Production process of liquid-helium-free superconducting magnet coil framework structure

A technology of superconducting magnets and coil bobbins, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve problems such as 2’ quenching of superconducting coils, and achieve ideal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0048] The invention discloses a production process of a liquid helium-free superconducting magnet coil framework structure, which is used for the production of the liquid helium-free superconducting magnet coil framework structure.

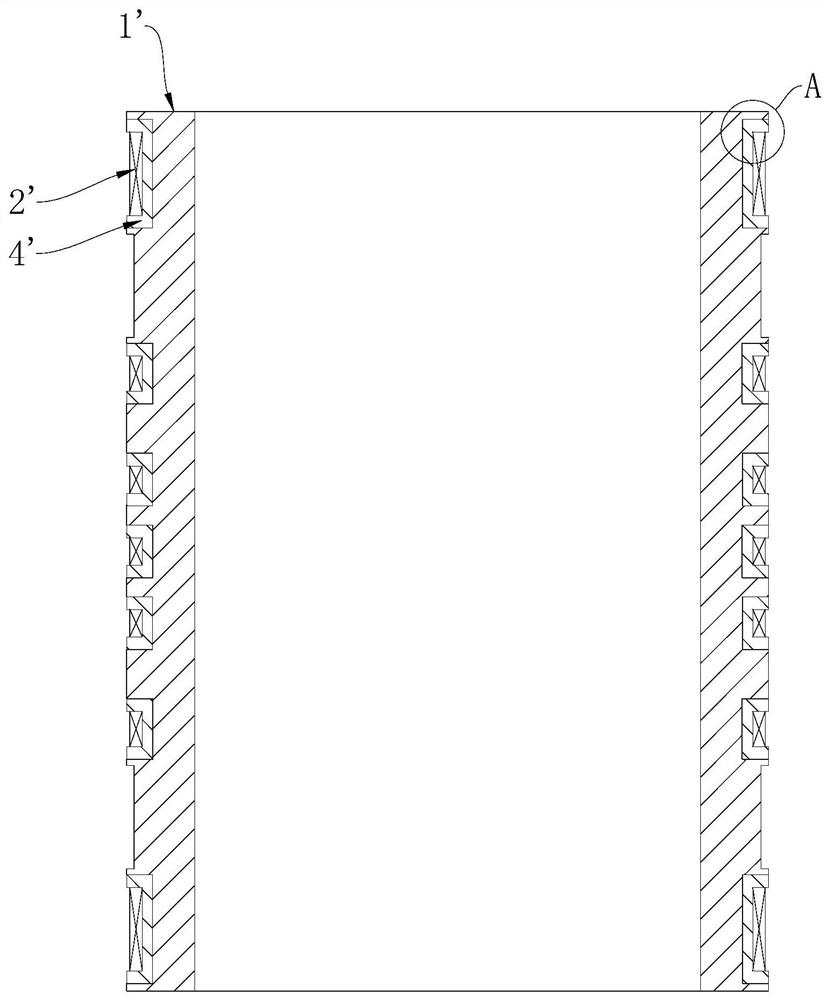

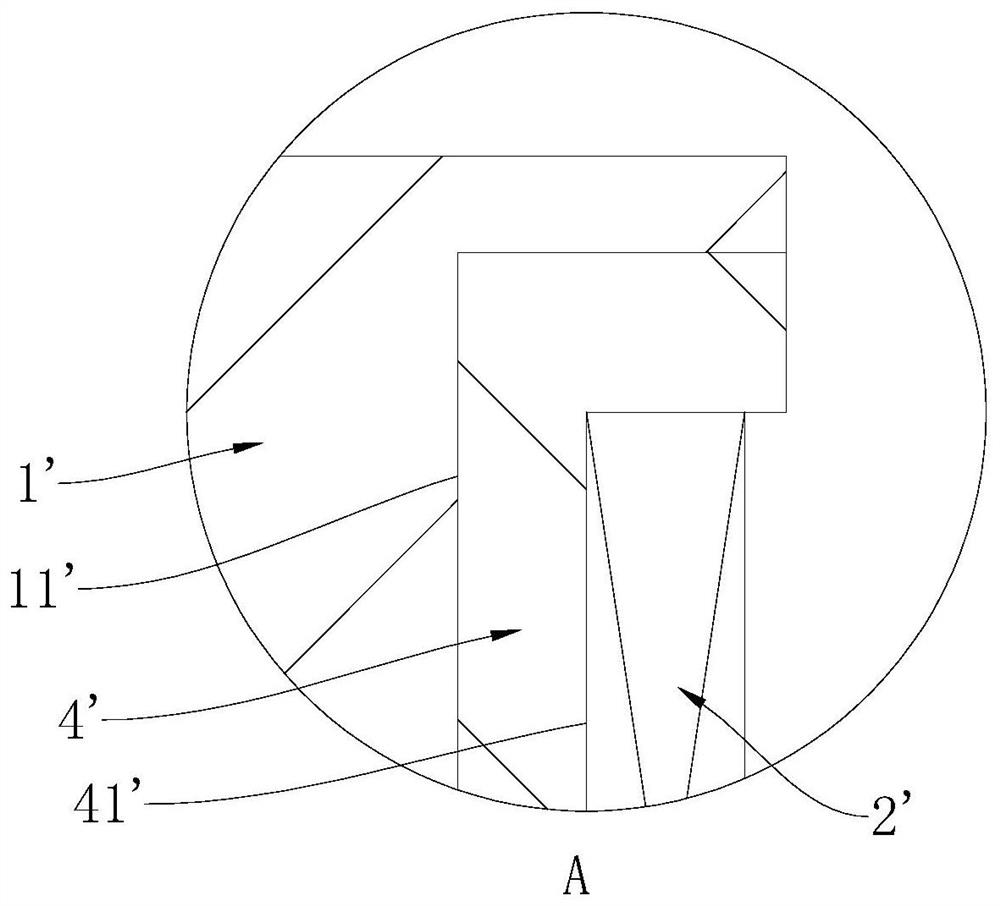

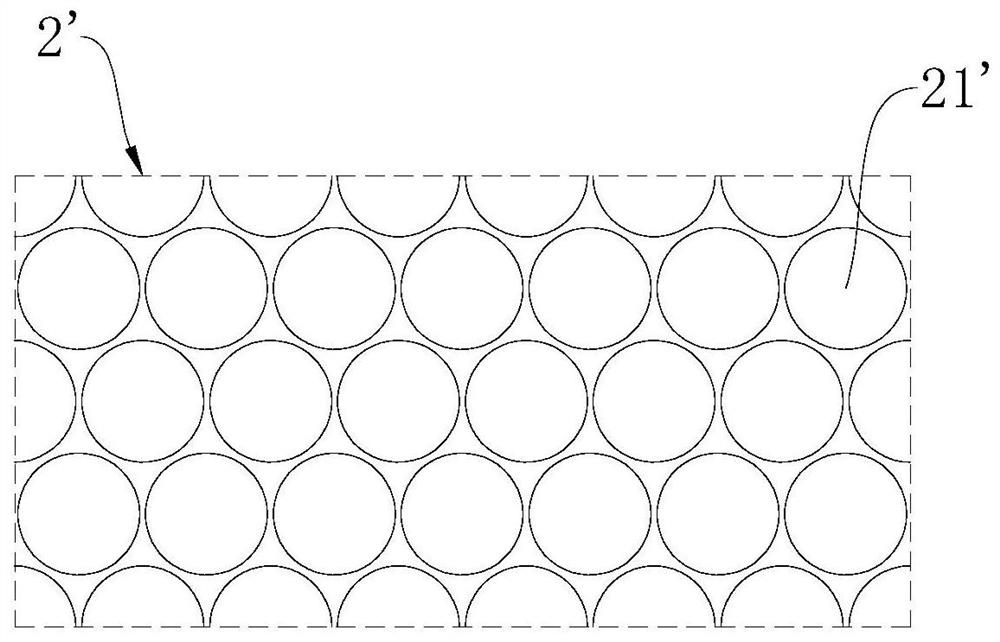

[0049] refer to Figure 4 , the above liquid helium-free superconducting magnet coil skeleton structure includes a skeleton body 1 and a superconducting coil 2 .

[0050] refer to Figure 4 and Figure 5 , The skeleton body 1 is made of aluminum alloy. The skeleton body 1 is arranged with skeleton wire slots 11 at intervals along the length direction of the skeleton body 1 . In this embodiment, the frame body 1 is provided with seven frame wire grooves 11, and the frame wire grooves 11 are ring groove structures.

[0051] refer to Figure 4 and Figure 5 , the frame body 1 is provided with an anti-adhesive layer 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com