Patents

Literature

35results about How to "Solve the problem of difficult alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collimating film and preparation method of collimating film

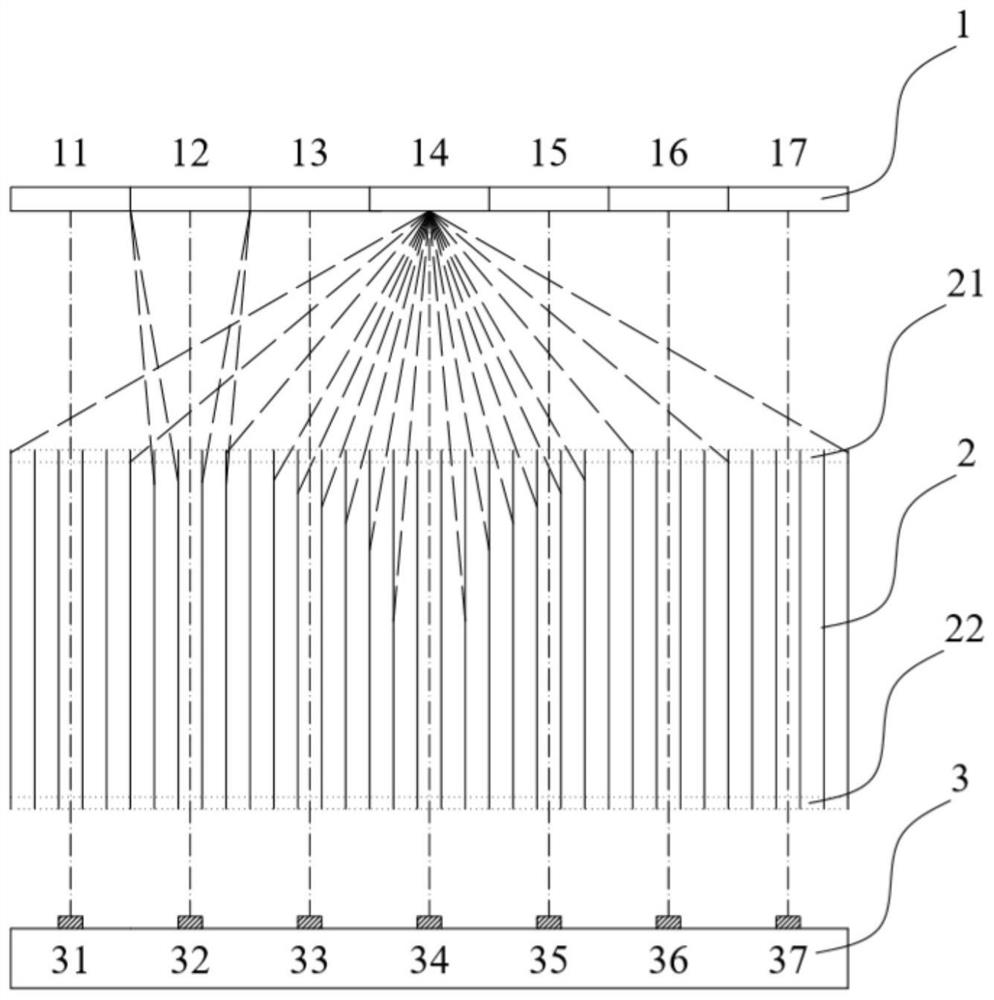

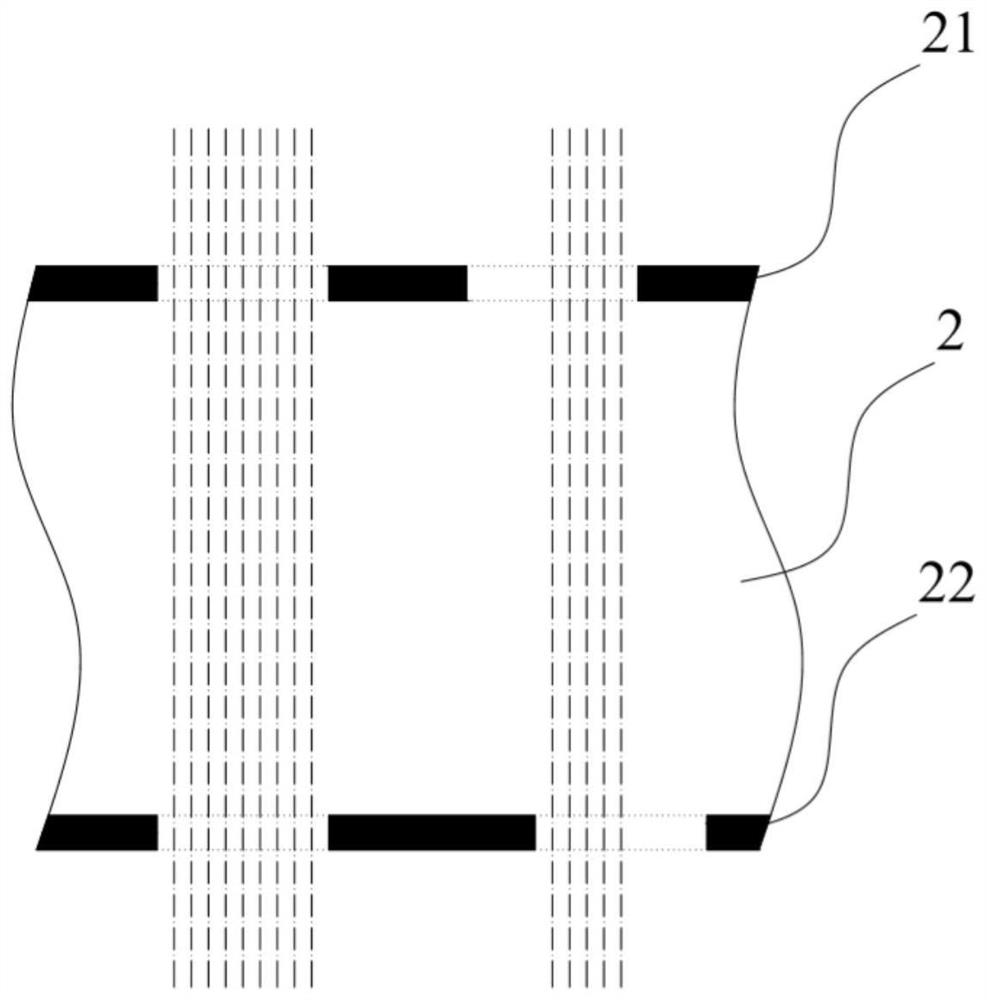

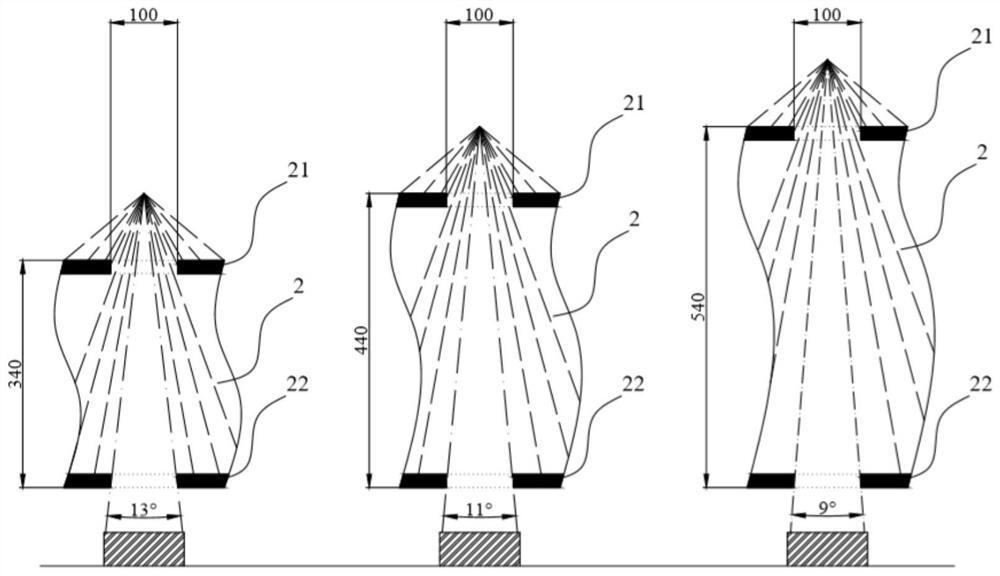

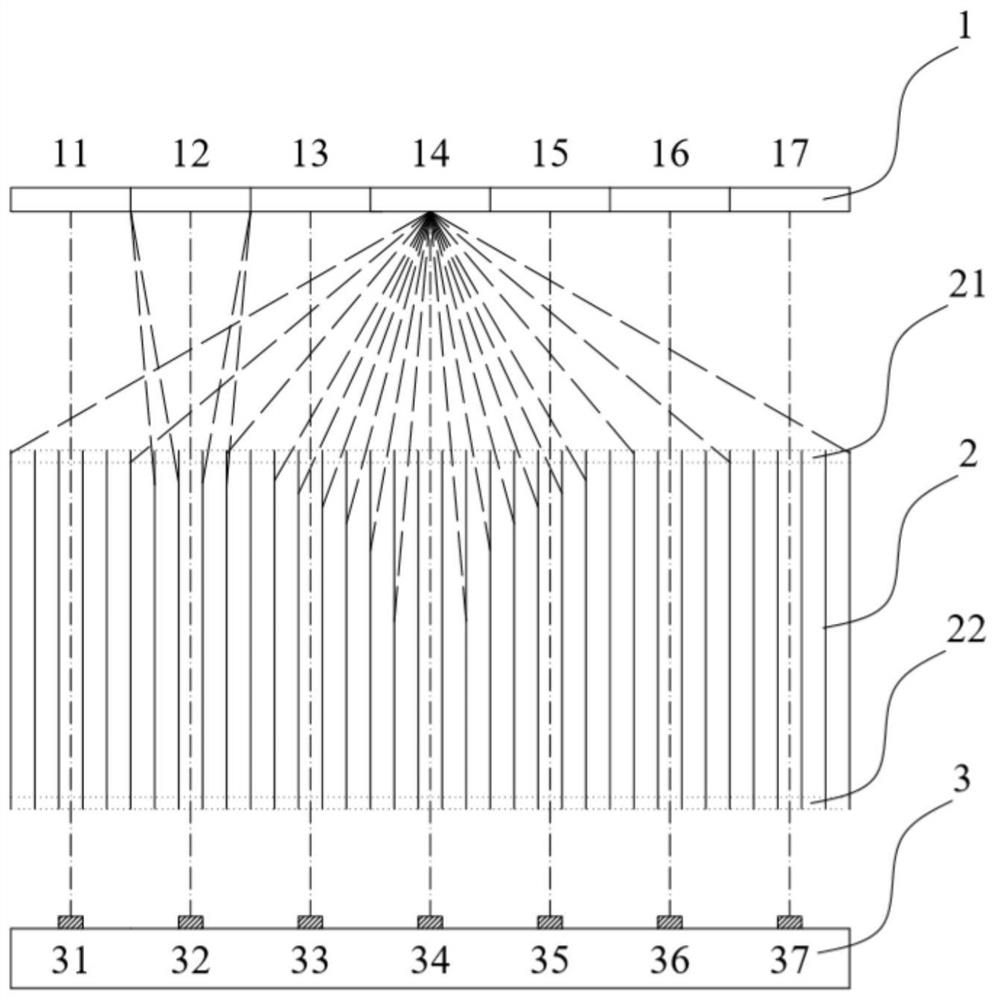

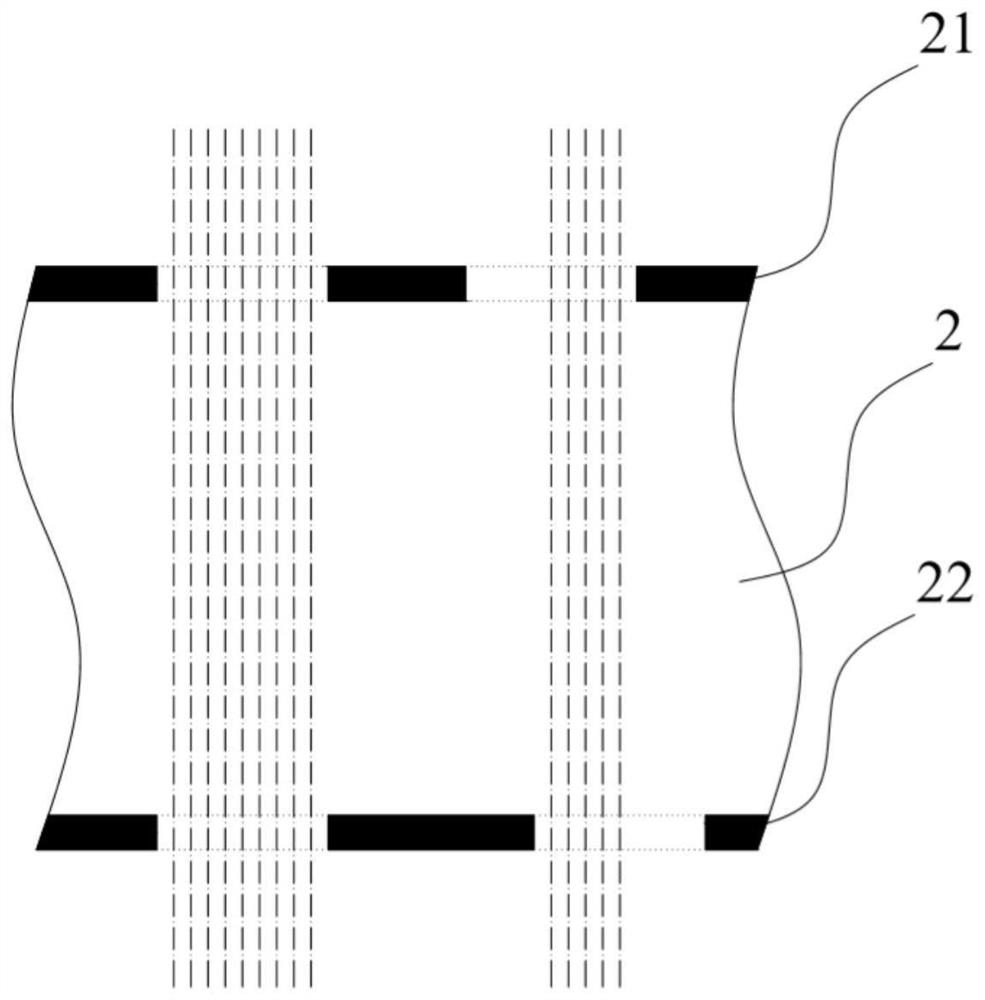

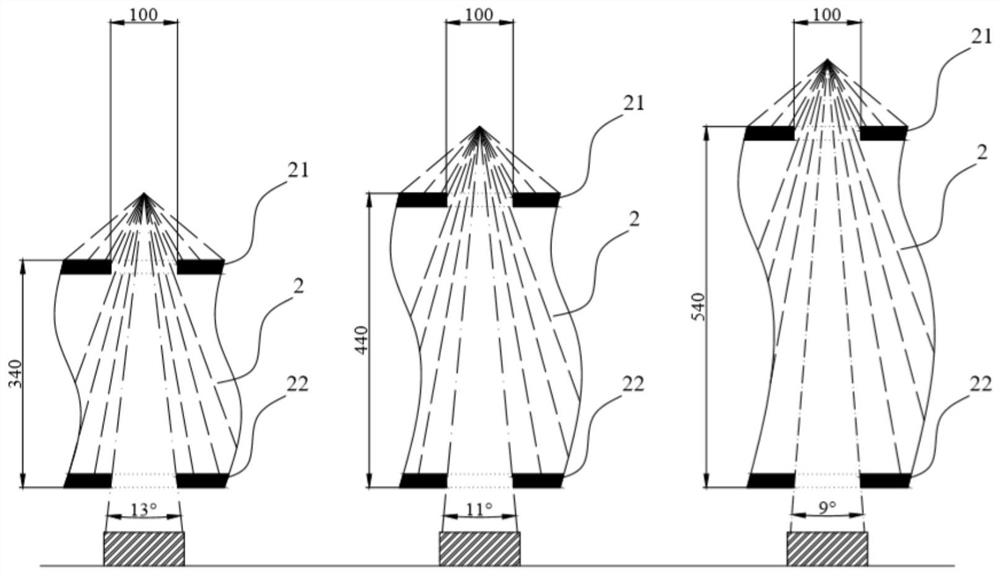

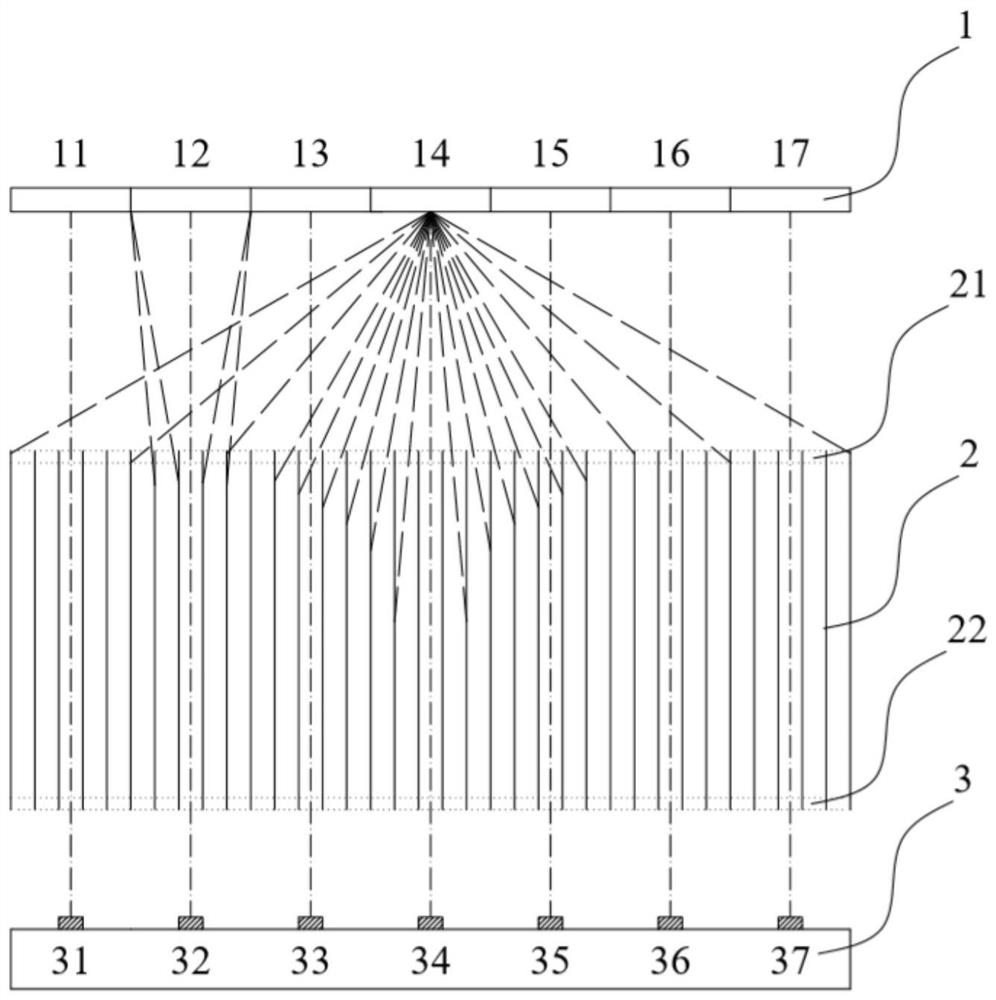

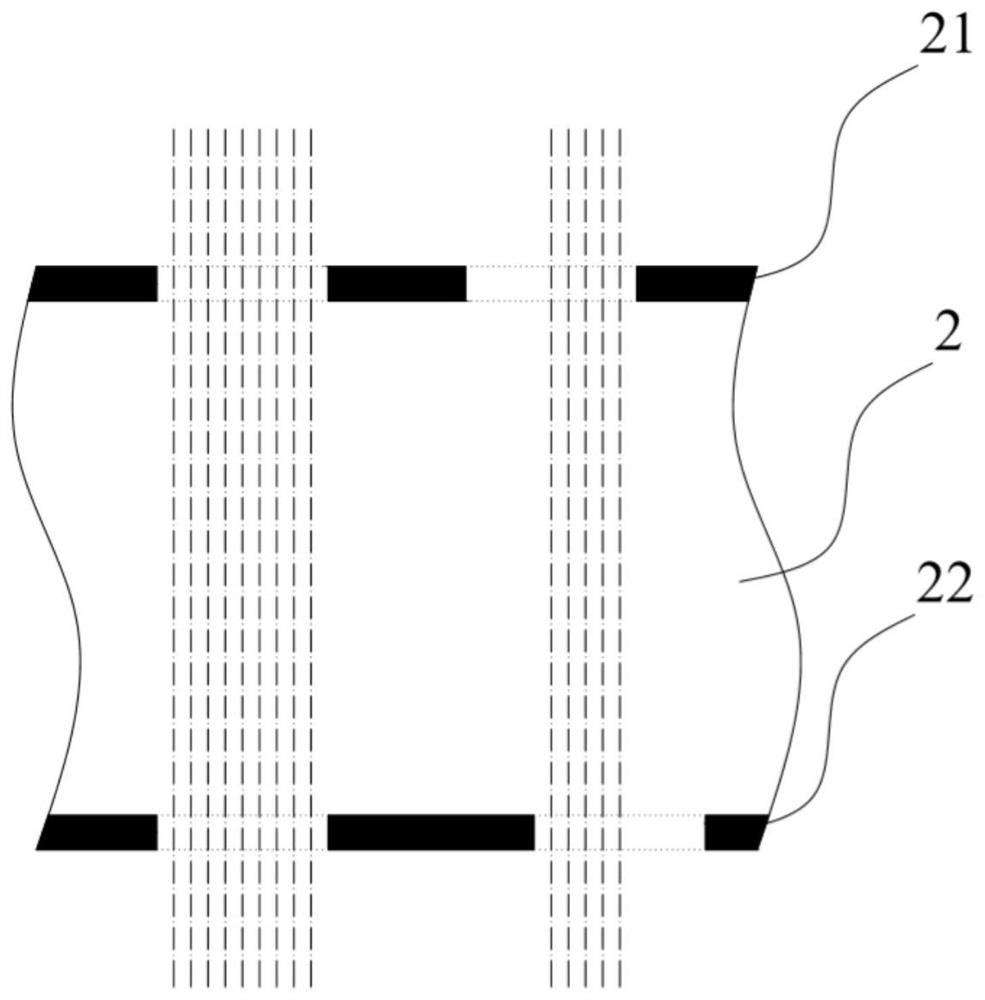

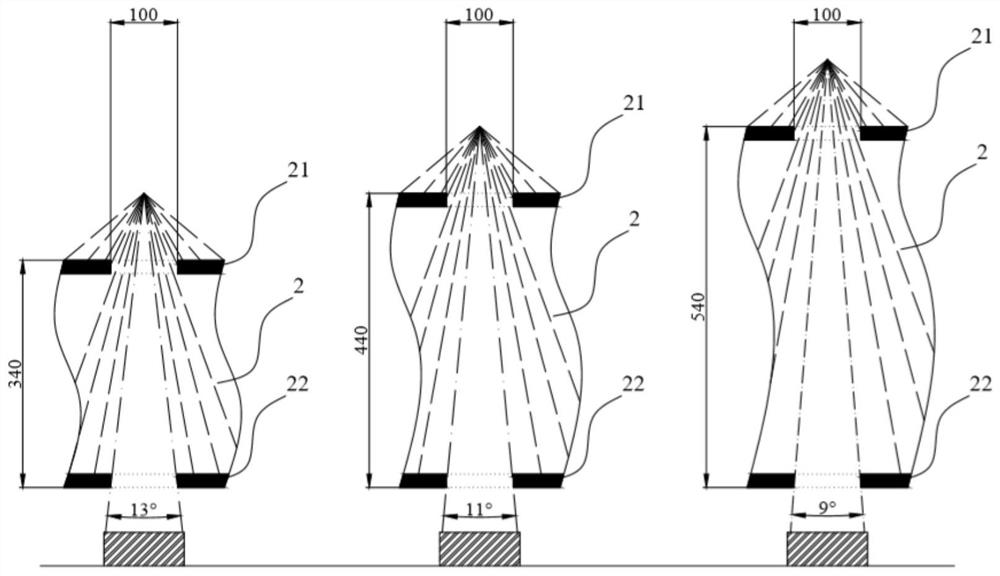

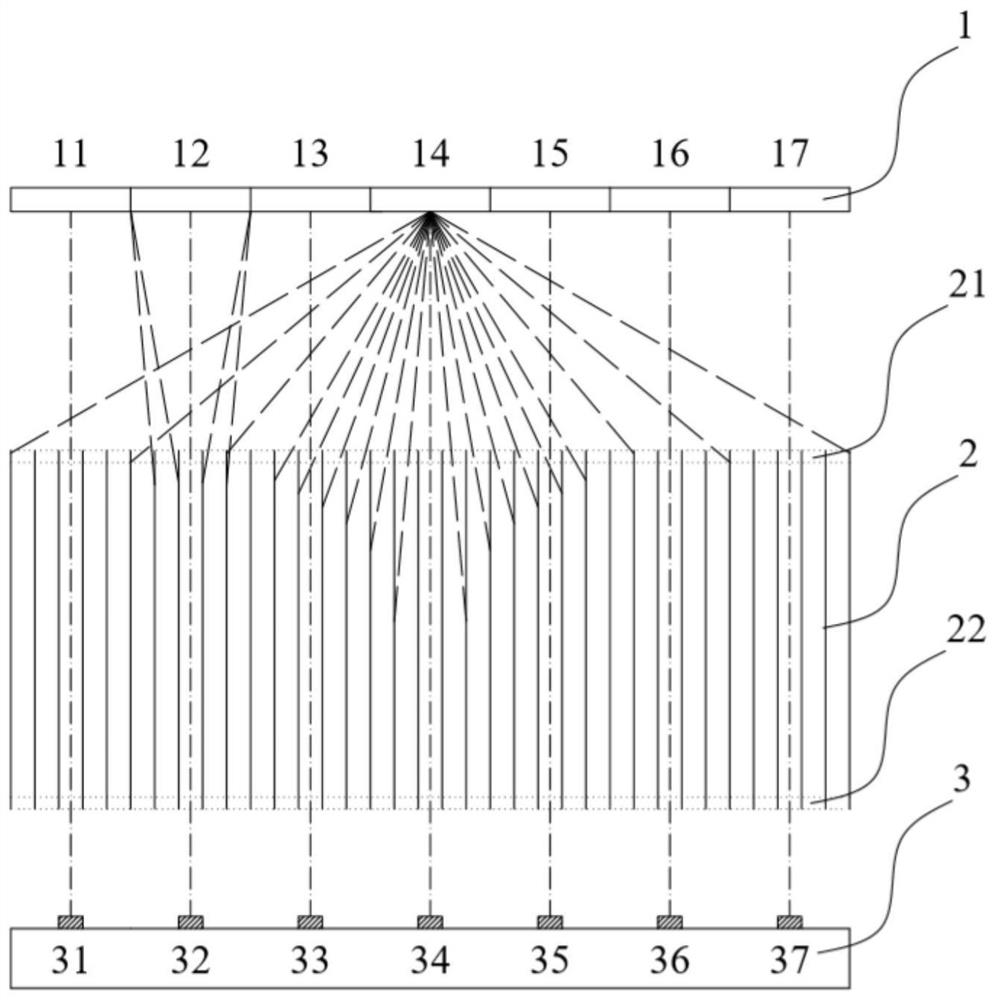

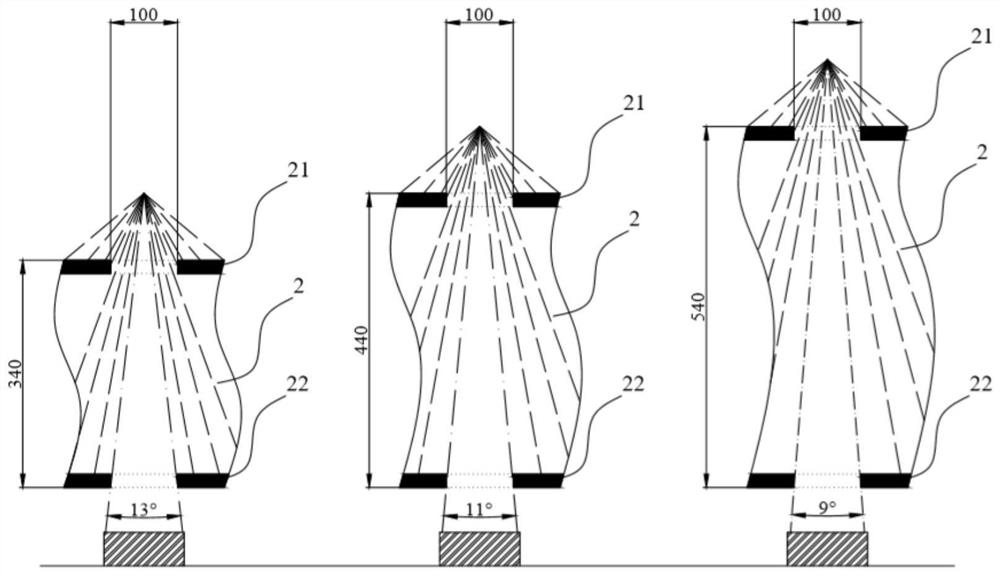

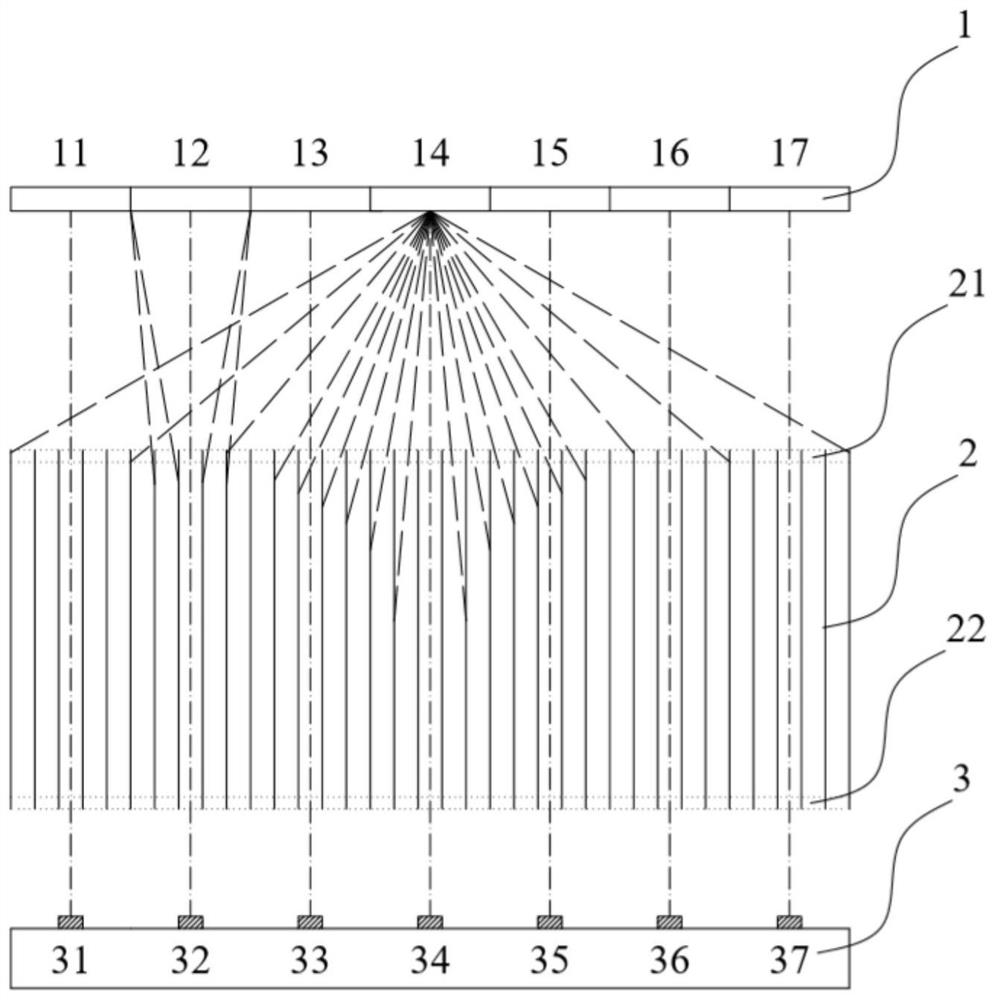

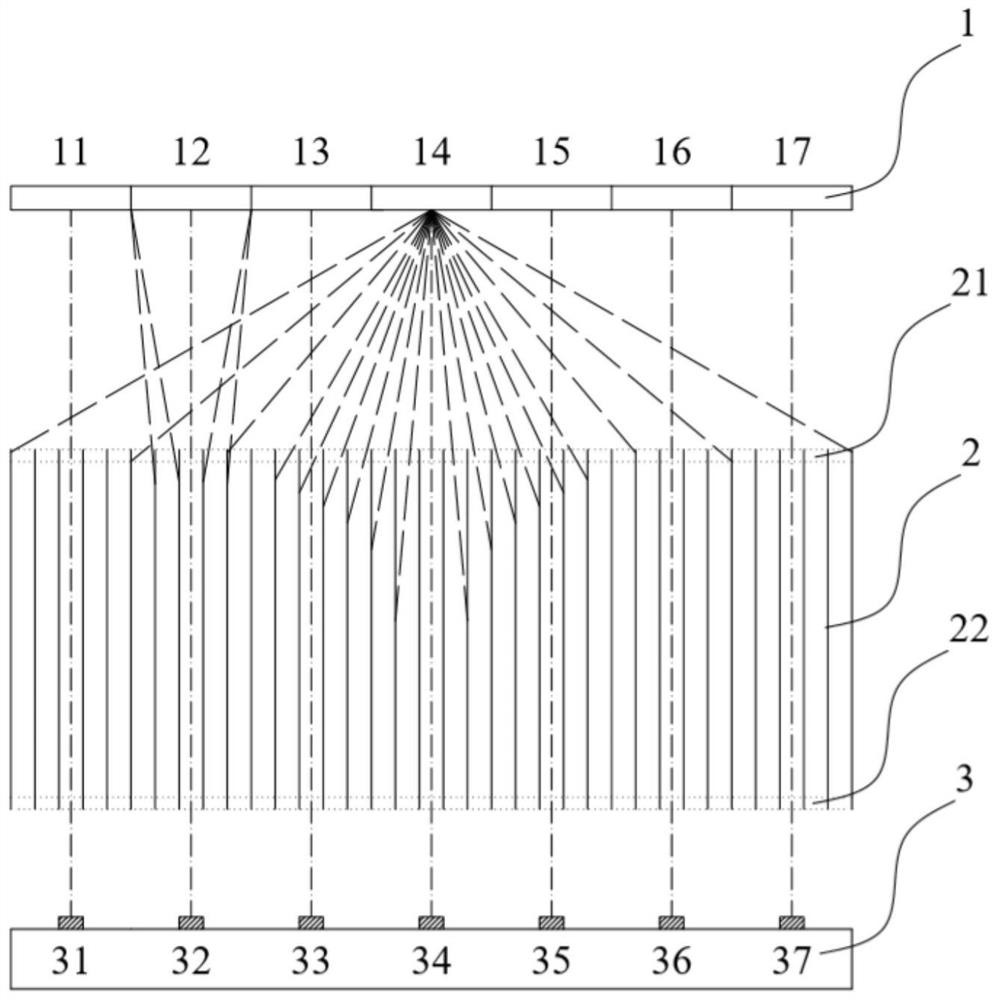

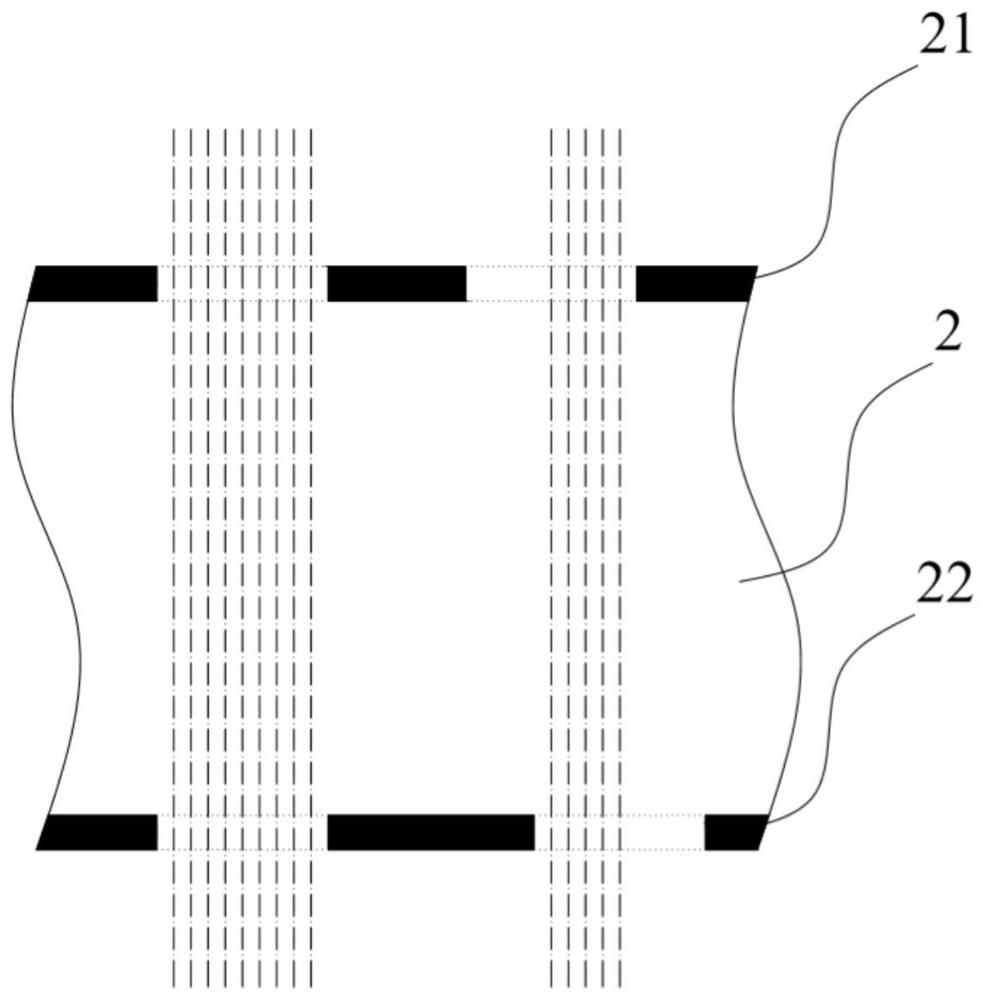

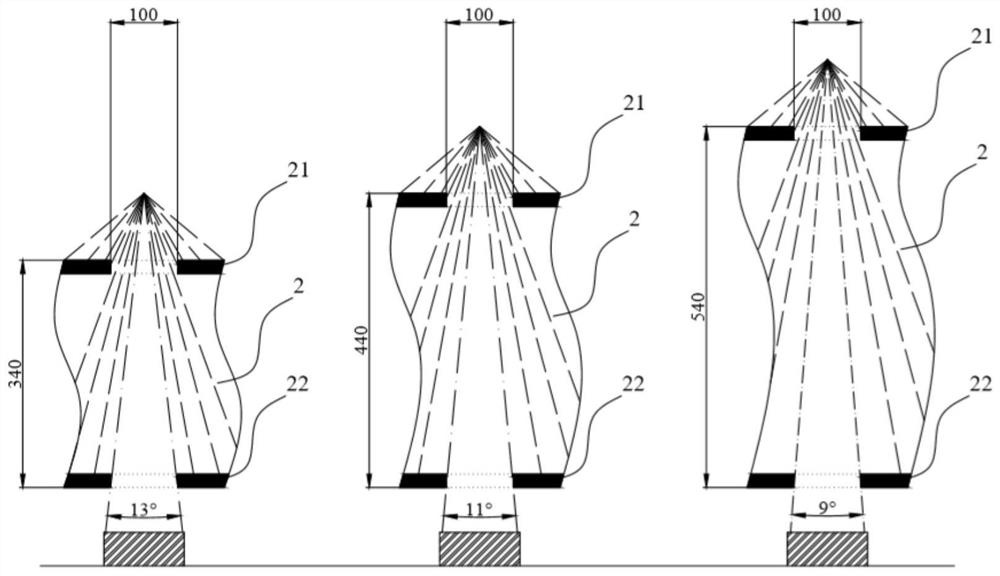

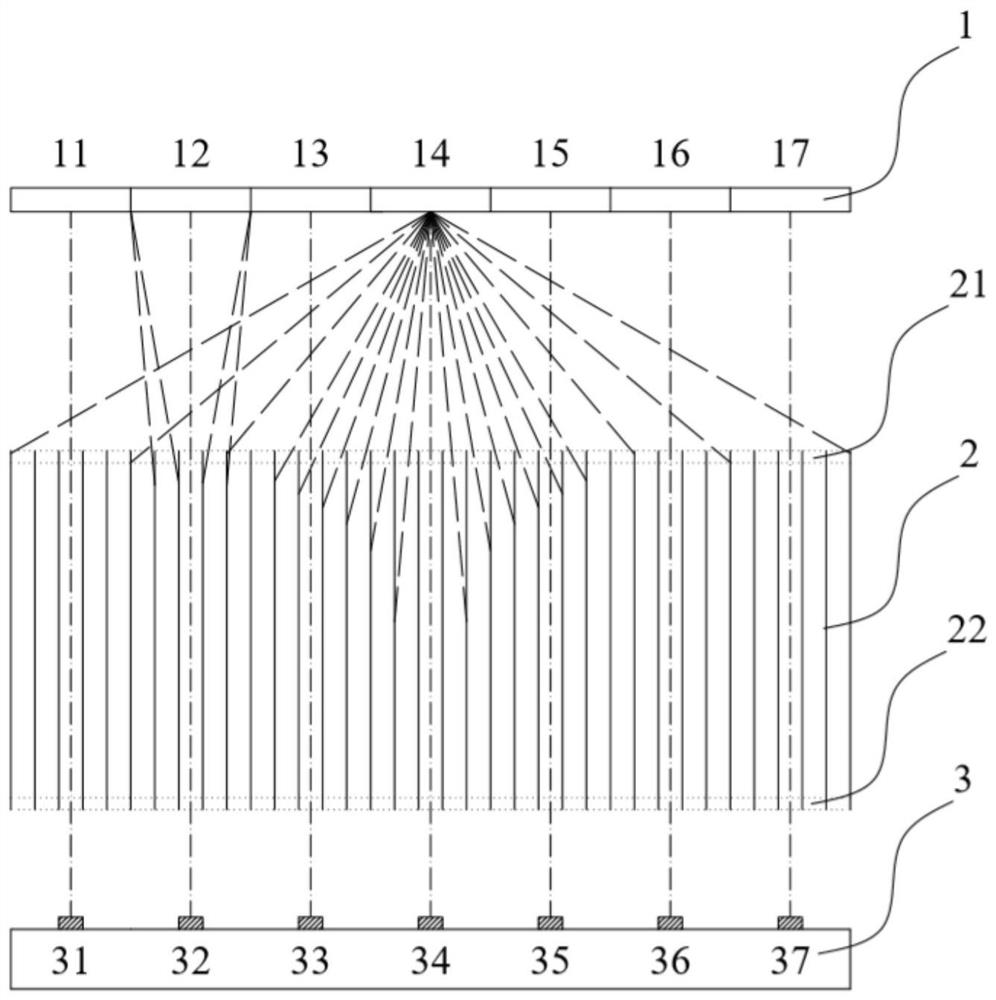

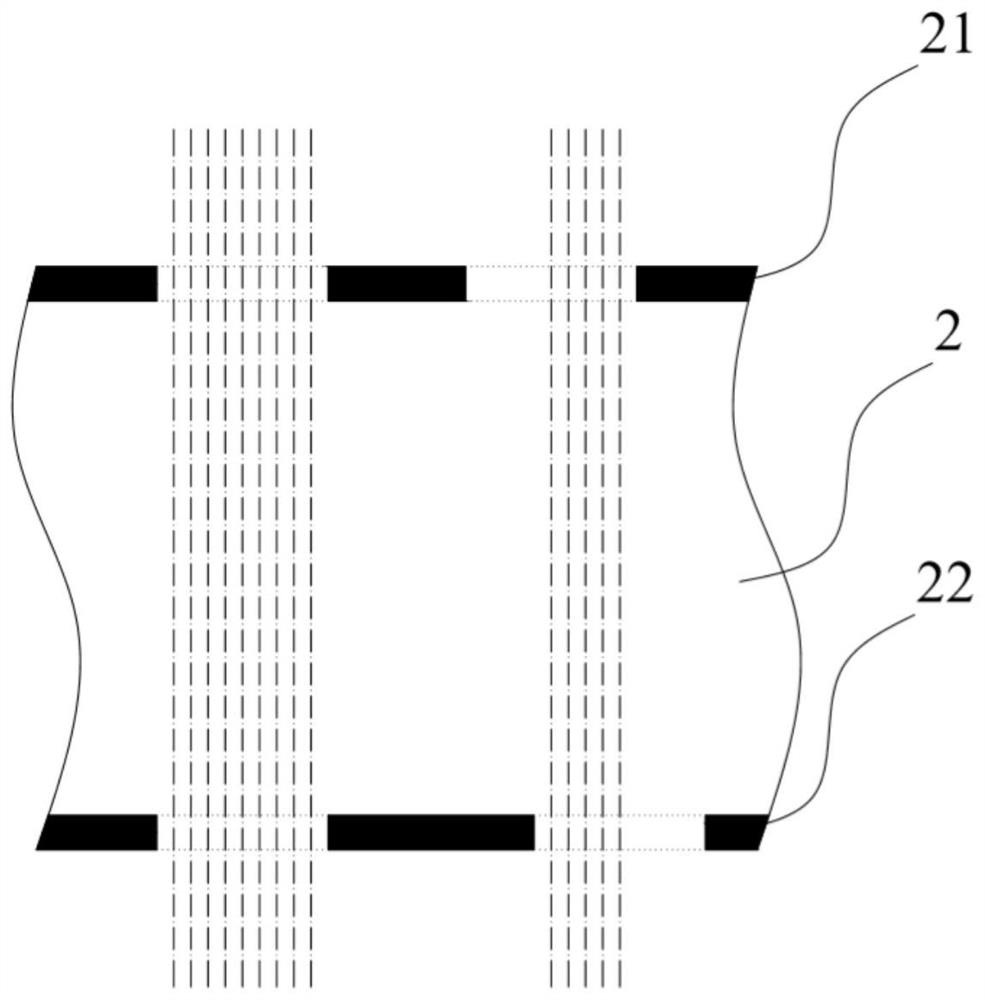

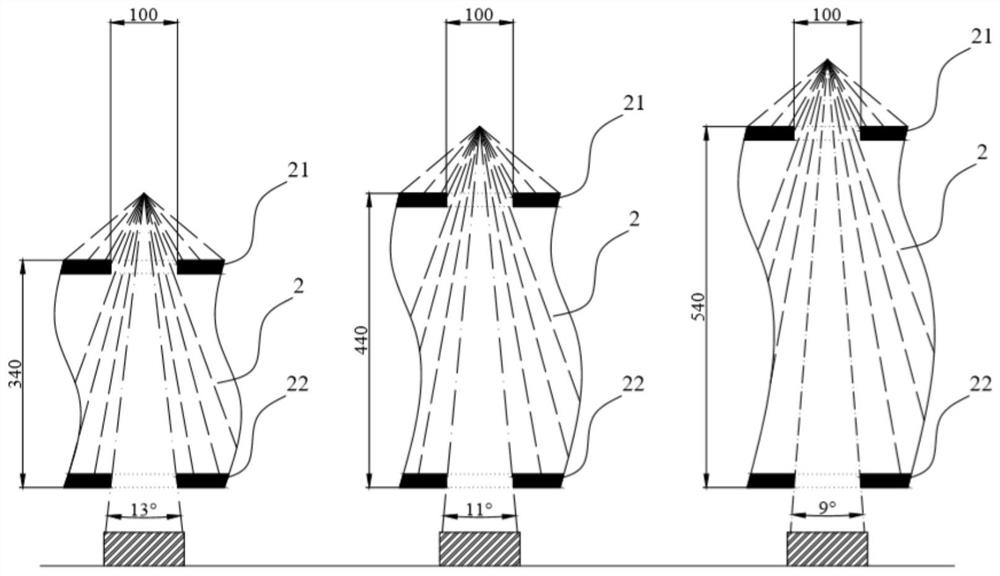

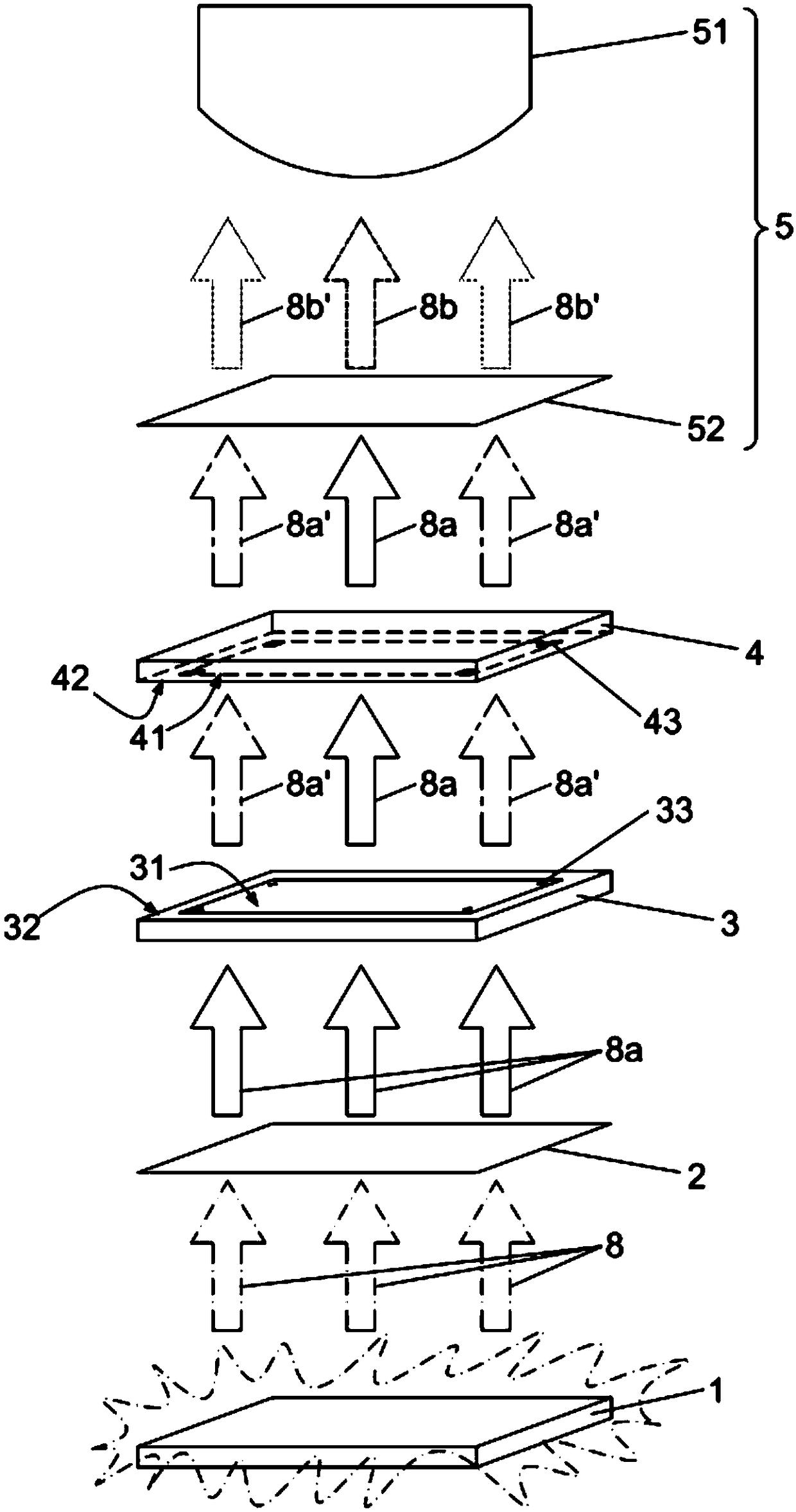

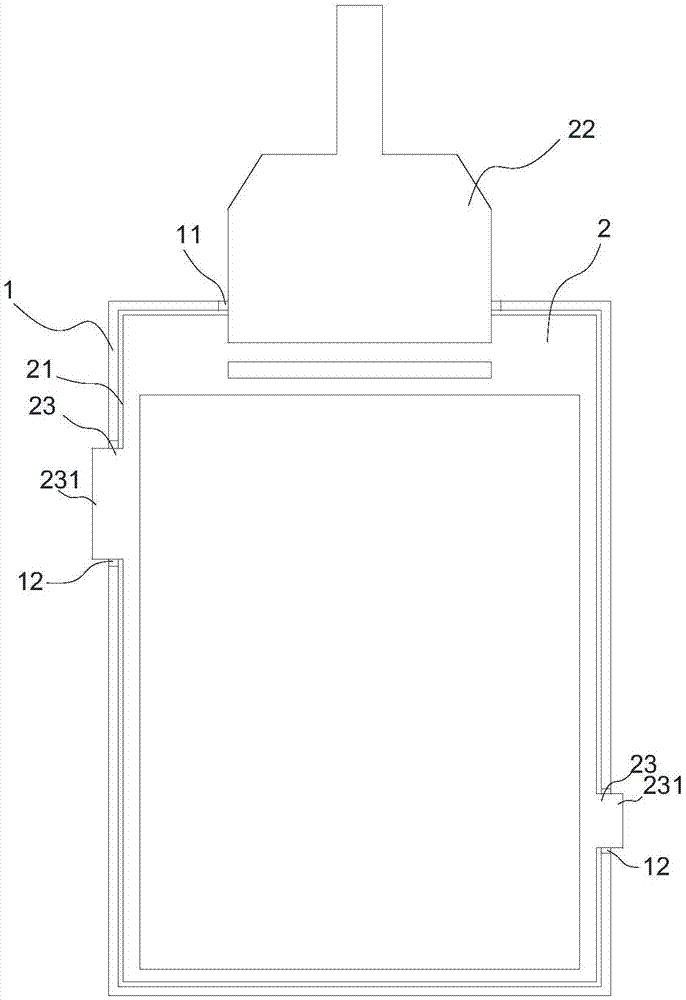

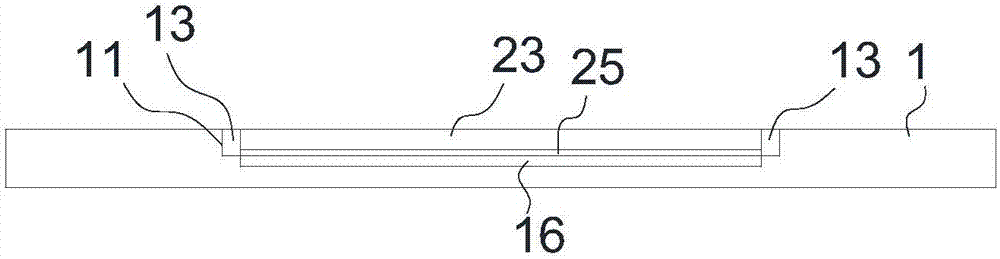

The invention relates to a collimating film, in particular to a collimating film in the field of image recognition and a preparation method of the collimating film. In order to solve the problem that two layers of collimating diaphragms in a traditional rigid collimating sheet are difficult to align, the invention provides a collimating film and a preparation method of the collimating film. The collimating film sequentially comprises a collimating lens layer, a flexible substrate layer and a collimating hole layer; the collimating lens layer comprises a micro-lens array and a lens layer, and the collimating hole layer comprises a collimating hole array; the distribution of the collimation hole array is completely consistent with that of the micro-lens array; and the micro lens arrays of the collimating lens layer are arranged in order. The collimating film provided by the invention only comprises one collimating hole layer, so that the problem that two collimating diaphragms are difficult to align is solved. The collimating film can collimate and filter diffused light at a single-point pixel of an image to a certain extent to form a normal small-beam optical signal, transmits the normal small-beam optical signal to a corresponding photoelectric sensor, and is particularly suitable for a large-size, ultrathin and even flexible image recognition module.

