Collimating film and preparation method of collimating film

A technology of collimating lens and straight hole, applied in the field of image recognition, can solve the problem of difficult alignment of two-layer collimating diaphragms, and achieve the effects of improved mass production, low thickness and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

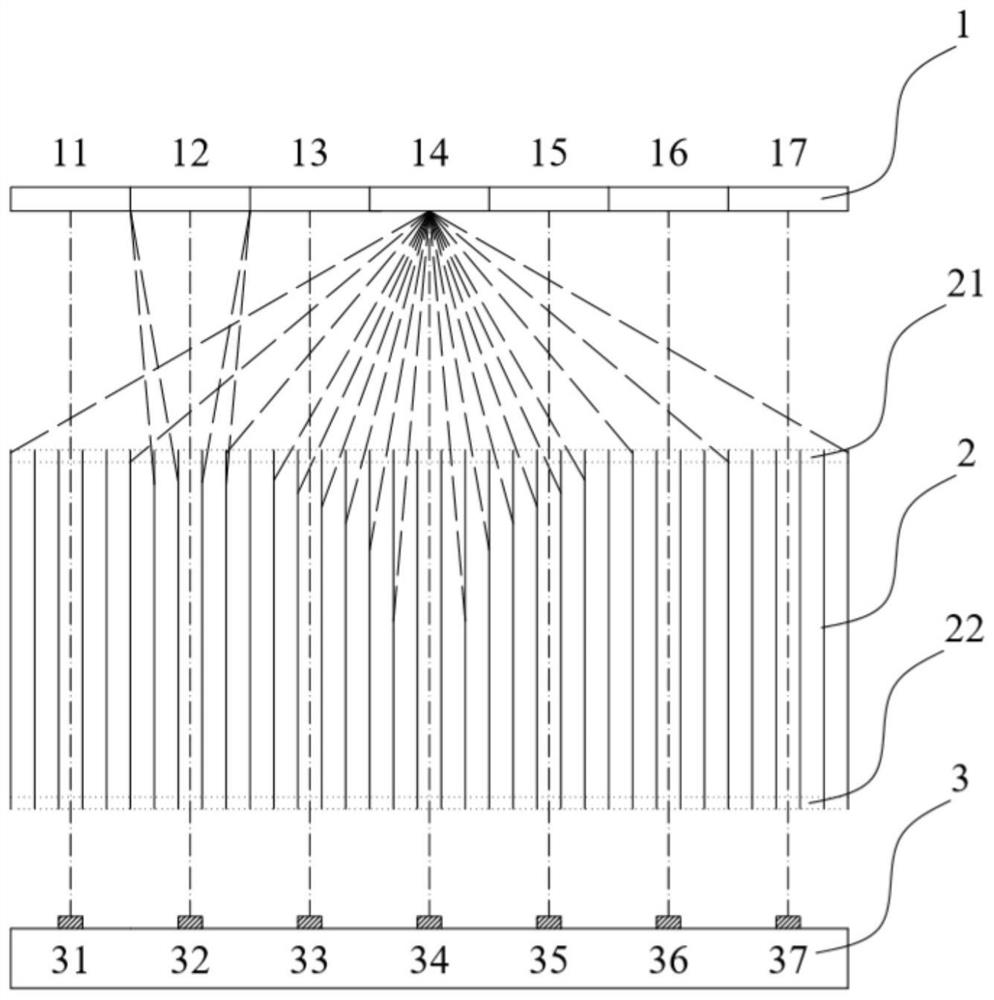

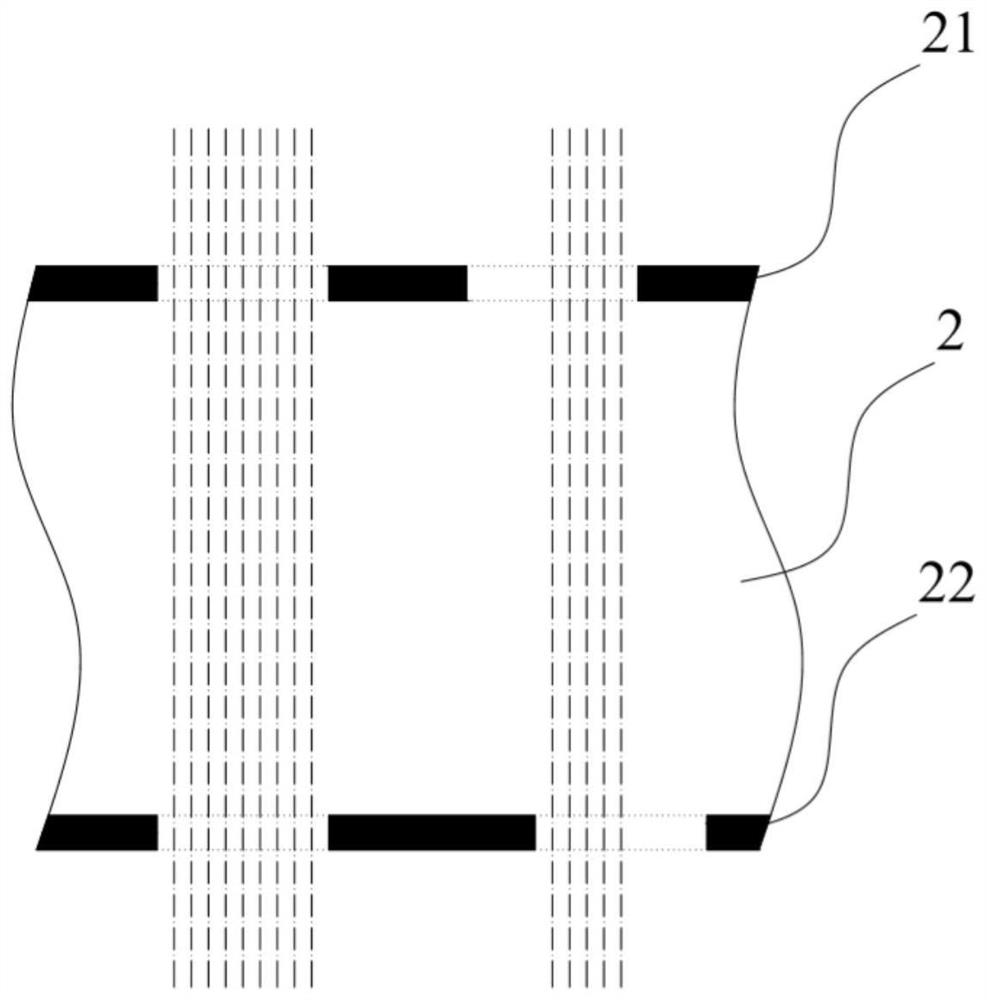

[0135] like Image 6 The display is shown in the present invention, including the collimating lens layer 41, the flexible substrate layer 42, and the collisional, the collimated lens layer is placed on the upper surface of the substrate, the collimated hole layer is placed in the lower surface of the substrate. The aligned direct lens layer 41 includes a microbial array 41a and a thickness 41b, and the pore layer 43 includes a collimated pore array formed after the light-shielding medium 43a and the dielectric hollow (constitute a certain number of quantity pores 43b); The thickness T of the flexible matrix layer is 25 μm. The collimated lens arrays and collimated pore arrays are closely arranged in a normal triangle array (eg Figure 8 Indicated). The main optical axis of the microlens is 18 μm, the radius of curvature R is 12.6 μm, the collimation lens layer thickness H is 8.5 μm, and the thickness T of the straight hole layer is 2 μm, the collimated hole diameter φ is 4 μm. . The...

Embodiment 2-24

[0144] As shown in Example 1, the collimated lens array and the collimated pore array in the collimator are closely arranged in a positive triangle, and the material of the straight lens layer 41 is PMMA, the flexible matrix layer 42. The light shielding medium 43a of the colored hole layer 43 is the inorganic coating, which is collected by the microlens in a microbial punch. The other parameters are listed in Table 1.

