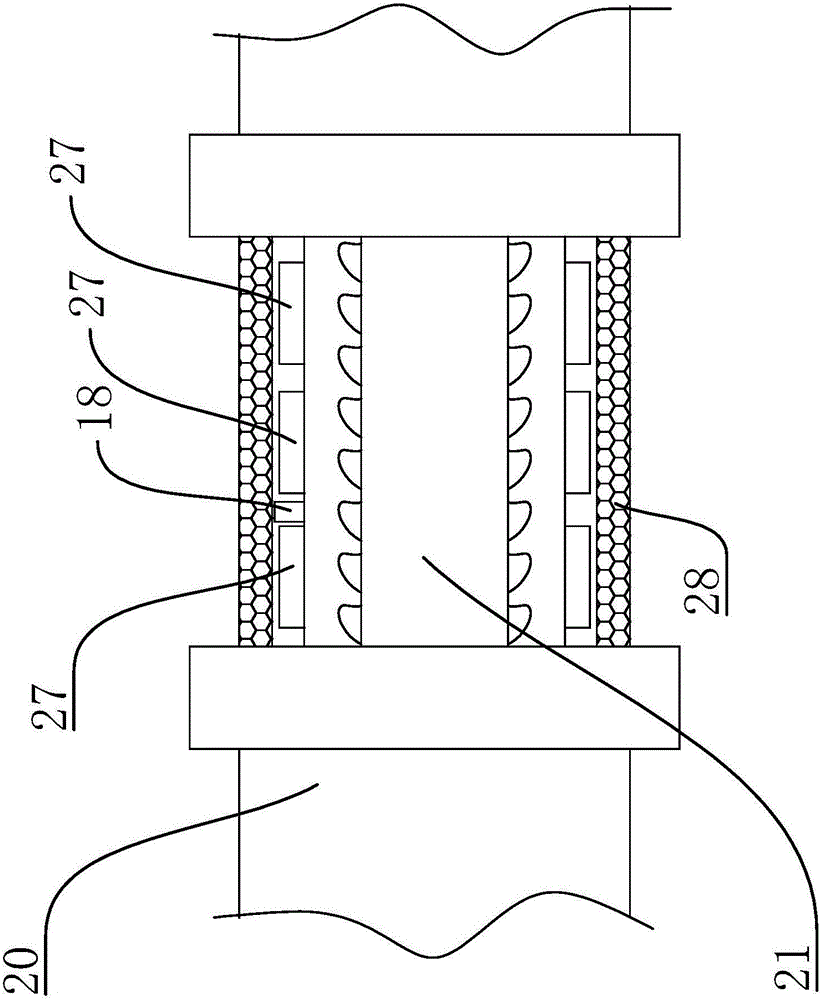

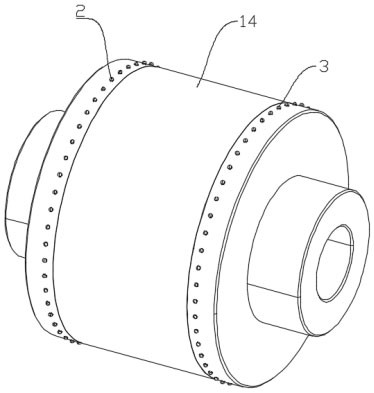

Production process of liquid-helium-free superconducting magnet coil framework structure

ActiveCN111668013AGood stabilityReduce the probability of quenchingCoils manufactureSuperconducting CoilsMaterials science

The invention discloses a production process of a liquid-helium-free superconducting magnet coil framework structure, and solves the problem of superconducting coil quench caused by relative frictionheat production of adjacent superconducting coils in the primary excitation process of the superconducting magnet coil framework structure at the present stage. According to the technical scheme, theproduction process of the liquid-helium-free superconducting magnet coil framework structure is characterized by comprising the steps of S1, pre-fixing an insulating framework in a framework wire groove; S2, brushing a layer of epoxy resin in an auxiliary wire slot of the insulating framework, winding the superconducting wire, and coating a layer of epoxy resin on each layer of superconducting wire; and repeating the steps S1 and S2 until the superconducting coils in all the framework wire slots of the framework body are wound. According to the production process of the liquid-helium-free superconducting magnet coil framework structure, the probability of the superconducting coil quench caused by relative friction heat production between adjacent superconducting wires or between the bottom-layer superconducting wire and the insulating framework in the excitation process of the superconducting coil is reduced.

Owner:宁波高思超导技术有限公司

Preparation method of high-toughness silicone nipple

The invention belongs to the technical field of nipples, and particularly relates to a preparation method of a high-toughness silicone nipple. The method concretely comprises the following steps of (1) weighing raw materials according to the parts by weight; (2) mixing liquid silicone rubber, amino silicon oil, gallic acid, Pulullan, sodium caseinate and sodium carboxymethylcellulose, stirring through a stirrer, and freezing in a freezing tank, so as to obtain a primary mixture; (3) mixing the primary mixture, Arabic gum and water, stirring through the stirrer, and magnetizing in a magnetic field, so as to obtain a secondary mixture; (4) putting the second mixture into a vacuum kneading machine, and vacuum kneading, so as to obtain a mixture; (5) injecting the mixture into a mould throughan injection moulding machine, moulding, and cooling, so as to obtain the high-toughness silicone nipple. The tensile strength, the tearing strength, the elongation and the resilience rate of the nipple are effectively improved, so that the nipple has higher toughness, the damage rate and the tearing rate of the nipple are effectively reduced, the service life of the nipple is prolonged, and the nipple is safe, health and reliable to use.

Owner:FENGYANG JIASONG NEW MATERIALS CO LTD

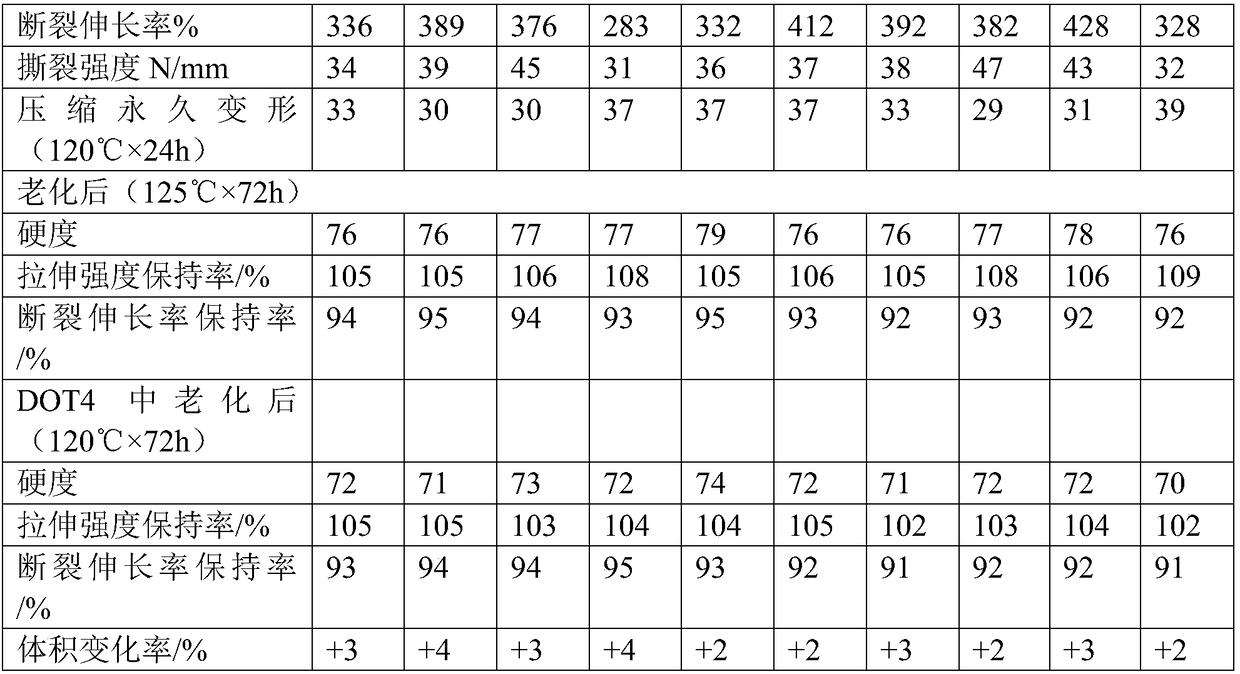

Rubber composition, processing method, rubber tube applying rubber composition and production method

ActiveCN108299745AHigh tensile strengthHigh tear performanceSynthetic resin layered productsVehicle componentsPolymer sciencePlasticizer

The invention discloses rubber composition, a processing method thereof, a rubber tube containing the rubber composition and a production method. The rubber composition comprises components in parts by unit weight as follows: 100 parts of a rubber matrix, 1.5-8 parts of a crosslinking agent, 50-200 parts of reinforcing filler, 10-100 parts of a plasticizer, 0.2-8 parts of an auxiliary crosslinkingagent, 2-15 parts of metal oxide, 1-3 parts of a stabilizer and 1-5 parts of polyethylene glycol, wherein in terms of 100 parts by weight of the rubber matrix, the rubber matrix is prepared from a parts of branched polyethylene, b parts of EPM rubber and c parts of EPDM rubber, a is larger than 0 and smaller than or equal to 100 parts, b is larger than or equal to 0 and smaller than 100 parts, and c is larger than or equal to 0 and smaller than 100 parts. The rubber composition has the beneficial effect that the rubber tube with good mechanical strength can be prepared from the rubber composition.