Owner:NINGBO EXCITON TECH

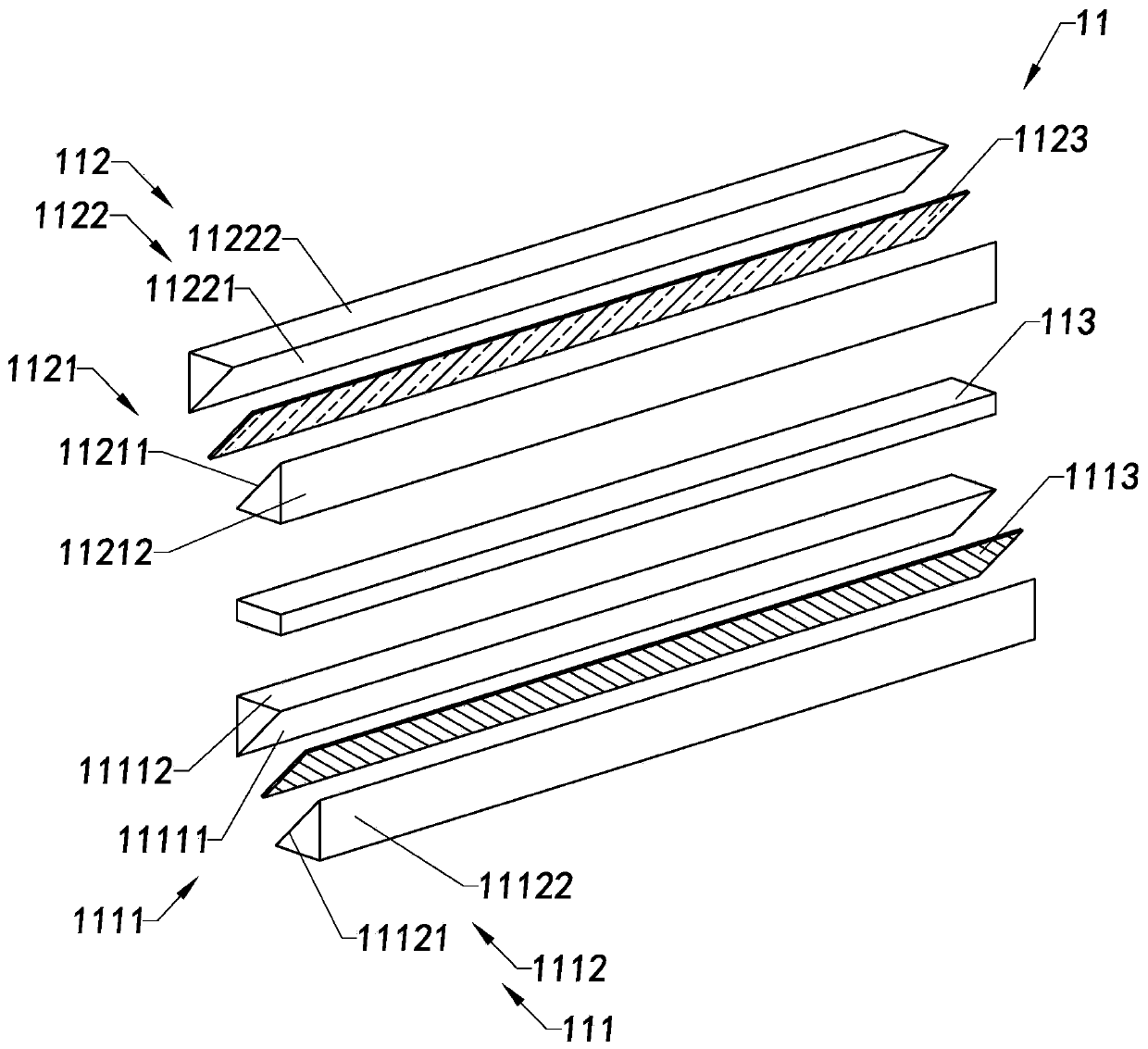

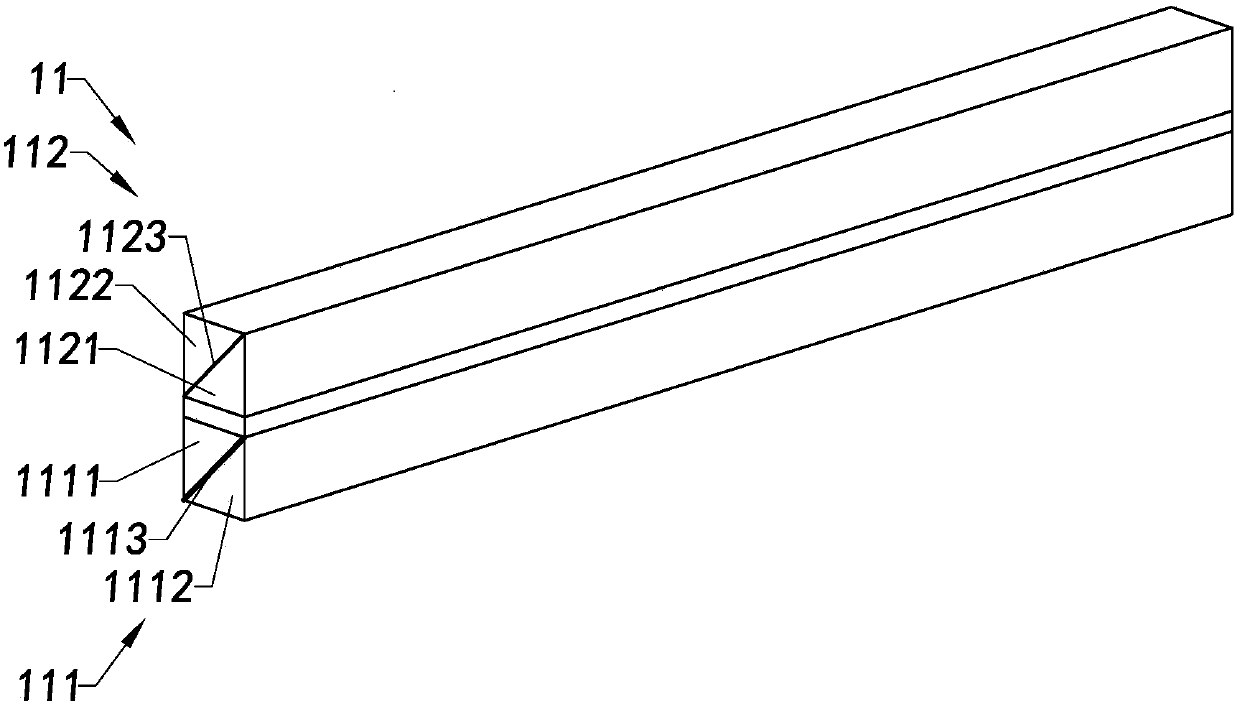

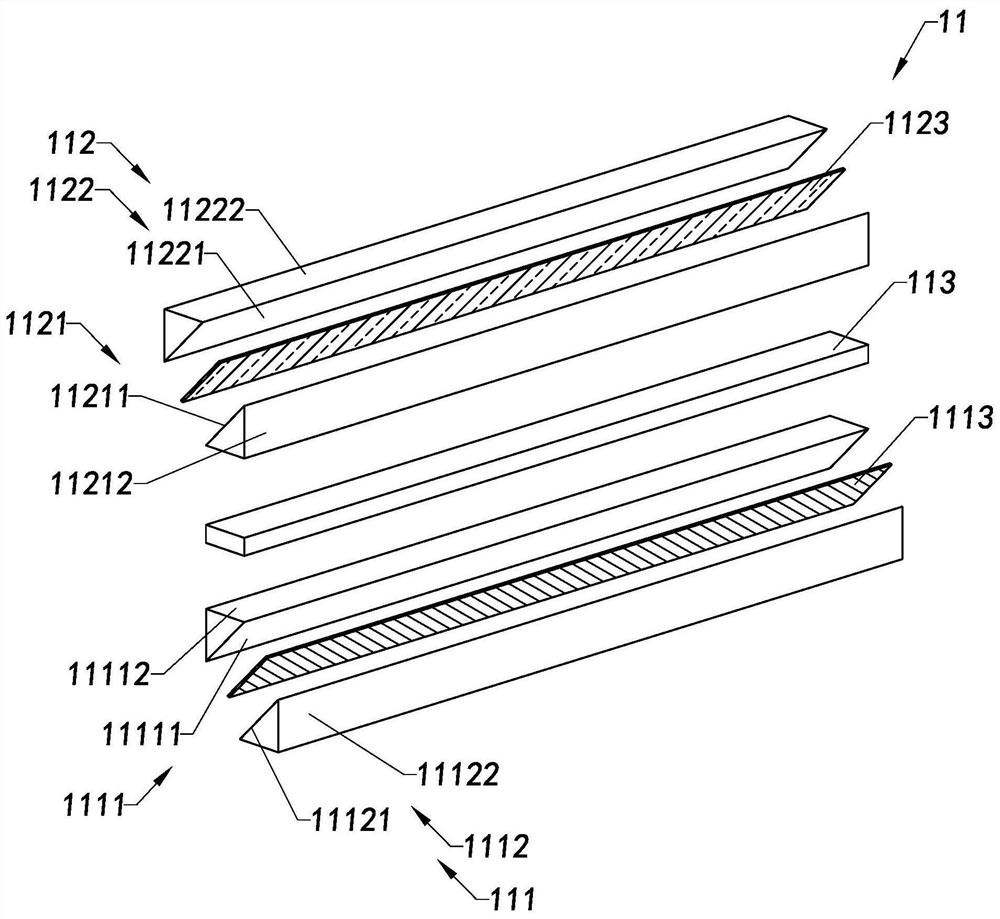

Collimating film, interference-reducing collimating film, laminated collimating film and hole-sealing laminated collimating film

ActiveCN113376849AImprove production yieldImprove performanceFinal product manufactureFilm/foil adhesivesMaterials scienceImage identification

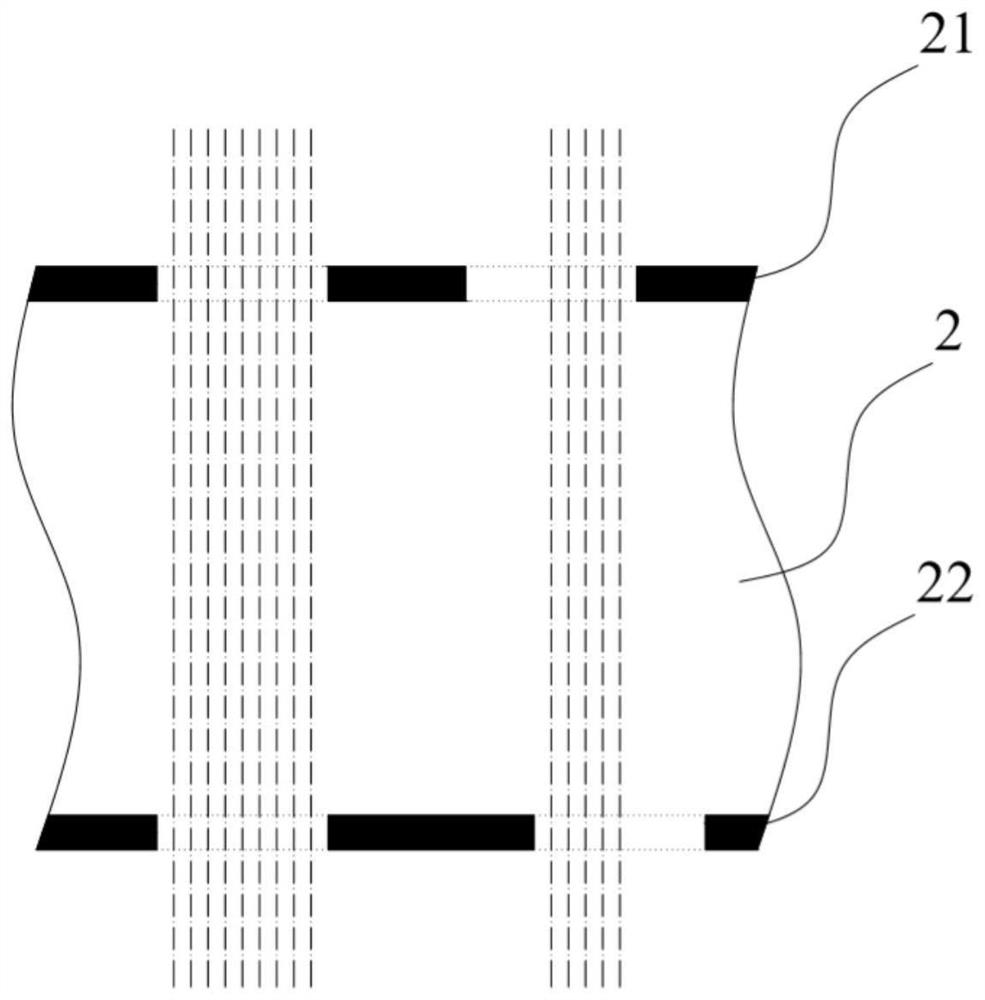

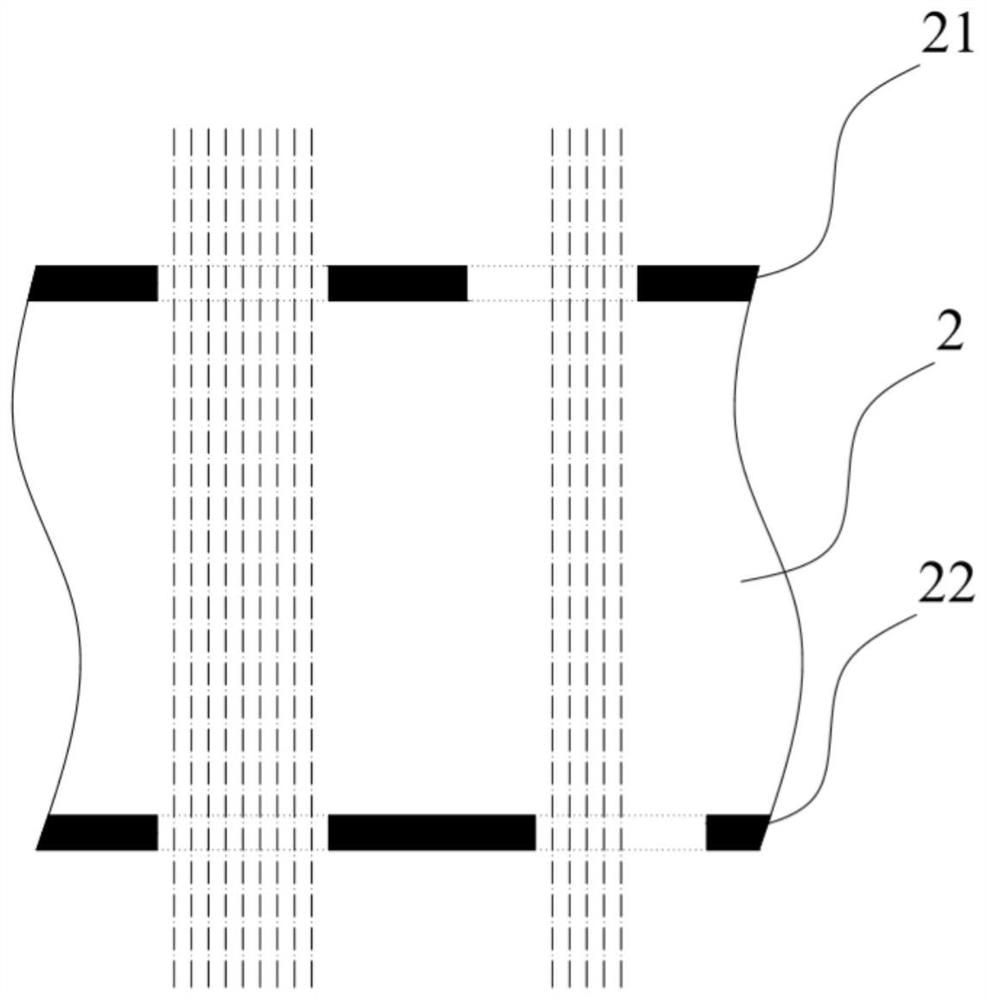

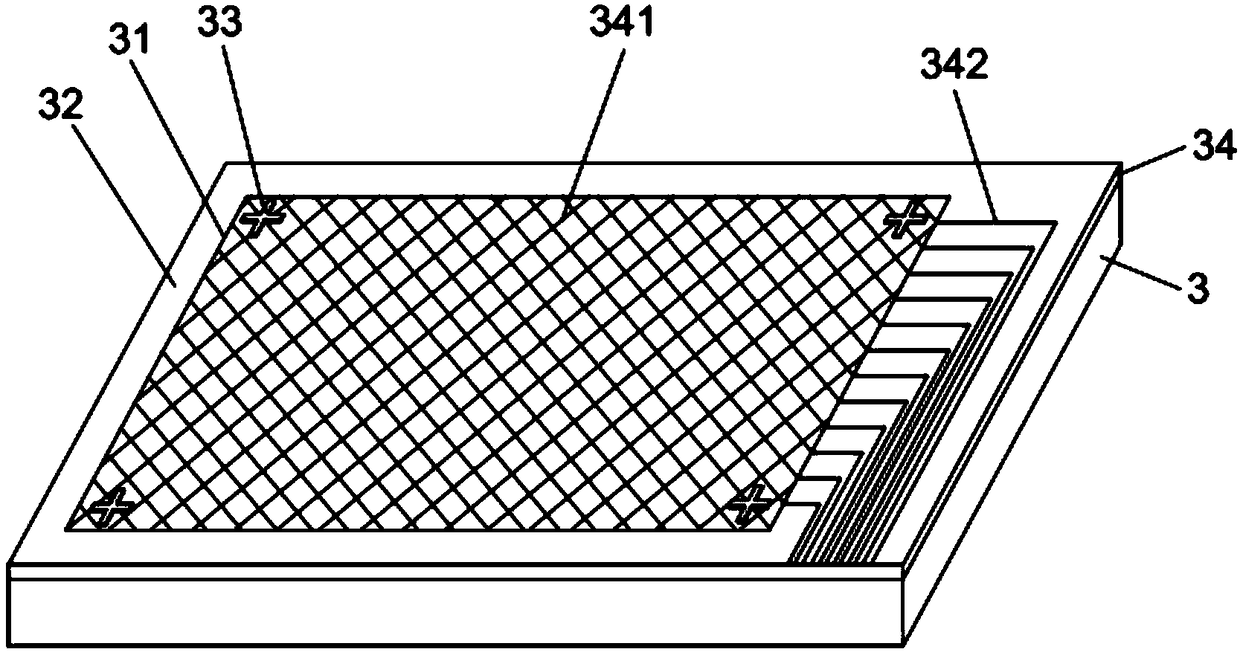

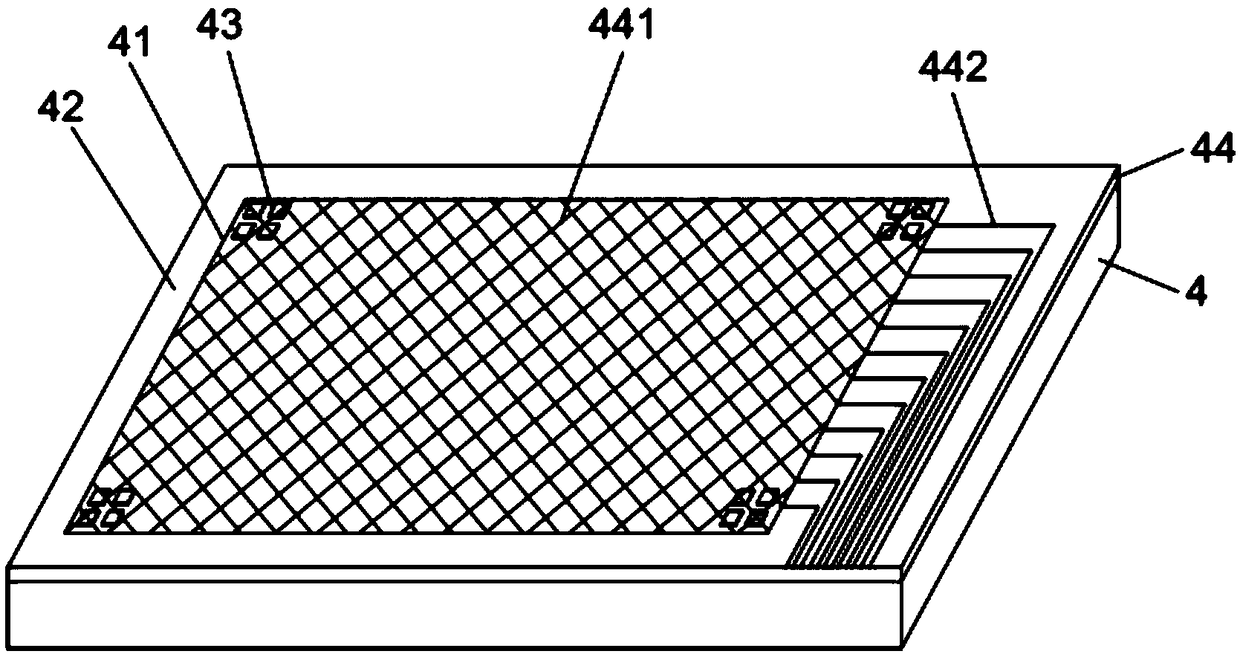

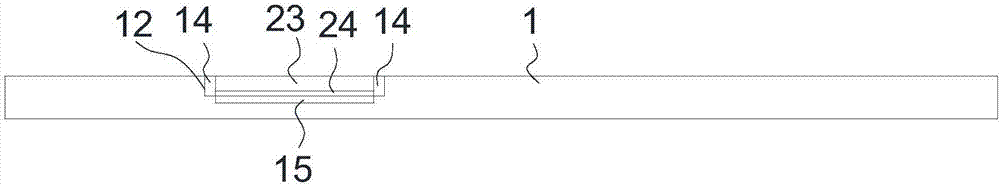

The invention belongs to the field of image recognition, and particularly relates to a collimating film, an interference-reducing collimating film, a laminated collimating film, a hole-sealing laminated collimating film and an image recognition module. The invention provides a collimating film, an interference-reducing collimating film, a laminated collimating film, a hole-sealing fitting type collimating film and an image recognition module in order to solve the problem of bubbles of a laminated collimating film designed by adopting a relatively thick light shielding layer. The hole-sealing laminated collimating film comprises the collimating film, a flat layer and a laminating adhesive layer, wherein the lower surface of the flat layer is smooth and flat, the upper surface of the flat layer is in full contact with the lower surface of the shading medium and the lower surface of the substrate layer in the area of the collimating hole, and the collimating hole is fully filled by the flat layer; and the lower surface of the flat layer is laminated to the laminating adhesive layer. The raw material of the flat layer is selected from a solvent type transparent resin system. The hole-sealing laminated collimating film provided by the invention is applied to an image recognition module, so that the recognition accuracy of the image recognition module is high.

Owner:NINGBO EXCITON TECH

Collimating film, interference-reducing collimating film, laminated collimating film, hole-sealing laminated collimating film and preparation method thereof

ActiveCN113376851AImprove production yieldImprove performanceFinal product manufactureFilm/foil adhesivesMicro lens arrayMaterials science

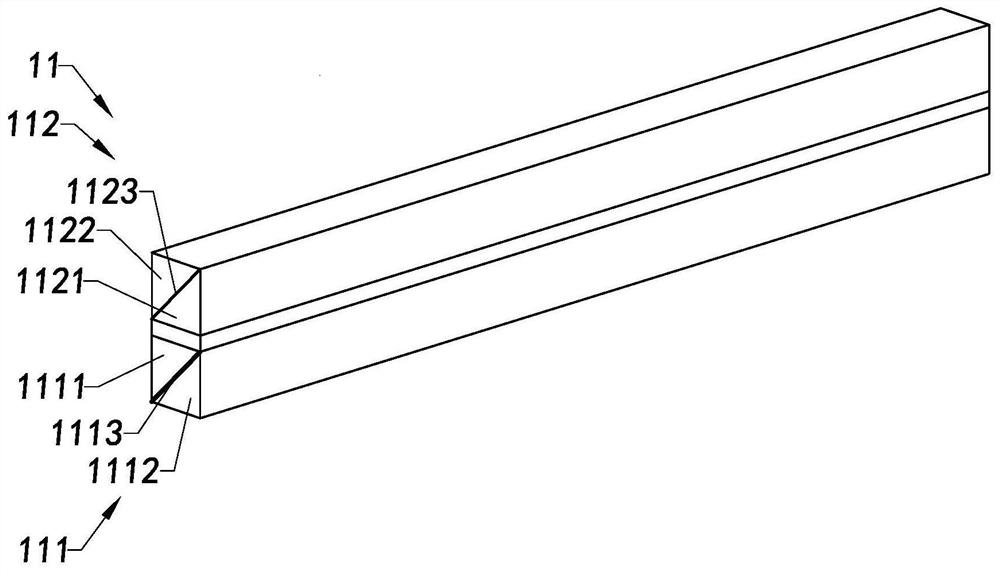

The invention belongs to the field of image recognition, and particularly relates to a collimating film, an interference-reducing collimating film, a laminated collimating film, a hole-sealing laminated collimating film and a preparation method thereof. In order to solve the problem of bubbles of a laminated collimating film designed by adopting a relatively thick light shielding layer, the invention provides the collimating film, the interference-reducing collimating film, the laminated collimating film, the hole-sealing laminated collimating film and the preparation method thereof. The hole-sealing laminated collimating film comprises a collimating lens layer, a flexible substrate layer, a collimating hole layer and a laminating adhesive layer, wherein the collimating lens layer comprises a micro-lens array and a lens layer; the collimating hole layer is a collimating through path layer, and the collimating through path layer comprises a columnar collimating through path array and a shading medium. The hole-sealing laminated collimating film provided by the invention is applied to an image recognition module, so that the recognition accuracy of the image recognition module is high.

Owner:NINGBO EXCITON TECH

Collimating film, interference-reducing collimating film, laminated collimating film and hole-sealing laminated collimating film

ActiveCN113376850AImprove production yieldImprove performanceFilm/foil adhesivesFinal product manufactureSolvent freeMaterials science

The invention belongs to the field of image recognition, and particularly relates to a collimating film, an interference-reducing collimating film, a laminated collimating film and a hole-sealing laminated collimating film. The invention provides a collimating film, an interference-reducing collimating film, a laminated collimating film and a hole-sealing laminated collimating film in order to solve the problem of bubbles of a laminated collimating film designed by adopting a relatively thick light shielding layer. The hole-sealing laminated collimating film comprises a collimating film, a flat layer and a laminating adhesive layer, wherein the lower surface of the flat layer is smooth and flat, the upper surface of the flat layer is in full contact with the lower surface of the shading medium and the lower surface of the substrate layer in the area of the collimating hole, and the collimating hole is fully filled by the flat layer; and the lower surface of the flat layer is laminated to the laminating adhesive layer. The raw material of the flat layer is selected from a solvent-free low-viscosity transparent resin system. The hole-sealing laminated collimating film provided by the invention is applied to an image recognition module, so that the recognition accuracy of the image recognition module is high.

Owner:NINGBO EXCITON TECH

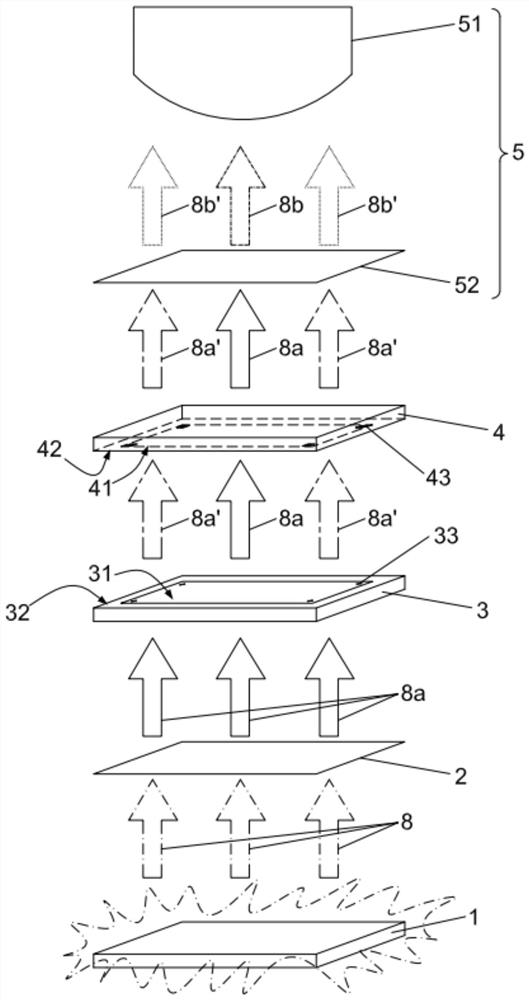

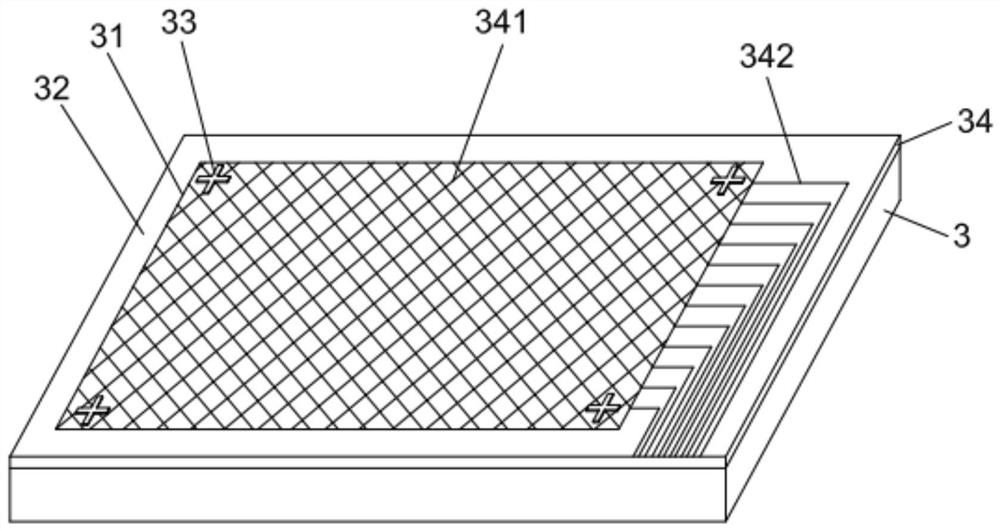

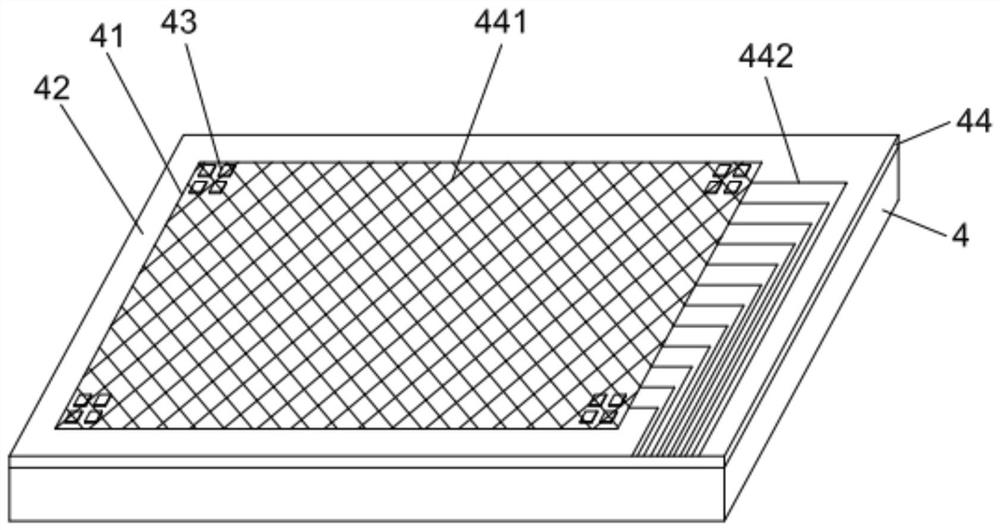

Collimating film, interference-reducing collimating film, laminated collimating film, image recognition module and preparation method thereof

PendingCN113296278AReduce thicknessGood toughnessFilm/foil adhesivesCharacter and pattern recognitionInterference phenomenonImage identification

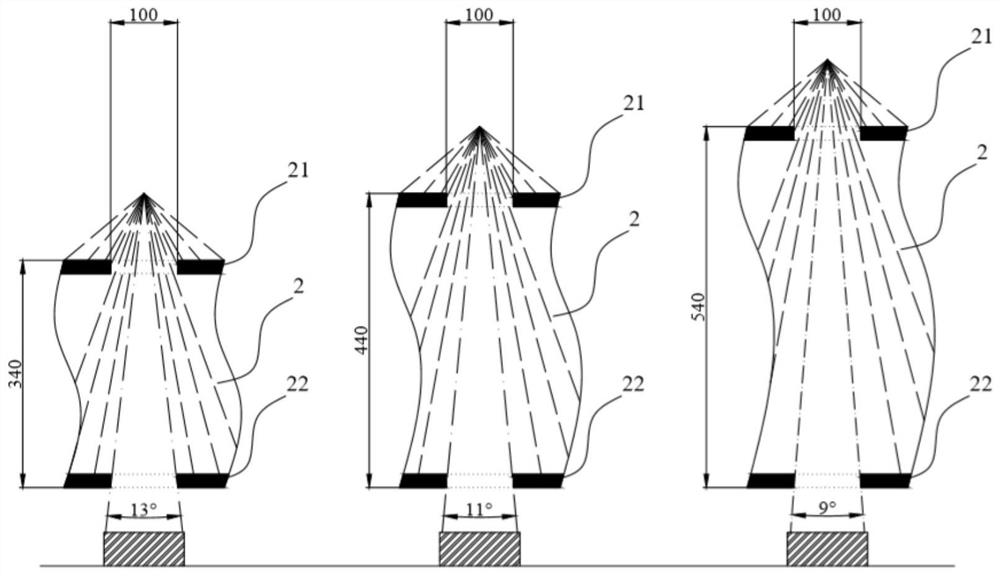

The invention belongs to the field of image recognition, and particularly relates to a collimating film, an interference-reducing collimating film, an attached collimating film, an image recognition module and a preparation method thereof. In order to solve the problem that two layers of collimation diaphragms in a traditional rigid collimation sheet are difficult to align, the invention provides a collimation film, an interference-reducing collimation film, an attached collimation film, an image recognition module and a preparation method thereof. The interference reducing collimating film sequentially comprises a collimating lens layer, a flexible substrate layer and a collimating hole layer. The collimating lens layer comprises a micro-lens array and a lens layer; the collimating hole layer comprises a collimating hole array; and the micro-lens array of the collimating lens layer is arranged in a disordered manner. The interference-reducing collimating film provided by the invention can reduce the light interference phenomenon and improve the image recognition accuracy. The image recognition module provided by the invention is high in recognition accuracy and can be applied to fingerprint unlocking and the like of consumer electronic products such as mobile phones (OLED screens).

