Length-controllable liquid crystal segmented copolymer micelle and preparation method thereof

A block copolymer and block polymer technology are applied in the field of liquid crystal block copolymer micelles and their preparation, which can solve the problems of large batch size difference, high preparation cost, difficult micelle size and the like, and achieve production Low cost, simple steps, and low polydispersity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

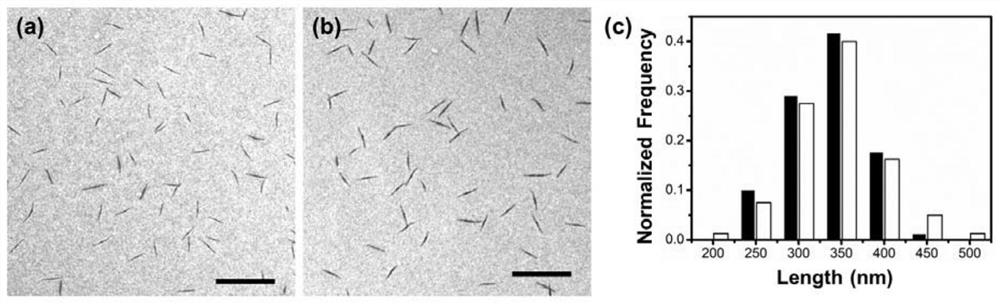

[0026] A preparation method of diblock polymer nano micelles, comprising: weighing block copolymer P2VP according to the above ratio 68 -b-PFMA 41 1.00mg, 0.09mg of phenylselenium bromide and 0.009mg of 4-dimethylaminopyridine were dispersed in 10ml of isopropanol to form a solution, and then the solution was heated to 80°C and kept at constant temperature for 30min, then cooled down to room temperature, that is Obtain; After measuring, the polymer nanomicelle average length is a columnar micelle of 337nm, and the dispersion coefficient is 1.000 (such as figure 1 shown in a).

Embodiment 2

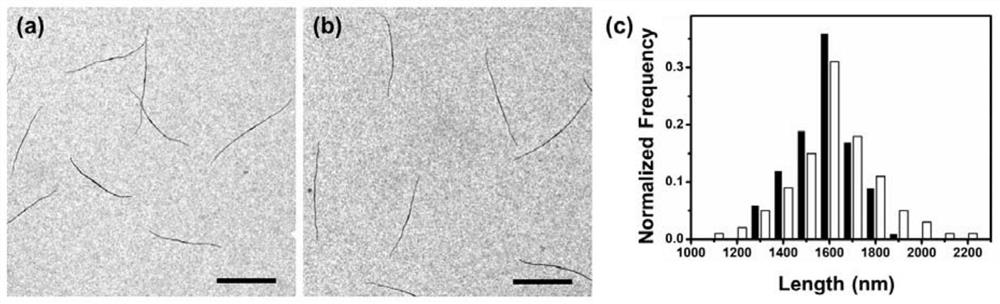

[0028] A preparation method of diblock polymer nano micelles, comprising: weighing block copolymer P2VP according to the above ratio 400 -b-PFMA 42 Disperse 1.0mg, 0.005mg of phenylselenium bromide and 0.0006mg of 4-dimethylaminopyridine into 10ml of methanol to form a solution, then heat the solution to 80°C for 30min at a constant temperature, and then cool down to room temperature to obtain the product; After measuring, described polymer nanomicelle average length is the columnar micelle of 1600nm, dispersion coefficient is 1.003 (as figure 2 shown in a).

Embodiment 3

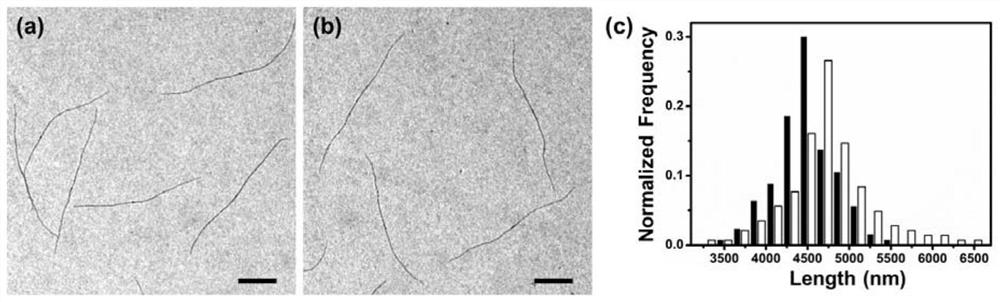

[0030] A preparation method of diblock polymer nano micelles, comprising: weighing block copolymer P2VP according to the above ratio 262 -b-PFMA 53 0.5mg, 0.0004mg of phenylselenium bromide and 0.0001mg of 4-dimethylaminopyridine were dispersed in 10ml of isopropanol to form a solution, and then the solution was heated to 80°C and kept at constant temperature for 30min, then cooled down to room temperature, that is Obtain; After measuring, the polymer nanomicelle average length is the columnar micelle of 4576nm, and dispersion coefficient is 1.006 (as image 3 shown in a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com