A slidable and tilt-assisted lifting device with a bracket

A lifting device and sliding technology, which is applied in the field of aerospace launch, can solve the problems such as the difficulty of aligning the vertical oil cylinder and the pin hole of the launch tube, and achieve the effects of reducing labor intensity, improving efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

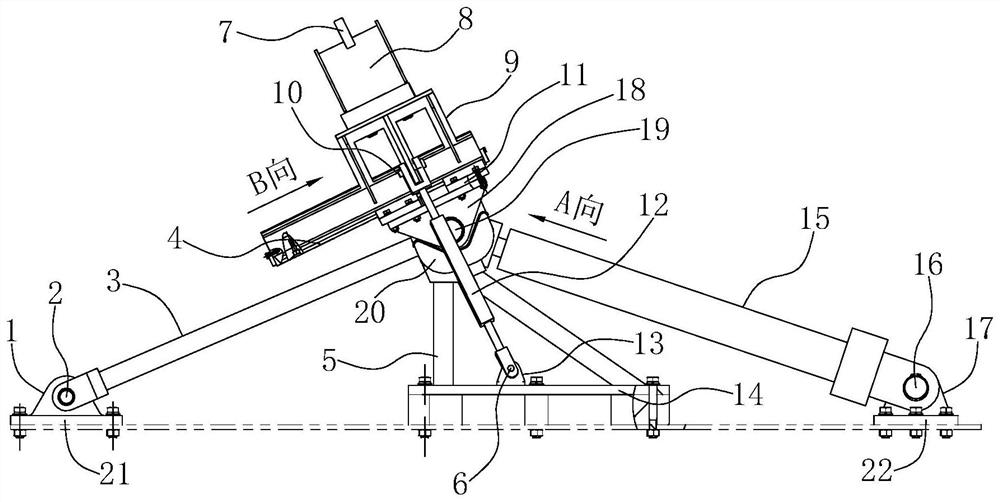

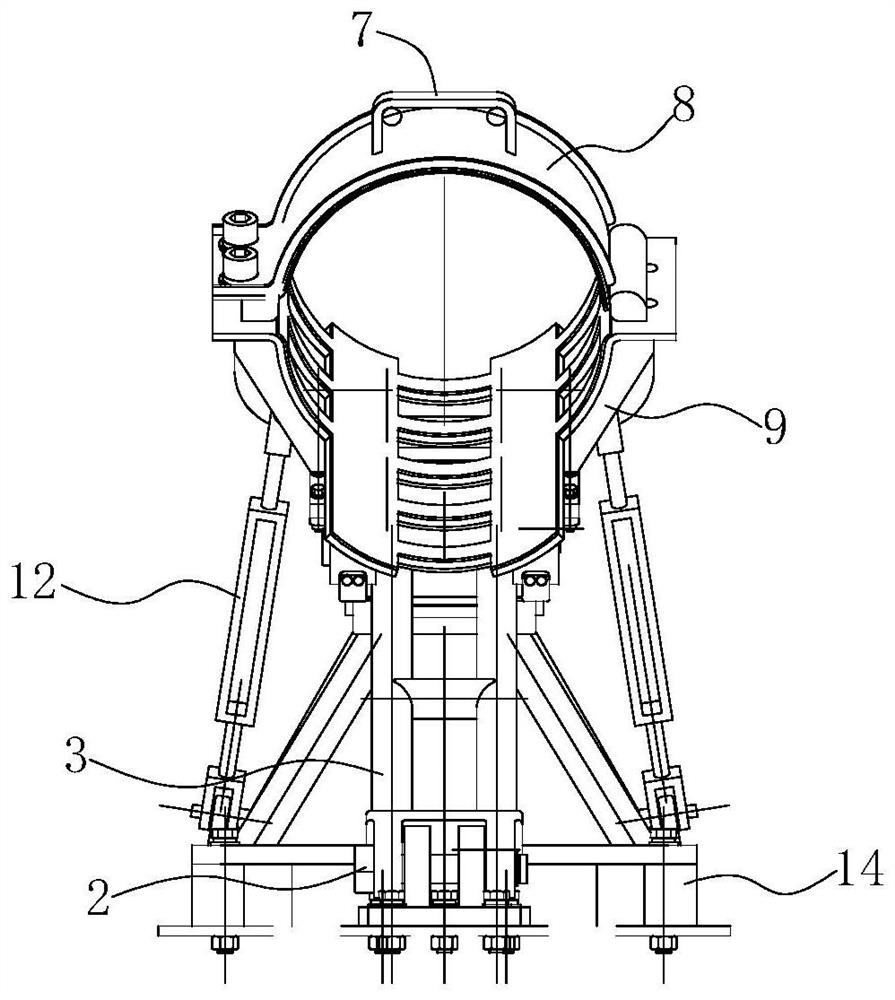

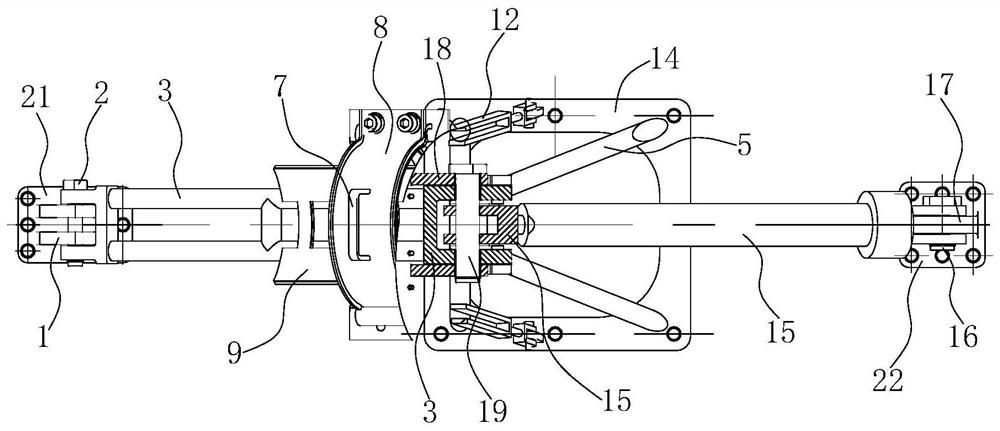

[0019] Such as figure 1 shown, combined with figure 2 , 3 As shown, the bracket of the present invention can slide and tilt the booster type lifting device, including a rotary bracket 3, a drive cylinder 15 and a first lug 18, the lower end of the rotary bracket 3 is hinged to the first support 21, the The lower end of the drive cylinder 15 is hinged to the second support 22 , and the upper ends of the slewing bracket 3 and the drive cylinder 15 are both hinged to the first lug 18 on which the bracket 9 is slidably mounted.

[0020] The bracket of the present invention can be slidable and tilted to assist the lifting device, wherein the bracket 9 is provided with a first semicircular groove, and the first semicircular groove is used for placing a vertical oil cylinder.

[0021] The bracket of the present invention can slide and tilt the booster lifting device, wherein the bracket 9 is provided with a cover plate 8, one side of the cover plate 8 is hinged with the bracket 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com