Owner:NINGBO EXCITON TECH

Collimation film, interference-reducing collimation film, sunlight prevention collimation film and image recognition module

ActiveCN113296170AImprove performanceReduced light interferenceFilm/foil adhesivesFinal product manufactureEngineeringInterference reduction

The invention belongs to the field of image recognition, and particularly relates to a collimation film, an interference reduction collimation film, a sunshine prevention collimation film and an image recognition module. In order to solve the problem that two layers of collimation diaphragms in a traditional rigid collimation sheet are difficult to align, the invention provides a collimation film, an interference reduction collimation film, a sunshine prevention collimation film and an image recognition module. The sunshine prevention collimation film sequentially comprises an upper attaching adhesive layer, a low-refractive-index filling layer, a high-refractive-index collimation lens layer, a flexible base body layer, a collimation hole layer and a lower attaching adhesive layer, and further comprises an infrared cut-off layer. The sunshine prevention collimation film provided by the invention solves the problem of fingerprint unlocking failure under strong sunlight, and can be applied to fingerprint unlocking and the like of consumer electronics such as mobile phones (OLED screens).

Owner:NINGBO EXCITON TECH

Collimating film, interference-reducing collimating film, fitting type collimating film, hole-sealing fitting type collimating film and preparation methods thereof

ActiveCN113296282AImprove production yieldImprove performanceFilm/foil adhesivesFinal product manufactureMicro lens arrayMaterials science

The invention belongs to the field of image recognition, and particularly relates to a collimating film, an interference-reducing collimating film, a laminated collimating film, a hole-sealing laminated collimating film and a preparation method thereof. The invention provides a collimation film, an interference-reducing collimation film, a fitting type collimation film, a hole-sealing fitting type collimation film and a preparation method thereof in order to solve the problem of bubbles of a fitting type collimation film designed by adopting a relatively thick light shielding layer. According to the invention, the hole sealing fitting type collimating film comprises a collimating lens layer, a flexible substrate layer, a collimating hole layer and a hole sealing fitting adhesive layer. The collimating lens layer comprises a micro-lens array and a lens layer; the collimation hole layer comprises a shading medium and a collimation hole array formed after the shading medium is hollowed out; and the hole sealing fitting adhesive layer fully fills the collimation hole array of the collimation hole layer. The hole sealing fitting type collimating film provided by the invention is applied to an image recognition module, so that the recognition accuracy of the image recognition module is high.

Owner:NINGBO EXCITON TECH

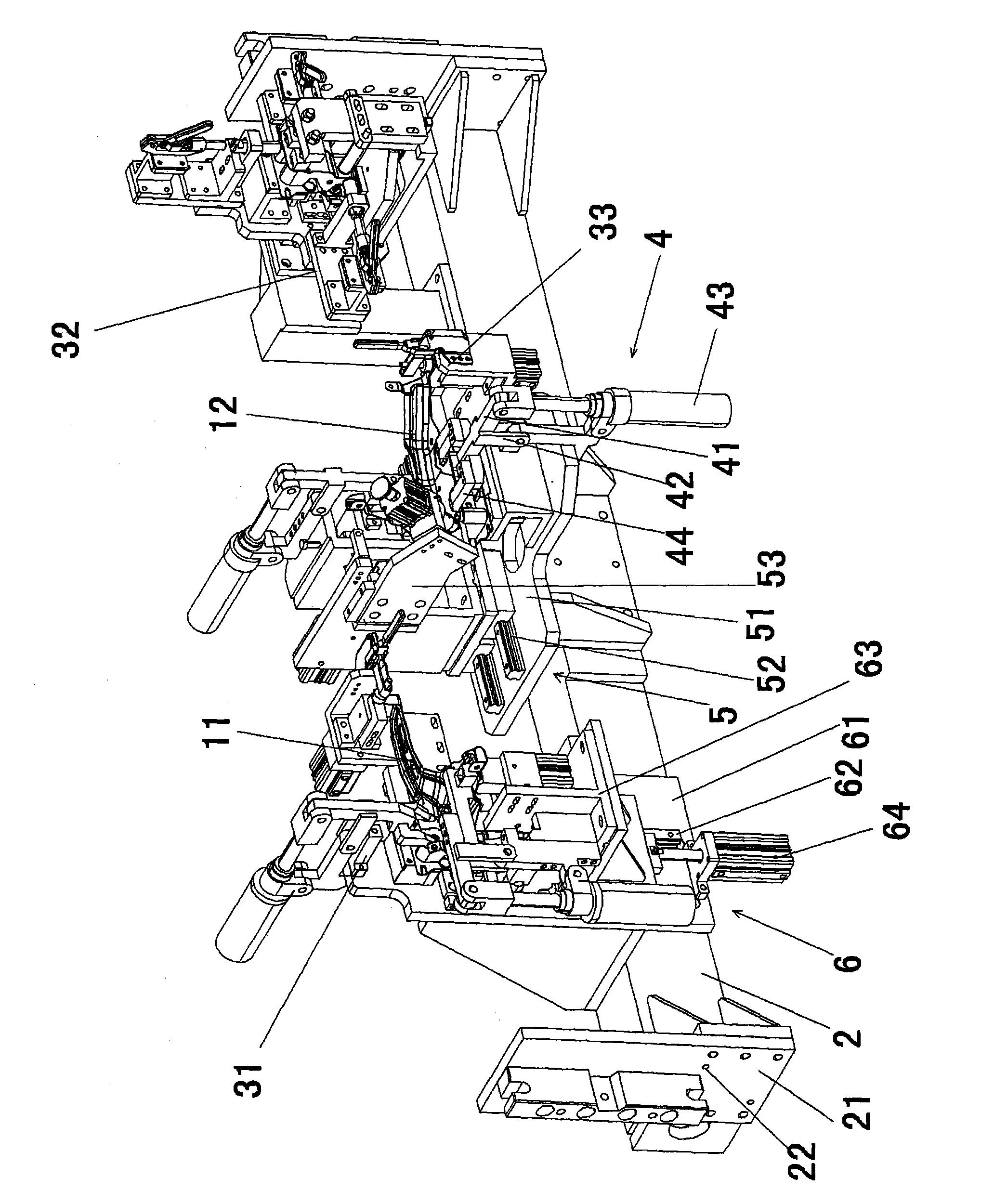

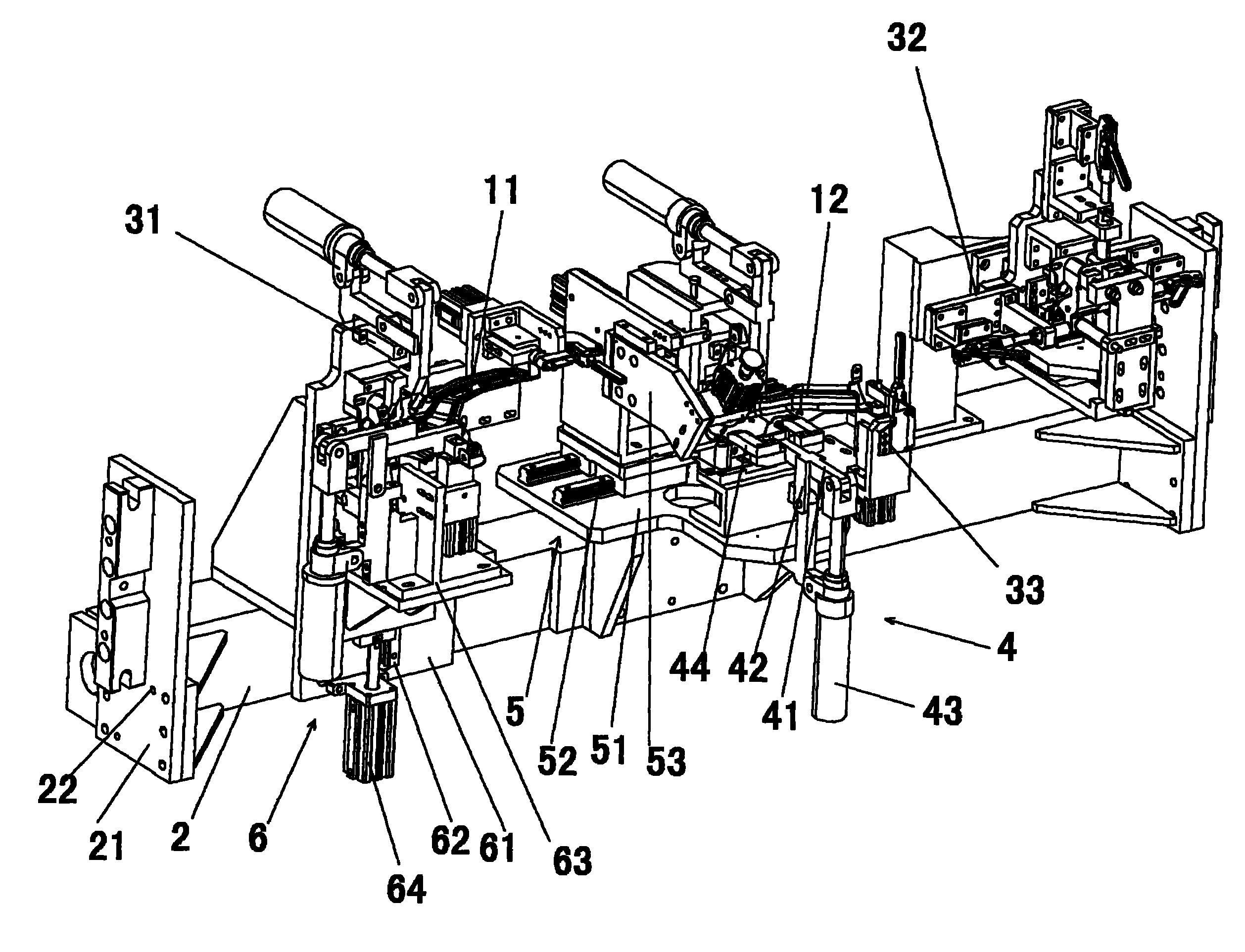

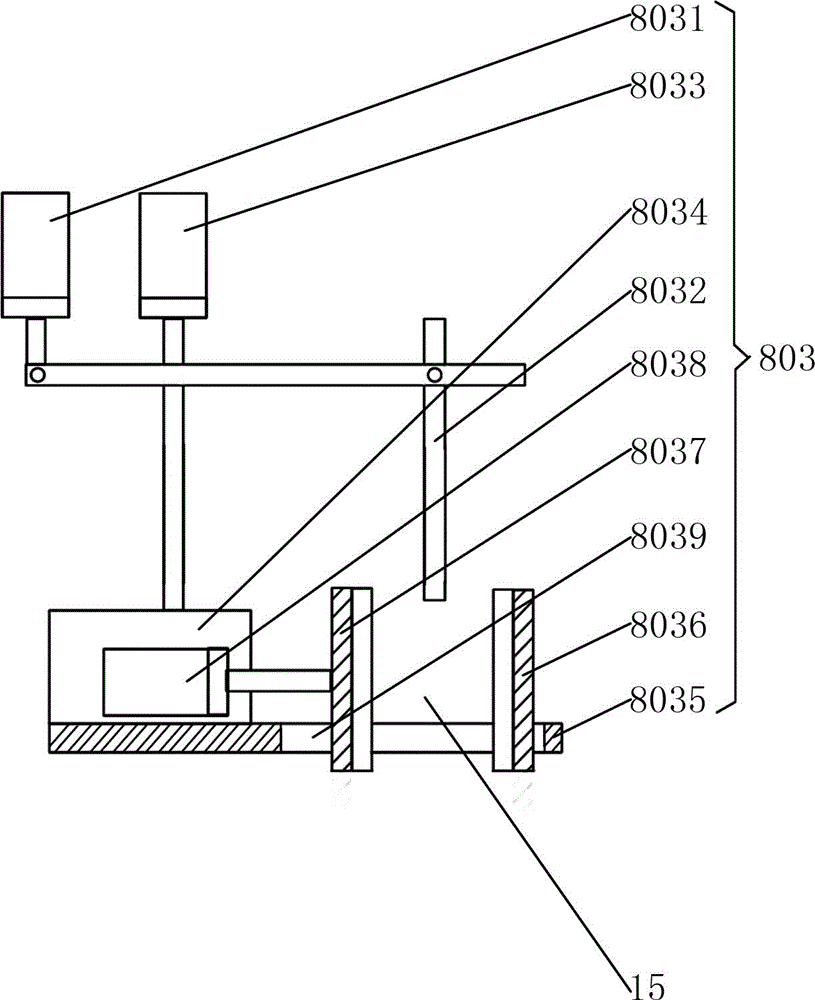

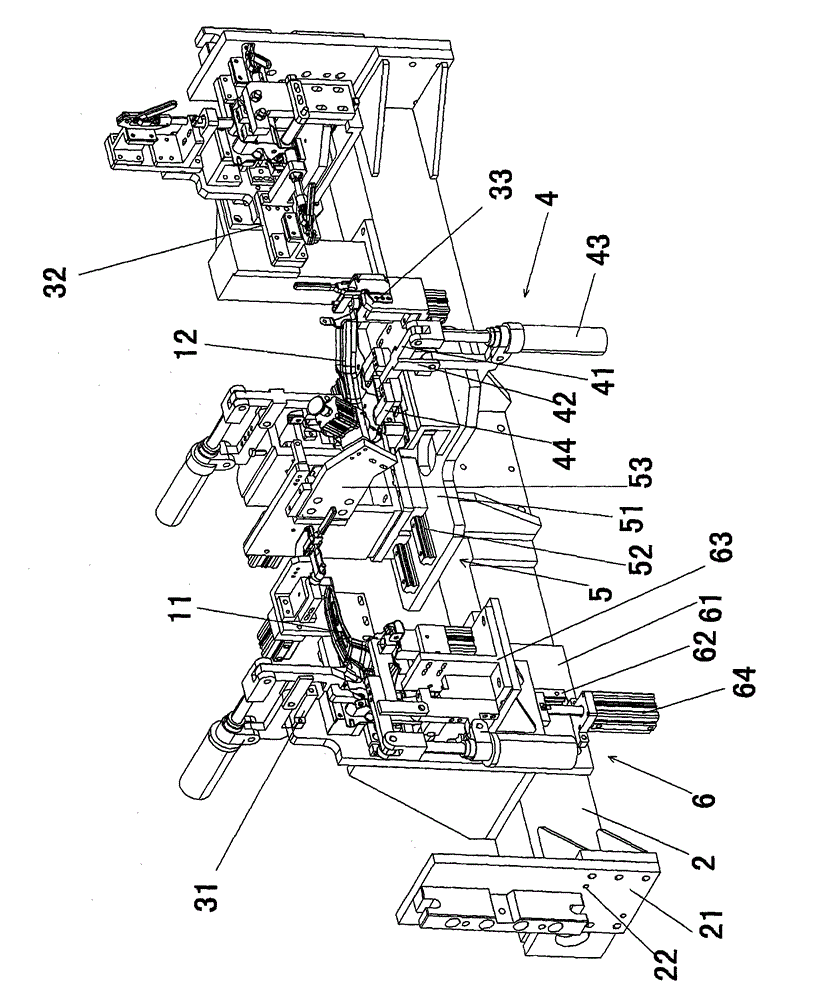

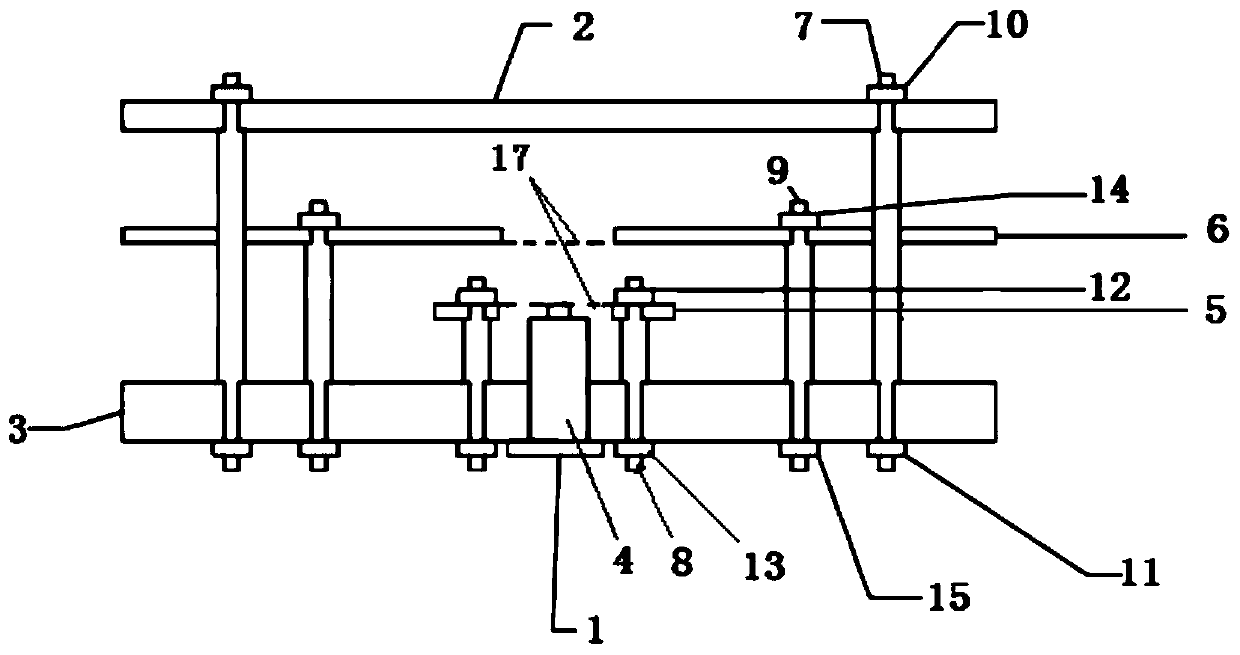

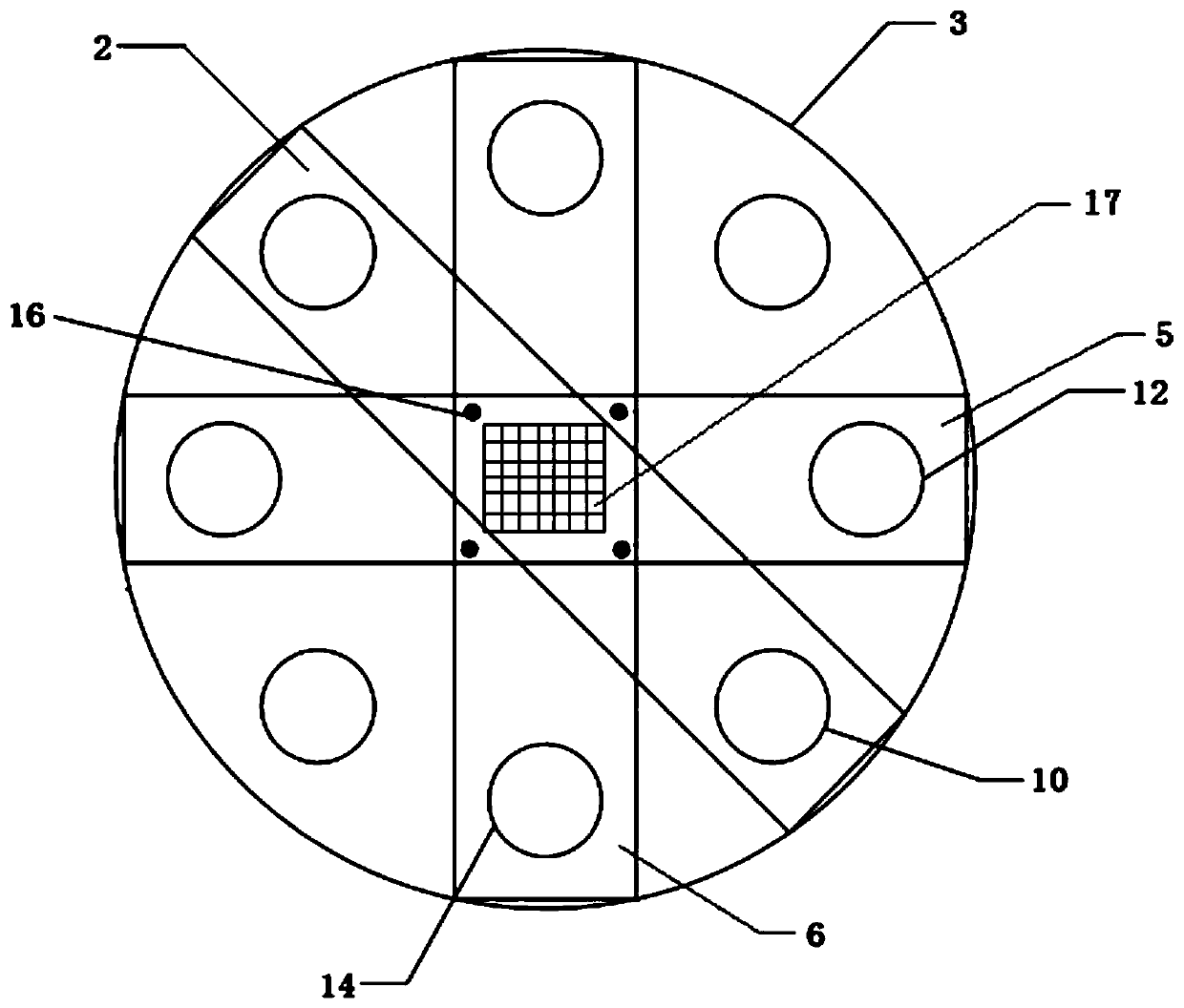

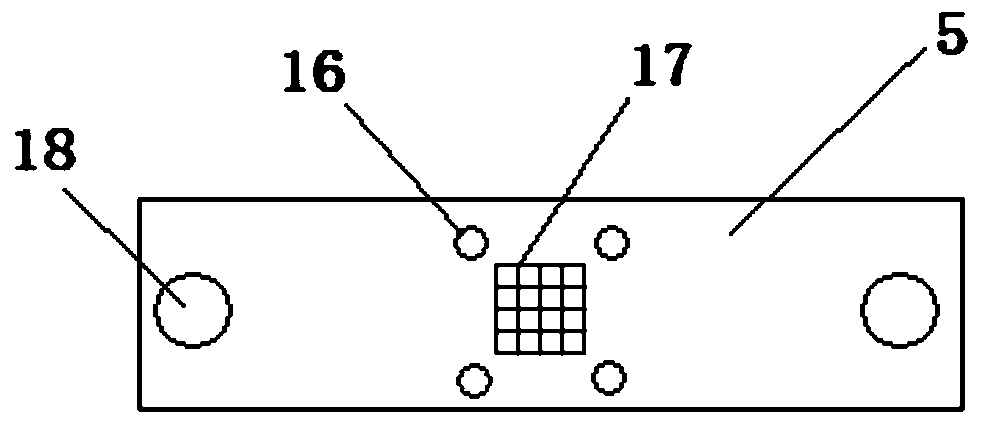

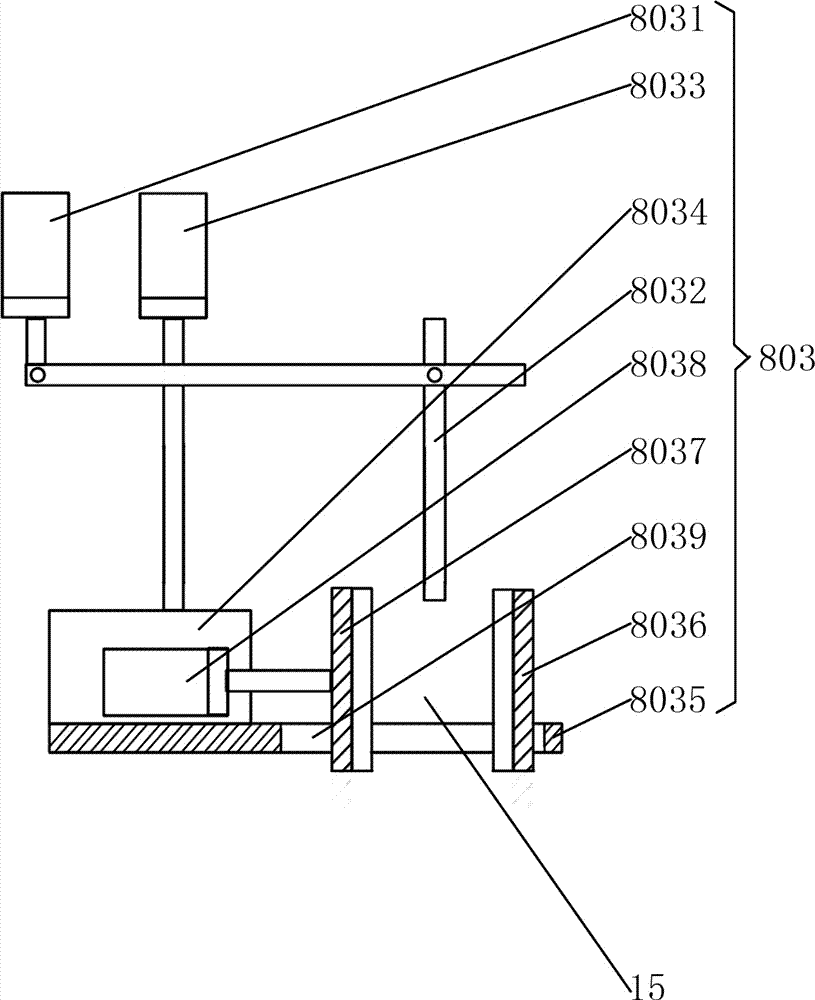

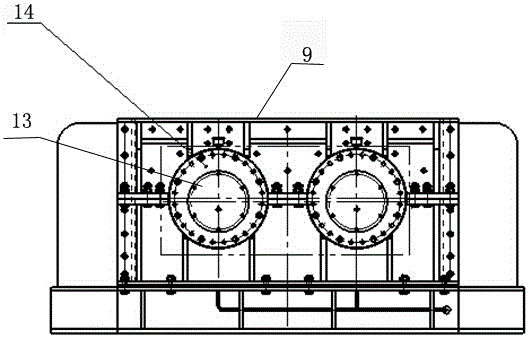

Fixture for manufacturing left and right supports of beam of automotive instrument

ActiveCN102114502ACost-effectiveReduce schooling costsMechanical counters/curvatures measurementsEngineeringCost performance

The invention provides a fixture for manufacturing left and right supports of a beam of an automotive instrument, which is high in cost performance, simple in operation and complete in alignment. The fixture comprises a beam-shaped base, and clamping mechanisms and an alignment mechanism that are arranged on the base, wherein the clamping mechanisms are arranged on two ends of the base and in the middle of the base, and the alignment mechanism is arranged in the middle of the base. By adoption of the structure, the fixture can accurately align the left and right supports of the beam of the automotive instrument, solve the problem of difficult alignment on the left and right supports of the beam of the automotive instrument, overcome the deficiency that the alignment efficiency is low and can not meet production requirement, and is especially suitable for alignment of mass-produced parts in industry, thus omitting complicated steps of an original device, and greatly improving the efficiency of alignment work.