Owner:HANGZHOU XINGLU TECH CO LTD +1

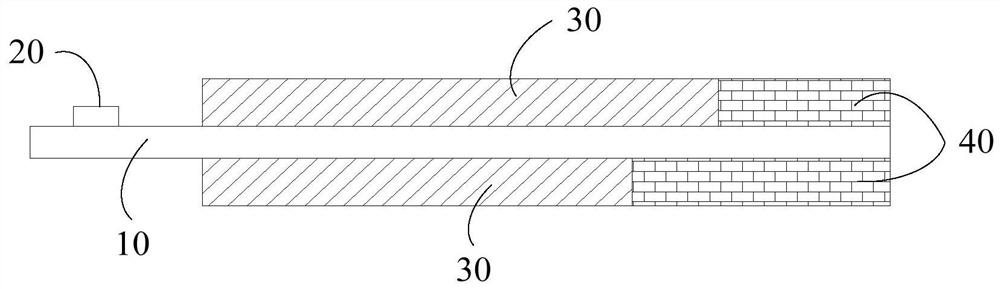

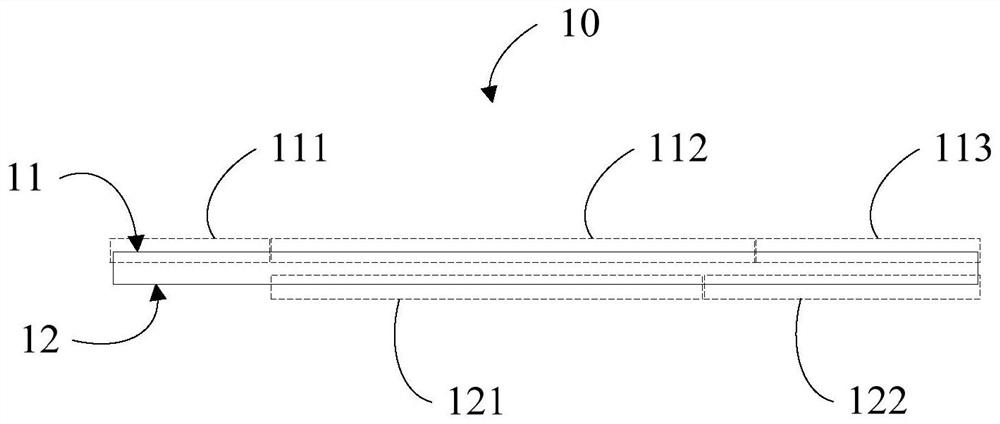

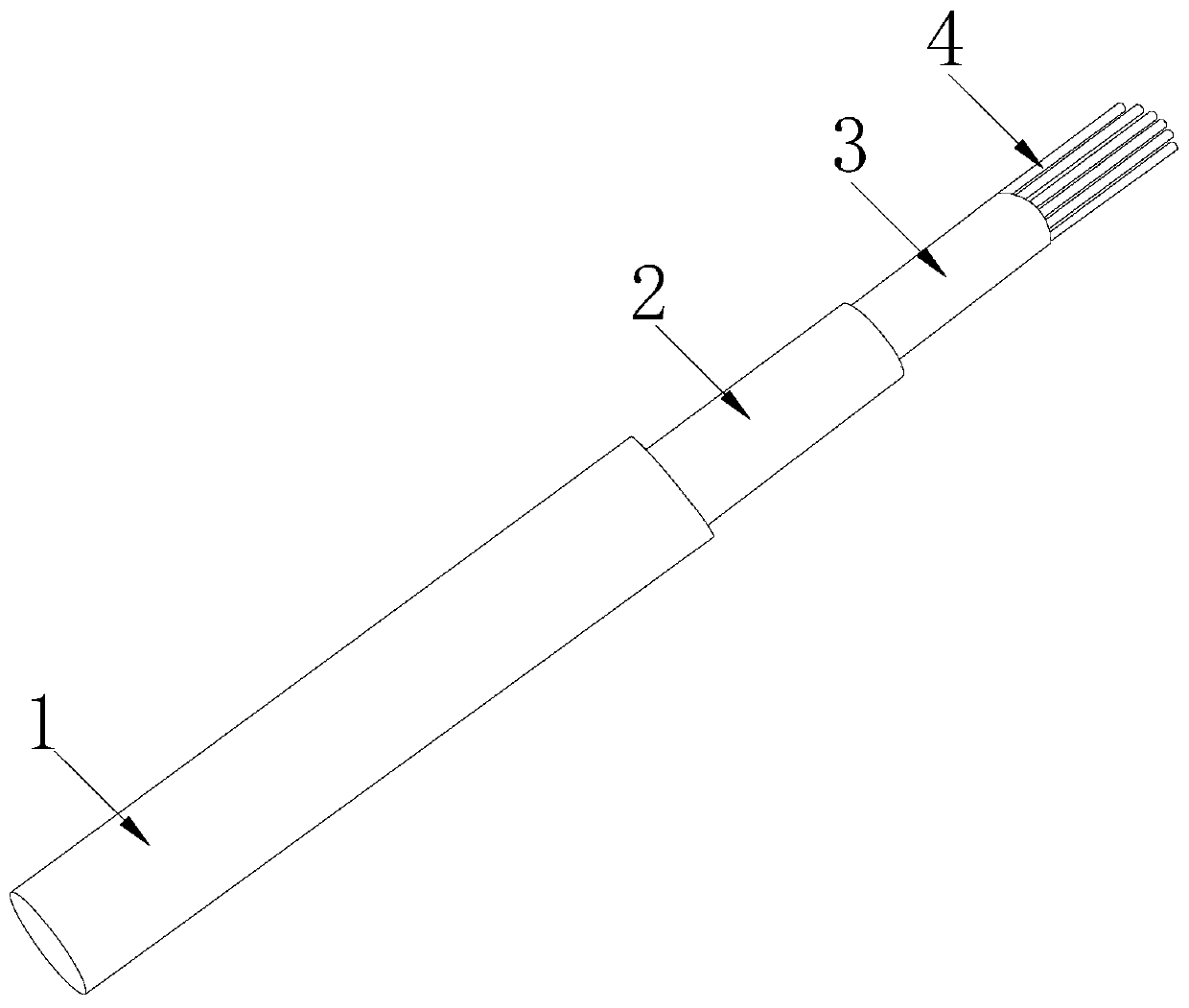

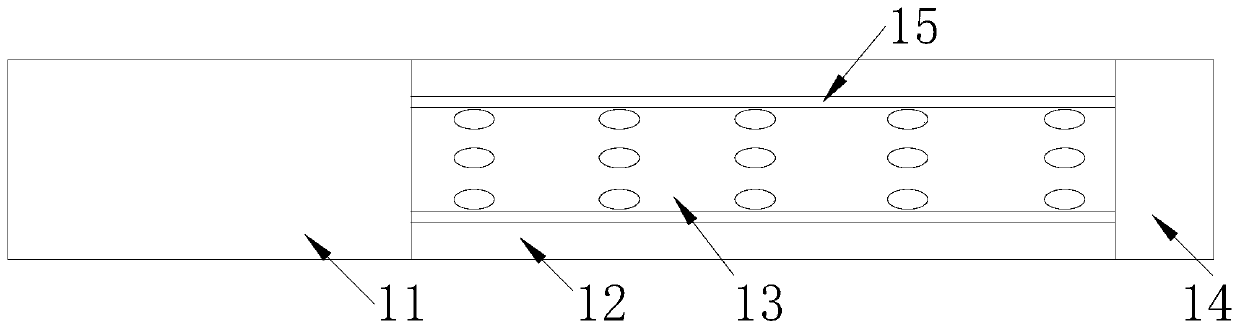

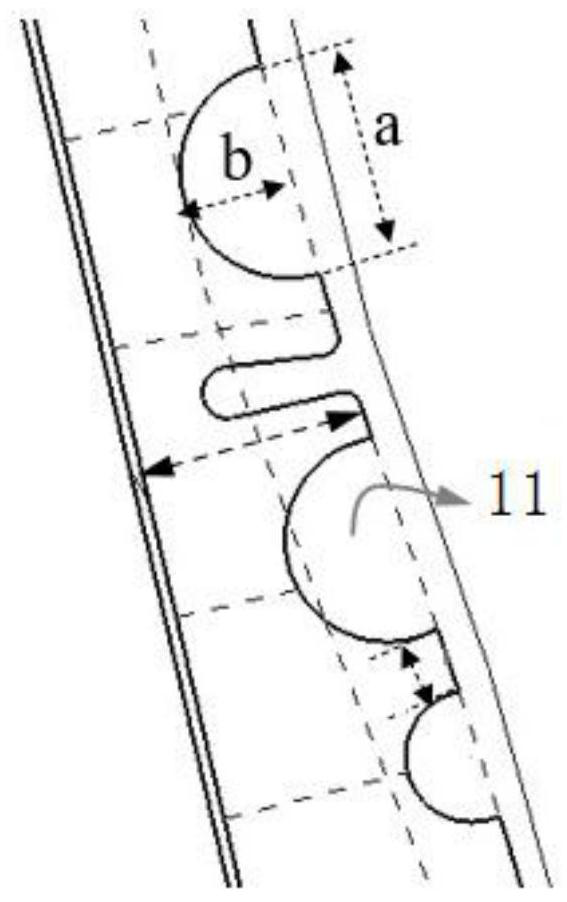

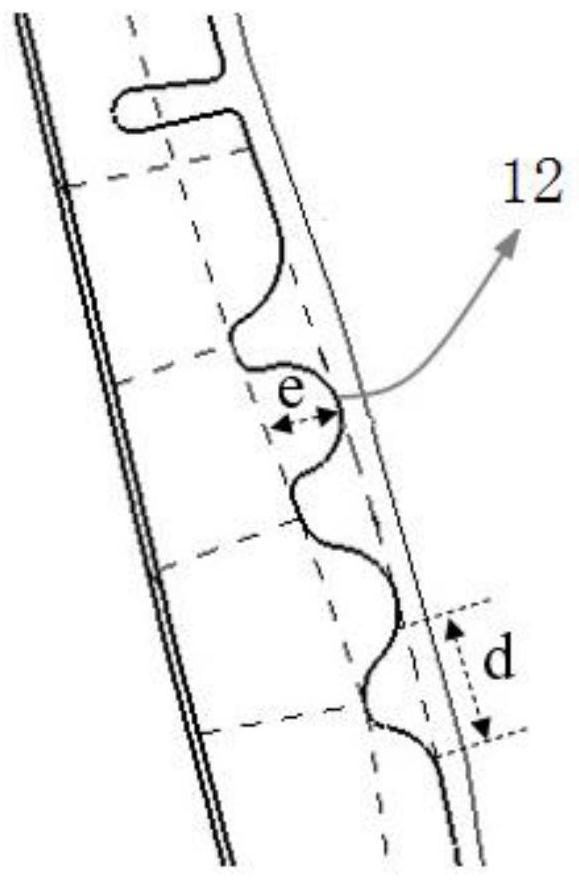

Positive plate, battery roll core, battery and preparation method of positive plate

ActiveCN112670442AImprove structural strengthReduce the chance of tearingFinal product manufactureSecondary cellsElectrical batteryElectrical connection

The invention discloses a positive plate, a battery roll core, a battery and a positive plate preparation method. The positive plate comprises a current collector, a tab, an active material layer and a mixed layer; the current collector comprises a first surface and a second surface which are oppositely arranged, the first surface comprises a first area, a second area and a third area, and the second surface comprises a fourth area and a fifth area; the fourth area is arranged corresponding to the second area, and the fifth area is arranged corresponding to the third area; the first region is provided with a tab electrically connected with the current collector, the second region and the fourth region are respectively provided with an active material layer, and the third region and the fifth region are respectively provided with a mixed layer; and the mixed layer is an elastic mixed solvent layer. Therefore, under the condition that the positive plate falls off or other machines are abused, the tearing phenomenon of the current collector can be reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

