Method for manufacturing guide groove of servomotor cylinder of runner cone of hydroturbine

A relay cylinder and drain cone technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of easy deformation of workpieces, increased labor costs, poor operability of workers, etc., and achieve low processing costs, The effect of easy operation, improved machining accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

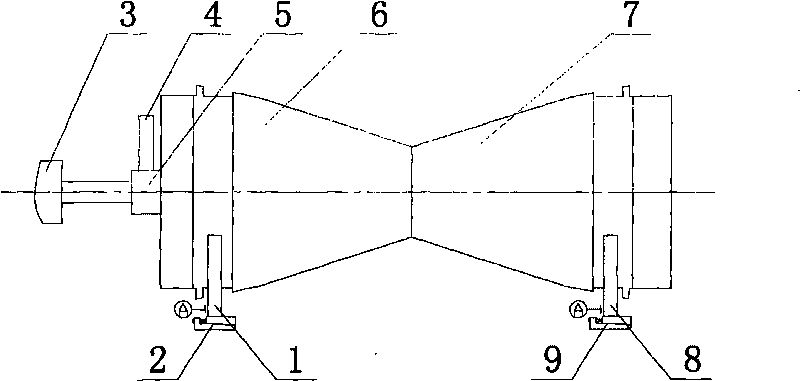

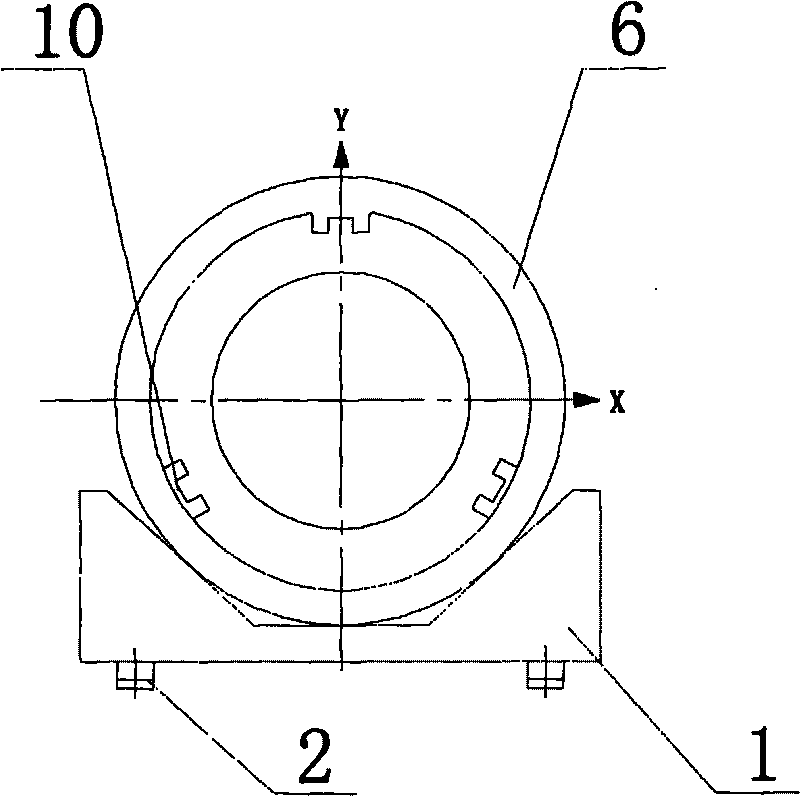

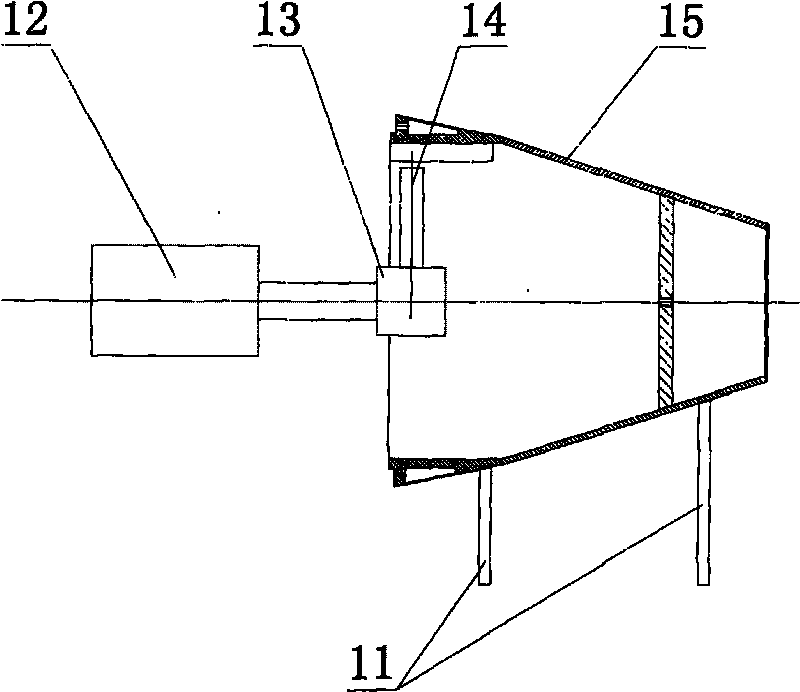

[0017] Such as figure 1 , figure 2 As shown, two V-shaped irons 1, 8 are installed on the boring machine workbench, and adjusting pad irons 2, 9 are installed below the two V-shaped irons. The water discharge cone is horizontally placed on the V-shaped iron, and the water discharge cone is the water discharge cone 6, 7 with two small ends butted. After aligning the drain cone with the boring machine main shaft 3, fix it, install the right-angle milling head 5 on the boring machine main shaft, and install the end mill 4 on the milling head to process the guide groove 10. The drain cone guide groove 10 is made according to the following process steps:

[0018] (1) Align the small ends of the two water discharge cones first, and spot weld t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com