Owner:宁波泰鸿冲压件有限公司

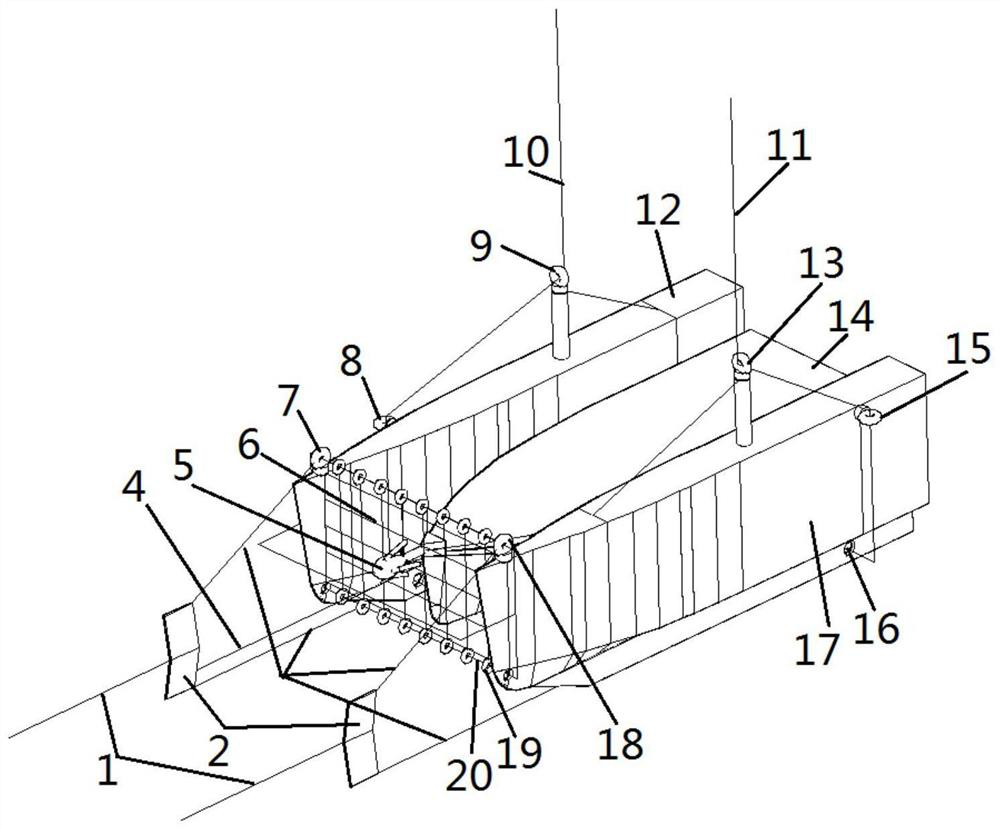

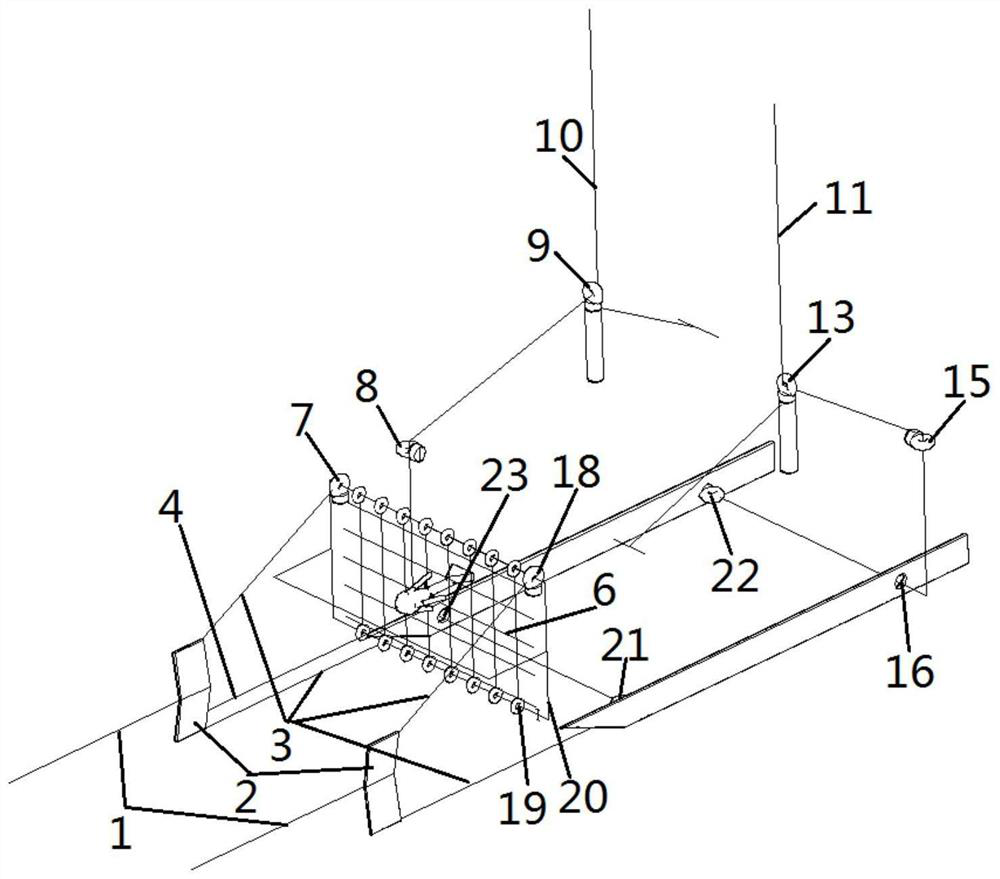

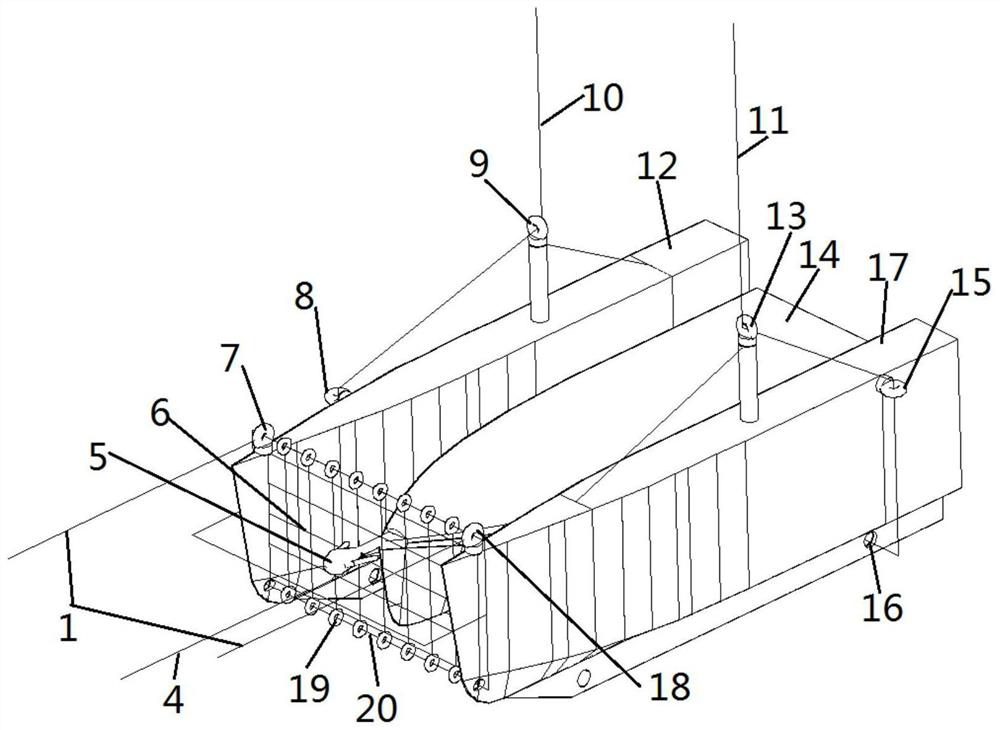

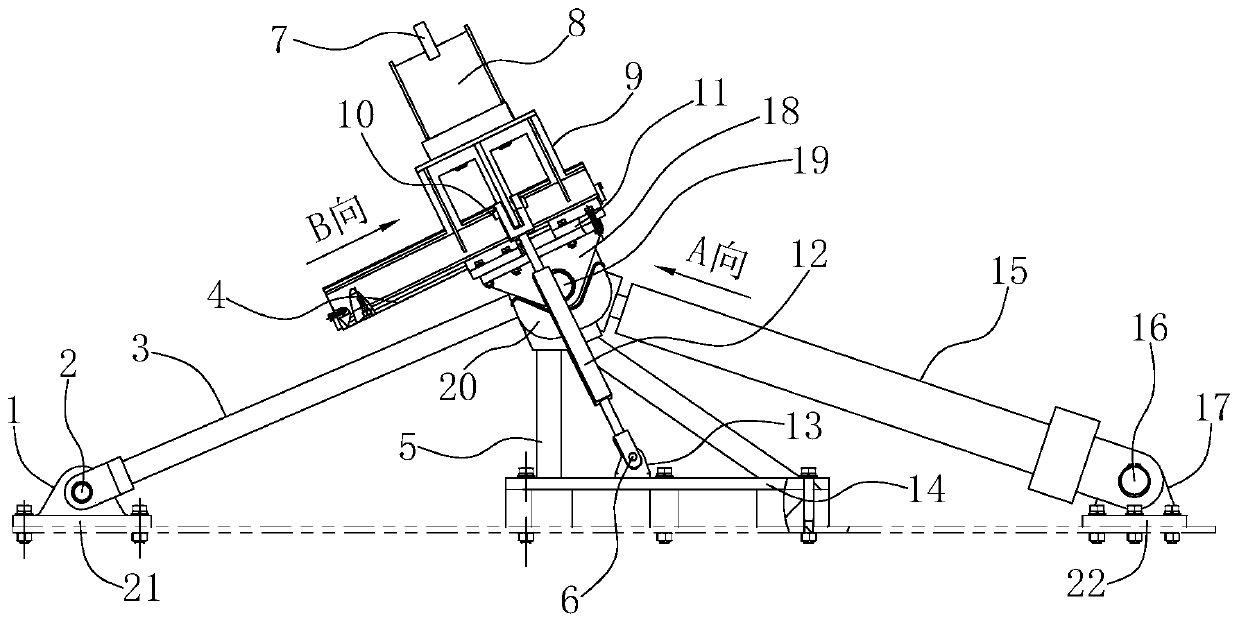

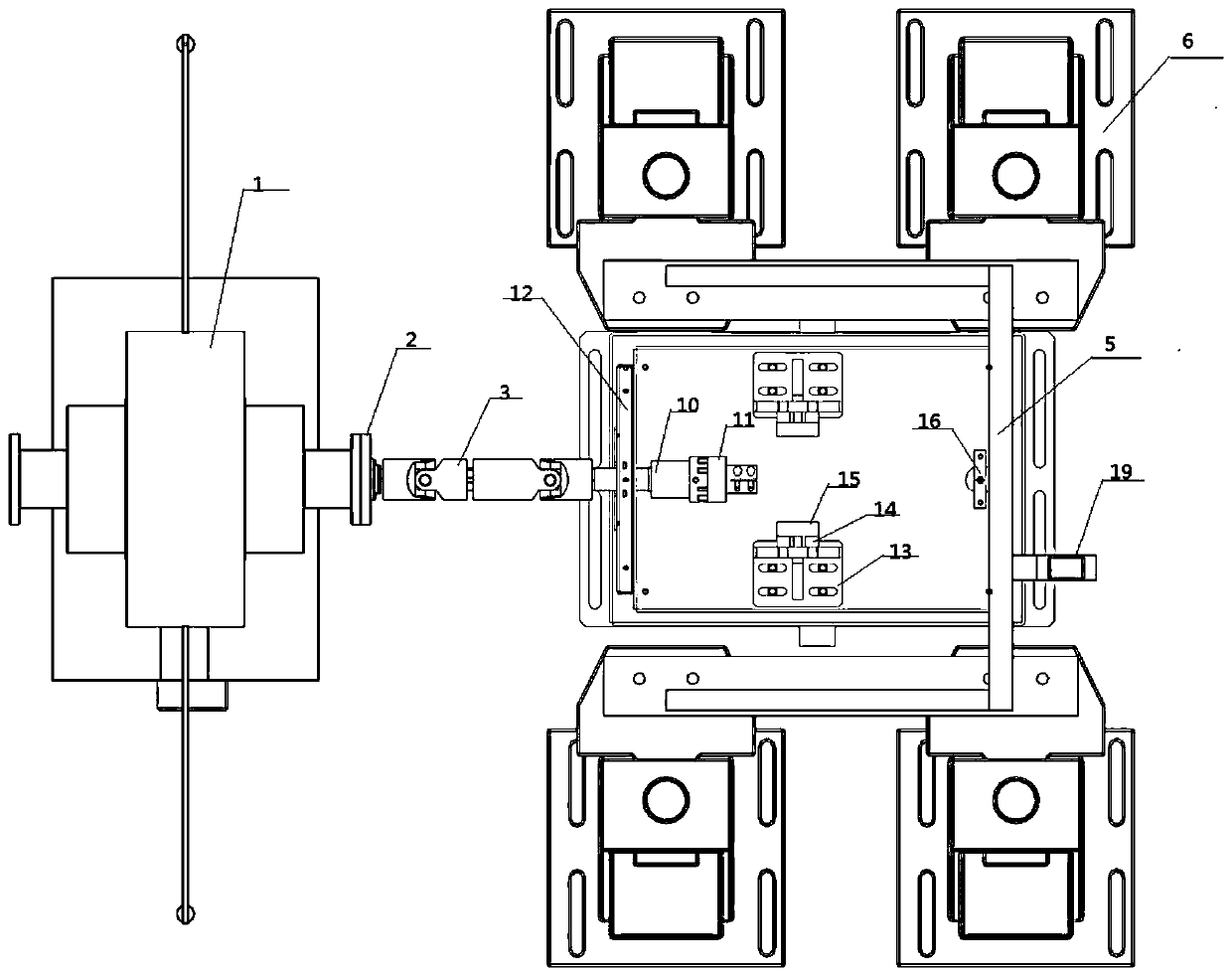

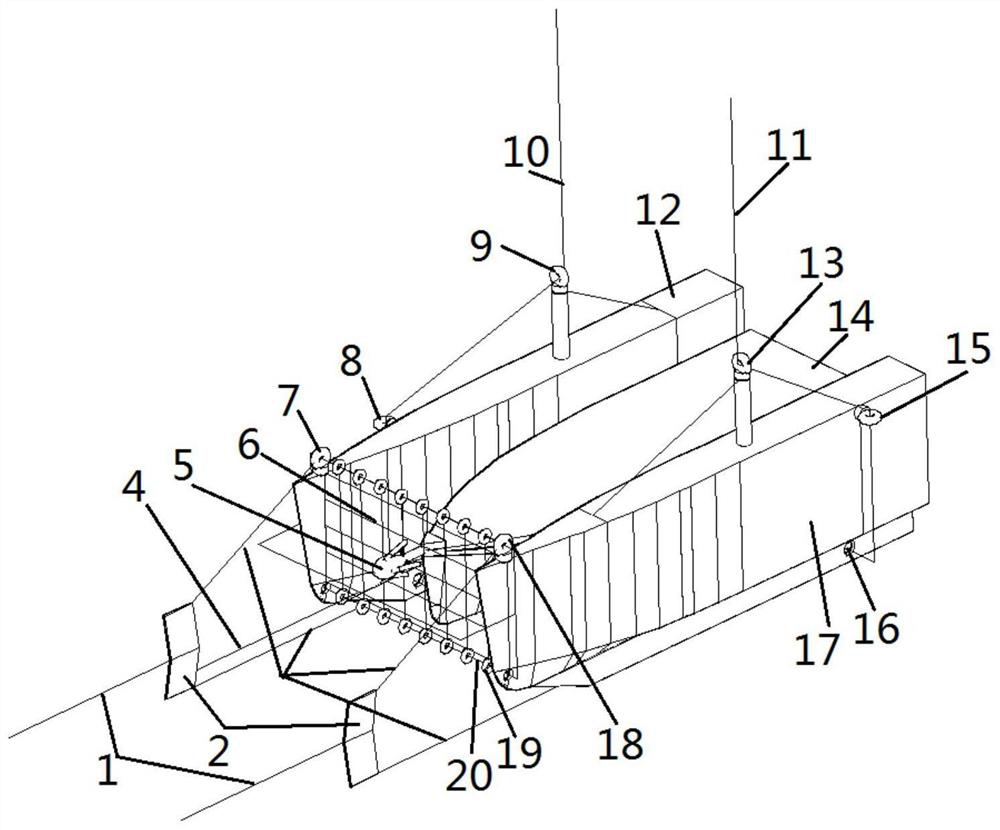

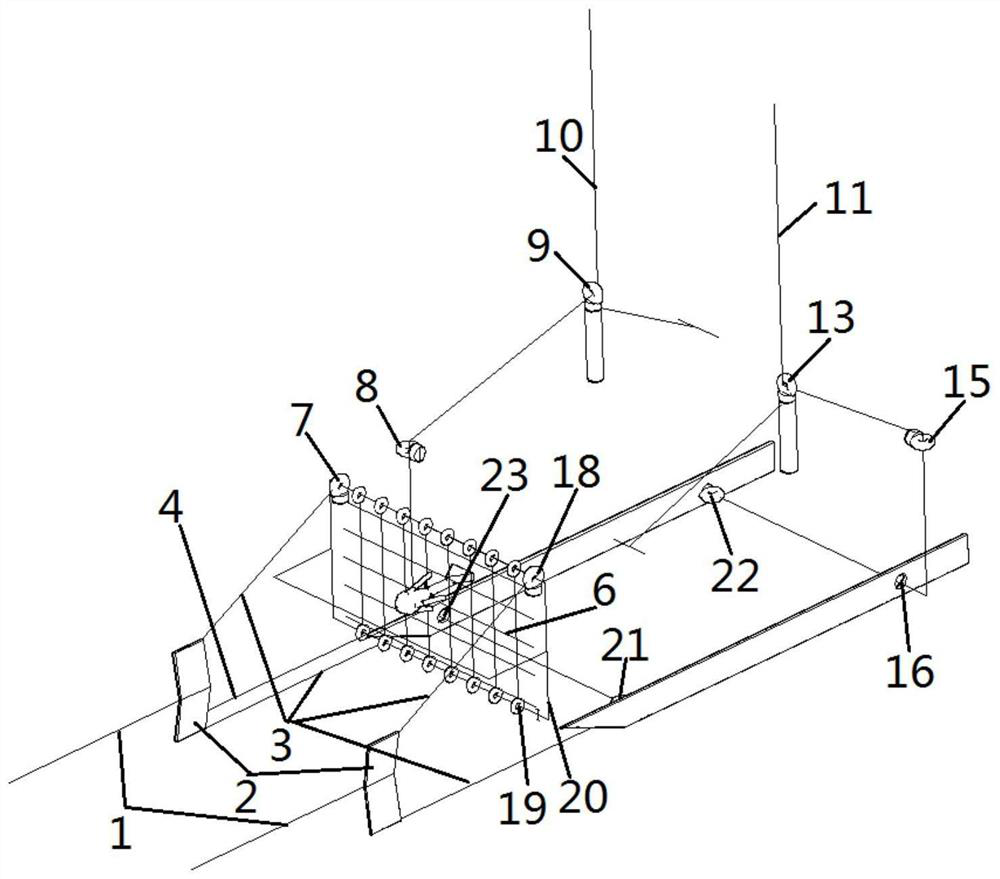

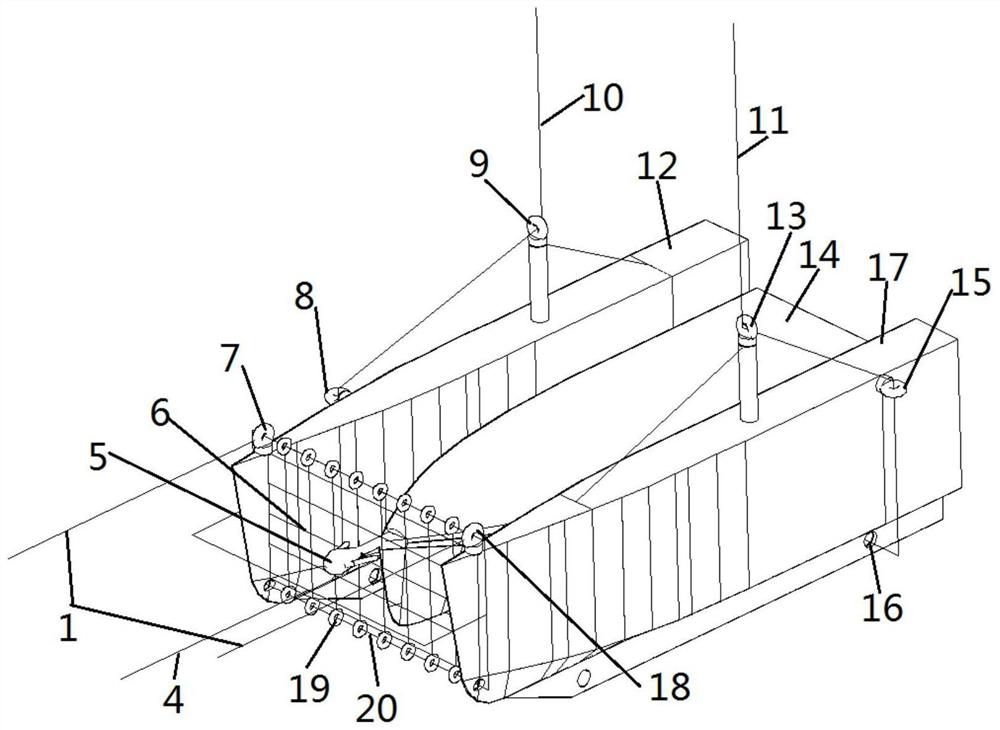

Sea condition self-adaptive laying and recovery device for rapid take-up and pay-off of unmanned ship

ActiveCN112918636ASolve the problem of difficult alignmentAddress reliabilityDry-dockingCargo handling apparatusMarine engineeringMechanical engineering

The invention discloses a sea-condition self-adaptive laying and recovery device for rapid take-up and pay-off of an unmanned ship, and relates to the technical field of ship facilities. The sea-condition self-adaptive laying and recovery device comprises an artificial floating dock, dragging cables, a net take-up cable, a net-supporting cable, a suspension cable, a recovery net and a net collision and locking device; a dock cabin is arranged in the middle of the artificial floating dock; the lifting cable is used for lifting the artificial floating dock and supporting a boat body; the net-supporting cable is arranged at the front part of the dock cabin, and the upper end and the lower end of the recovery net are connected with the upper end and the lower end of the net supporting cable respectively; the net take-up cable is connected with the net-supporting cable; the dragging cables are arranged on two sides of the front part of the dock cabin; and the net collision and locking device is arranged at the front end of a manned boat or an unmanned boat. The lifting cable not only can lift the artificial floating dock, but also can support the manned boat or the unmanned boat, the recovery net is hooked by combining the net collision and net locking device, and the left-right, front-back and up-down displacement of the manned boat or the unmanned boat is controllable, so that the take-up and pay-off difficulty is reduced, and the problems that the boat is collided and damaged, the boat shakes violently and is uncontrollable in the lifting process and the like are solved.

Owner:沈海龙

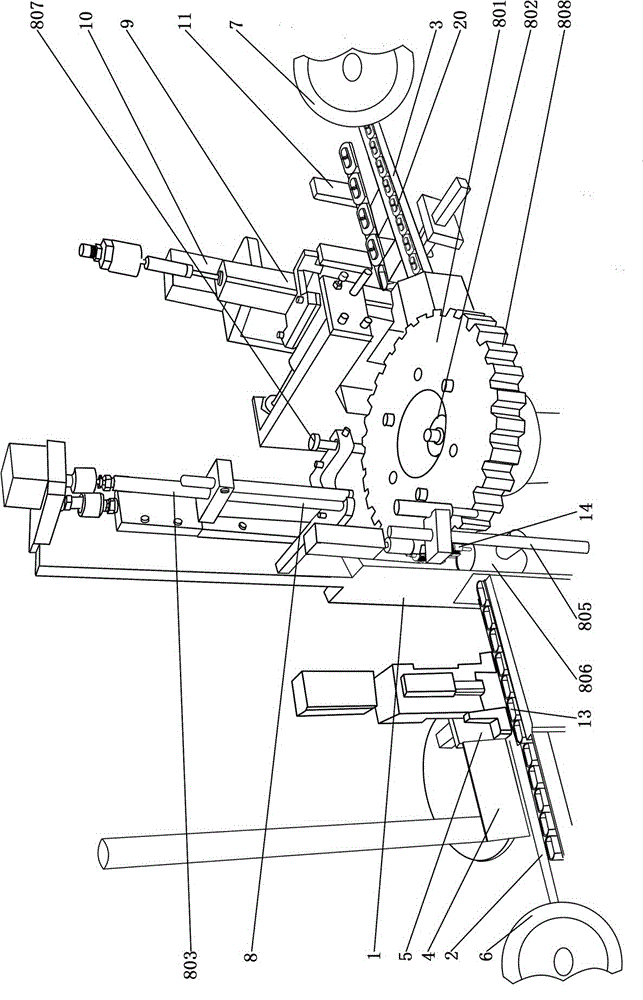

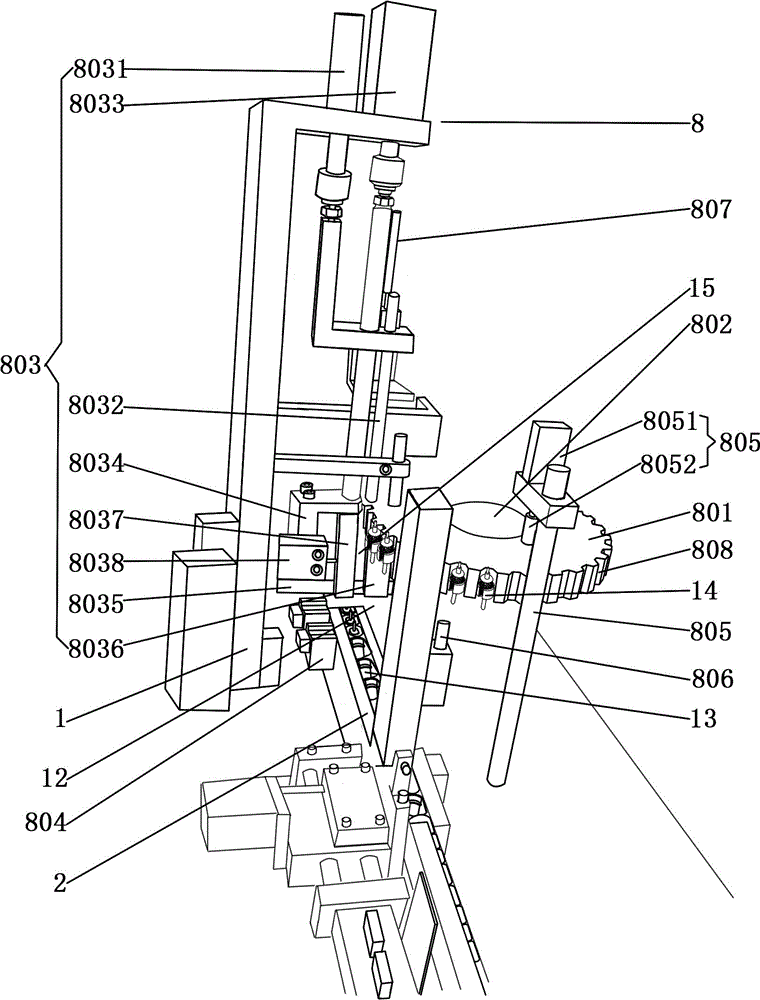

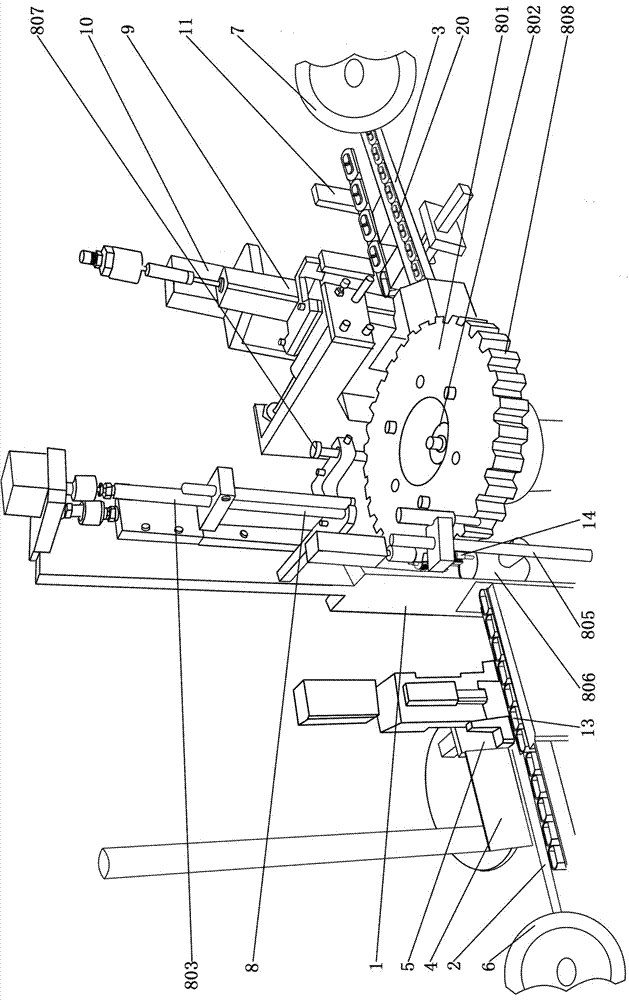

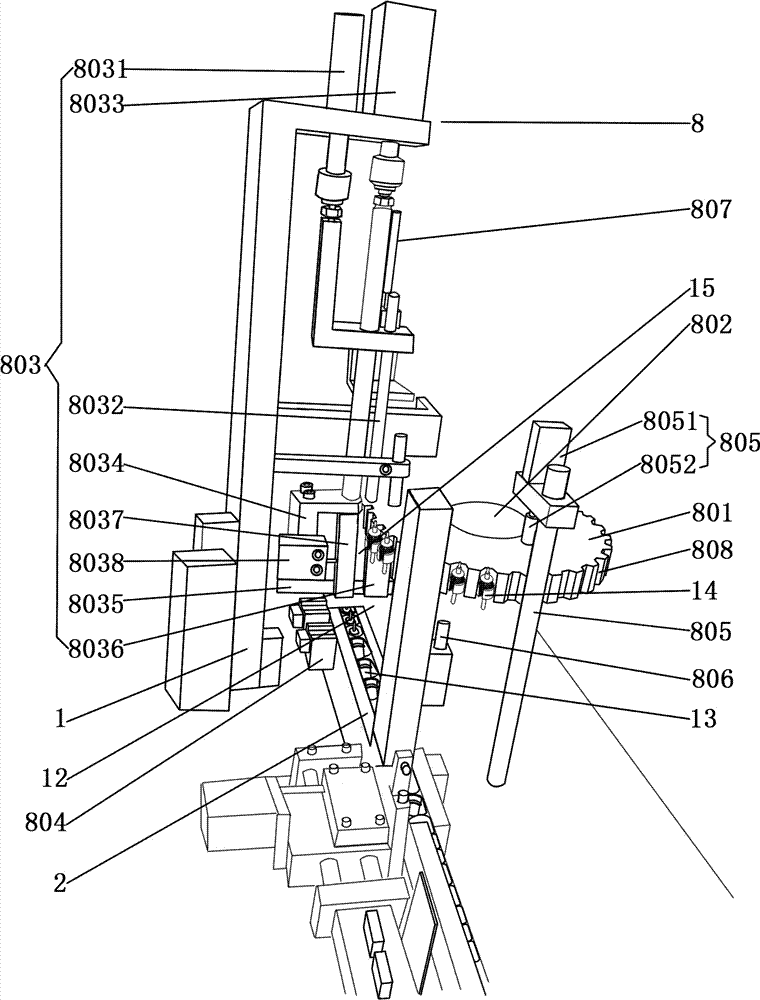

Micro motor fully automatic packaging machine

ActiveCN104901486AAccurate insertionSolve the problem of difficult alignmentManufacturing dynamo-electric machinesEngineeringMicro motor

The invention relates to a micro motor fully automatic packaging machine. The micro motor fully automatic packaging machine includes a rack, a shell guide rail, a turntable, a steeping driving device and a rotor pushing and pressing mechanism; a plurality of magnetic attraction grooves of which the section is half round are distributed on the turntable along the circumferential direction of the turntable at equal intervals; and the rotor pushing and pressing mechanism includes a push-in lifting mechanism, a rotor pushing rod, an adapting lifting mechanism, an adapting lifting seat, an adapting bottom plate, an adapting fixed clamping sheet, an adapting movable clamping sheet and an adapting air cylinder. Since the adapting movable clamping sheet and the adapting fixed clamping sheet are adopted to form a guide cylinder to perform adapting transition, and therefore, the problem of difficulty in realizing accurate alignment of the magnetic attraction grooves on the turntable and the shell guide rail can be solved; a rotor is constantly limited by the guide cylinder, so that a transient suspension state of the rotor in a push-in process can be avoided, and therefore, the constant stability of the rotor can be ensured in the push-in process, and accurate alignment of the rotor and a shell can be ensured; the lower end of the rotation shaft of the rotor can be accurately inserted into a shaft hole at the lower end of the shell, so that fully automatic production of the packaging of micro motors can be realized.