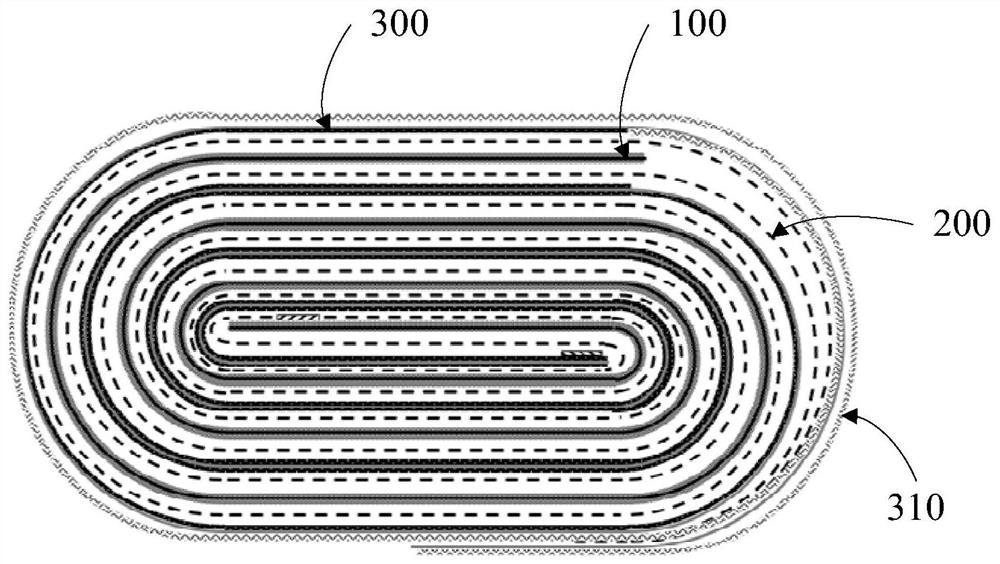

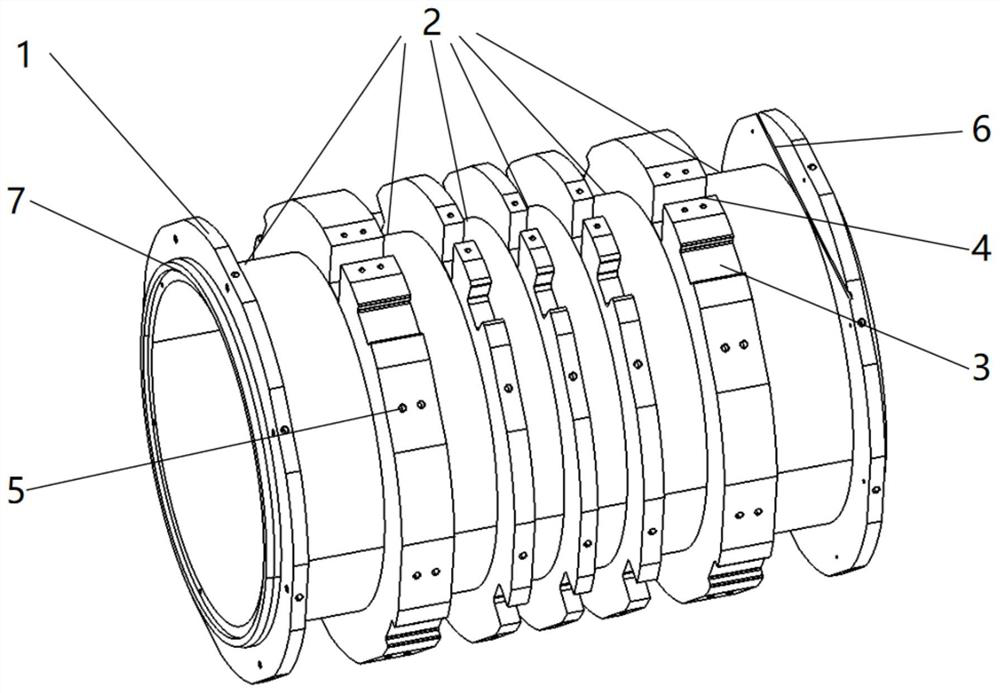

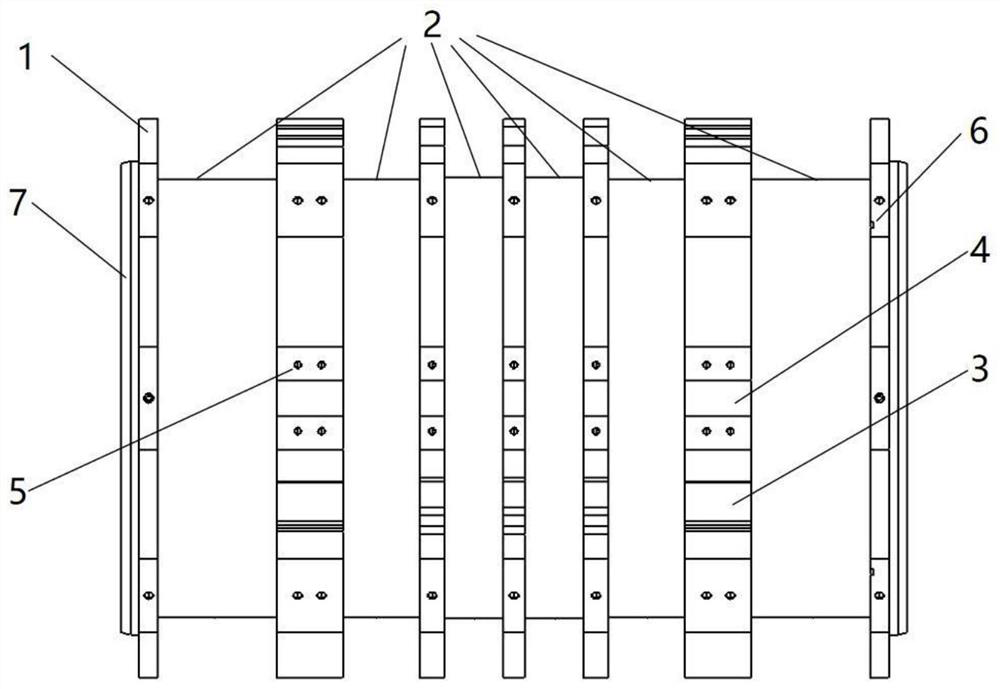

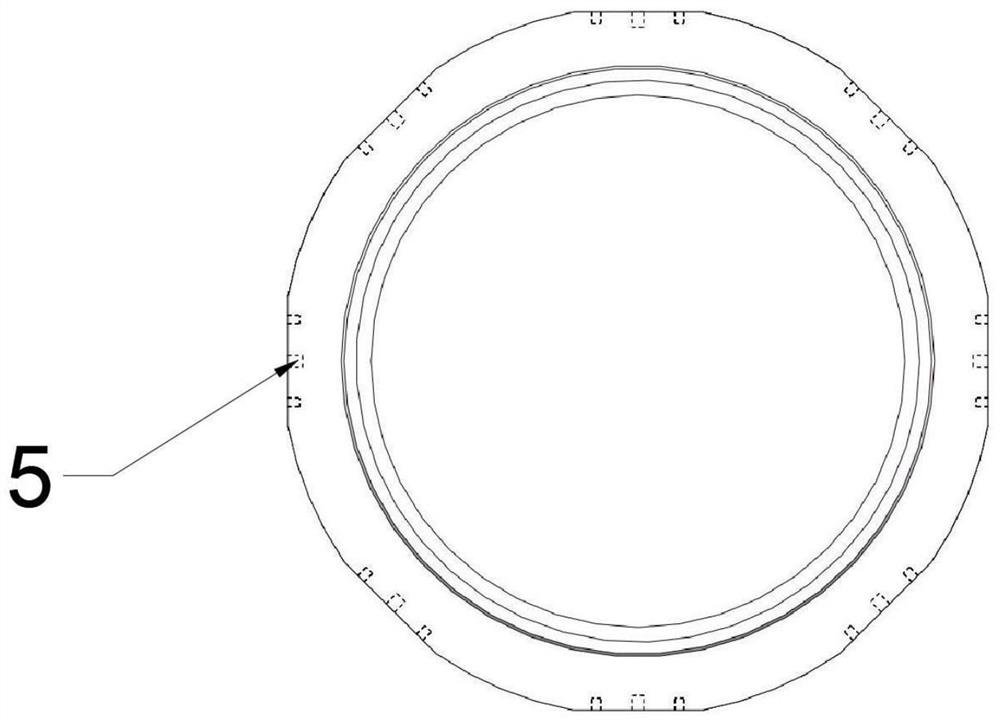

Liquid-helium-free superconducting magnet framework, superconducting magnet and winding method

ActiveCN113450995AReduce processing difficultyLow costSuperconducting magnets/coilsCoils manufactureSuperconducting CoilsEngineering

The invention provides a liquid-helium-free superconducting magnet framework, a superconducting magnet and a winding method. The liquid-helium-free superconducting magnet framework comprises a cylindrical main body; annular partition plates are arranged on the cylindrical main body at intervals in the axial direction of the cylindrical main body, and annular wire grooves are formed between the adjacent annular partition plates; the annular wire grooves are symmetrically distributed relative to the central cross section of the cylindrical main body; the annular partition plates comprise an annular end plate and at least one annular partition plate in the direction from the two ends of the cylindrical main body to the center; a wire groove and at least one heating piece groove are formed in the annular partition plate in the axial direction of the cylindrical main body, and a heating piece is arranged in the heating piece groove; and at least one group of cold conduction holes are formed in the annular partition plate in the circumferential direction. According to the liquid-helium-free superconducting magnet framework, the superconducting magnet and the winding method of the invention, the functions of winding a superconducting magnet coil, placing the heating sheet, feeding the wire and conducting cold are realized; and the basis of the wet winding process winding of layer-by-layer winding, interlayer insulation and outer layer binding, the processing difficulty of the liquid-helium-free superconducting magnet framework is greatly reduced, and the processing and material cost is reduced.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

Blown film machine with improved winding mechanism

The invention provides a film blowing machine with an improved winding mechanism. Th film blowing machine comprises an extrusion mechanism, a film blowing mechanism, a traction mechanism and the winding mechanism. The film blowing mechanism comprises a die head, an air ring and a rack. The air ring is arranged on the die head. The die head and the air ring are fixedly arranged at the lower end of the rack. The traction mechanism is arranged at the upper end of the rack. The extrusion mechanism is provided with a discharge outlet connected with the die head. The winding mechanism comprises a winding shaft, a belt and a motor, wherein the winding shaft is used for winding thin films. The motor is in transmission connection with the winding shaft through the belt. The thin films blown out from the die head are conveyed to the winding shaft through the traction mechanism. A press shaft capable of pressing the thin films is arranged above the winding shaft. The winding mechanism further comprises a support frame and elastic suspended arms. The press shaft is connected to the support frame through the elastic suspended arms. According to the film blowing machine with the improved winding mechanism, deviation of the thin films in the winding process can be avoided, and dislocation of an upper layer and a lower layer of a thin film is prevented.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

A kind of plastic film processing equipment

ActiveCN106113477BImprove compactnessImprove extrusion efficiencyFlat articlesEngineeringPlastic film

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Rubber composition and processing method, and rubber hose using same and production method

ActiveCN108299745BHigh tensile strengthHigh tear performanceSynthetic resin layered productsVehicle componentsPolymer sciencePlasticizer

Owner:HANGZHOU XINGLU TECH CO LTD +1

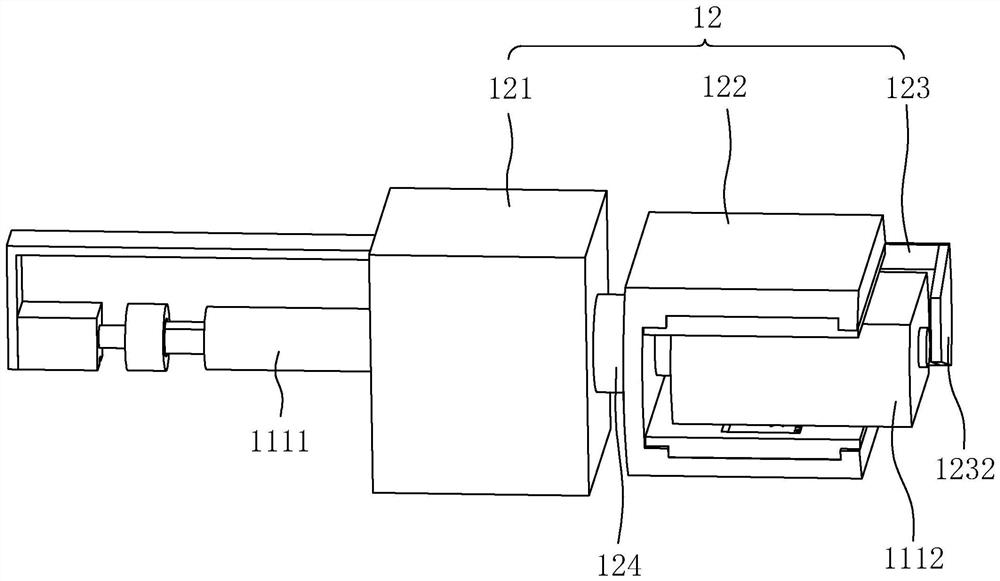

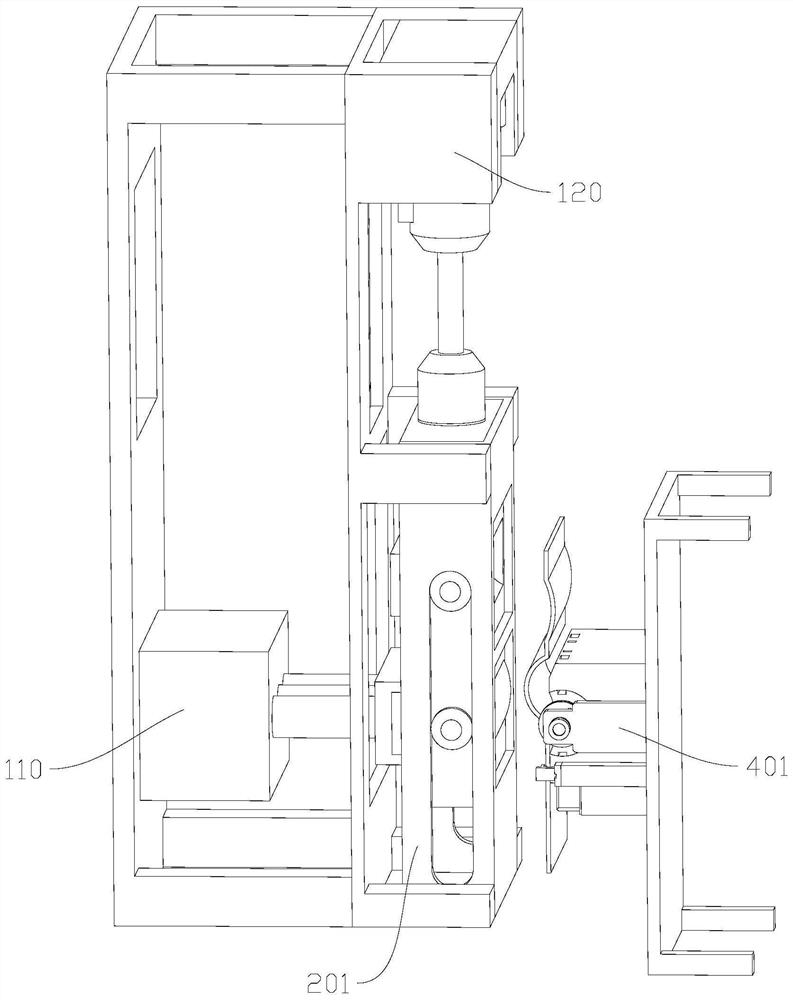

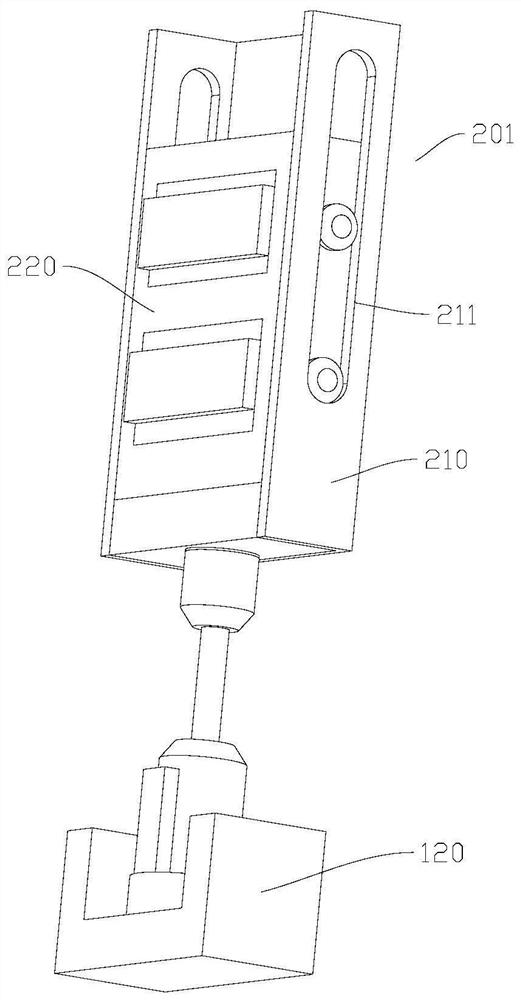

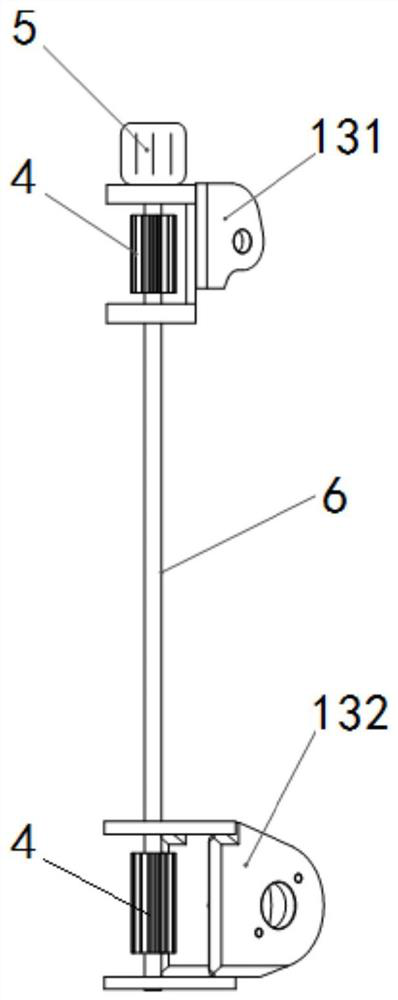

Clamping device and automatic detinning reel machining system with same

PendingCN114229618AReduce the chance of being ripped offImprove quality and qualityFilament handlingPhysicsEngineering

