Clamping device and automatic detinning reel machining system with same

A clamping device and automatic processing technology, used in transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve problems such as trouble, achieve high quality and quality, and reduce the possibility of being torn off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is attached Figure 3-15 The application is described in further detail.

[0053] The embodiment of the present application discloses a clamping device.

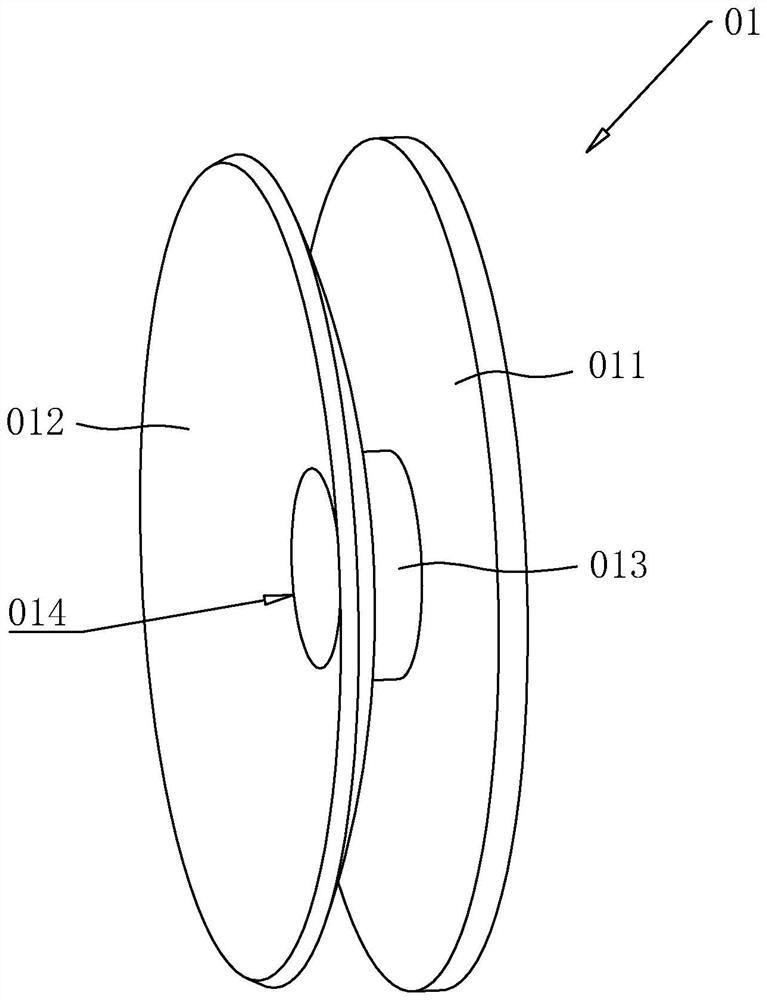

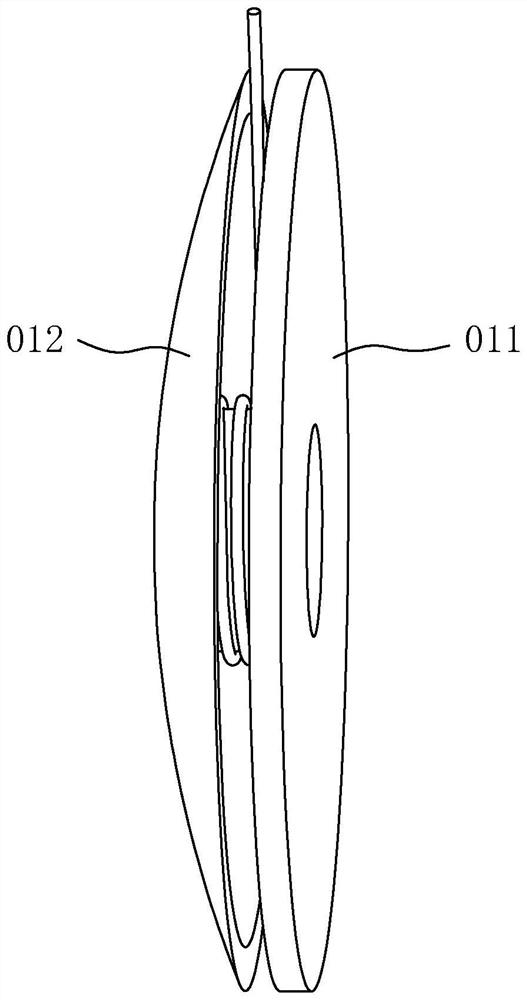

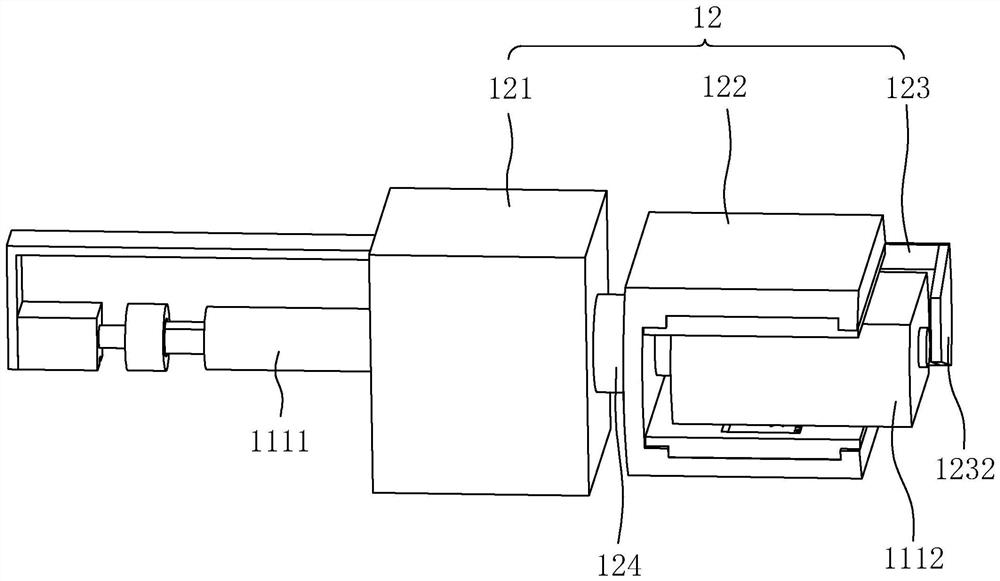

[0054] refer to image 3 , Figure 4 and Figure 5 , a clamping device includes a rotating mechanism 11 , a clamping mechanism 12 and a driving mechanism 13 .

[0055] refer to Figure 4 , the rotating mechanism 11 includes a rotating member 111 and an insertion end 112 .

[0056] refer to Figure 4 , in this embodiment, the rotating part 111 includes a rotating shaft 1111 and a placement part 1112, the rotating shaft 1111 is a cylindrical shaft, the placement part 1112 is welded to one end of the rotating shaft 1111, and the placement part 1112 is a structure formed by cutting off both sides of a cylinder, The cutting surfaces on both sides of the mounting part 1112 are the first cutting surfaces 1113, the two first cutting surfaces 1113 are parallel to each other, and the two first cutting surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com