Method for producing polyphenylene sulfide film

A technology of polyphenylene sulfide film and manufacturing method, applied in the direction of coating, wax coating, etc., can solve the problem of low toughness and tensile tear elongation of polyphenylene sulfide film, complex film production process and process conditions, etc. Problems, achieve tear strength and tear elongation and other performance improvements, small crystallinity, use temperature and melting point increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

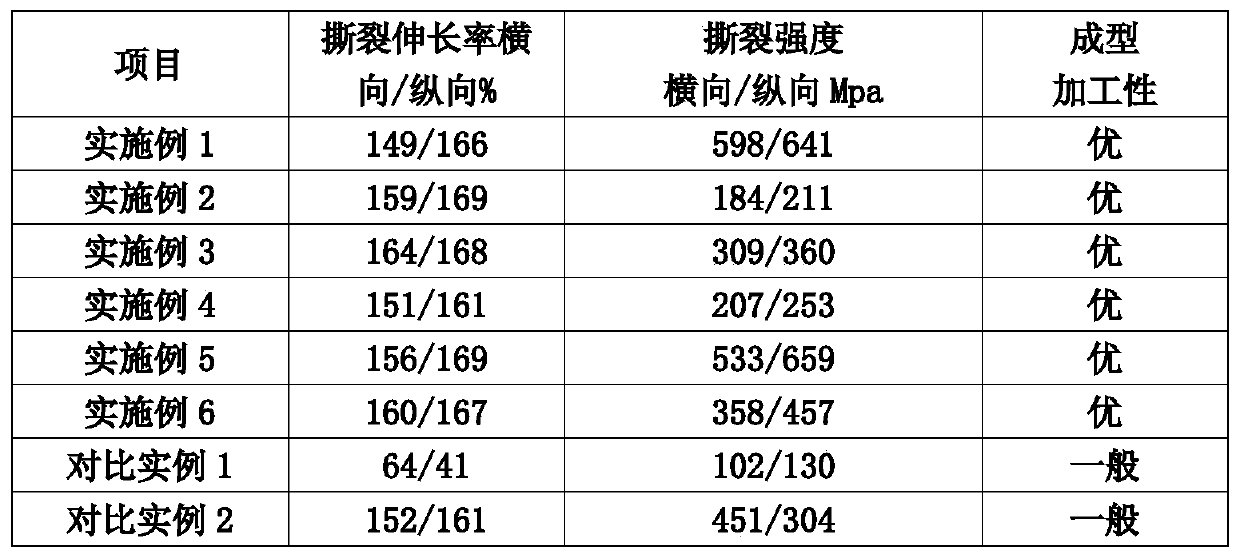

Examples

Embodiment 1

[0035] A kind of manufacture method of polyphenylene sulfide film, concrete steps are as follows:

[0036] Using sodium sulfide and p-dichlorobenzene as raw materials, N-methyl-2-pyrrolidone as solvent, sodium sulfide: p-dichlorobenzene: 1,3,5-trichlorobenzene: 2,4,6-trichlorobenzene The molar ratio is 1: 0.988: 0.006: 0.006, polyphenylene sulfide resin is synthesized by polycondensation under the condition of not adding any co-solvent, and the obtained resin is added to the purification treatment mixed solvent at 3% wt for purification treatment. The composition of the purification treatment mixed solvent is Deionized water 13%wt, NMP40%wt and methanol 47%wt, then add 0.025g of HCl10%wt deionized aqueous solution per 100g of polyphenylene sulfide resin, then the temperature rises to 240 ° C, keep warm for 0.8h, and then 13 Cool at a rate of ℃ / min, and when the temperature drops to 120°C, filter while it is hot to obtain polyphenylene sulfide resin, and repeat the above purifi...

Embodiment 2

[0039] Sodium sulfide and p-dichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, polyphenylene sulfide resin is synthesized by polycondensation without adding any co-solvent, sodium sulfide: p-dichlorobenzene: 1,3, The molar ratio of 5-trichlorobenzene: 2,4,6-trichlorobenzene is 1: 0.994: 0.003: 0.003, and the obtained resin is added into the purification treatment mixed solvent with 6% wt for purification treatment, and the composition of the purification treatment mixed solvent is Deionized water 18%wt, NMP60%wt and methanol 22%wt, then add 0.05g of HCl10%wt deionized aqueous solution per 100g of polyphenylene sulfide resin, then the temperature rises to 260 ° C, keep warm for 0.5h, and then 16 Cool at a rate of ℃ / min, and when the temperature drops to 130°C, filter while it is hot to obtain polyphenylene sulfide resin, and repeat the above purification steps twice to obtain polyphenylene sulfide with a volatile content of less than 0.001%. ...

Embodiment 3

[0042] Sodium sulfide and p-dichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, polyphenylene sulfide resin is synthesized by polycondensation without adding any co-solvent, sodium sulfide: p-dichlorobenzene: 1,3, The molar ratio of 5-trichlorobenzene: 2,4,6-trichlorobenzene is 1: 0.991: 0.004: 0.005, and the obtained resin is added into the purification treatment mixed solvent with 4% wt for purification treatment, and the composition of the purification treatment mixed solvent is Deionized water 16%wt, NMP48%wt and methanol 36%wt, then add 0.035g of HCl10%wt deionized aqueous solution per 100g of polyphenylene sulfide resin, then the temperature rises to 249 ° C, keep warm for 0.7h, and then 14 Cool at a rate of ℃ / min, and when the temperature drops to 129°C, filter while it is hot to obtain polyphenylene sulfide resin, and repeat the purification steps more than two times to obtain polyphenylene sulfide with a volatile content of less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com