The invention relates to a clamping device and an automatic detinning reel machining system with the clamping device, and relates to the field of detinning wire machining, the automatic detinning reel machining system comprises a rotating mechanism, and the rotating mechanism comprises a rotating piece; the clamping mechanism comprises a movable seat, a follower and a pressing and fixing piece; the rotating part penetrates through the movable seat, the movable seat slides in the penetrating direction of the rotating part, and the movable seat is used for allowing the rotating part to rotate; the rotating part penetrates through the follower and penetrates out to the side, away from the movable seat, of the follower, the follower is rotationally connected with the movable seat, the follower is driven to slide when the movable seat slides, and the follower is driven to rotate when the rotating part rotates; the pressing and fixing piece is arranged on the follower and comprises an abutting piece, the abutting piece is located on the side, away from the follower, of the end, stretching out of the follower, of the rotating piece, and the portion between the abutting piece and the end, stretching out of the follower, of the rotating piece is used for clamping materials. The detinning wire winding device has the effect that the detinning wire can be conveniently wound on the reel.

Owner:NINGBO ZHONGDI INDUSTRY & TRADE CO LTD

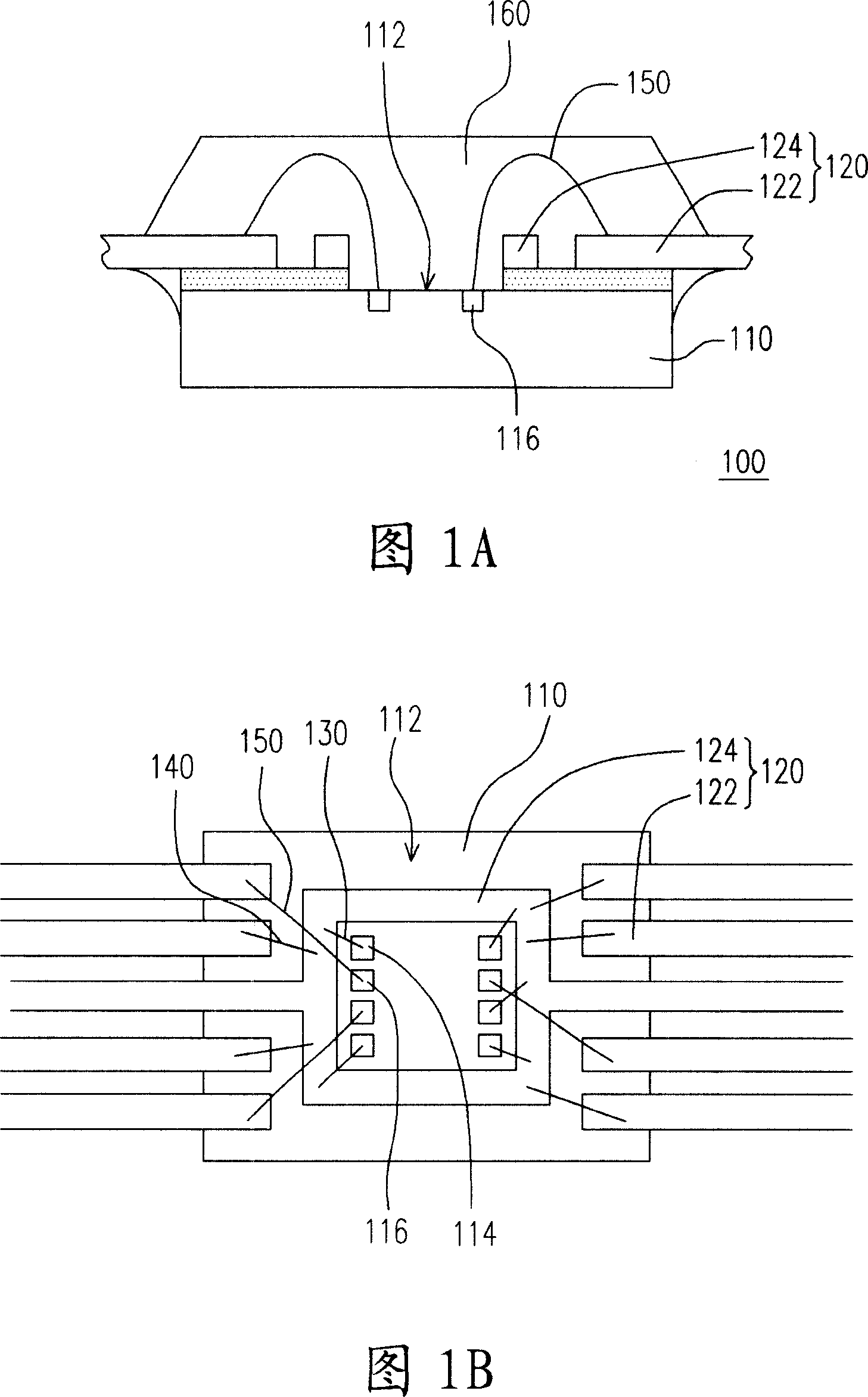

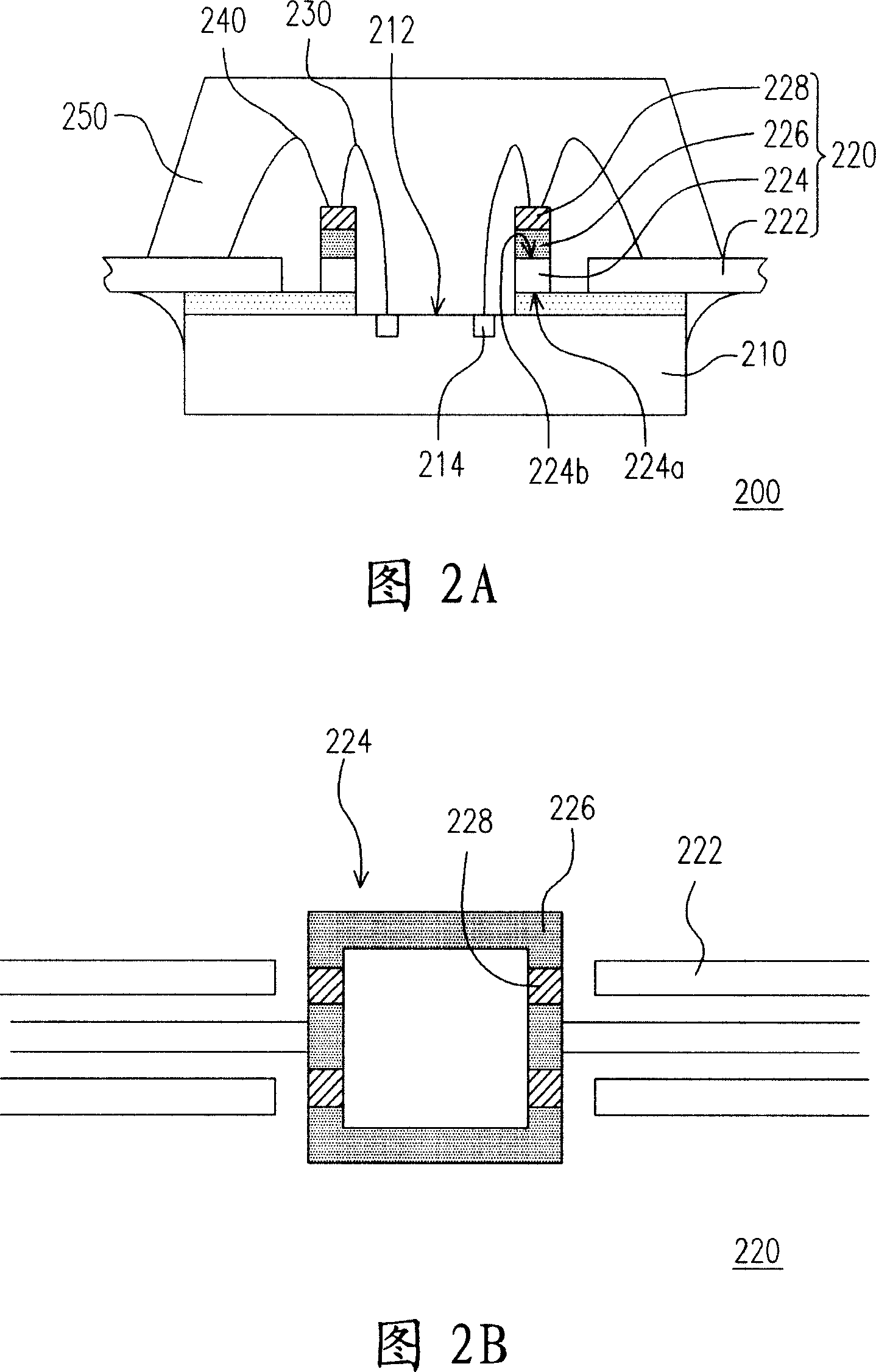