Owner:GUANGDONG CHAOLI MOTOR CO LTD

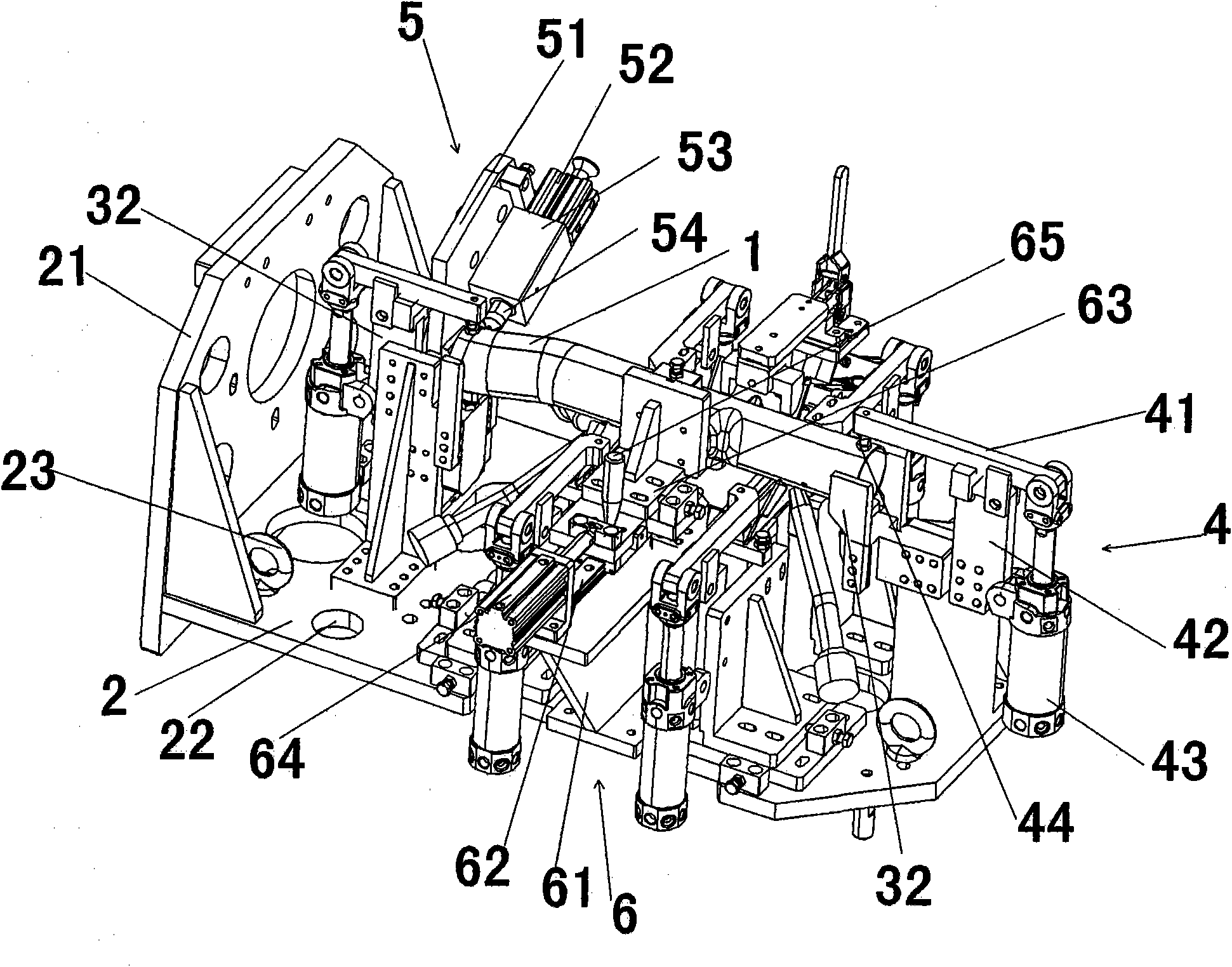

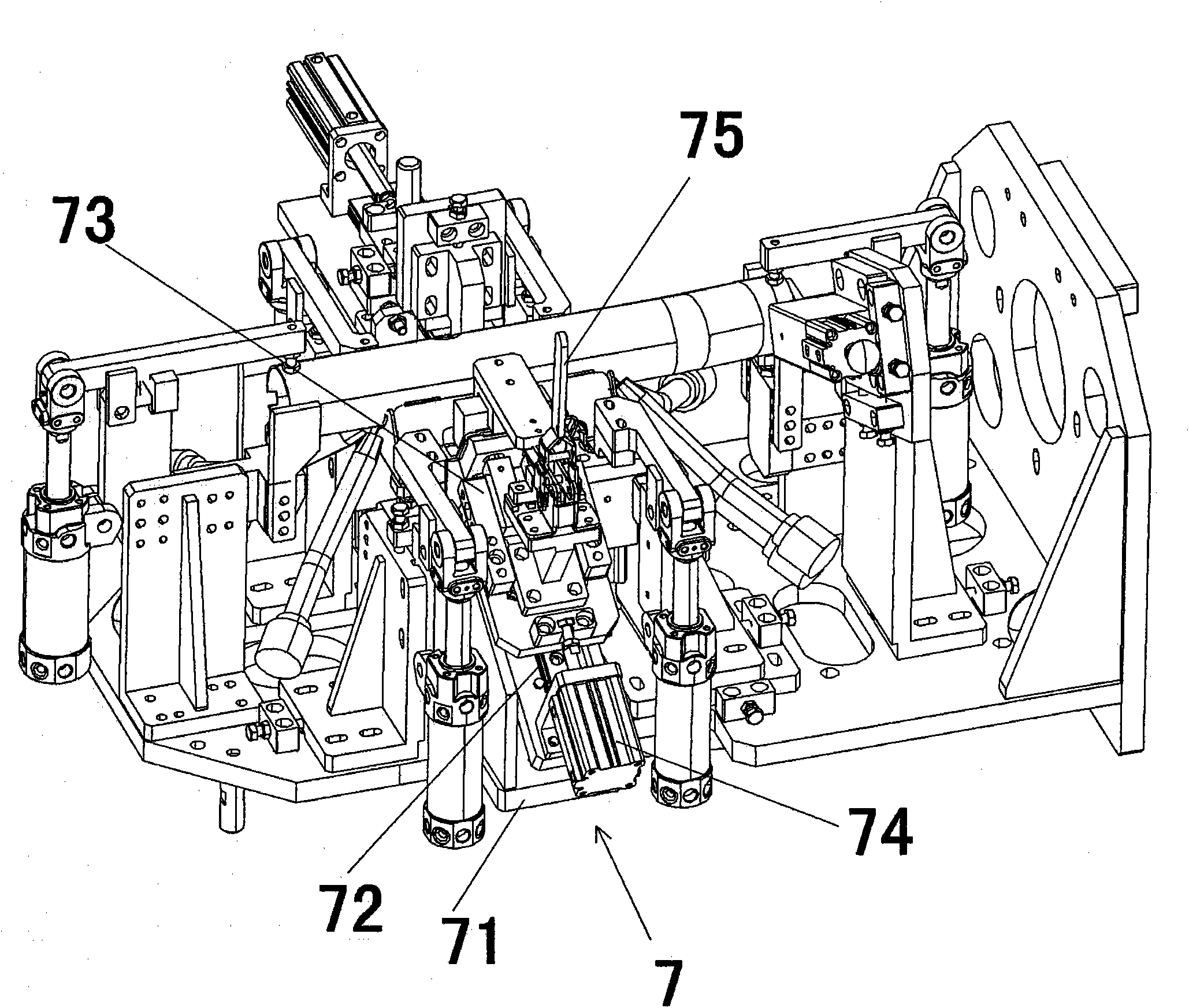

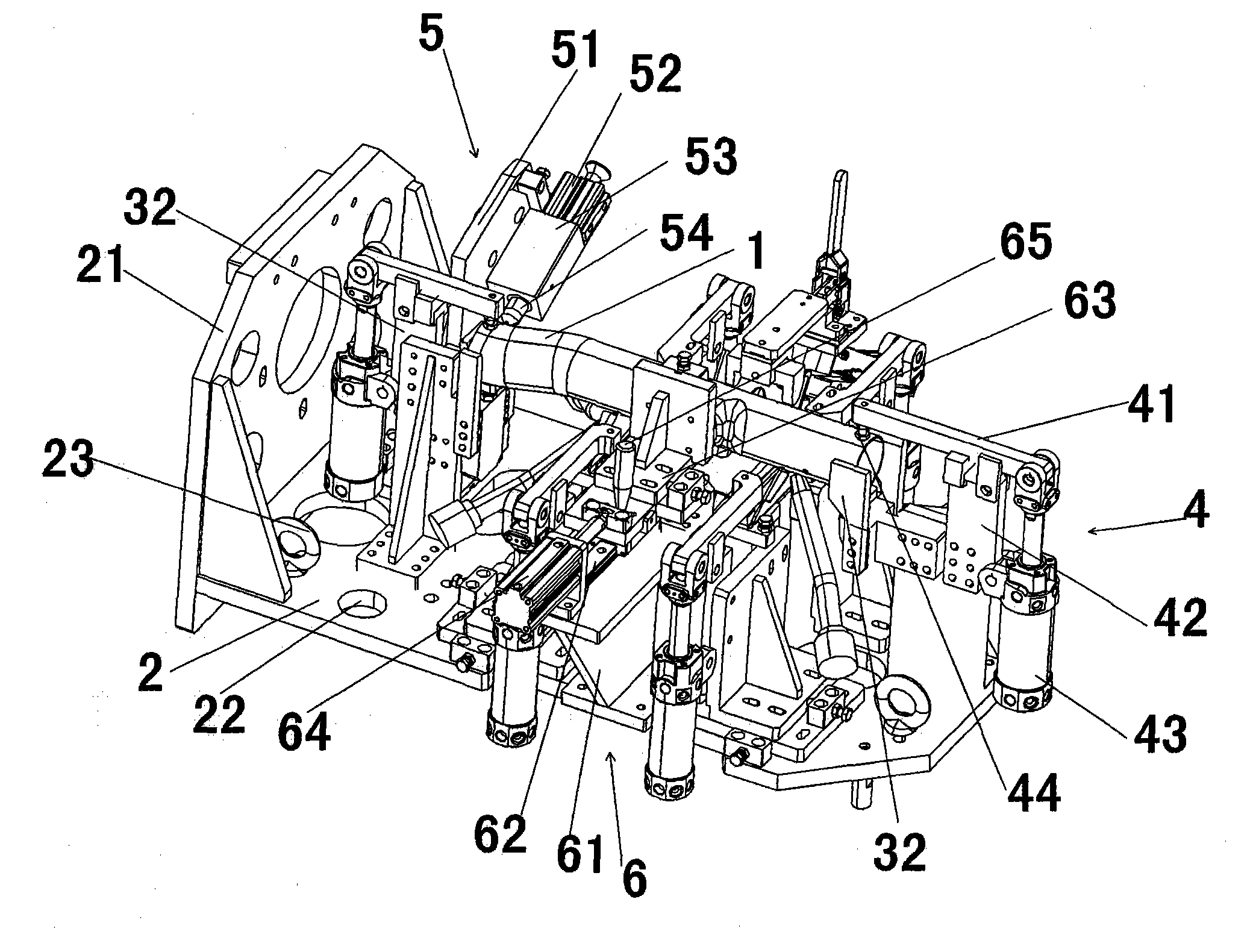

Clamp for manufacturing lower bracket of automobile redirector

ActiveCN102114500ACost-effectiveReduce schooling costsMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides a clamp for manufacturing a lower bracket of an automobile redirector, and the clamp has high performance-price ratio, is simple to operate, and can calibrate roundly. The clamp comprises a base, a clamping mechanism and a calibrating mechanism, wherein, the clamping mechanism and the calibrating mechanism are arranged on the base. The clamp is characterized in that the clamping mechanism comprises two end part clamping mechanisms used for clamping the end parts of the lower bracket of the redirector; the lower bracket of the redirector is horizontally arranged at the top part of the clamping mechanism in the length direction of the lower bracket; and the calibrating mechanism is arranged on both sides of the lower bracket of the redirector between the two end part clamping mechanisms. By adopting the structure, the clamp can accurately calibrate the lower bracket of the bracket of the redirector for an automobile instrument panel beam, solves the problem of difficulty in calibrating the lower bracket of the bracket of the redirector for the automobile instrument panel beam, overcomes the disadvantages that the calibration efficiency is low and the production requirements are difficult to satisfy, and is especially suitable for the calibration of mass-produced parts in industry. Therefore, a great deal of fussy steps in the conventional device can be omitted, and the efficiency of the calibration operation can be improved greatly.

Owner:SHANGHAI HEDA AUTOMOBILE FITTINGS

Counterpoint identification system

ActiveCN109062452ASolve the problem of difficult alignmentInput/output processes for data processingGraphicsPolarizer

A system for identify counterpoint marks is provide, The visible area of the touch control module is used to set the transparent alignment mark made of phase delay material, and then two polarizers are used to make the light receiver recognize the pattern of the touch control module for alignment program, which improves the problem that the alignment mark is not empty in the frame trace area of the narrow frame product.

Owner:INTERFACE TECH CHENGDU CO LTD +2

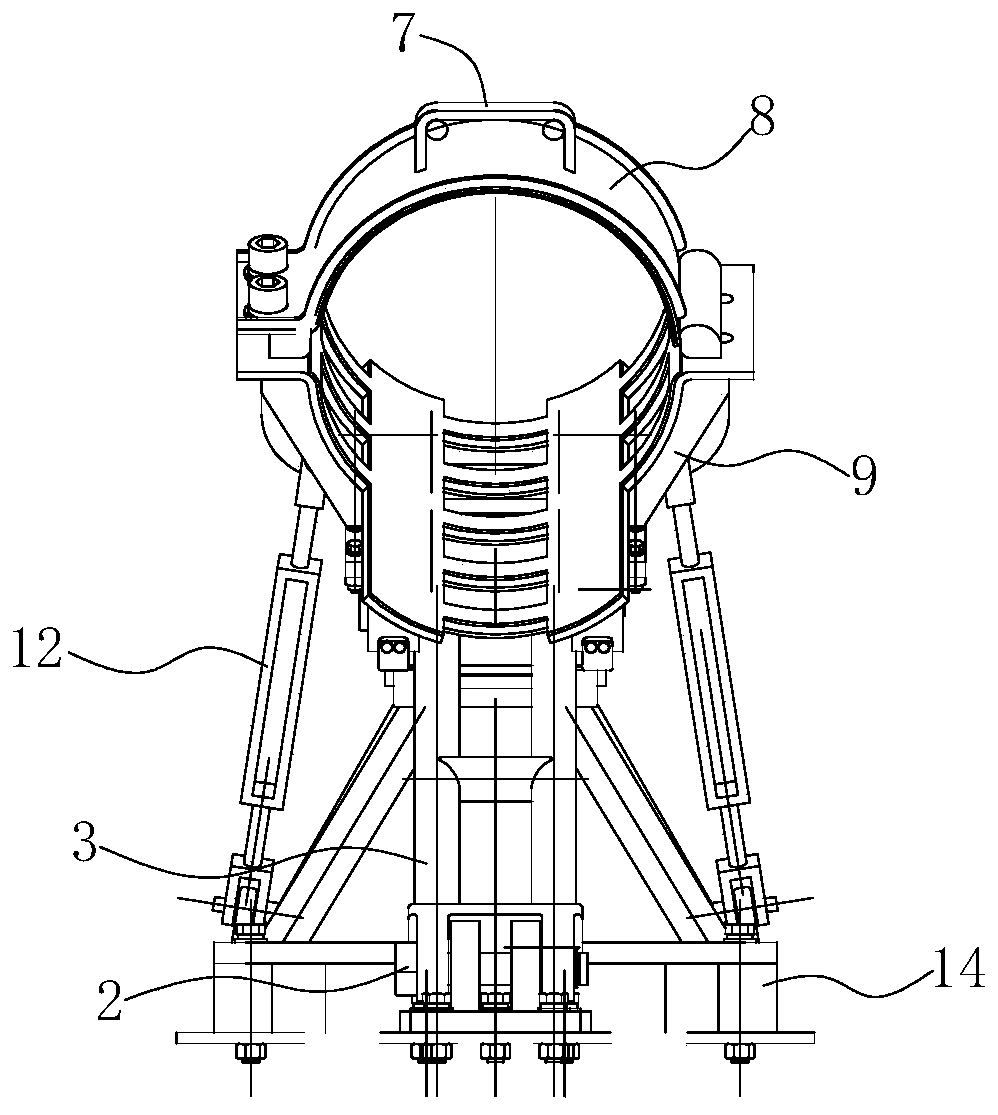

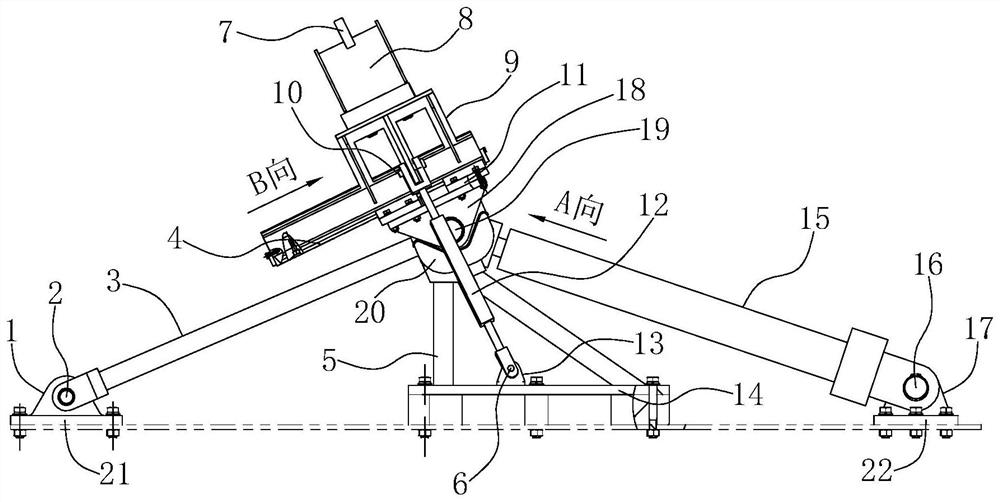

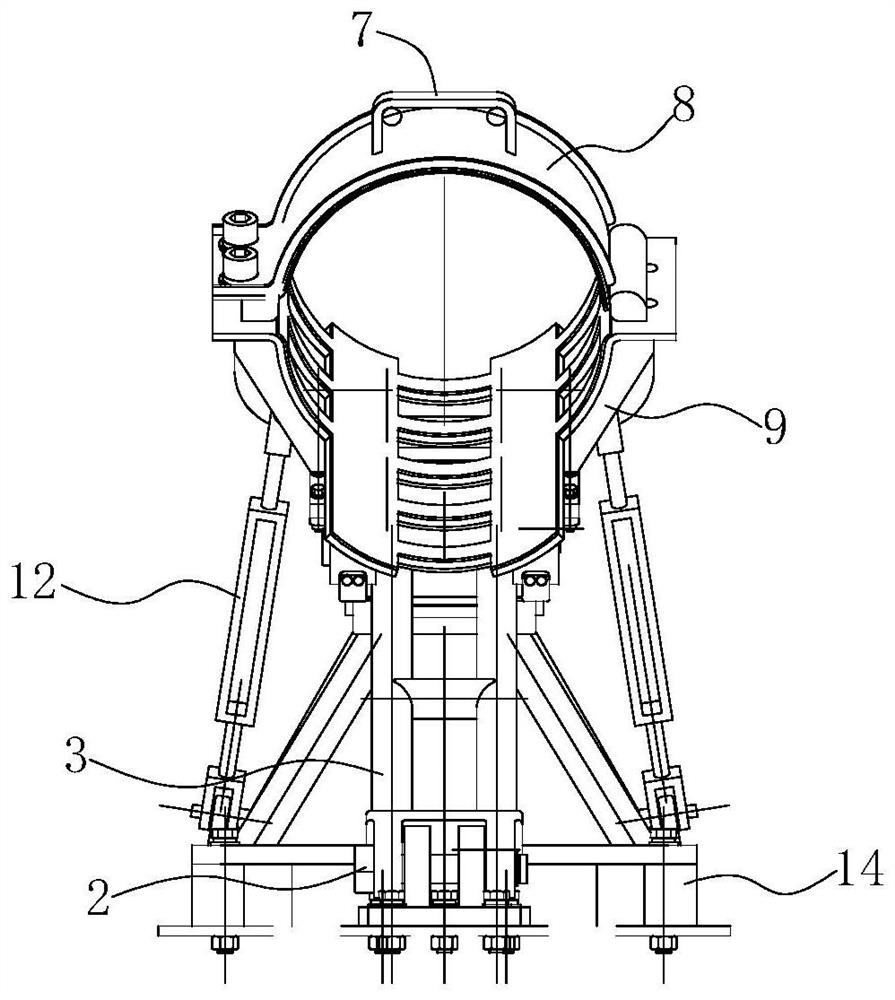

An inclined boosting type lifting device with a slidable bracket

ActiveCN110341991ASolve the problem of difficult alignmentReduce labor intensityCosmonautic ground equipmentsEngineeringCentring

The invention discloses an inclined boosting type lifting device with a slidable bracket. The lifting device comprises a rotary bracket, a driving cylinder and a first support lug. The lower end of the rotary bracket is hinged to a first support; the lower end of the driving cylinder is hinged to a second support; and the upper ends of the rotary bracket and the driving cylinder are hinged on thefirst support lug; and a bracket is slidably installed on the first support lug. The purpose of the invention is to provide an inclined boosting type lifting device with a slidable bracket. The inclined boosting type lifting device can conveniently and quickly lift an erecting oil cylinder, solves the problem that the centring of the erecting oil cylinder and a pin hole of a launching cylinder aredifficult, reduces the labor intensity, improves the efficiency, and significantly improves the safety during the operation.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Layered nano silicon oxide sheet modified polyamic acid resin composition and polyimide film prepared from the same

ActiveCN100491468CLow Coefficient of Thermal Expansion (CTE) ValueGood dimensional stabilityNano siliconLiquid-crystal display

The invention discloses a polyamic acid resin component, which contains layered nanometer silica and or nanometer powder to prepare polyimide film with modified size safety, low hydroscopicity, high transparent property and low thermal bulking coefficient (CTE) for flexible printing circuit board and LED circuit board.

Owner:CHANG CHUN PLASTICS CO LTD

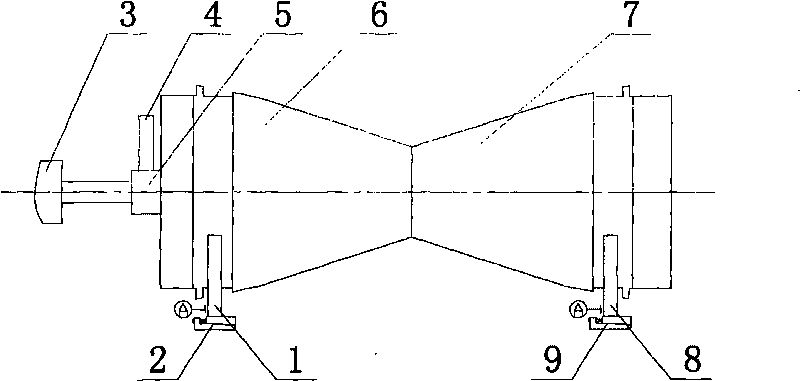

Method for manufacturing guide groove of servomotor cylinder of runner cone of hydroturbine

InactiveCN101708561ASolve the difficulty of loading cardsSolve the problem of difficult alignmentMilling equipment detailsEnd millEnd milling

The invention relates to a method for manufacturing a guide groove of a servomotor cylinder of a runner cone of a hydroturbine. The method is characterized in that a boring lathe workbench is provided with two V-shaped irons; a regulating parallel is arranged under each V-shaped iron; small ends of two runner cones are aligned with each other and firmly welded by a butt strap; then, the two runner cones are arranged on the V-shaped irons horizontally, and are fixed after being aligned with a principal axis of a boring lathe in each direction; the principal axis of the boring lathe is provided with a right-angle milling head; and the milling head is provided with an end mill manufacturing guide groove. The method solves the problems of difficult assembly and difficult alignment in manufacturing the guide groove of the runner cones, greatly improves the manufacture accuracy and production efficiency, and has the advantages of easy operation and low manufacture cost.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

