A kind of fluorine rubber oil seal composition and preparation method thereof

A technology of fluororubber and composition, which is applied in the field of preparation of small skeleton fluororubber oil seal composition in the engine machinery industry. The problems such as low efficiency can be solved, and the effects of delaying vulcanization time, low cross-linking density and high production efficiency can be achieved.

Active Publication Date: 2019-09-27

JIANGMEN XINHUI SEALING TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual production, a vulcanization temperature of 170-180 degrees and a rapid vulcanization system are often required for production efficiency to achieve short vulcanization time and low cost. However, due to the special lip structure of the multi-lip oil seal and the relatively poor hot tear performance of fluororubber , the traditional fluororubber oil seal is relatively weak in the production process, and it is easy to tear the lip when the product is out of the mold, and the production pass rate is low.

[0003] Yang Wenliang et al.'s paper "Factors Influencing the Tearing of Fluororubber Oil Seals in the Manufacturing Process" only discussed the mechanism, and did not give the composition formula design and actual industrialization data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

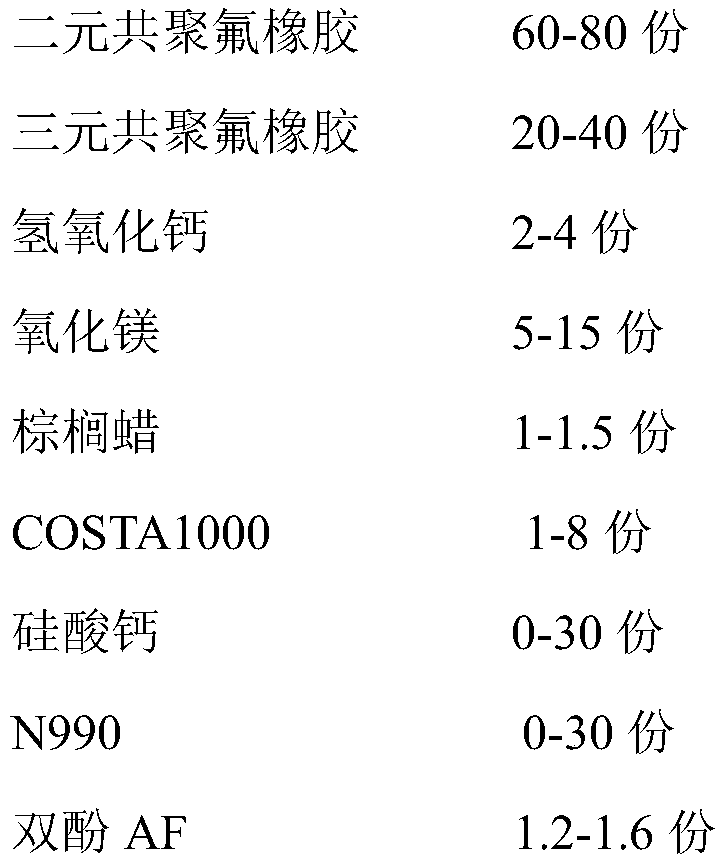

The present invention relates to the technical field of rubber compounding and vulcanization, and disclosed thereby is a fluororubber oil sealing composition. The fluororubber oil sealing composition is prepared by means of the following components in parts by weight: a binary copolymerized fluororubber (60-80 parts), a ternary copolymerized fluororubber (20-40 parts), calcium hydroxide (2-4 parts), magnesium oxide (5-15 parts), palm wax (1-1.5 parts), COSTA1000 (1-8 parts), calcium silicate (0-30 parts), N990 (0-30 parts), bisphenol AF (1.2-1.6 parts), bisphenol A (0.4-0.8 parts) and BPP (0.4-0.6 parts); the composition greatly reduces the probability of a lip portion of a product tearing during one-time molding due to the poor tearing strength of fluororubber, increases the rate of passes during production and saves costs, while ensuring the product features of obtaining a good compression permanent set and radial sealing force, and granting a long service life in the work of oil sealing.

Description

technical field [0001] The invention relates to the technical field of rubber sealing products, in particular to a preparation method of a small-skeleton fluororubber oil seal composition used in the engine machinery industry. Background technique [0002] Fluorine rubber is widely used in the field of high temperature resistant oil seals. The TC form of fluorine rubber skeleton oil seals widely used in the engine machinery industry has unique structural parameters. The oil seal spring groove is relatively deep, and it is easy to cause tearing of the lips during molding and vulcanization. . In actual production, a vulcanization temperature of 170-180 degrees and a rapid vulcanization system are often required for production efficiency to achieve short vulcanization time and low cost. However, due to the special lip structure of the multi-lip oil seal and the relatively poor hot tear performance of fluororubber , Due to the relatively weak lip part of the traditional fluoror...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L27/12C08K13/02C08K3/22C08K3/34C08K5/13C08K5/136

Inventor 章宏清

Owner JIANGMEN XINHUI SEALING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com