Fully-automatic tray loader for cylindrical lithium ion batteries

A lithium-ion battery, fully automatic technology, applied in packaging, conveyors, storage devices, etc., can solve the problems of low production efficiency, affecting the yield rate, affecting the safety and service life of lithium-ion batteries, and achieve saving manpower handling, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

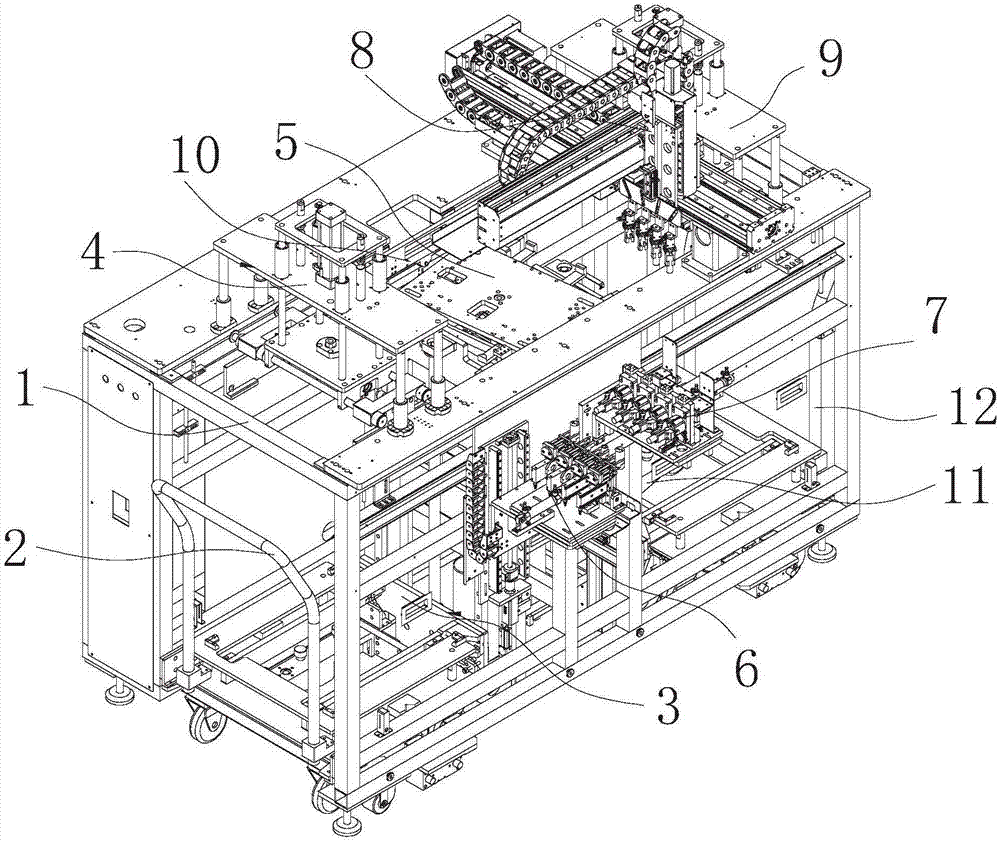

[0054] Automatic tray loading machine for cylindrical lithium-ion batteries, such as figure 1 As shown, it is applied to the automatic loading of cylindrical lithium-ion batteries or the loading process before the cells are put into the shell, including rack 1; loading trolley 2, which is set on the left side of rack 1 for supplying multiple Empty cell trays stacked on top of each other; the empty tray lifting mechanism 3 is set and installed on the frame 1 inside the loading trolley 2, and lifts the stacked stacked empty trays on the loading trolley 2 respectively. High to the predetermined position; the empty tray transfer mechanism 4 is set on the top side of the frame 1 directly above the empty tray lifting mechanism 3, and raises the empty tray lifting mechanism 3 to the empty cell material at the predetermined position The trays are moved horizontally to the next station respectively; the tray positioning mechanism 5 is arranged in the middle of the top of the frame 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com