A kind of grid array device flatness detection tool and detection method

A technology for flatness detection and tooling inspection, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of difficult operation, easy-to-damage device leads, and insufficient detection, so as to achieve effective measurement, ensure flatness, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

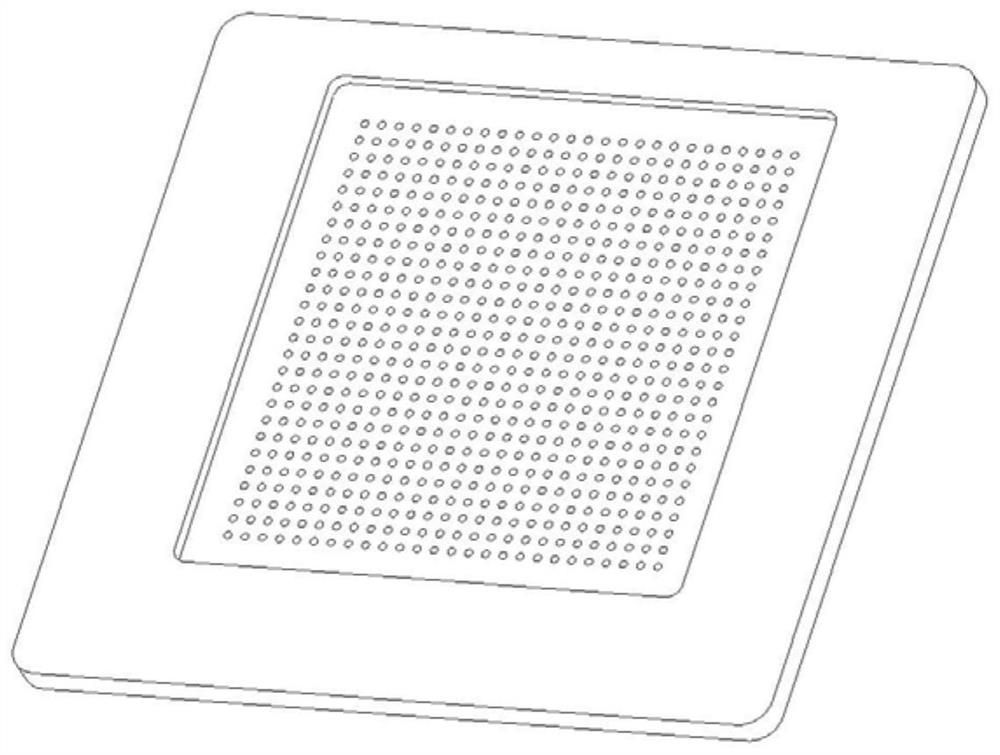

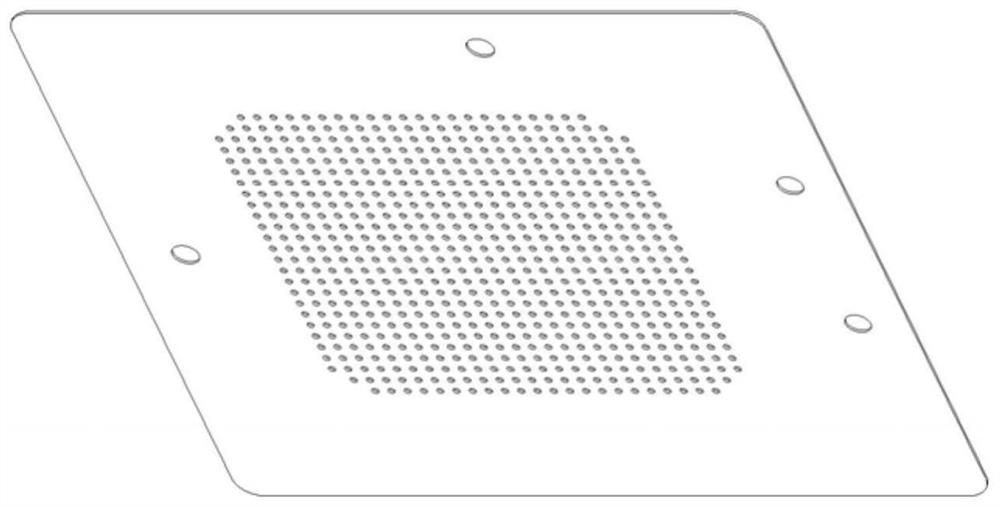

[0024] like figure 1 and figure 2 As shown, a flatness detection tool for grid array devices, the tool includes a reference tool, a measurement tool A, a measurement tool B and a lead screw; the lead screw can drive the measurement tool A to move up and down;

[0025] The benchmark tooling is a hollow cylinder with a flat plate on the top; there are several through holes on the top plate of the benchmark tooling, and the number of through holes on the top plate of the benchmark tooling is the same as the number of soldering posts on the columnar grid array CG717 device. The diameter of the through hole on the top plate of the tooling is larger than the diameter of the welding post on the columnar grid array CG717 device, preferably 0.9mm, and the distance between the through holes on the top plate of the reference tooling is consistent with the spacing between the welding posts on the columnar grid array CG717 device. The material of the benchmark tooling is stainless steel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com