A screw-type centering adjustment method for a double-toothed roller crusher

A centering adjustment and crusher technology, which is applied in the direction of grain processing, etc., can solve the problems of high difficulty in adjusting the particle size of the eccentric cup structure, increasing the difficulty of particle size adjustment of the crusher, and short maintenance time, so as to reduce the difficulty of particle size adjustment and ensure The effect of shortening the service life and maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment

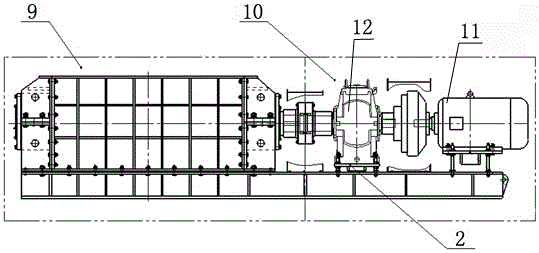

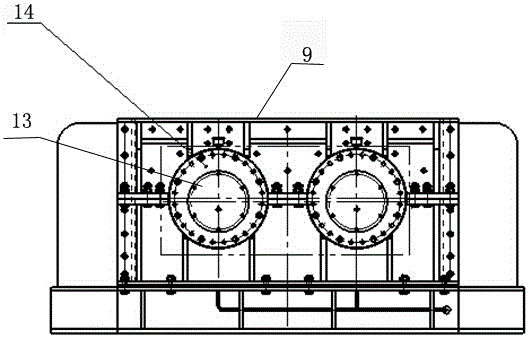

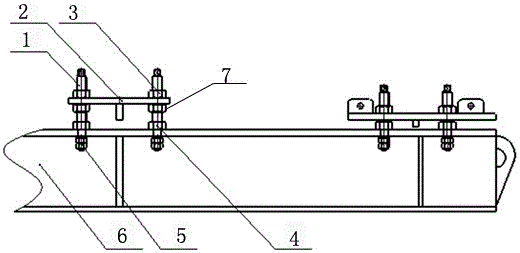

[0021] A screw-type centering adjustment device for a double-toothed roller crusher, including a crushing system adjustment device and a drive system adjustment device, the crushing system adjustment device is an eccentric cup structure, the drive system adjustment device is a screw rod adjustment structure, and the structure includes a support Plate 2, screw nut mechanism and base 6, the support plate is square, and the four corners are respectively provided with screw nut mechanism, each screw nut mechanism is composed of lead screw 1, support plate 2, lock nut 3, lower nut 7, The upper fixing nut 4 and the lower fixing nut 5 are formed, the lower end of the leading screw passes through the base, the upper surface of the base is provided with an upper fixing nut matching the leading screw, and the lower surface of the base is provided with a lower fixing nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com