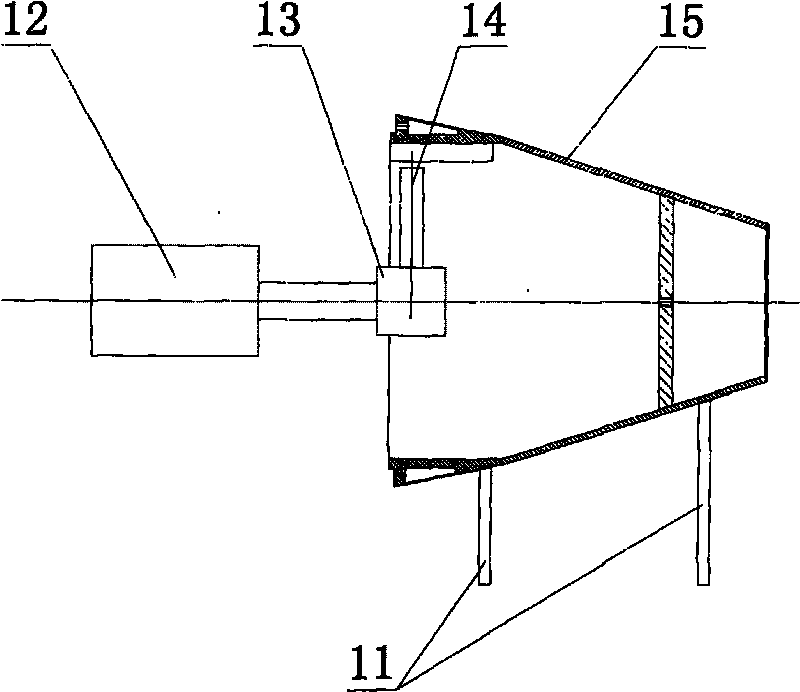

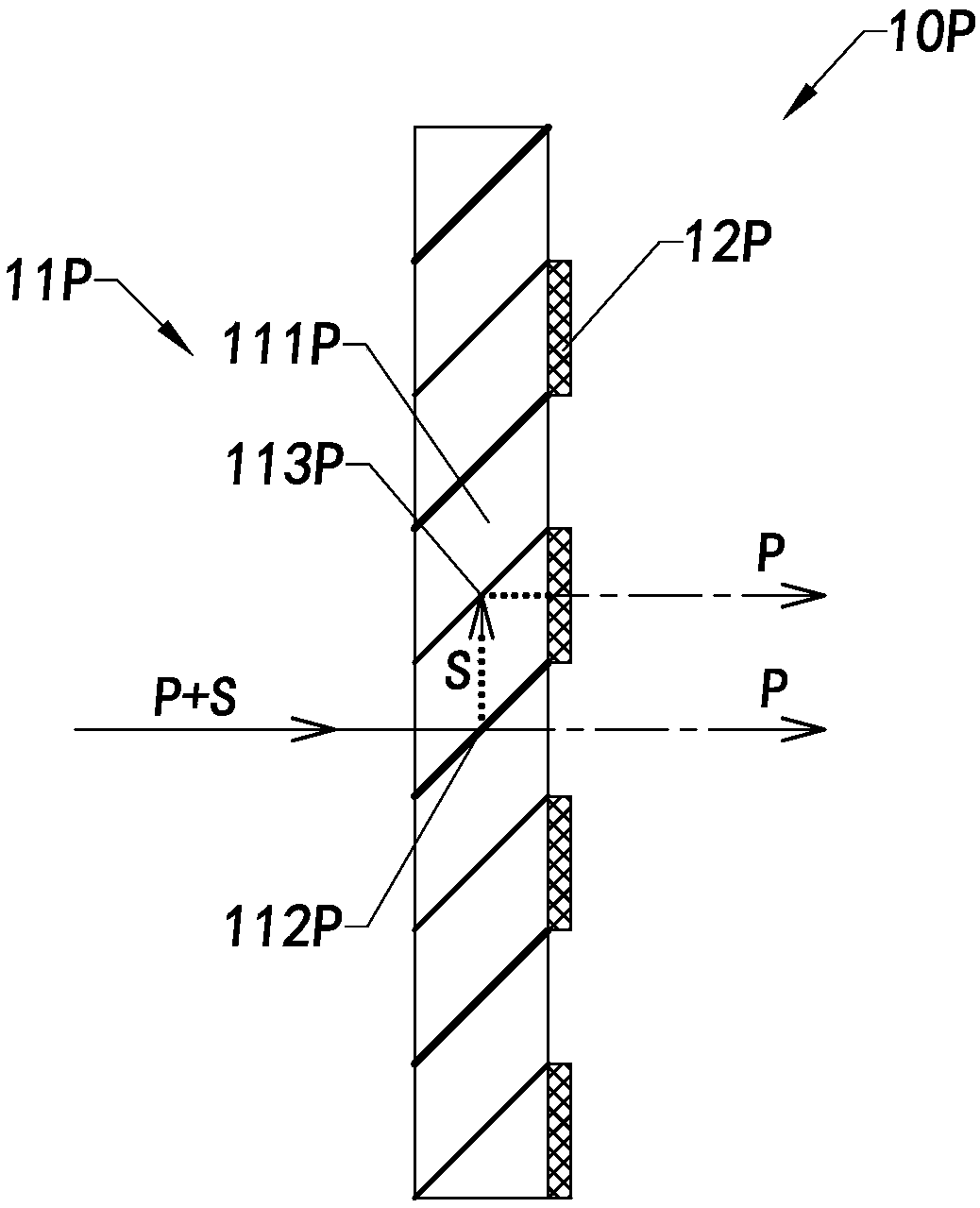

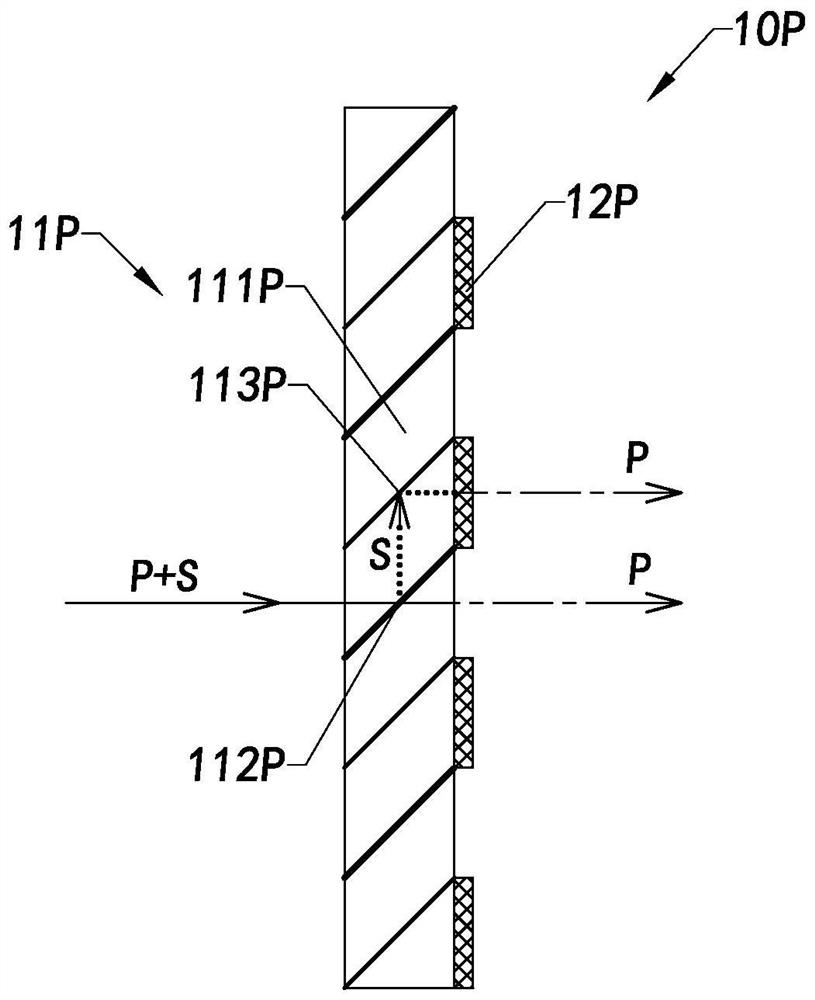

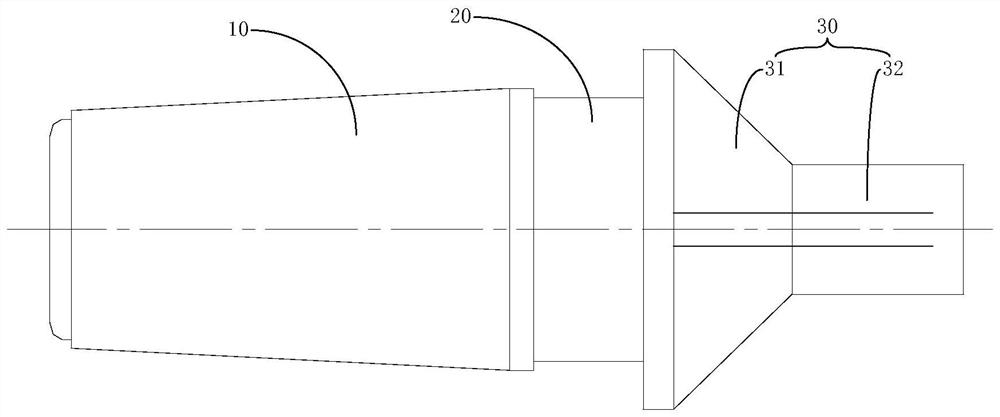

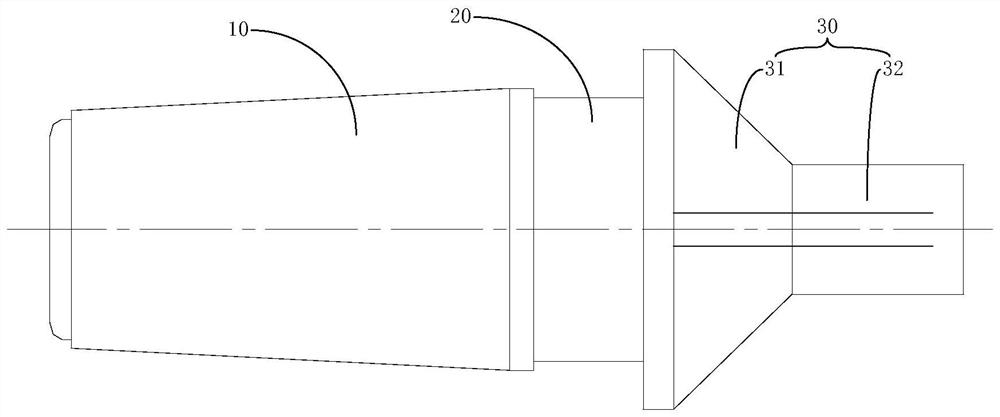

A polarization multiplexing device for projection system

ActiveCN111158159ASolve the problem of difficult alignmentReduce manufacturing difficultyProjectorsOptical elementsExit surfaceProjection system

A polarization multiplexing device for a projection system is used for converting non-polarized light into polarized light with the same polarization state. The polarization multiplexing device comprises a group of polarization multiplexing units. All the polarization multiplexing units are arranged in an end-to-end mode, and each polarization multiplexing unit is provided with an incident plane and an emergent plane opposite to the incident plane and comprises a light conversion element, a light beam splitting assembly and a light reflection assembly. The light conversion element is used forconverting the first polarized light into second polarized light. The light beam splitting assembly is located at one side of the light conversion element and is used for separating the non-polarizedlight incident from the incident surface into second polarized light emitted from the emergent surface and first polarized light emitted to the light conversion element. The light reflection assemblyis located on the other side of the light conversion element and used for reflecting the second polarized light converted by the light conversion element so that the second polarized light can be emitted out from the emergent face.

Owner:SUNNY OPTICAL ZHEJIANG RES INST CO LTD

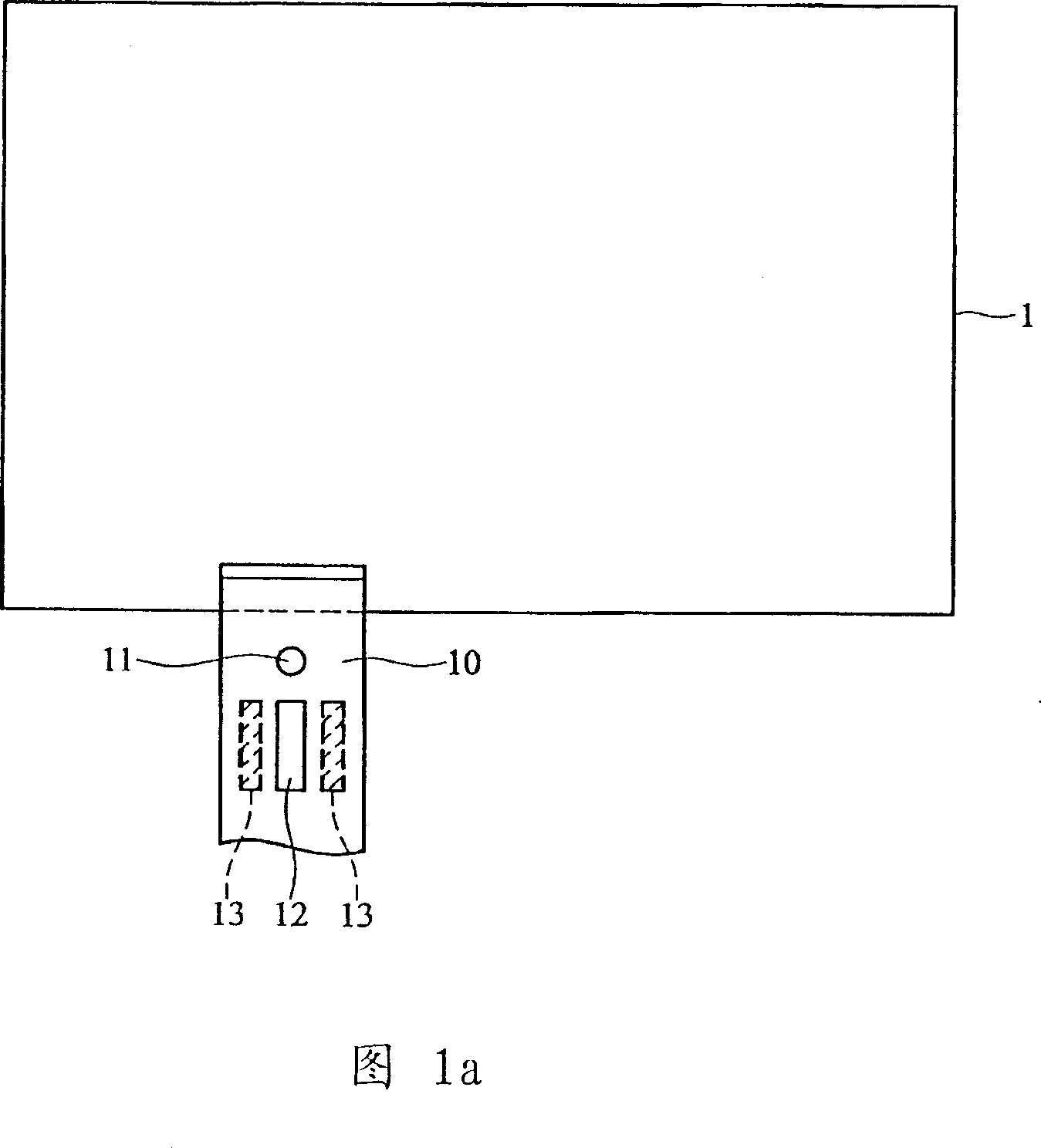

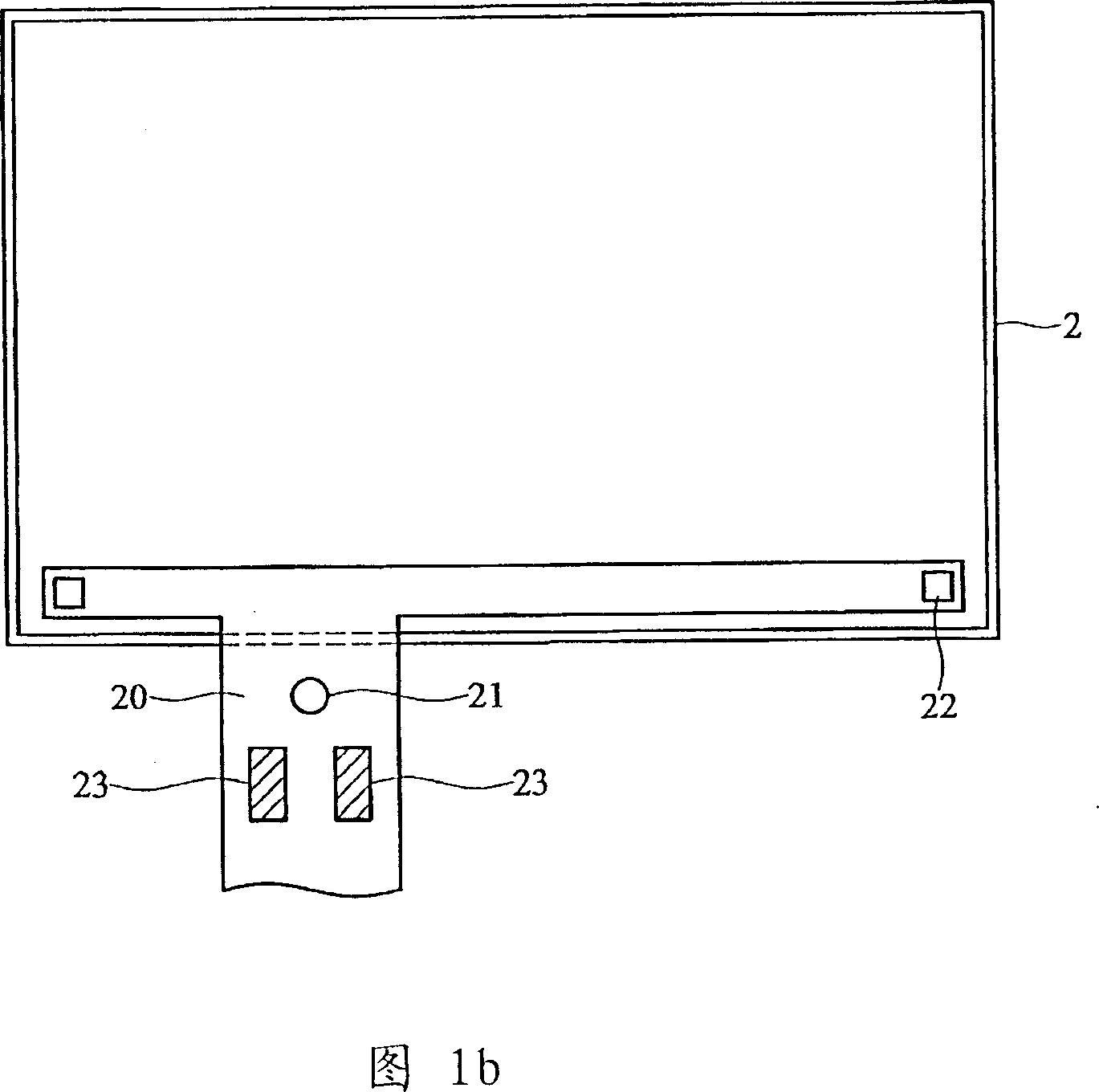

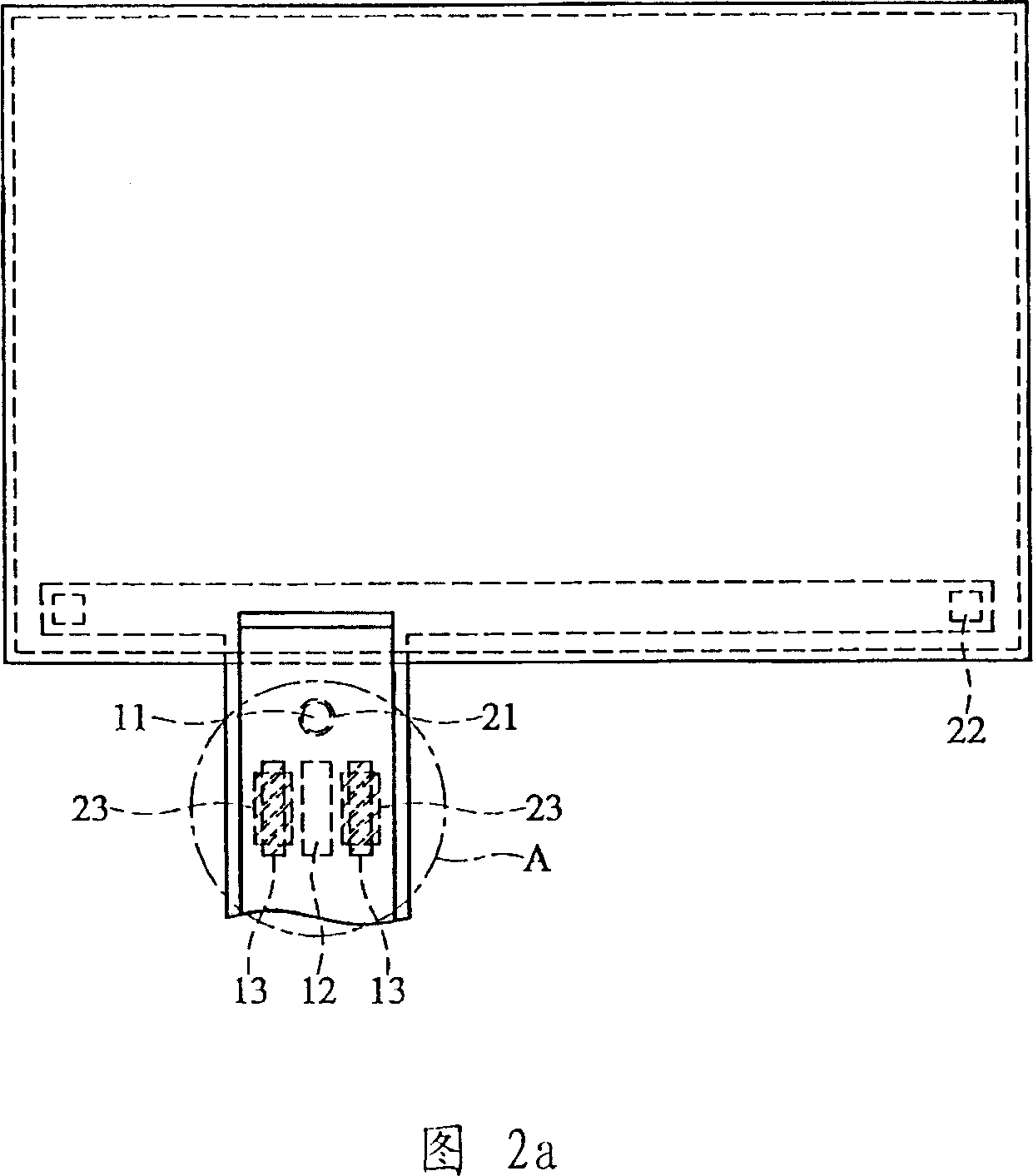

Middle frame used for fixing flexible display panel and flexible display device

ActiveCN107393948ASolve heavy industry difficultiesSolve the problem of difficult alignmentCircuit bendability/stretchabilityCasings with display/control unitsPrinted circuit boardEngineering

The invention provides a middle frame used for fixing a flexible display panel. The middle frame comprises a middle frame body. A first through groove and a second through groove are respectively arranged on sides of the middle frame body. The invention further provides a flexible display device. The flexible display device comprises the middle frame and the flexible display panel arranged in the middle frame. The flexible display panel comprises a flexible substrate and a printed circuit board. A substrate protruding part is arranged on at least one side edge in two side edges, which are adjacent to the printed circuit board, of the flexible substrate. The first through groove is located at a position corresponding to the printed circuit board. The second through groove is located at a position corresponding to the substrate protruding part. The substrate protruding part is fixed in the second through groove. A part of the circuit board of the printed circuit board is fixed in the first through groove. Compared with the prior art, the middle frame used for fixing the flexible display panel and the flexible display device have the advantages that the problem of difficult alignment between the flexible display panel and the middle frame is solved; when the flexible display panel in displacement and the like needs to be re-worked, the substrate protruding part is clamped to re-fix the flexible display panel; and the problem of difficult re-working is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Fixture for manufacturing left and right supports of beam of automotive instrument

ActiveCN102114502BSolve the problem of difficult alignmentAccurate CalibrationMechanical counters/curvatures measurementsDashboardEngineering

The invention provides a fixture for manufacturing left and right supports of a beam of an automotive instrument, which is high in cost performance, simple in operation and complete in alignment. The fixture comprises a beam-shaped base, and clamping mechanisms and an alignment mechanism that are arranged on the base, wherein the clamping mechanisms are arranged on two ends of the base and in the middle of the base, and the alignment mechanism is arranged in the middle of the base. By adoption of the structure, the fixture can accurately align the left and right supports of the beam of the automotive instrument, solve the problem of difficult alignment on the left and right supports of the beam of the automotive instrument, overcome the deficiency that the alignment efficiency is low and can not meet production requirement, and is especially suitable for alignment of mass-produced parts in industry, thus omitting complicated steps of an original device, and greatly improving the efficiency of alignment work.

Owner:宁波泰鸿冲压件有限公司

Panel display and electronic means thereof

ActiveCN100353223CSolve the problem of difficult alignmentIncrease production speedPrinted circuit assemblingStatic indicating devicesFlexible circuitsDisplay device

Owner:AU OPTRONICS CORP

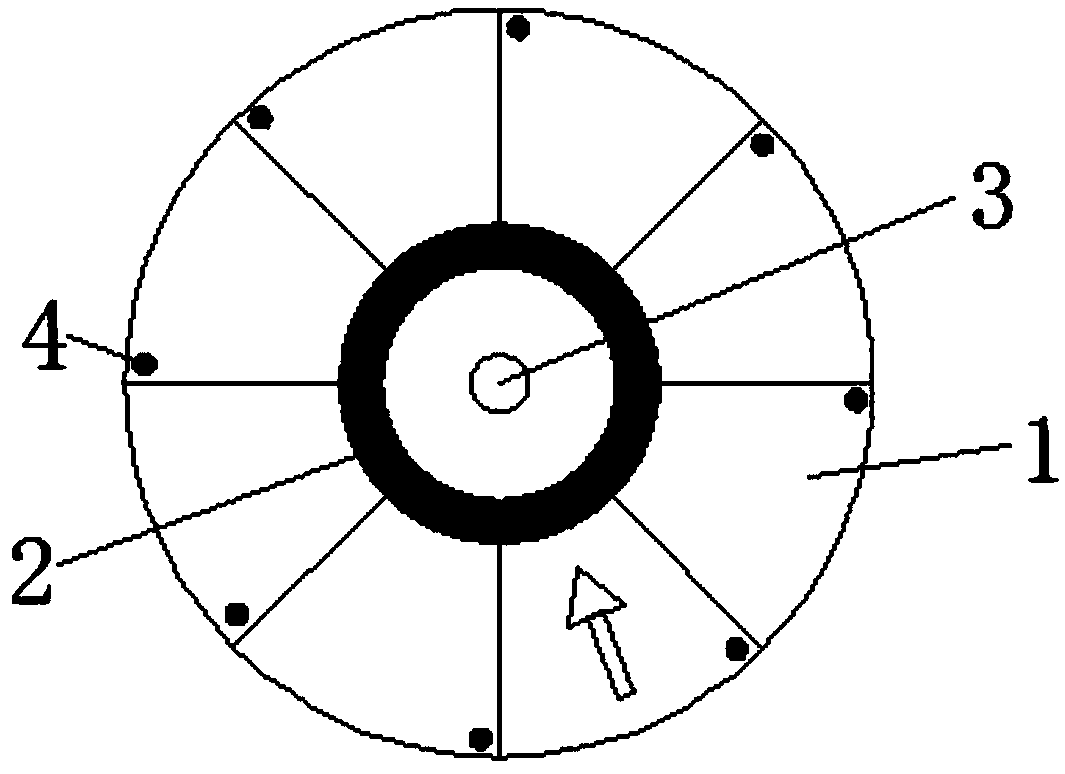

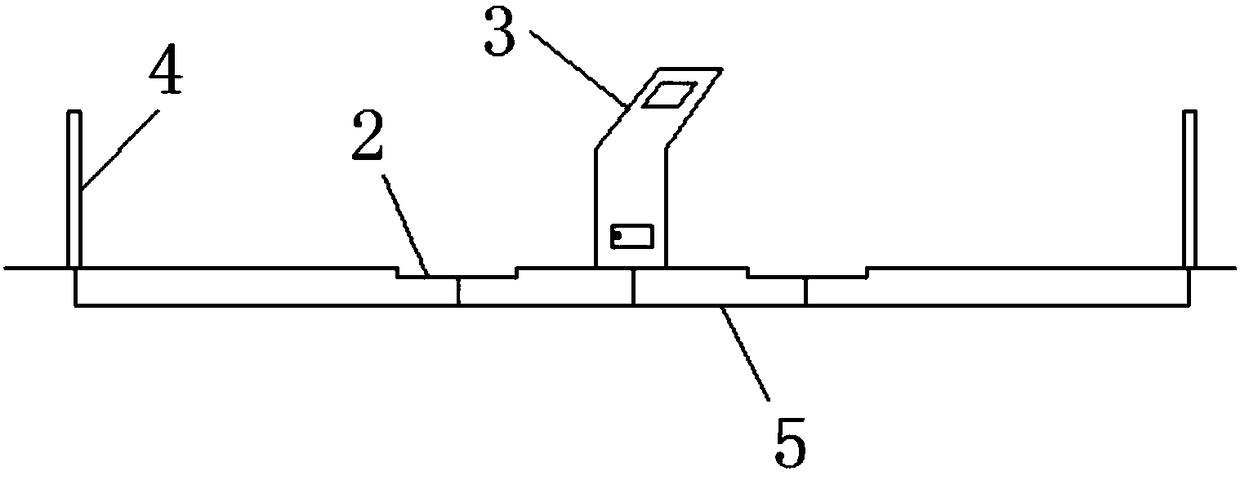

Surrounding type wireless charging parking lot

InactiveCN108442754ASolve the problem of difficult alignmentAvoid private occupationCharging stationsIndication of parksing free spacesLED displayControl system

The invention discloses a surrounding type wireless charging parking lot. The surrounding type wireless charging parking lot comprises parking spots (1), and the parking spots (1) surround a wirelesscharging effective area (2). A charging control system (3) is arranged in the middle of the wireless charging effective area (2). LED display screens (4) are arranged at corners of the parking spots (1). The wireless charging effective area (2), the charging control system (3) and the LED display screens (4) are connected through connecting lines (5). The surrounding type wireless charging parkinglot effectively solves the problem of difficult alignment with a receiving coil under a vehicle; a plurality of vehicles can be charged at the same time by adopting surrounding distributed parking and managed uniformly; the parking spots are provided with the LED display screens to display current charging information and status, and private occupancy of wireless charging by conventional vehiclesis avoided; and the surrounding type parking method greatly increases the opening range of car doors, and the adjacent car door knock phenomenon is not caused.

Owner:INNER MONGOLIA JUNENG ENERGY SAVING SERVICE

Alignment Mark Recognition System

ActiveCN109062452BSolve the problem of difficult alignmentInput/output processes for data processingGraphicsEngineering

The invention provides an alignment mark recognition system, which uses the visible area of the touch module to set a transparent alignment mark made of a phase delay material, and then passes through two polarizers so that the light receiver can effectively identify the alignment mark. The alignment procedure for graphics has improved the problem that there is no space to set the alignment mark in the border wiring area of narrow bezel products.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Field emission high-precision double-gate structure for reducing electron interception and its installation method

ActiveCN108447753BSolve the problem of difficult alignmentEasy alignmentCathode ray tubes/electron beam tubesMetallurgyTransmittance

The invention discloses a field-emission high-accuracy double-gate structure for reducing electron interception and an installation method thereof. The double-gate structure comprises a negative electrode substrate, a ceramic bottom plate, a negative electrode, a first gate net metal sheet, a second gate net metal sheet, a positive electrode plate, first ceramic posts, second ceramic posts and third ceramic posts, wherein the positive electrode plate is arranged on the ceramic bottom plate and is connected with the ceramic bottom plate via the two first ceramic posts, the first gate net metalsheet is arranged between the positive electrode plate and the ceramic bottom plate and is connected with the ceramic bottom plate via the two second ceramic posts, the second gate net metal sheet isarranged between the positive electrode plate and the first gate net metal sheet and is connected with the ceramic bottom plate via the two third ceramic posts, the first gate net metal sheet and thesecond gate net metal sheet are arranged in a cross way, positioning rods are arranged among the positioning holes, the negative electrode substrate is arranged at a central part of a bottom surface of the ceramic bottom plate, and the negative electrode penetrates through the ceramic bottom plate and is connected with the negative electrode substrate. By the double-gate structure, the problem ofdifficulty in alignment between a pattern negative electrode and a gate net hole can be solved, the alignment of a gate net can be substantially improved, and the transmittance of the gate net is improved.