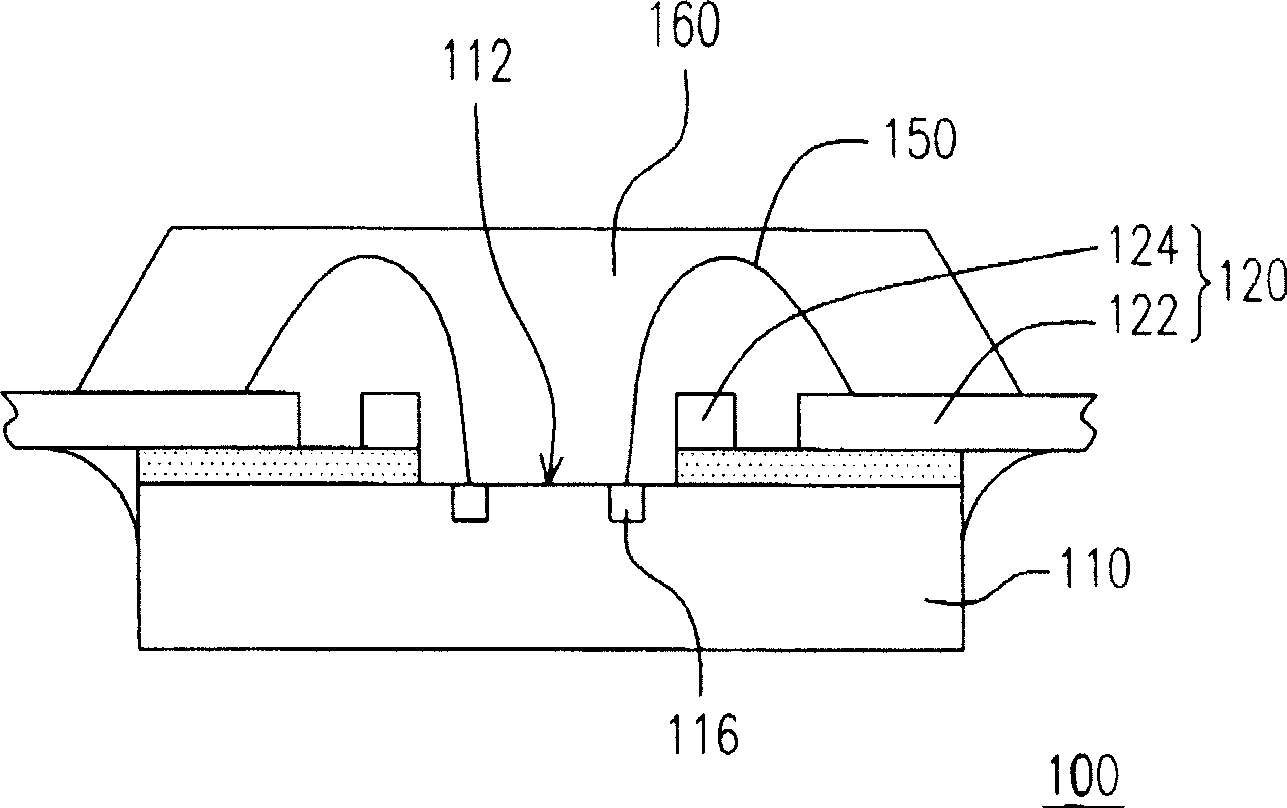

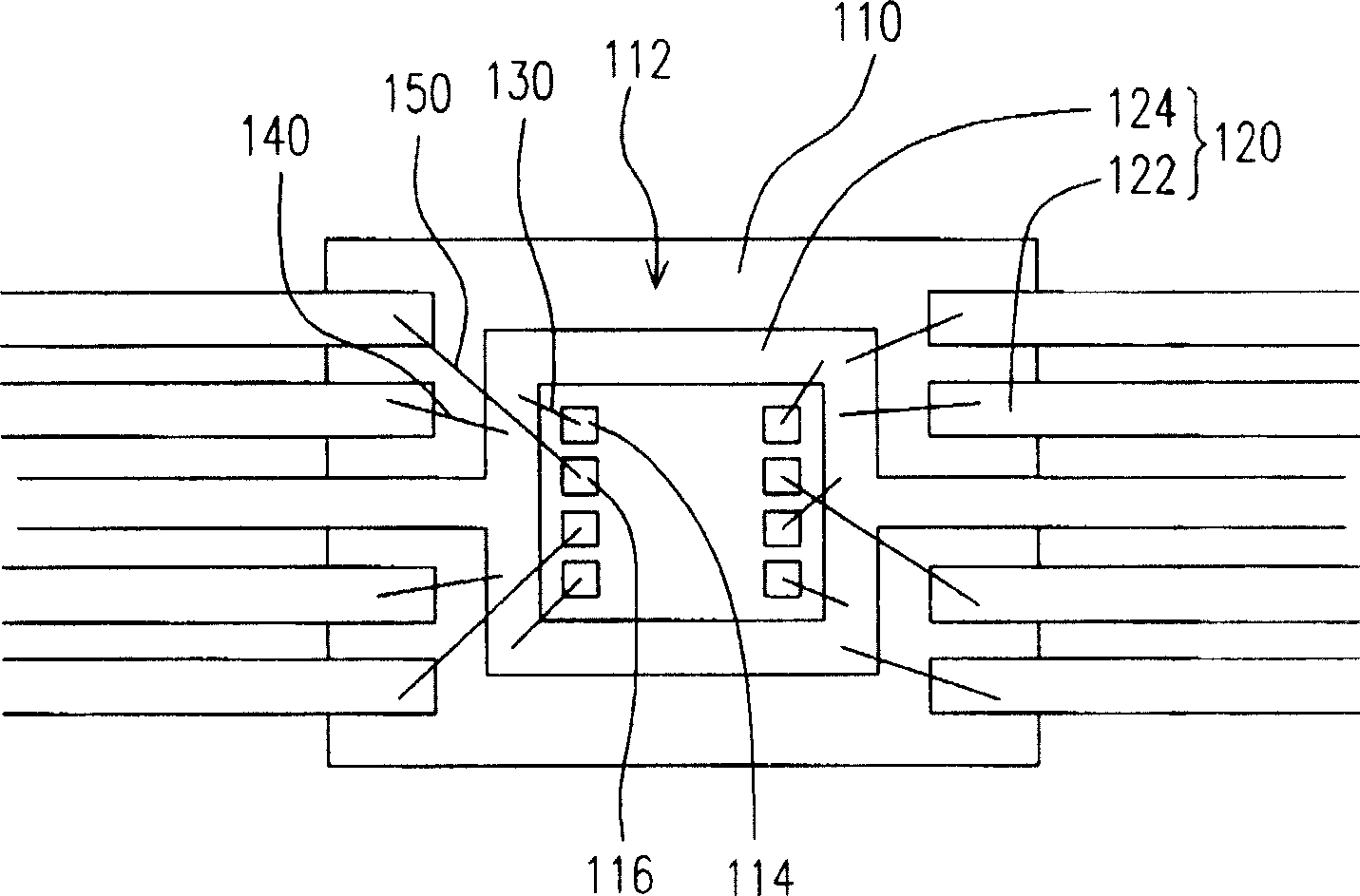

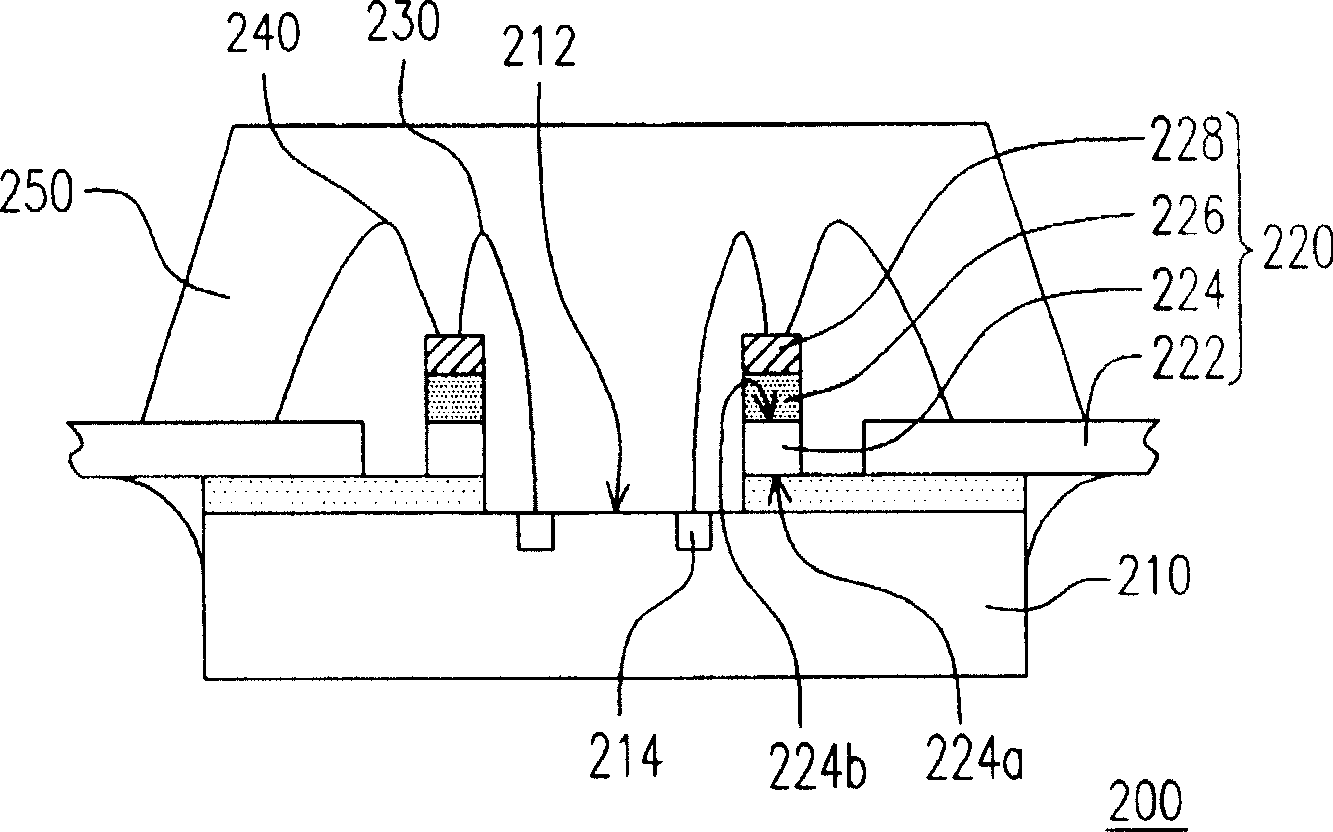

Chip packaging structure and manufacturing method therefor

InactiveCN101118894AShorten the lengthReduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The present invention relates to a wafer packaging structure, which comprises a wafer, a lead frame, a plurality of first welding lines and a plurality of second welding lines. The wafer is provided with an active face and a plurality of wafer welding mats positioned on the active face. The lead frame fixedly positioned on the wafer comprises a plurality of pins, at least one flow concentration frame, an insulating layer and a plurality of shifting welding mats. The flow concentration frame is arranged between the wafer welding mats and the inner pins. The insulating layer is positioned on the flow concentration frame. The shifting welding mat is positioned on the insulating layer, and the inner pins and the flow concentration frame are arranged above the active face, and the wafer and the insulating layer are respectively arranged on the two surfaces face to face of the flow concentration frame. The first welding lines are respectively connected with the wafer welding mats and the shifting welding mats, and the second welding lines are respectively connected with the shifting welding plate and the inner pins. The wafer packaging structure can reduce the falling possibility of the welding line.

