Micro motor fully automatic packaging machine

A fully automatic packaging machine and micro-motor technology, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve the problems that micro-motors are difficult to achieve fully automatic assembly, micro-motors are unqualified, and cannot be tightly held.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

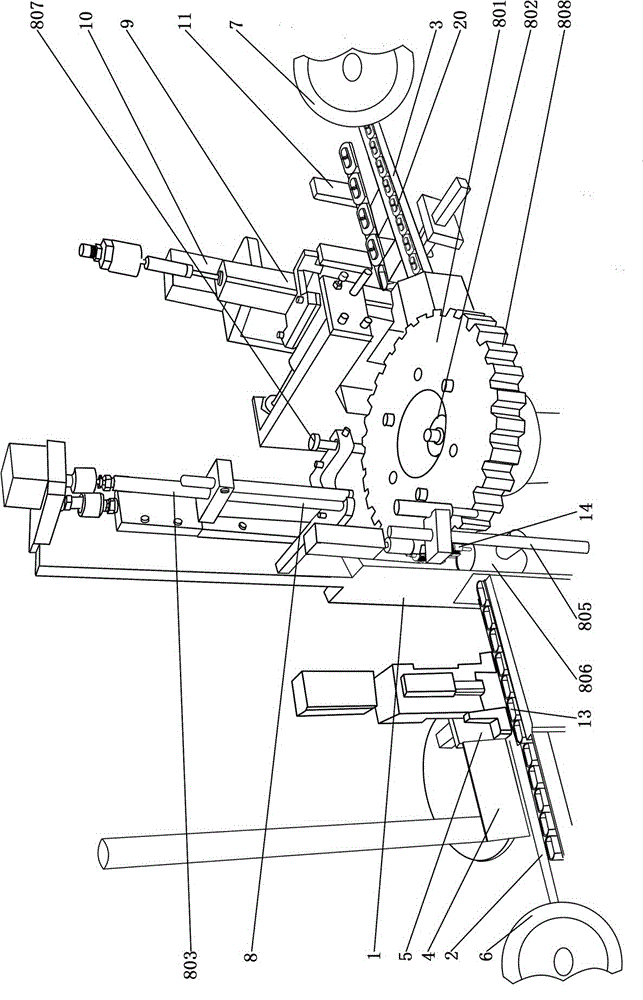

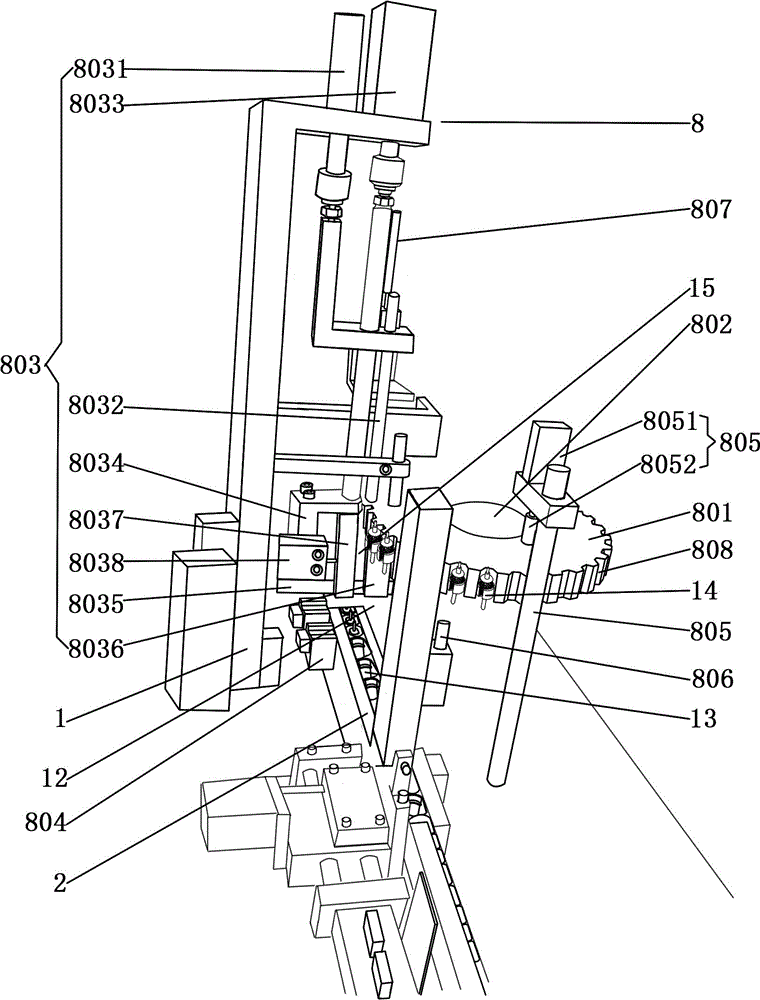

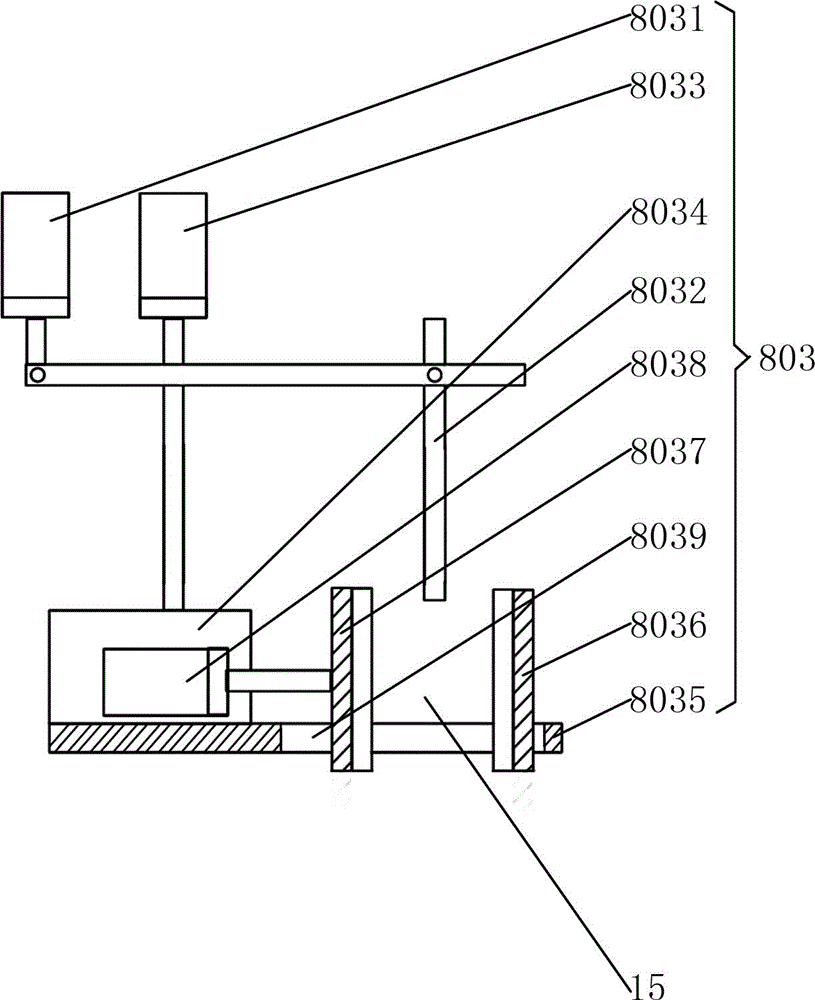

[0036] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0037] like figure 1 As shown, this micro-motor automatic packaging machine includes a frame 1, and a shell guide rail 2, an end cover guide rail 3, a shell push mechanism 4, a shell detection and rectification device 5, and a shell finishing shock plate arranged on the frame 1. 6. End cover finishing oscillating disk 7, rotor and casing assembly device 8, end cover assembly device 9, riveting device 10 and finished product exit mechanism 11; the output port of casing finishing oscillating disk 6 is connected with the starting end of casing guide rail 2; the casing is pushed The mechanism is set at the starting end of the shell guide rail 2; the rotor and shell assembly device 8 is set in the middle of the shell guide rail 2; the shell detection and rectification device 5 is set between the shell propulsion mechanism 4, the rotor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com