Manufacturing device for plastic film

A technology for manufacturing devices and plastic films, which is applied in the field of plastic woven bag manufacturing devices, can solve the problems of complex raw material composition, shortened equipment life, and large safety hazards, and achieves the effects of improving purity, reducing safety hazards, and reducing thermal energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

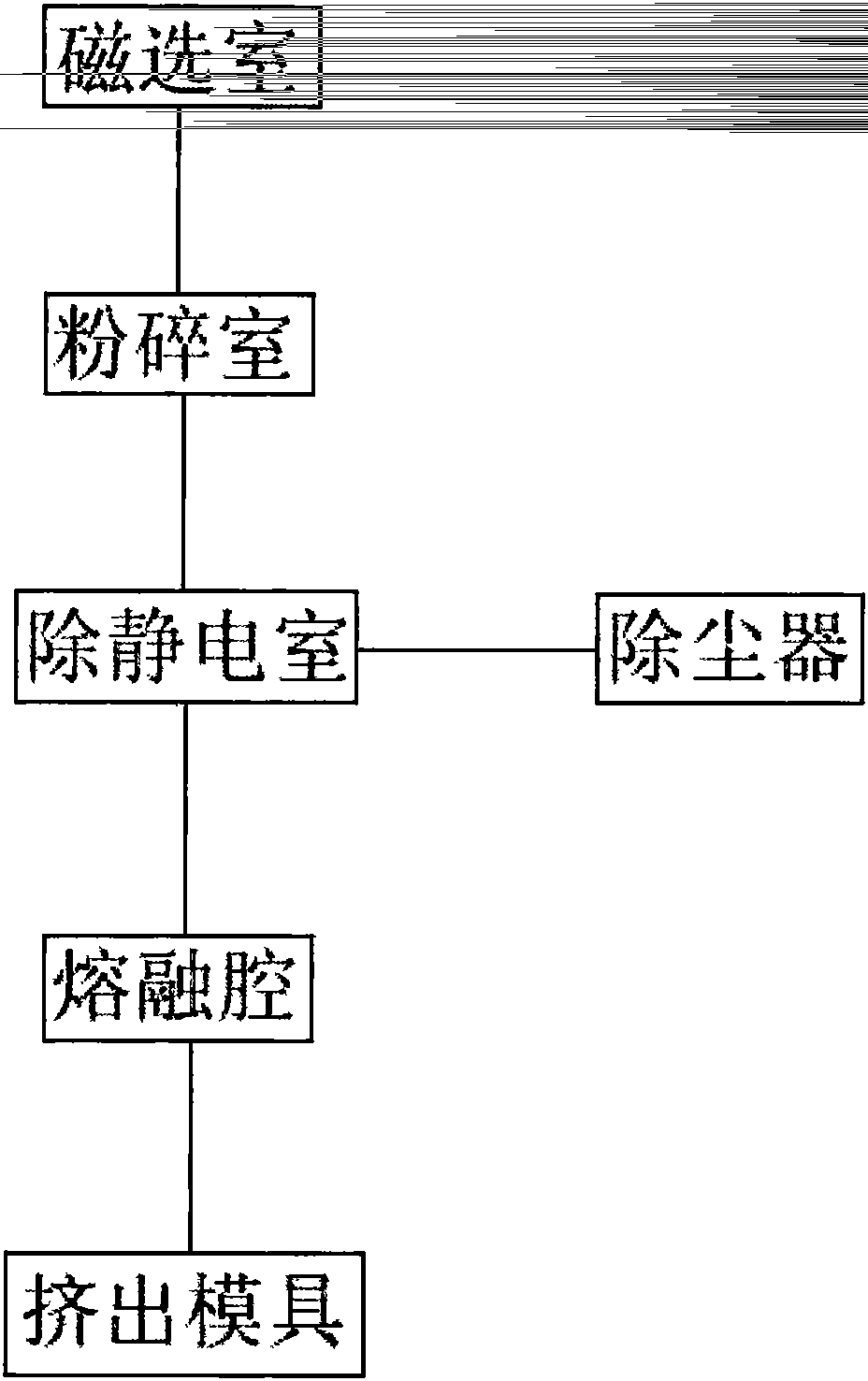

[0009] Such as figure 1 A plastic film manufacturing device, comprising a magnetic separation chamber, a crushing chamber, a static removal chamber, a melting chamber, an extrusion die and a dust collector, the bottom of the magnetic separation chamber is provided with a crushing chamber, and the bottom of the crushing chamber is provided with a static removal chamber A melting chamber is provided at the bottom of the static removal chamber, a dust collector is provided on one side of the static removal chamber, an extrusion screw is provided at one end of the melting chamber, and an extrusion die is provided at the other end of the melting chamber.

[0010] The working process of this example: the material enters the magnetic separation room after preliminary classification. Due to the complex composition of the secondary recycled material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com