Owner:CHIPMOS TECHSHANGHAI +1

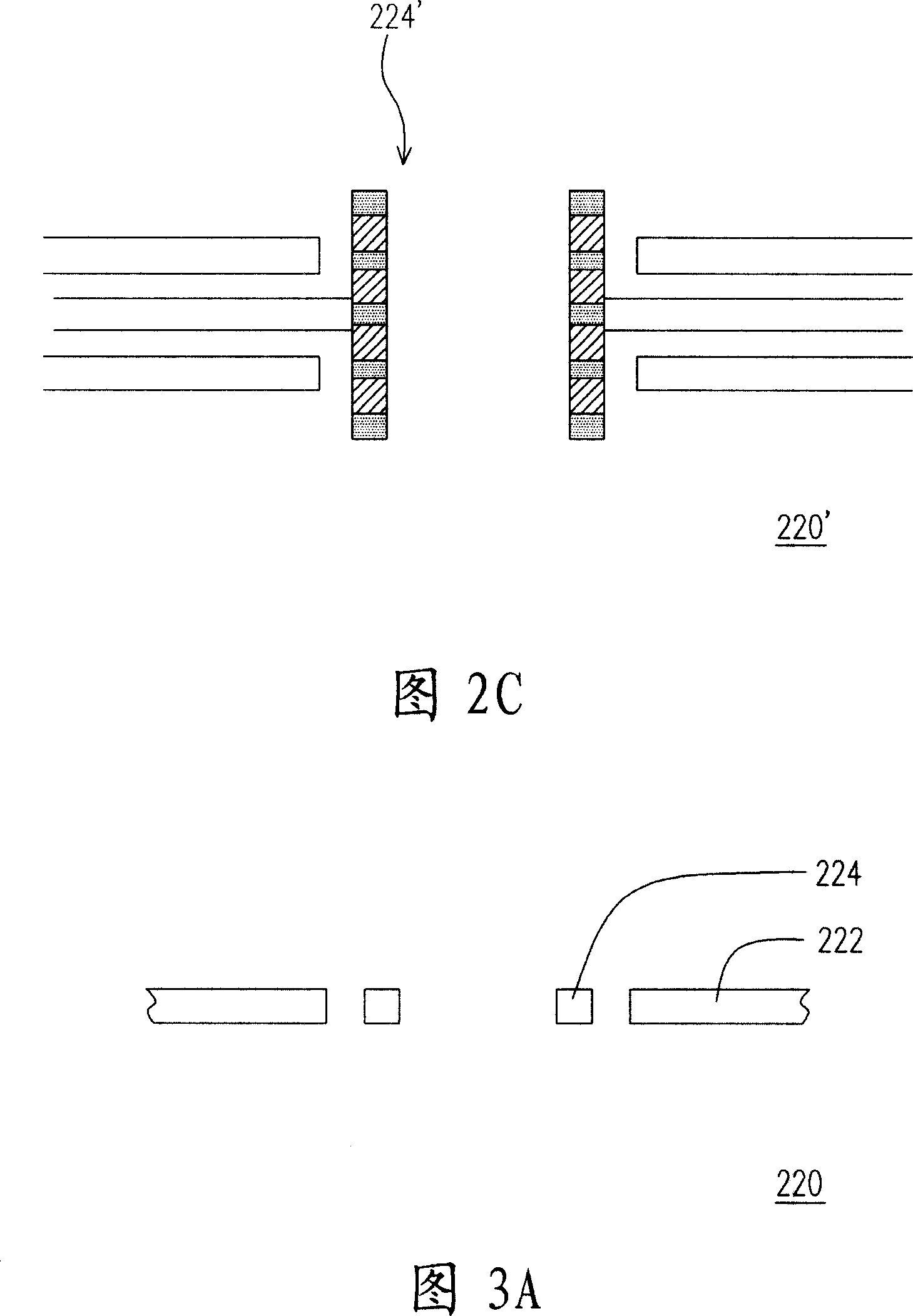

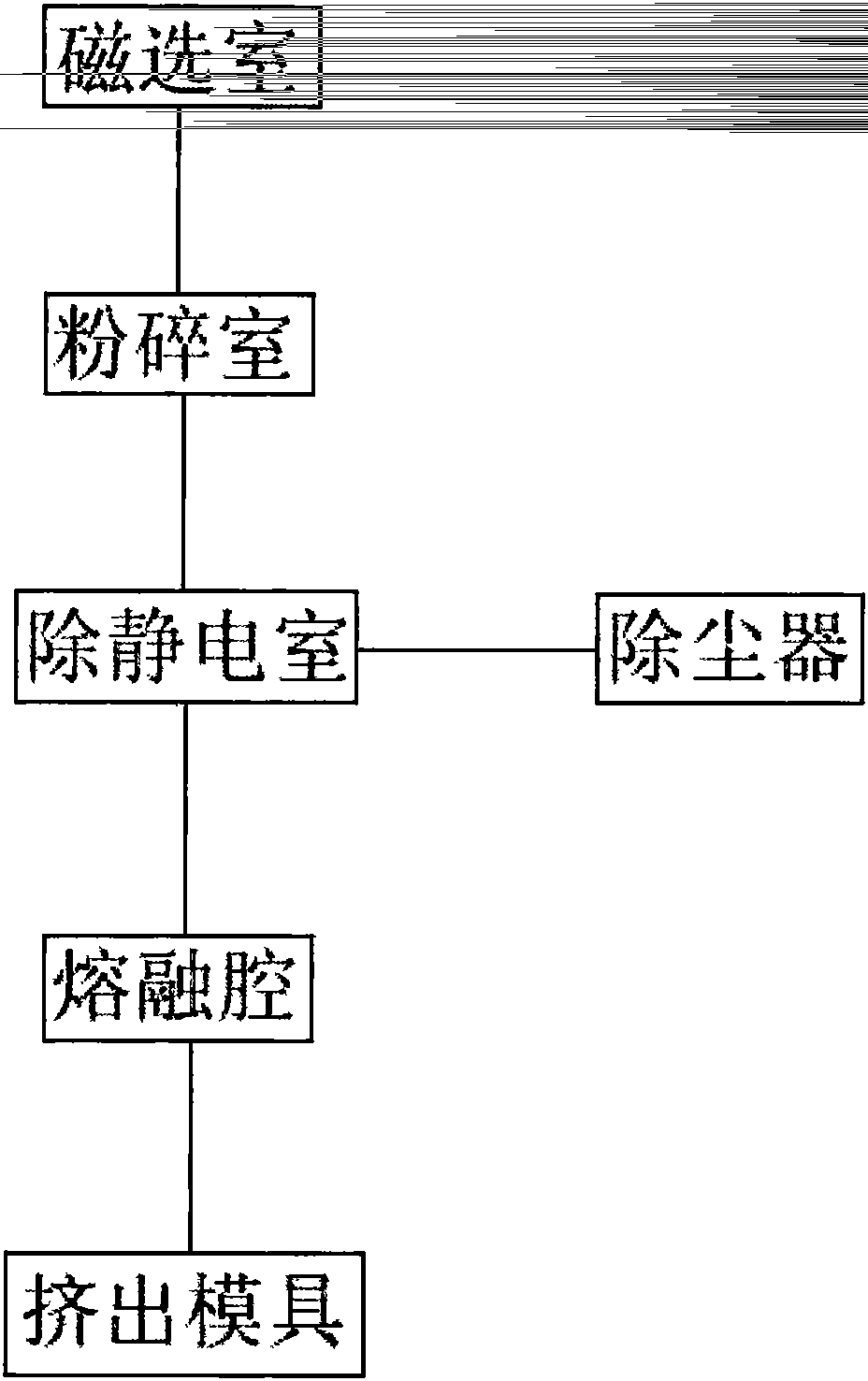

Plastic film manufacturing device

InactiveCN107553851AReasonable structureEasy to useFlat articlesElectrostatic precipitatorThermal energy

The invention provides a plastic film manufacturing device, comprising a magnetic separation chamber, a crushing chamber, a static removal chamber, a melting chamber, an extrusion die and a dust collector, a crushing chamber is arranged at the bottom of the magnetic separation chamber, and a crushing chamber is arranged at the bottom of the crushing chamber There is a static removal chamber, the bottom of the static removal chamber is provided with a melting chamber, one side of the static removal chamber is provided with a dust collector, one end of the melting chamber is provided with an extrusion screw, and the other end of the melting chamber is provided with an extrusion die . The invention has a reasonable structure and is easy to use, can effectively reduce the wear and tear on the machine caused by metal impurities, prolong the practical life of the equipment, reduce the potential safety hazards caused by static electricity and moisture in production, improve the purity of materials, reduce the consumption of heat energy and produce The tearing probability of plastic film can help analyze the quality of raw materials and improve product quality.

Owner:天津华美佳业仿真花卉有限公司

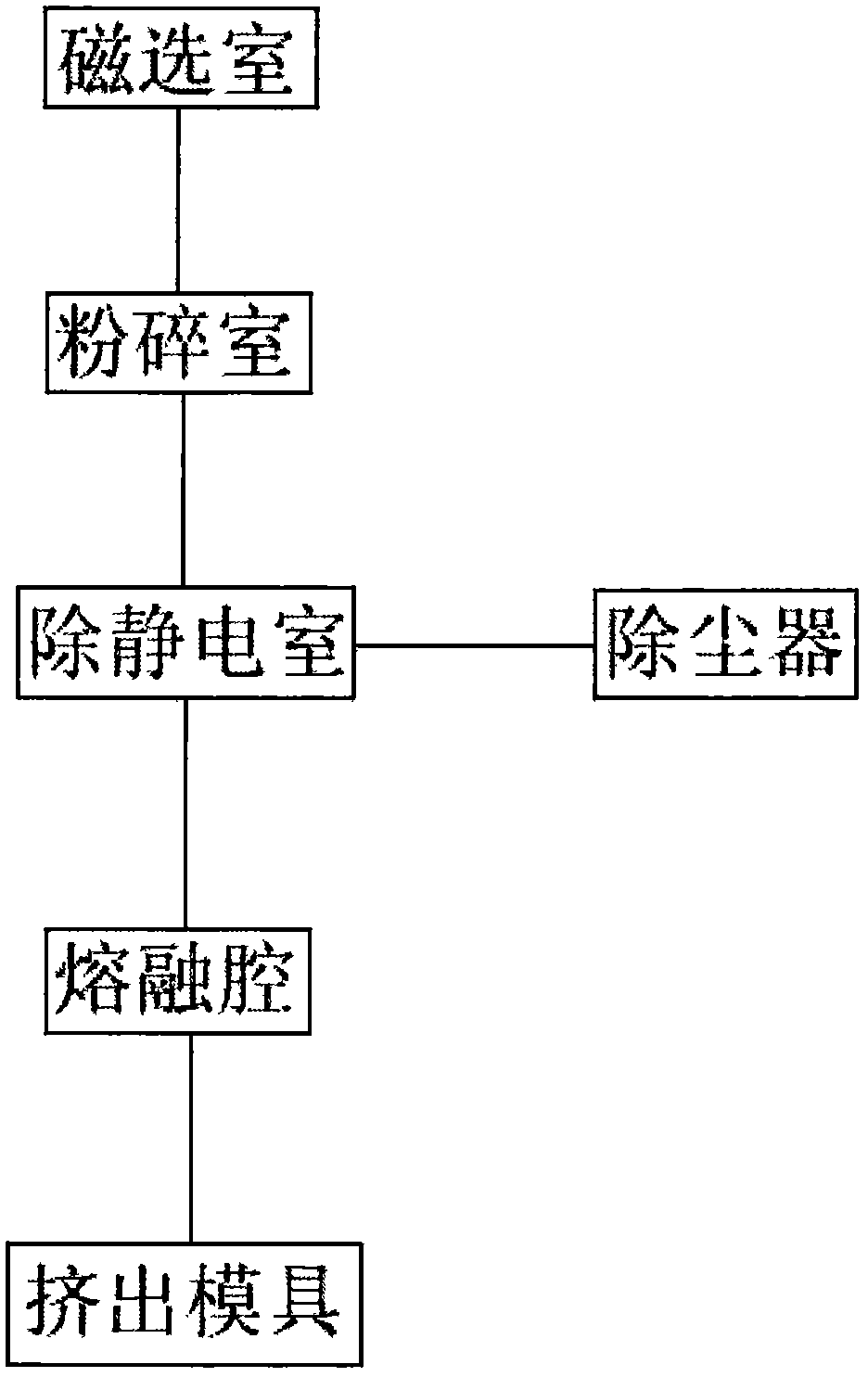

Wind sand preventive cable

InactiveCN110085363AReasonable designFunctionalInsulated cablesInsulated conductorsEngineeringWind direction

The invention discloses a wind sand preventive cable which structurally comprises a wind sand preventive bushing, an outer protective glue layer, a coating sleeve and signal lines. The outer protective glue layer is buckled inside the wind sand preventive bushing via a buckle and coaxial with the wind sand preventive bushing, and the coating sleeve is glued to the inner side of the outer protective glue layer. Wind sand sucked in can be introduced via an air inlet, and rushed out towards a wind direction plate in the end close to the wind direction, grooming leaves are rushed out, wind and sand are guided to the periphery via deflecting branches and leaves and rubber strips, the wind sand is prevented from keeping friction with the wind sand preventive bushing and the outer protective gluelayer, the safety of an oversheath is protected, wind is blown into a primary sand transmitting plate via defection buckles at the two ends, sand is filtered and settled, wind in the two ends fix theouter protective glue layer and the signal lines therein to form a balanced force, the cable is decreased when being shaken, and the possibility that the cable is damaged by being pulled is reduced.

Owner:南安市傅泉机械科技有限公司

Multi-hardness automobile seat foam one-time forming mold and method

The invention belongs to the technical field of automobile seat foam forming, and particularly relates to a multi-hardness automobile seat foam one-time forming mold and method. The mold comprises a male mold and a female mold, the male mold comprises a male mold body, a plurality of infinitesimal elements of the same kind are arranged on the male mold body, and the infinitesimal elements of the same kind are sequentially arranged on the male mold body from top to bottom; the infinitesimal elements are divided into bulges and grooves, and the bulges and the grooves are semicircular, 1 / 4 circular or irregular arc-shaped; and the shape of the male mold for foam forming is controlled through the infinitesimal design on the male mold, then foaming forming of multi-hardness foam is achieved, foam with multiple macrohardness subareas can be obtained through forming only through one kind of filler, and the foam hardness needed by different subareas is easy to control.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Film Blowing Machine with Improved Traction Mechanism

The invention provides a film blowing machine provided with an improved drawing mechanism. The film drawing machine comprises an extrusion mechanism, a film blowing mechanism, the drawing mechanism and a reeling mechanism, wherein the film blowing mechanism comprises a die head, an air ring and a rack; the air ring is arranged above the die head; the die head and the air ring are separately fixedly arranged on the lower end of the rack; the drawing mechanism is arranged on the upper end of the rack; the extrusion mechanism is provided with a material outlet which is connected with the die head; the reeling mechanism comprises a reel which is used for reeling a film; the film blown from the die head is conveyed to the reel through the drawing mechanism; the upper end of the rack is provided with a cross support base; the drawing mechanism comprises a herringbone plate; the herringbone plate is arranged on the cross support base; the upper end of the herringbone plate is provided with a first pressing roll, a second pressing roll and a third pressing roll; the second pressing roll and the third pressing roll are separately pressed against the first pressing roll; the first pressing roll is in transmission connection with a motor I; and a first drawing assembly, a second drawing assembly and a third drawing assembly are sequentially arranged along the transmission direction of the film.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Special-shaped part bending die and control method

PendingCN114505375ASmall specification errorReduce the chance of tearingShaping toolsMetal-working feeding devicesStructural engineeringIndustrial engineering

The invention discloses a special-shaped part bending die and a control method, the special-shaped part bending die comprises a first support, the first support is provided with a hydraulic device, a linear driving device and an upper die assembly, and the hydraulic device and the linear driving device are used for driving the upper die assembly to work; the lower die assembly is arranged on the side right opposite to the upper die assembly, and other devices and structures are arranged on the lower die assembly; and the corresponding control method is matched, so that the materials can be conveniently and efficiently bent, and meanwhile, the production specification, particularly the bending distance, can be conveniently adjusted.

