Multi-hardness automobile seat foam one-time forming mold and method

A car seat, multi-hardness technology, applied in the field of car seat foam molding, can solve the problem of uneven foam hardness affecting driver and passenger's perception of ride comfort, reduce the probability of foam tearing, and facilitate molding and demoulding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

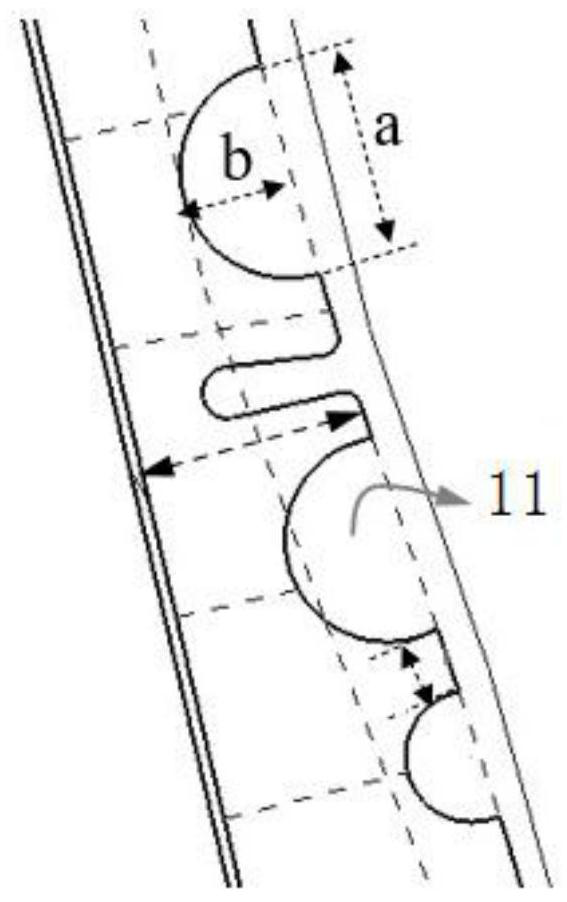

[0059] like Figure 1-5 As shown, a multi-hardness one-time molding automobile seat foam mold includes a male mold 1 and a female mold 2, wherein the female mold 2 and its carrier are arranged in conformity with the shape, and the seat part made by the male mold 1 in the foam mold can be directly Assembled with the cover (mask) in the mode of buckle or Velcro, the carrier of the seat part produced by the female mold 2 in the foam mold is a skeleton steel wire (curtain) or a skeleton steel plate or a skeleton plastic plate. The structure of the female mold 2 involved in the present invention can be freely designed. Generally, it can follow the shape of its supporting body, and can also be used as a design structure for weight reduction.

[0060] Described male mold 1 comprises male mold body, and the male mold body is provided with a plurality of microelements of the same type, and the microelements of the same type are sequentially arranged on the male mold body from top to bo...

Embodiment 2

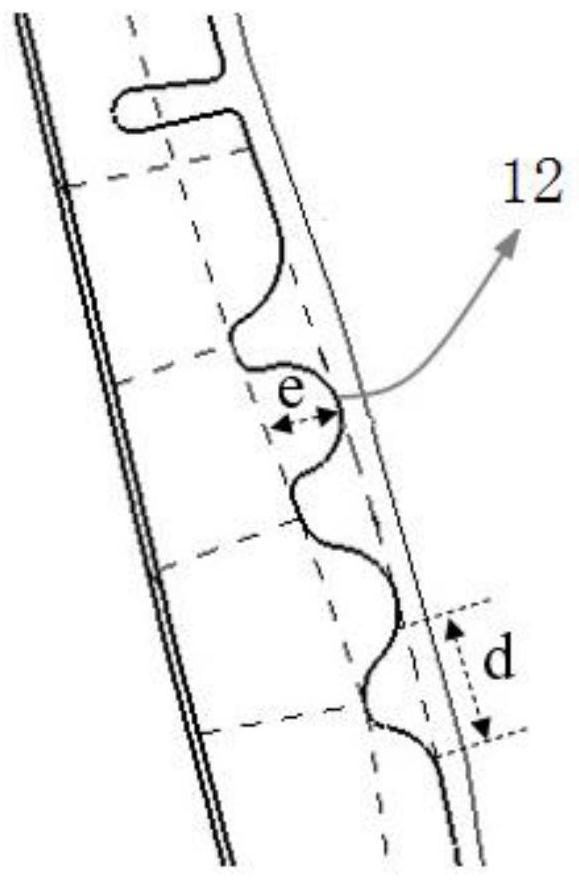

[0109] The main body of the male mold 1 is provided with micro-units in various forms to realize the macroscopic control of the foaming hardness of a cavity of an isocyanate polyester polyether filler. The micro-units involved refer to the multiple arc-shaped protrusions 11 or grooves 12 provided on the male mold 1 from top to bottom, and the area and depth of different arc-shaped protrusions 11 or grooves 12 are arranged by design Realize multi-hardness zonal foam. During the foam molding process, only one isocyanate polyester polyether filler enters the cavity of the male mold 1 from the filling port of the male mold 1, avoiding the dual-hardness conventional chemical foaming molding method to obtain uneven hardness of the foam body. Debugging difficult puzzles with controlled hardness. The foam body obtained through the mold forms a surface contact between every two arc-shaped protrusions or grooves and the protective surface to support the protective surface.

[0110] The...

Embodiment 3

[0118] Take the semicircular groove 12 designed on the male mold 1 as the microelement as an example, the diameter of the microelement in the upper part of the back is 40mm, the depth is 30mm, the diameter of the microelement in the lower part of the back is 40mm, the depth is 20mm, and the attitude maintaining area is not large when turning. Involving the tactile area, the tactile area of the lumbar spine (part) has a diameter of 30 mm and a depth of 10 mm, the diameter of the micro-element of the hip bone and sacrum tactile area is 20 mm, and the depth of 20 mm, and the diameter of the micro-element of the hip bone and coccyx tactile area of the seat cushion of the car seat is 10 mm , the depth is 10mm, the microelement diameter of the thigh tactile area is 20mm, the depth is 15mm, the microelement diameter of the calf tactile area is 40mm, and the depth is 20mm;

[0119] The present invention improves the method of controlling hardness by interfering with foam micropores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com