Owner:SOUTHEAST UNIV

Polarization multiplexing devices for projection systems

ActiveCN111158159BSolve the problem of difficult alignmentReduce manufacturing difficultyProjectorsOptical elementsPolarization multiplexedLight reflection

A polarization multiplexing device used in projection systems to convert unpolarized light into polarized light with the same polarization state. The polarization multiplexing device includes a group of polarization multiplexing units. All the polarization multiplexing units are arranged in an end-to-end manner, wherein each polarization multiplexing unit has an incident surface and an exit surface opposite to the incident surface, and includes a light conversion element, a light beam splitting component and a light reflective components. The light conversion element is used to convert the first polarized light into the second polarized light. The light beam splitting component is located on one side of the light conversion element, and is used to split the unpolarized light incident from the incident surface into the second polarized light emitted from the exit surface and the first polarized light directed to the light conversion element. polarized light. The light reflection component is located on the other side of the light conversion element, and is used for reflecting the second polarized light converted by the light conversion element so that the second polarized light is emitted from the exit surface.

Owner:SUNNY OPTICAL ZHEJIANG RES INST CO LTD

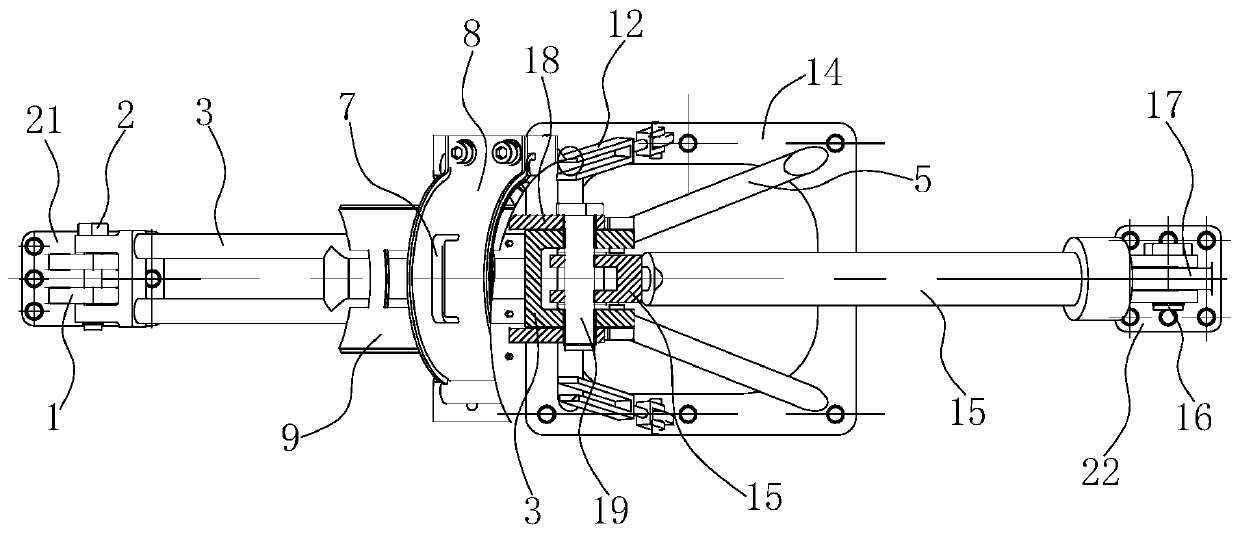

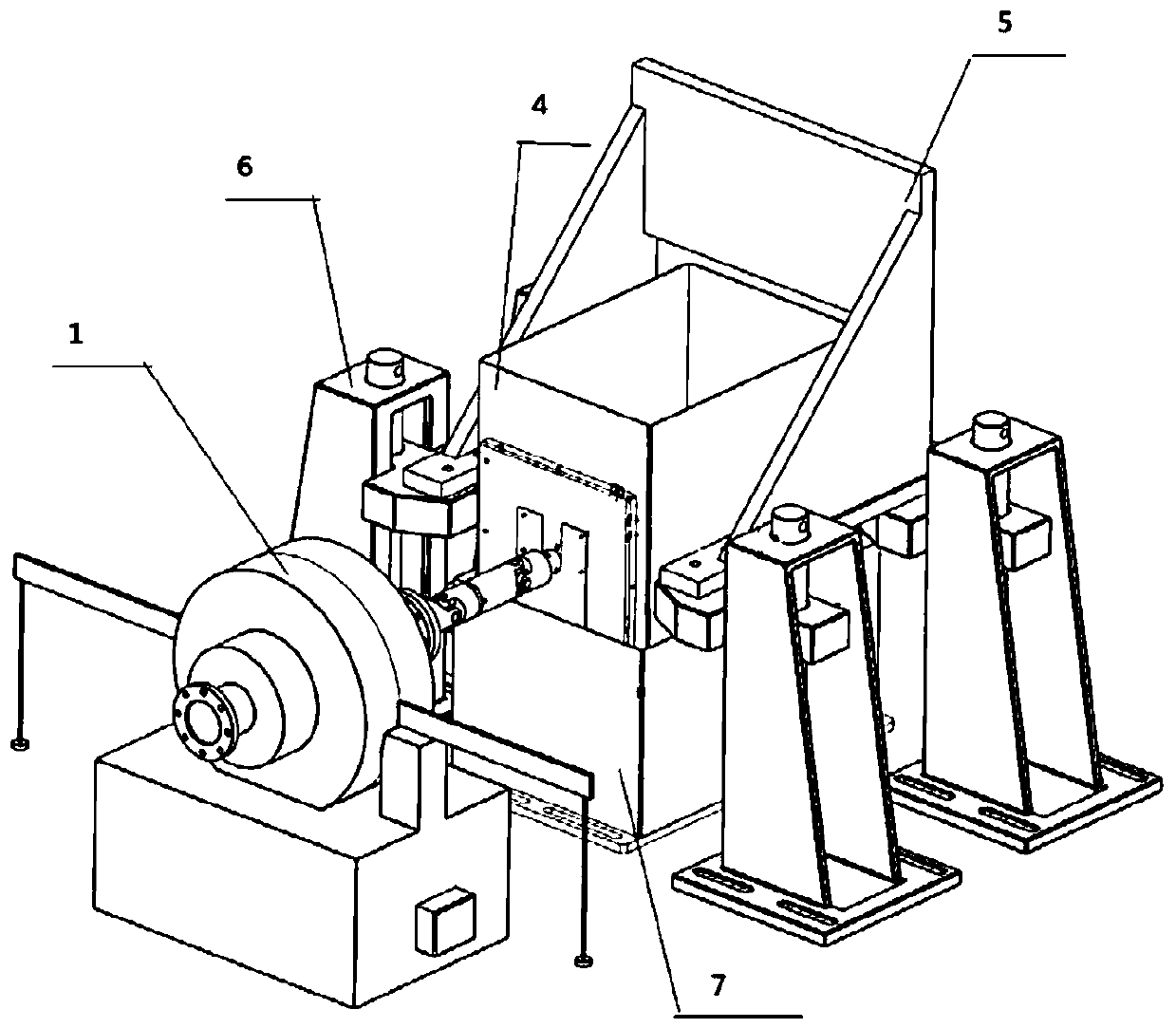

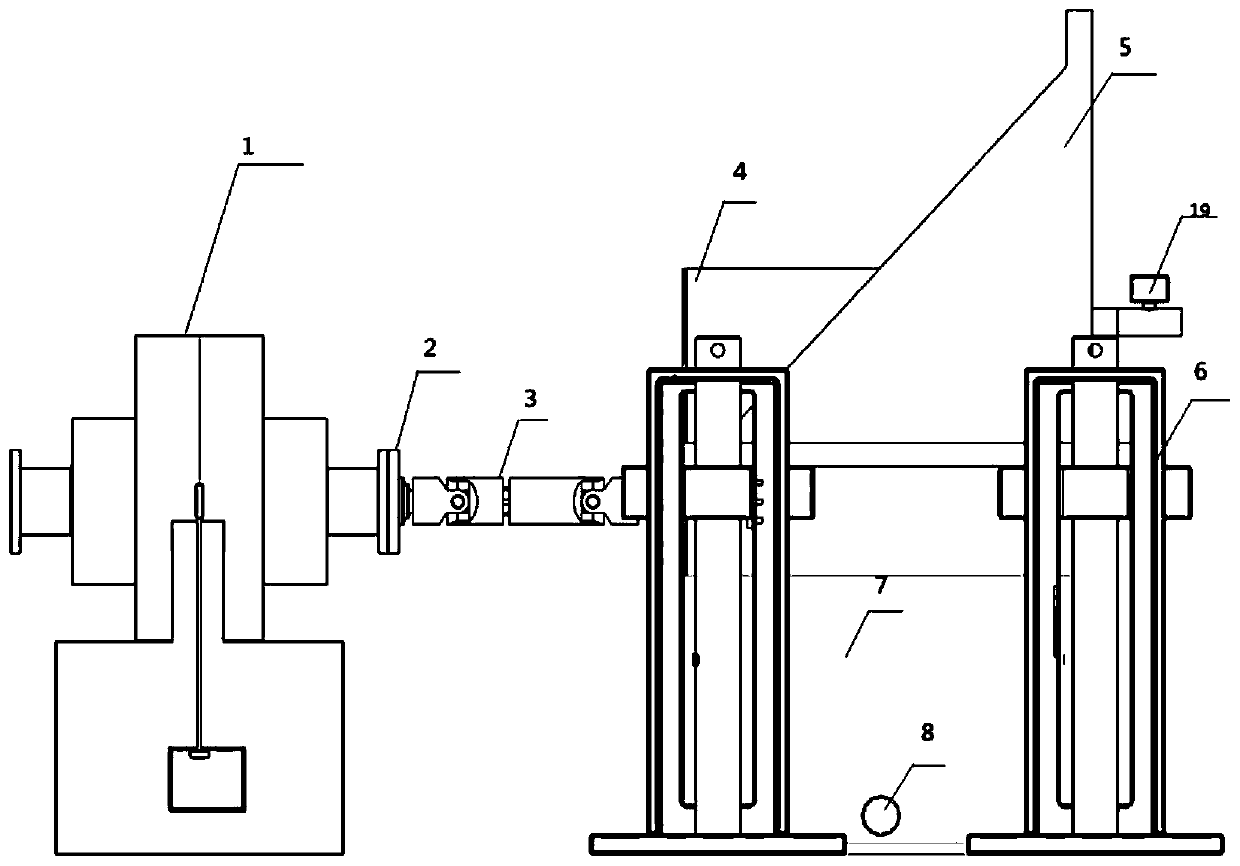

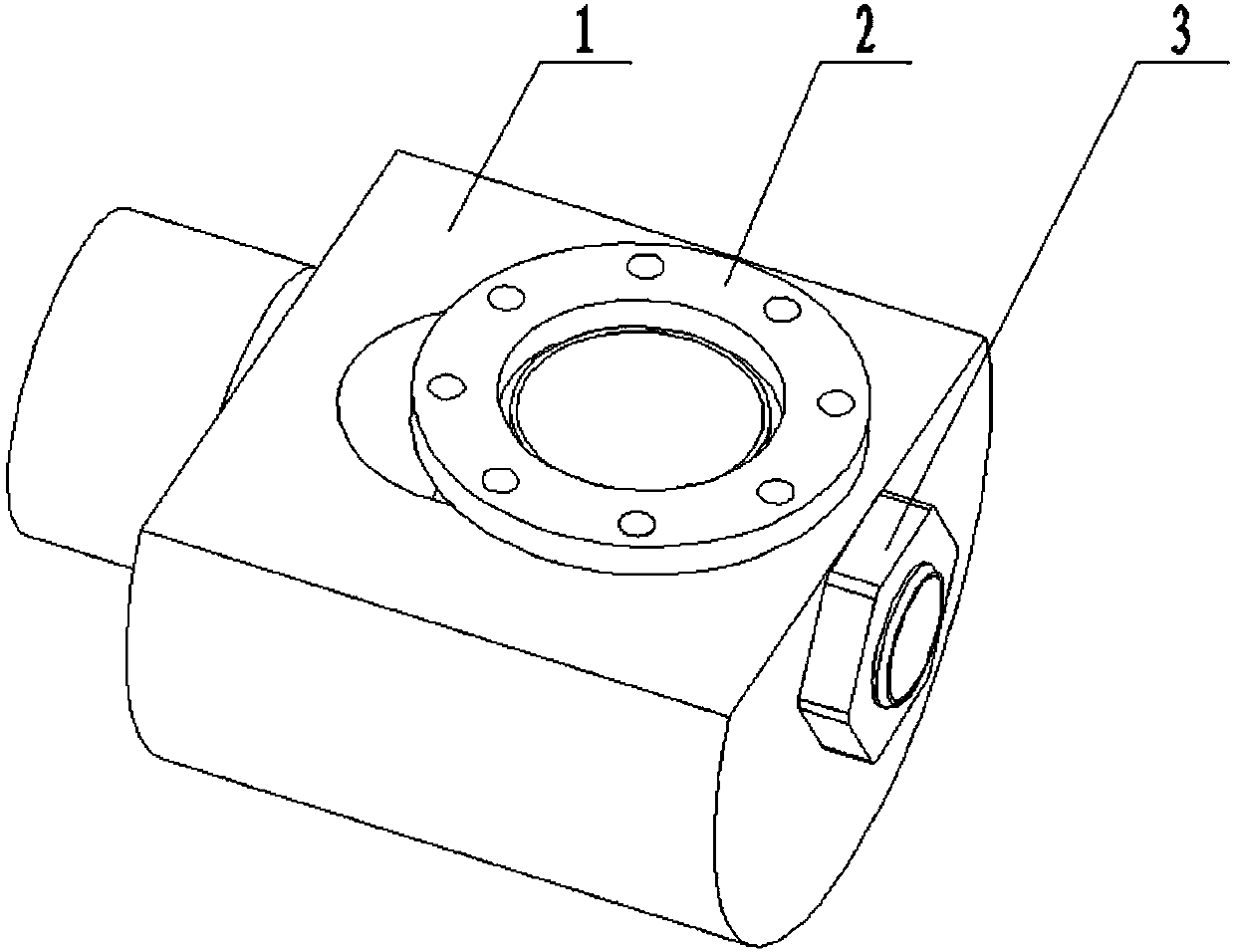

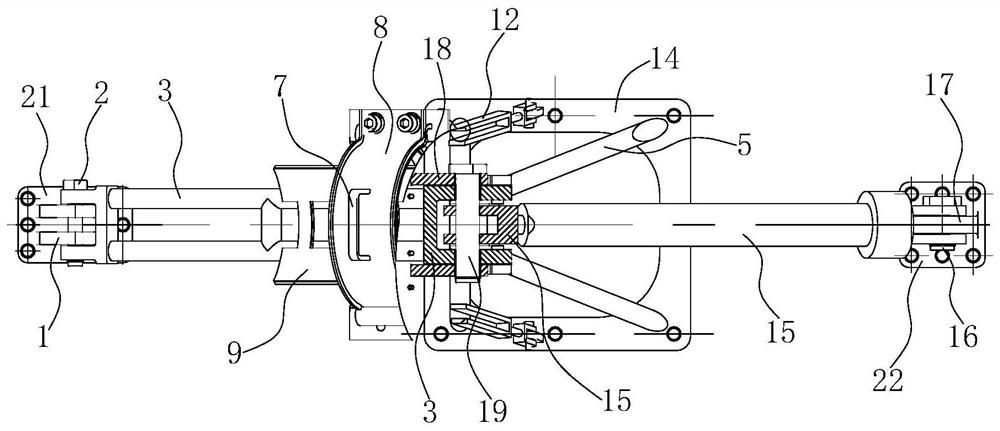

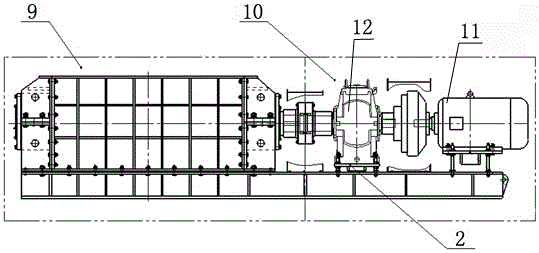

Outboard Motor Comprehensive Performance Test Bench, Alignment Method and Test Method

ActiveCN109060358BReduced risk of fatigue fracturesSolve the problem of poor sealing and water leakageEngine testingDrive shaftFatigue fractures

The invention discloses an outboard propulsion engine comprehensive performance test bed and test method and an outboard propulsion engine comprehensive performance test bed centering method. The problem that in the prior art, a propeller output shaft is liable to fracture and is difficult to center is solved. The test bed, the test method and the centering method have the beneficial effects thata true working water environment of an outboard propulsion engine can be accurately simulated and a fatigue fracture risk of the propeller output shaft can be reduced. According to the scheme, the outboard propulsion engine comprehensive performance test bed comprises an inner water tank which is used for simulating a working water environment of the outboard propulsion engine, wherein the inner water tank is set in an outer water tank and protrudes out of the outer water tank; the inner water tank is equipped with a water outlet communicated with the outer water tank; the outboard propulsionengine can be set in the inner water tank; the outboard propulsion engine is connected with a fixing frame; the propeller output shaft of the outboard propulsion engine is connected with a power transmission shaft; and the power transmission shaft passes through the inner water tank and is connected with a dynamometer.

Owner:SHANDONG UNIV

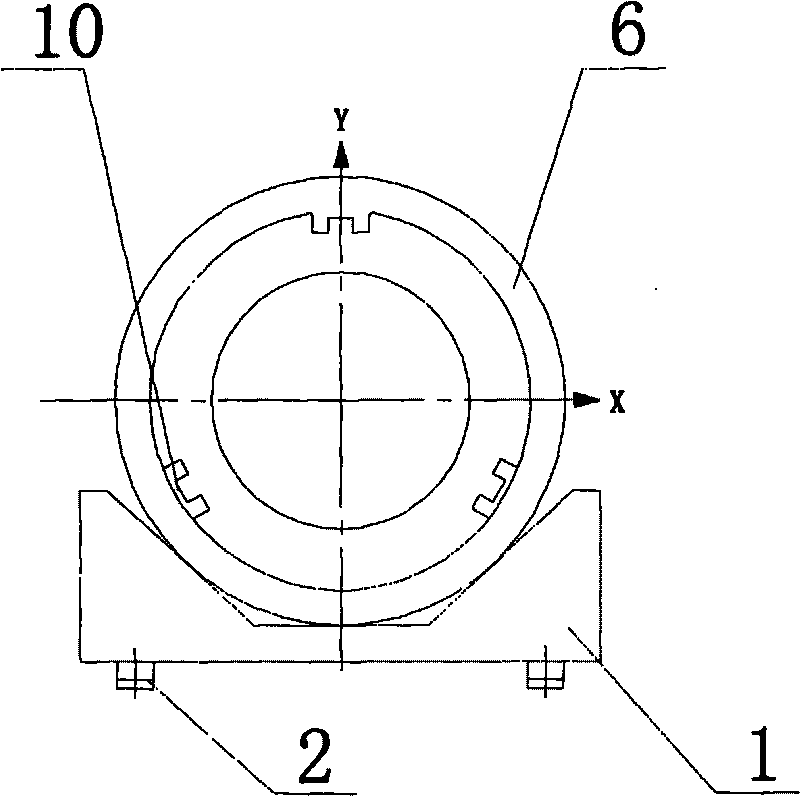

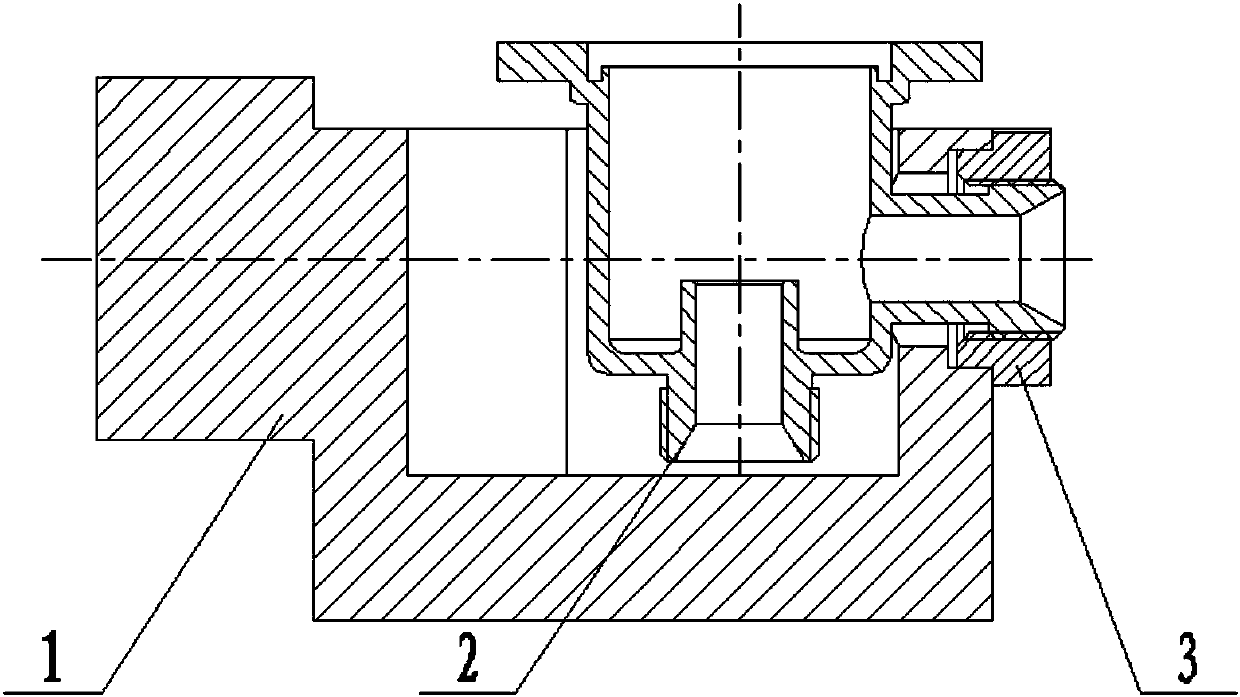

Polishing fixture for conical orifice

PendingCN107671695ASolve the problem of difficult alignmentGuaranteed sealing reliabilityPolishing machinesGrinding work supportsPolishingEngineering

The invention discloses a polishing fixture for a conical orifice. The polishing fixture for the conical orifice comprises a body (1) and a locking nut (3), wherein one side of the body (1) is of a cylindrical structure, and a platform is arranged at the other side of the body (1); a groove is formed in a direction from the platform to the cylindrical structure; a circular hole (6) is formed in one end part of the body (1); one end of the circular hole (6) communicates with the groove; and the locking nut (3) is arranged on the end part of a valve body part (2) in a sleeving manner. Accordingto the polishing fixture for the conical orifice, an inner groove for placing the valve body part is formed in a body, and the valve body part is locked onto the body by the locking nut and through anexternal thread on a valve body part connector after being placed in the groove, so that the problem of difficult centering and alignment for a sealing surface is thoroughly solved, polishing for theconical orifice of a specially-shaped part is realized, and then the sealing reliability of the product is ensured.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

A slidable and tilt-assisted lifting device with a bracket

ActiveCN110341991BSolve the problem of difficult alignmentReduce labor intensityCosmonautic ground equipmentsClassical mechanicsEngineering

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

A Sea Condition Adaptive Deployment and Recovery Device for Rapid Retraction and Deployment of Unmanned Boats

ActiveCN112918636BSolve the problem of difficult alignmentAddress reliabilityDry-dockingCargo handling apparatusHullElectrical and Electronics engineering

The invention discloses a sea condition self-adaptive deploying and recovering device for rapid deployment and deployment of an unmanned boat, and relates to the technical field of ship facilities, including artificial floating docks, towing cables, netting cables, netting cables, hanging cables, Recycling net, collision net and net locking device; a dock cabin is provided in the middle of the artificial floating dock; suspension cables are used to hoist the artificial floating dock and support the hull; It is connected with the upper end and lower end of the net-supporting cable; the net-retracting cable is connected with the net-supporting cable; the dragging cable is arranged on both sides of the front of the dock; the net-crashing and net-locking device is arranged at the front end of the manned or unmanned boat. The suspension cable can not only hoist the artificial floating dock, but also support manned or unmanned boats. Combined with the collision net and locking device to hook the recovery net, it can ensure that the left and right, front and rear, and up and down displacements of manned or unmanned boats can be controlled. , so as to reduce the difficulty of recovery and deployment, and avoid problems such as collision damage of the small boat, severe and uncontrollable shaking of the boat during lifting.

Owner:沈海龙

Micro motor automatic packaging machine

ActiveCN104901486BAccurate insertionSolve the problem of difficult alignmentManufacturing dynamo-electric machinesMicromotorEngineering

The invention relates to a rotor and housing assembly device of a micro-motor automatic packaging machine, including a frame, a housing guide rail, a turntable, a stepping drive device and a rotor pushing mechanism, and a plurality of semicircular cross-sections are arranged at equal intervals on the circumference of the turntable The magnetic suction groove; the rotor pushing mechanism includes a push-in lifting mechanism, a rotor push rod, a transfer lifting mechanism, a transfer lifting seat, a transfer base plate, a transfer fixed clip, a transfer movable clip and a transfer cylinder. Due to the transfer of the movable clip and the transfer of the fixed clip to form the guide cylinder for transfer and transition, the problem of difficult alignment between the magnetic groove on the turntable and the guide rail of the housing is solved, and the rotor is always under the limit of the guide cylinder. , to avoid the momentary suspended state of the rotor during the push-in process, to ensure that the rotor remains stable during the push-in process, to ensure that the rotor and the housing are accurately aligned, and the lower end of the rotor shaft can be accurately inserted into the shaft hole at the lower end of the housing, so that the micro The packaging of the motor enables fully automated production.

Owner:GUANGDONG CHAOLI MOTOR CO LTD

Hollow Shaft Processing Method of Coal Shearer and Grinding Top Used for Grinding Hollow Shaft

ActiveCN108637595BConvenient and precise grinding workOptimize the grinding processGrinding work supportsElectric machineryEngineering

Owner:NINGXIA NORTHWEST HORSE ELECTRIC MFG

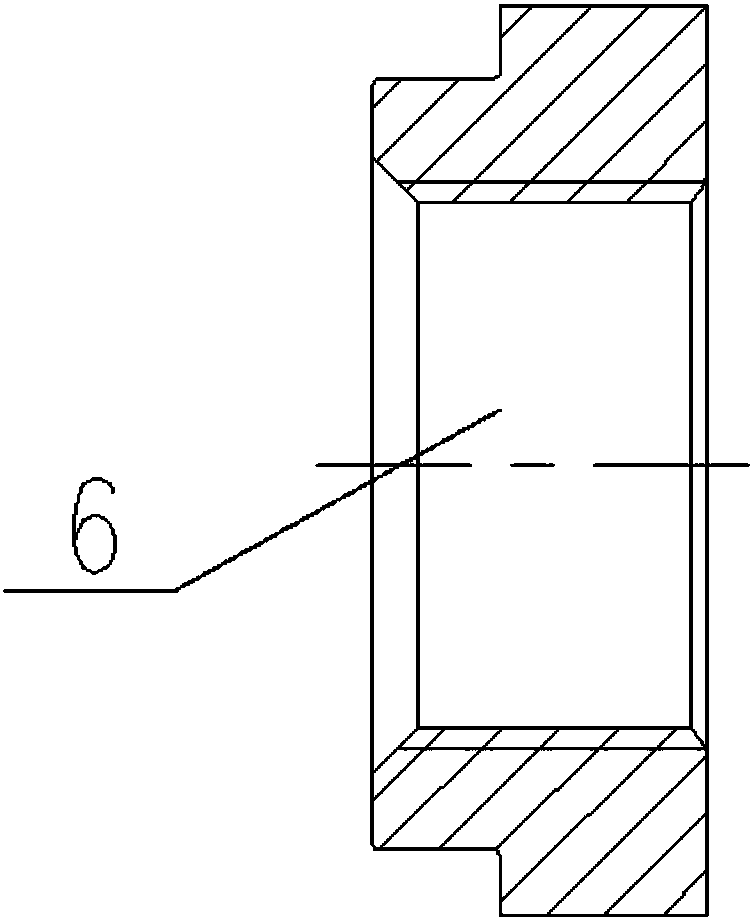

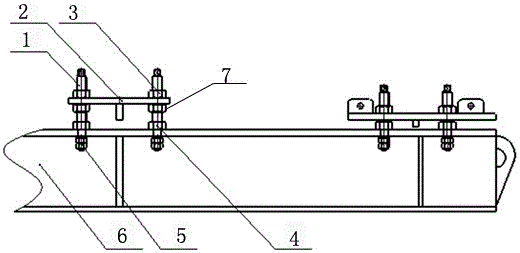

A screw-type centering adjustment method for a double-toothed roller crusher

The invention relates to a screw rod centering method and a device of a double-geared roller crusher and belongs to the technical field of adjustment of the double-geared roller crusher. The invention adopts the technical scheme that a crushing system adjustment device is in an eccentric cup structure; a support plate is square; a lead screw nut mechanism is arranged at each of four corners; each lead screw nut mechanism consists of screw rods (1), a support plate (2), lock nuts (3), lower nuts (7), upper fixing nuts (4) and lower fixing nuts (5); a base (6) is fixed; and a plurality of strip-shaped mounting holes (8) are formed in the support plates. According to the method and the device, a horizontal center distance between two rollers of a crushing system is adjusted by adjusting the eccentric cup structure; free ascent and descent of the support plates is achieved by a lead screw adjustment structure; a horizontal position of a motor or a speed reducer is adjusted via the strip-shaped mounting holes, so as to achieve center height centering jointly; on-site particle size adjustment difficulty is reduced; overhaul time is shortened; and further, stable operation and a rated service life of the double-geared roller crusher are ensured.

Owner:TANGSHAN TIANHE TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com