Owner:深圳市泰能特模具技术有限公司

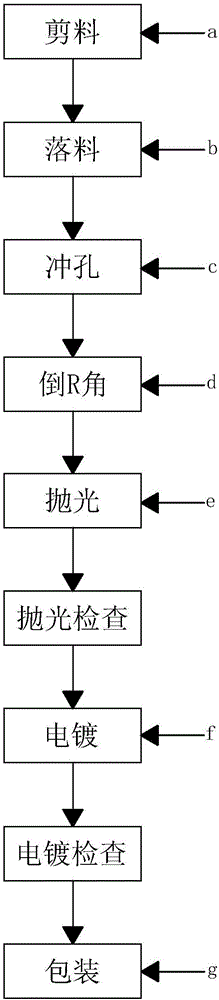

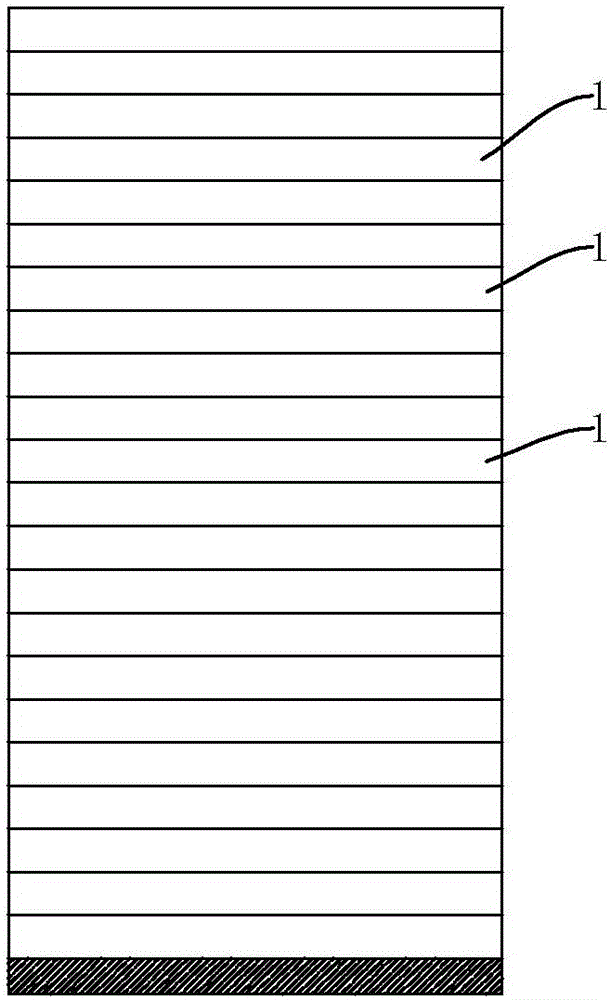

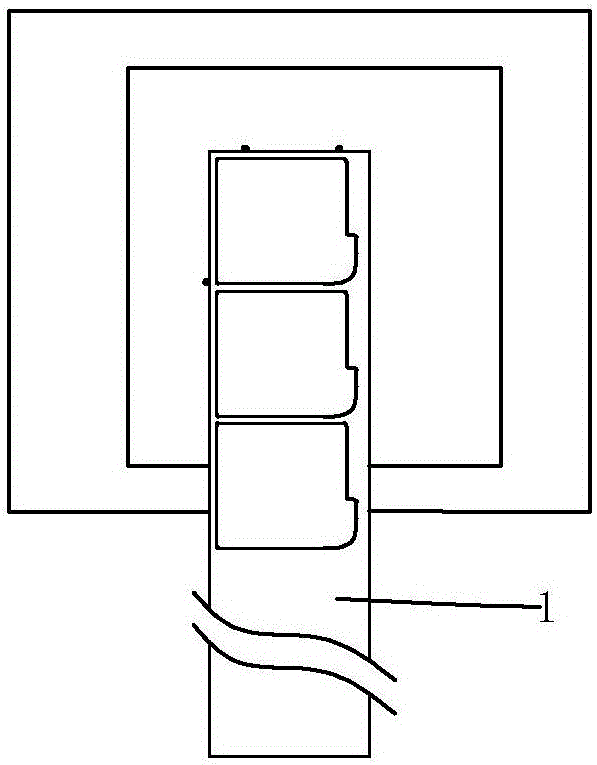

Machining process for drip tray

The invention discloses a machining process for a drip tray. The machining process comprises the first step of material tailoring, wherein a flaky raw material is tailored into a plurality of strip materials; the second step of blanking, wherein the strip materials in the first step are fixed to working stations of an oil press and are punched into the drip tray in a preset shape; the third step of punching, wherein the drip tray in the second step is punched to form a plurality of through holes in a preset shape; the fourth step of chamfering R corners, wherein R corner chamfering is carried out at the edge position of the drip tray in the third step; the fifth step of polishing, wherein the surface of the drip tray in the fourth step is subjected to polishing treatment; and the sixth step of electroplating, wherein the surface of the drip tray in the fifth step is subjected to electroplating treatment. The process is simple, the machining efficiency is improved, the drip tray is formed through stamping, generation of coarseness of the surface of the drip tray machined through the stamping technology will be reduced, favorable conditions are laid for later machining, and the efficiency of the whole process is further accelerated.

Owner:ZHONGSHAN HENGRUN METAL PROD

Chip packaging structure and manufacturing method therefor

InactiveCN100463156CShorten the lengthReduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesLead frameWeld line

The present invention relates to a wafer packaging structure, which comprises a wafer, a lead frame, a plurality of first welding lines and a plurality of second welding lines. The wafer is provided with an active face and a plurality of wafer welding mats positioned on the active face. The lead frame fixedly positioned on the wafer comprises a plurality of pins, at least one flow concentration frame, an insulating layer and a plurality of shifting welding mats. The flow concentration frame is arranged between the wafer welding mats and the inner pins. The insulating layer is positioned on the flow concentration frame. The shifting welding mat is positioned on the insulating layer, and the inner pins and the flow concentration frame are arranged above the active face, and the wafer and the insulating layer are respectively arranged on the two surfaces face to face of the flow concentration frame. The first welding lines are respectively connected with the wafer welding mats and the shifting welding mats, and the second welding lines are respectively connected with the shifting welding plate and the inner pins. The wafer packaging structure can reduce the falling possibility of the welding line.

Owner:CHIPMOS TECHSHANGHAI +1

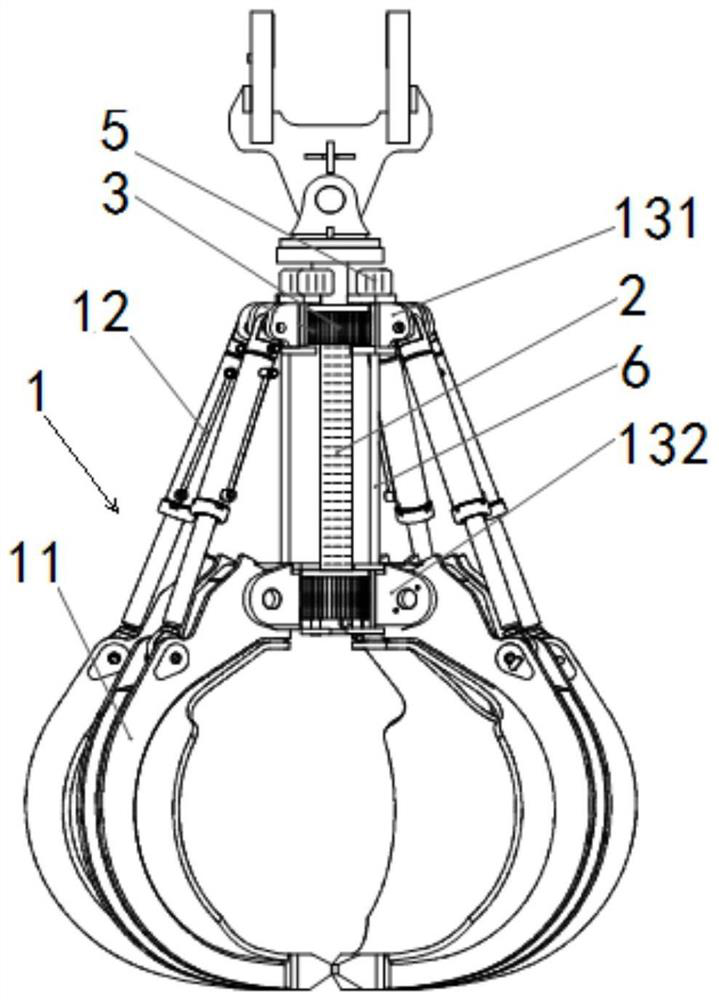

Grabs and Grabbers

ActiveCN110194412BAvoid damageExtended service lifeLoad-engaging elementsStructural engineeringMechanical engineering

The invention provides a gripper and a grabbing machine, which relate to the technical field of grabbing materials. The gripper includes a column and a plurality of grabbing valve assemblies; a plurality of the grabbing flap assemblies are respectively arranged on the column; It moves along the circumference of the column and can be fixed at a preset position. When the gripper grabs the material, according to the shape and size of the material, the gripping flap assembly can be adjusted to move to a suitable position along the circumference of the column, and the gripping flap assembly can be fixed at the suitable position, so that the gripper can be used to grab When picking up materials, the position of the flap assembly can be adjusted according to the shape and size of the material, and the material can be stuck between the two flap assemblies, thereby reducing the circumferential extrusion force of the material on the flap assembly and preventing the flap assembly from shifting toward both sides. Reduce the chance of tearing the root of the gripper valve assembly, prevent damage to the gripper, and prolong the service life of the gripper.

Owner:SANY MARINE HEAVY IND

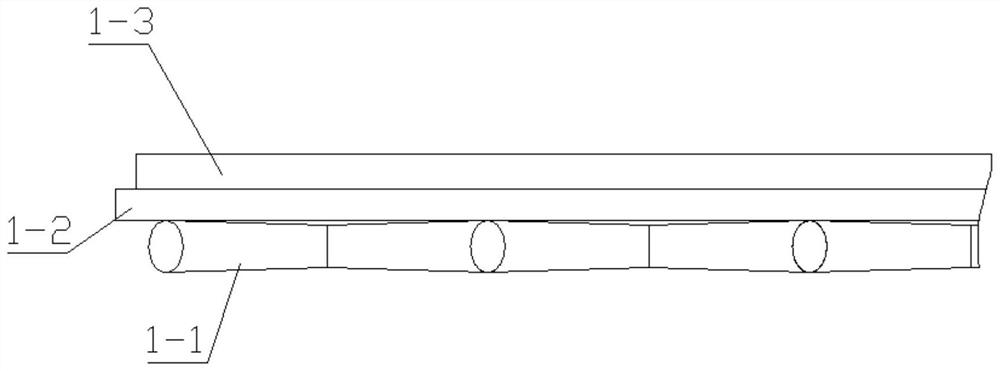

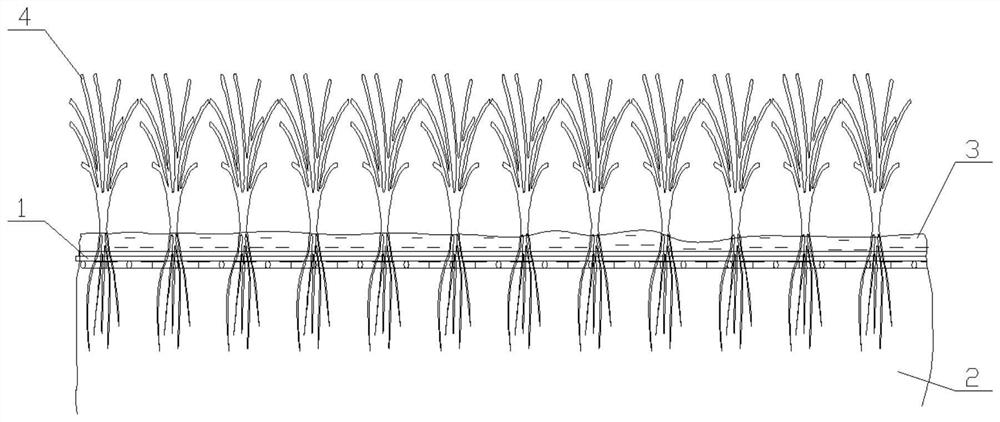

A heavy metal ion adsorption blanket, its preparation method and its application in removing heavy metals from soil

ActiveCN109289810BAvoid secondary pollutionAffect normal growthOther chemical processesContaminated soil reclamationSoil scienceSoil heavy metals

The application discloses a heavy metal ion adsorption blanket, its preparation method and its application in removing heavy metals from soil, which belongs to the technical field of soil environment improvement. The heavy metal ion adsorption blanket made of bentonite and polypropylene blocks the secondary pollution of the soil by foreign substances. Combined with the adsorption of green plants on heavy metal ions in deep soil, the purpose of comprehensive treatment of heavy metals in soil can be achieved.

Owner:海岱生态建设有限公司

Manufacturing device for plastic film

The invention provides a plastic film manufacturing device, comprising a magnetic separation chamber, a crushing chamber, a static removal chamber, a melting chamber, an extrusion die and a dust collector, a crushing chamber is arranged at the bottom of the magnetic separation chamber, and a crushing chamber is arranged at the bottom of the crushing chamber There is a static removal chamber, the bottom of the static removal chamber is provided with a melting chamber, one side of the static removal chamber is provided with a dust collector, one end of the melting chamber is provided with an extrusion screw, and the other end of the melting chamber is provided with an extrusion die . The invention has a reasonable structure and is easy to use, can effectively reduce the wear and tear on the machine caused by metal impurities, prolong the practical life of the equipment, reduce the potential safety hazards caused by static electricity and moisture in production, improve the purity of materials, reduce the consumption of heat energy and produce The tearing probability of plastic film can help analyze the quality of raw materials and improve product quality.

