Cascade variable double amplitude limit temperature control system in ladle baking control and method

A technology of control system and cascade regulation, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve problems such as waste of energy, incomplete combustion of fuel, large pollution, etc., to improve quality and quality, save energy Emission reduction effect and service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

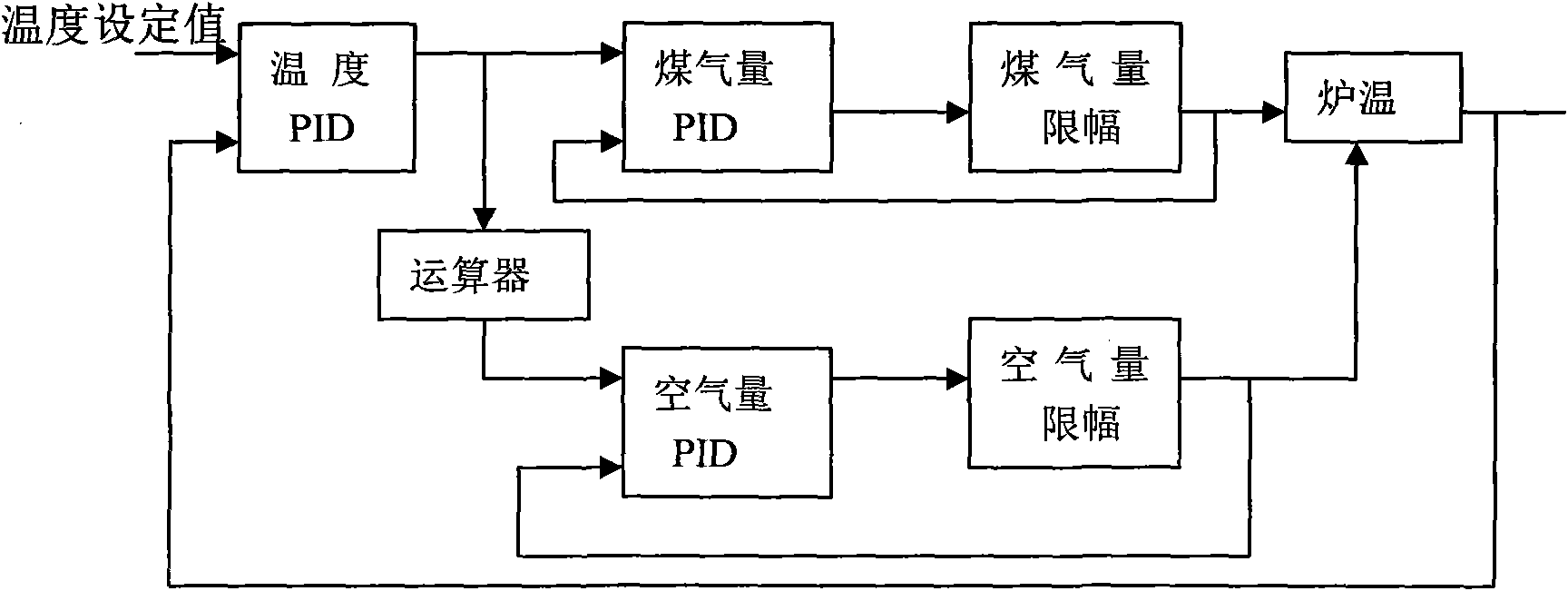

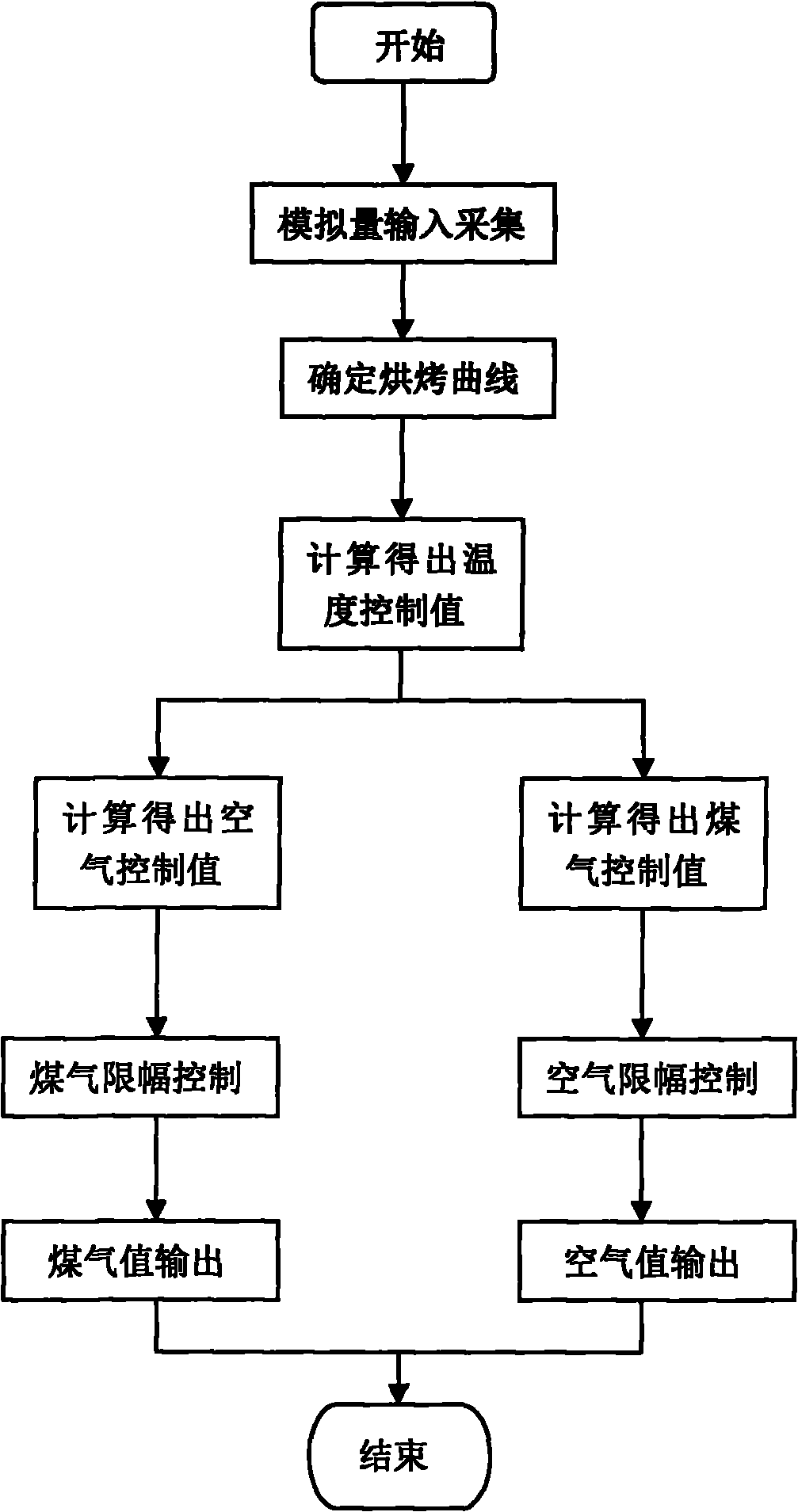

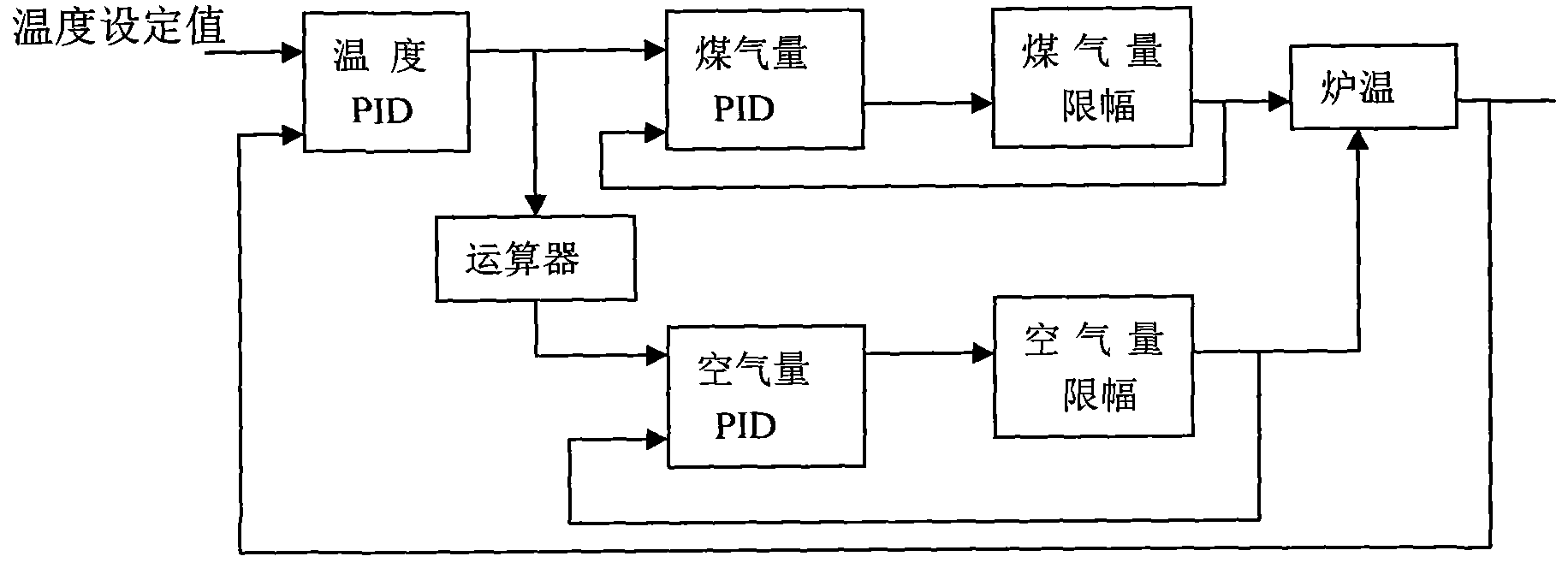

[0034] The present invention uses the temperature series-parallel adjustment system as the main system. In the temperature feedback control mode, the purpose of selecting the cascade adjustment control method is to control the baking temperature of the ladle, and the temperature control is realized by changing the combustion gas flow rate and air flow rate. . Analyzing these measurement signals and temperature control objects, it can be concluded that temperature measurement and control is a large lag link, and its transfer function is approximately a second-order inertial link plus a pure lag link, while the gas flow and air flow are transferred from the measurement signal to the control signal The response is very fast, and its transfer function is approximately a first-order inertial link. The main source of interference is also from the gas and air pipelines. Such a system is most suitable for the cascade regulation control method. The cascade adjustment control method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com