[0145] Table 1 Examples 1 to 24 design parameters and optical properties

[0146]

[0147]

[0148] Note 1: P is the minimum spacing of the main optical axis of the microlens, the unit μm; R is the radius of curvature of the microlens, the unit μm; H is the thickness of the collimation lens layer, the unit μm; N1 is the refractive index of the collimation lens layer, no quantity The unit; T is the thickness of the flexible matrix layer, the unit μm; N2 is the refractive index of the flexible matrix layer, and the dimensiony unit; D is a spot diameter formed on...

Embodiment 25-30

[0151] As shown in Example 1, the column of the straight film is closely arranged in a positive triangle, and the material of the straight lens layer 41 is a material of PMMA and a material of the flexible matrix. For the PET, the light shielding medium 43a of the collimating hole layer 43 is a inorganic coating carbide, the ratio of the metallic film, which is collected by the microlens, and the other parameters are listed in Table 2.

[0152] Table 2 Embodiments 25 to 30 design parameters and optical properties

[0153]

[0154] Note 1 with Table 1.

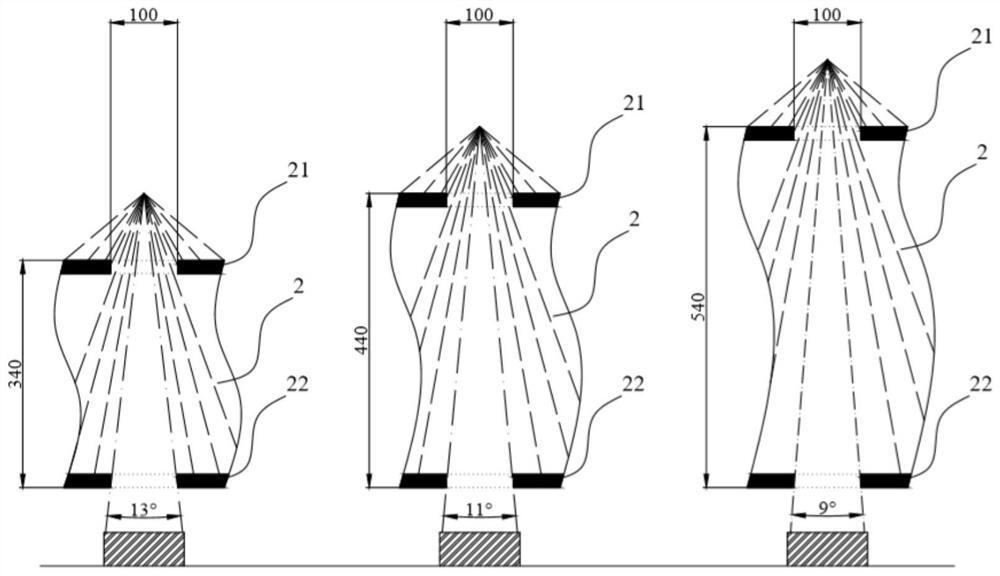

[0155] As shown in Table 2, embodiments 25 to 30 are different from different flexible substrates. Examples 25 to 27 are p = 10 μm, and the other parameter is unchanged, T = 10, 15, 20 μm is a set of quasi-metallic films, and Examples 28 to 30 are P = 25 μm, respectively, and other parameters constant Next, T = 25, 38, 50 μm is another set of quasi-straight film. When t is increasing, in order to keep the microsocratic effect (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com