Owner:天津伊伊仿真花有限公司

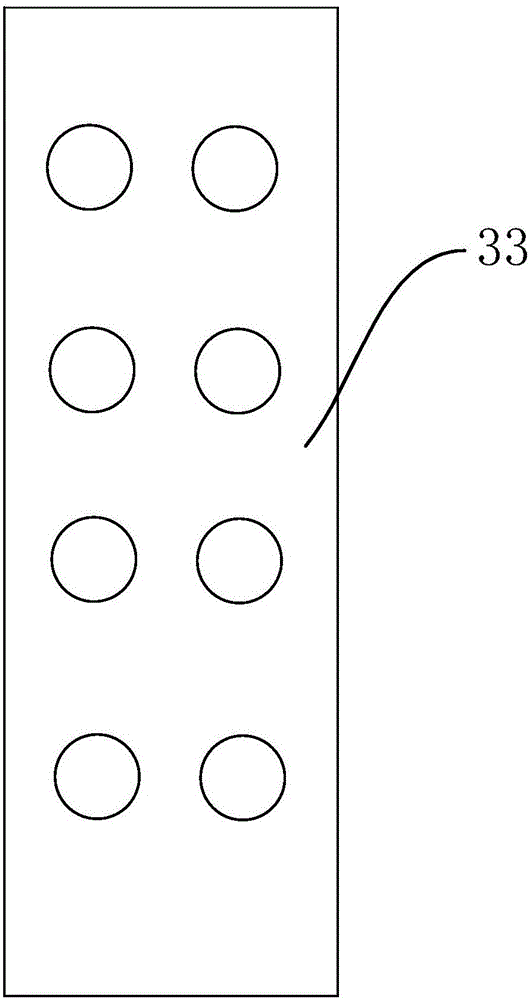

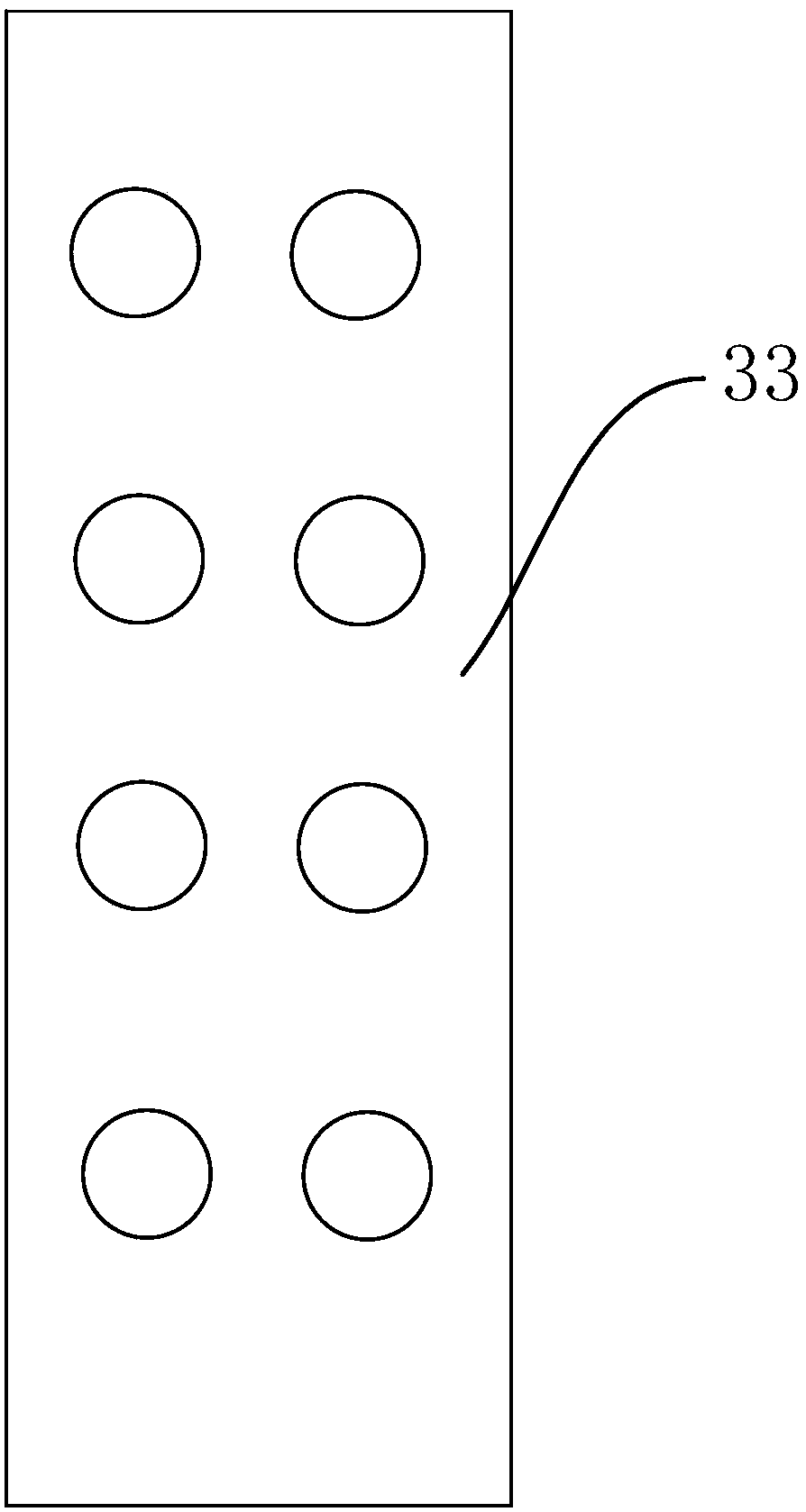

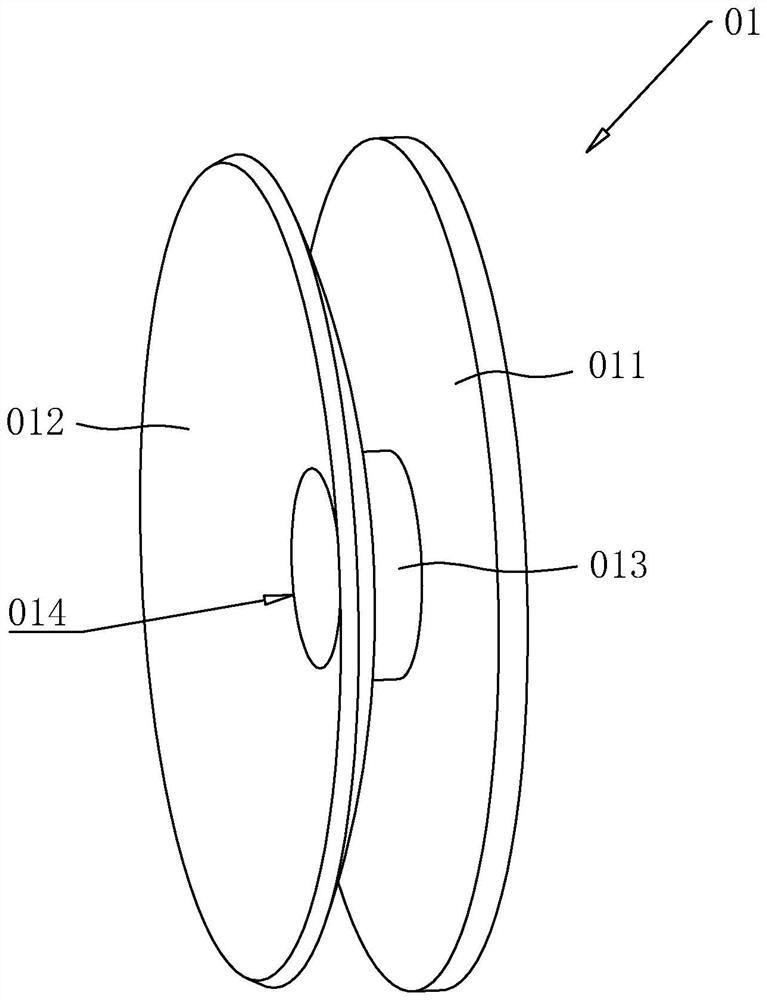

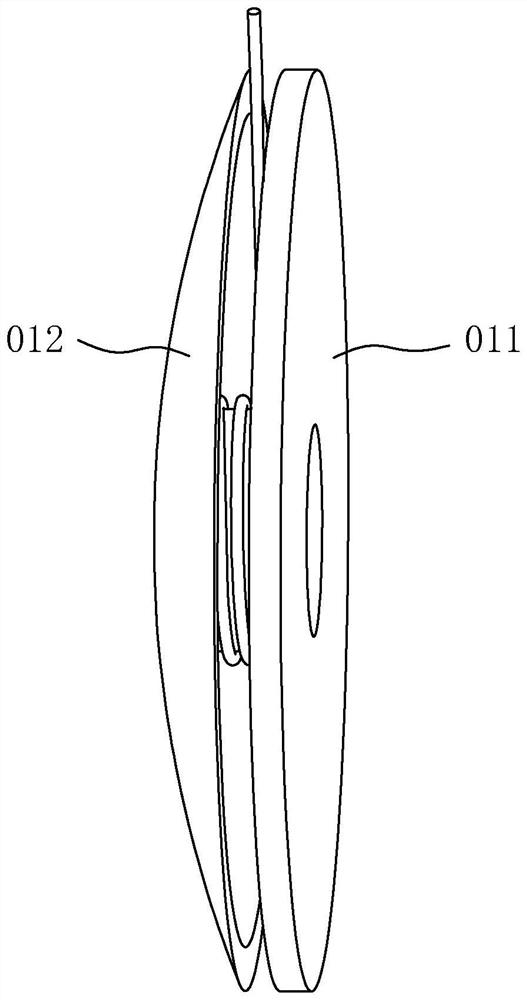

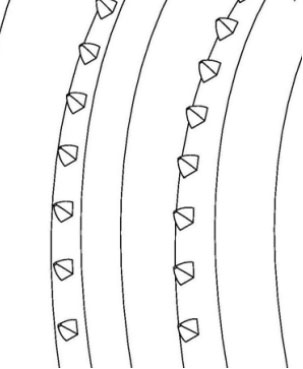

Ratchet wheel for COF carrier tape conveying and using method thereof

The invention discloses a ratchet wheel for COF carrier tape conveying and a using method thereof.The ratchet wheel for COF carrier tape conveying comprises a cylindrical ratchet wheel body, the left side and the right side of the surface of the ratchet wheel body are provided with a plurality of first positioning teeth and a plurality of second positioning teeth respectively, and the first positioning teeth and the second positioning teeth are arranged in parallel; a plurality of first through holes and a plurality of second through holes are formed in the left side and the right side of the COF carrier tape respectively, and the first through holes and the second through holes are arranged in parallel; when the COF carrier tape is installed on the ratchet wheel body, the first positioning teeth can penetrate through the first through holes, the second positioning teeth can penetrate through the second through holes, the peripheral faces of the first positioning teeth and the peripheral faces of the second positioning teeth are smooth surfaces, and the COF carrier tape can be prevented from being scratched. According to the COF carrier tape, the peripheral surfaces of the first positioning teeth and the second positioning teeth are designed into smooth surfaces without sharp right angles and edges, so that the edges of the first through holes and the second through holes can be prevented from being scratched during conveying, and the tearing rate and the reject ratio of the COF carrier tape in later use are reduced.

Owner:APLUS SEMICON TECH CO LTD

Rubber composition and processing method, and brake fluid-resistant product using same and production method

ActiveCN108314848BReduce the chance of tearingImproved compression set resistanceBraking membersFlexible pipesPolymer scienceEthylene-propylene-diene-monomer

The invention discloses a rubber composition and a processing method thereof, and also provides an application of the rubber composition and a method for producing the application. In parts by weight, the rubber composition includes: rubber matrix: 100 parts; Crosslinking agent: 1.5 to 8 parts; Reinforcing filler: 40 to 140 parts; Plasticizer: 0 to 40 parts; Among them, the rubber matrix contains the following components, all of which are calculated in parts by weight: content of branched polyethylene a: 0 < a ≤ 100 parts; content of binary ethylene propylene rubber b: 0 ≤ b < 100 parts; content of EPDM rubber c: 0 ≤ c < 100 parts, the application of the rubber composition is to manufacture resistant Hydraulic brake hoses, brake cups. The beneficial effect is that, because the rubber composition has branched polyethylene, the tear strength of the rubber compound can be improved, thereby reducing the probability of tearing of the product during the production process and improving the overall processing performance.

Owner:HANGZHOU XINGLU TECH CO LTD +1

A kind of fluorine rubber oil seal composition and preparation method thereof

Owner:JIANGMEN XINHUI SEALING TECH

A front subframe

ActiveCN103832473BTroubleshoot Connection Strength IssuesPrecise positioningUnderstructuresPunchingVehicle frame

The invention provides a front auxiliary frame. The front auxiliary frame comprises a front auxiliary frame body and a front side component. The front auxiliary frame body comprises an upper plate and a lower plate, the upper plate and the lower plate are connected together, and a front mounting support of a lower suspension arm and a rear mounting portion of the lower suspension arm are arranged between the upper plate and the lower plate. The front side component is used for connecting the front auxiliary frame body onto a vehicular body. The front side component and the front mounting support are integrally formed by punching, and the front side wall of the front mounting support is connectedly welded to the upper plate or the lower plate while the bottom wall is connectedly welded to the lower plate to form a front-rear double-layer reinforcement structure and an upper-lower double-layer reinforcement structure. A cushion plate is welded between two side walls of the front side component, and the cushion plate and an upper end cover of the front side component jointly clamp a sleeve. The front auxiliary frame has the advantages of high strength, convenience in welding and high positioning precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com