Patents

Literature

34results about How to "Good tinning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

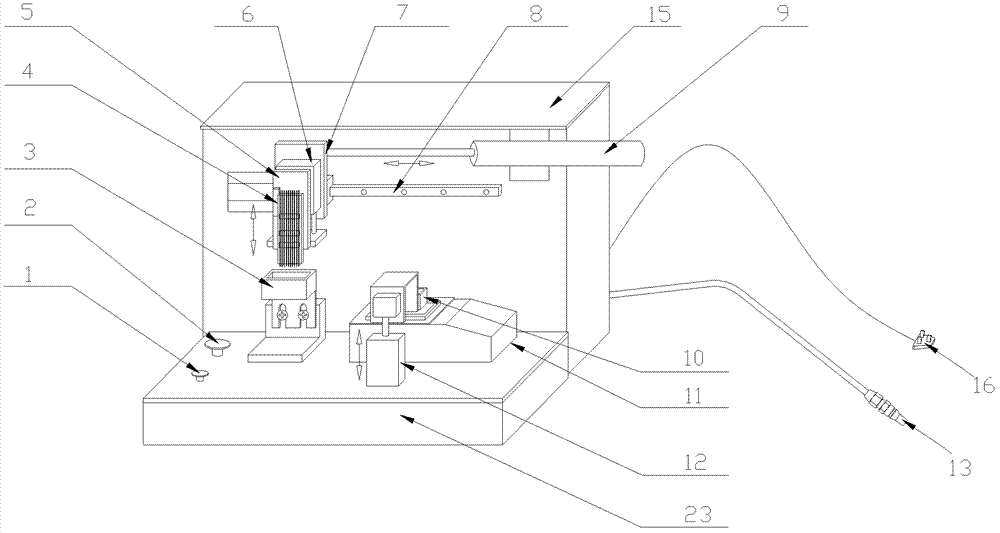

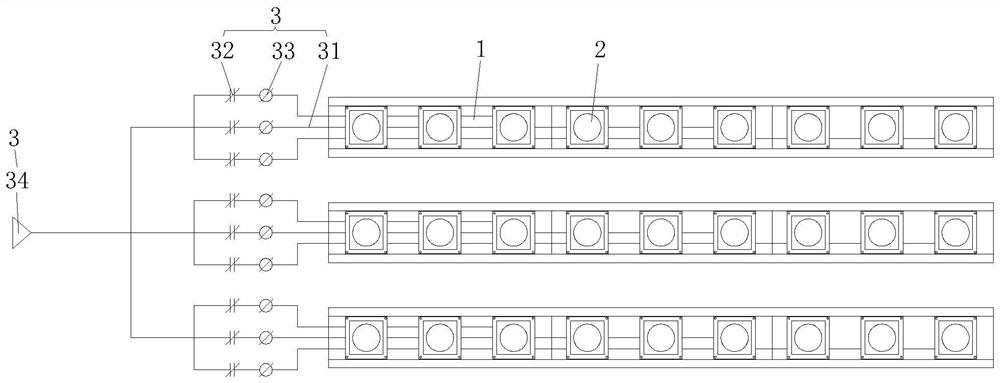

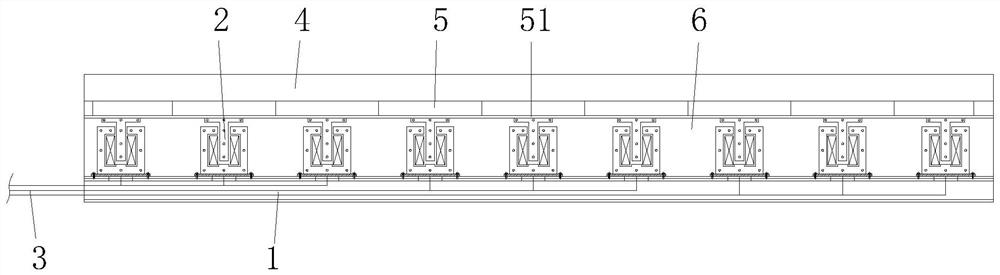

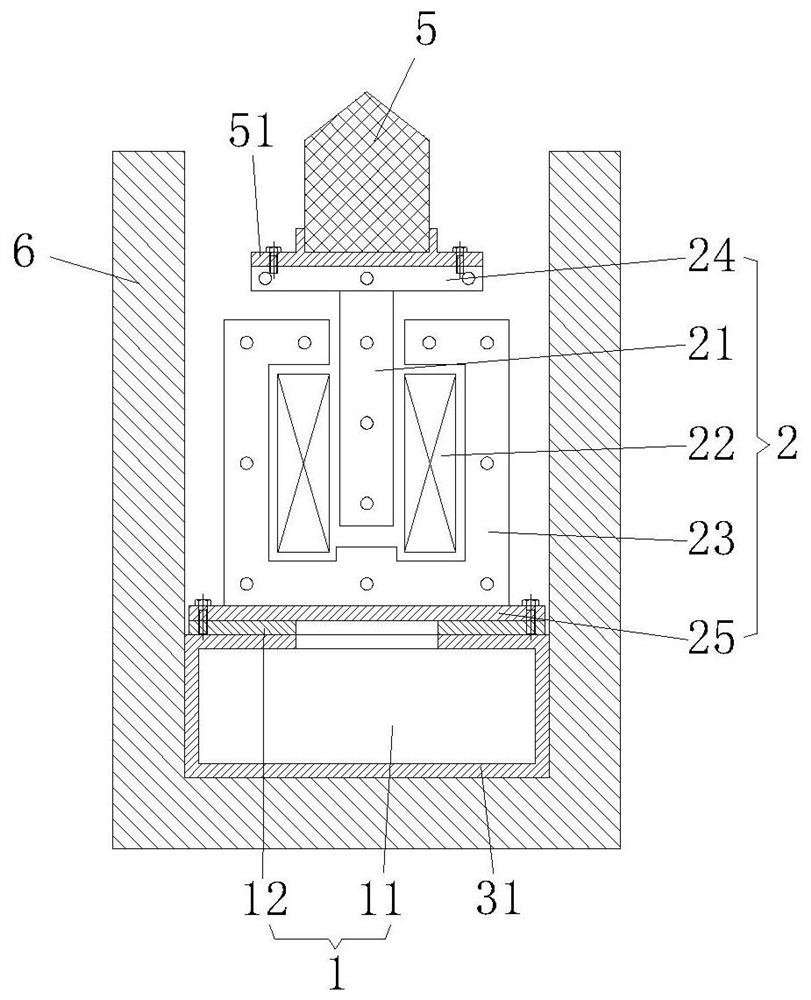

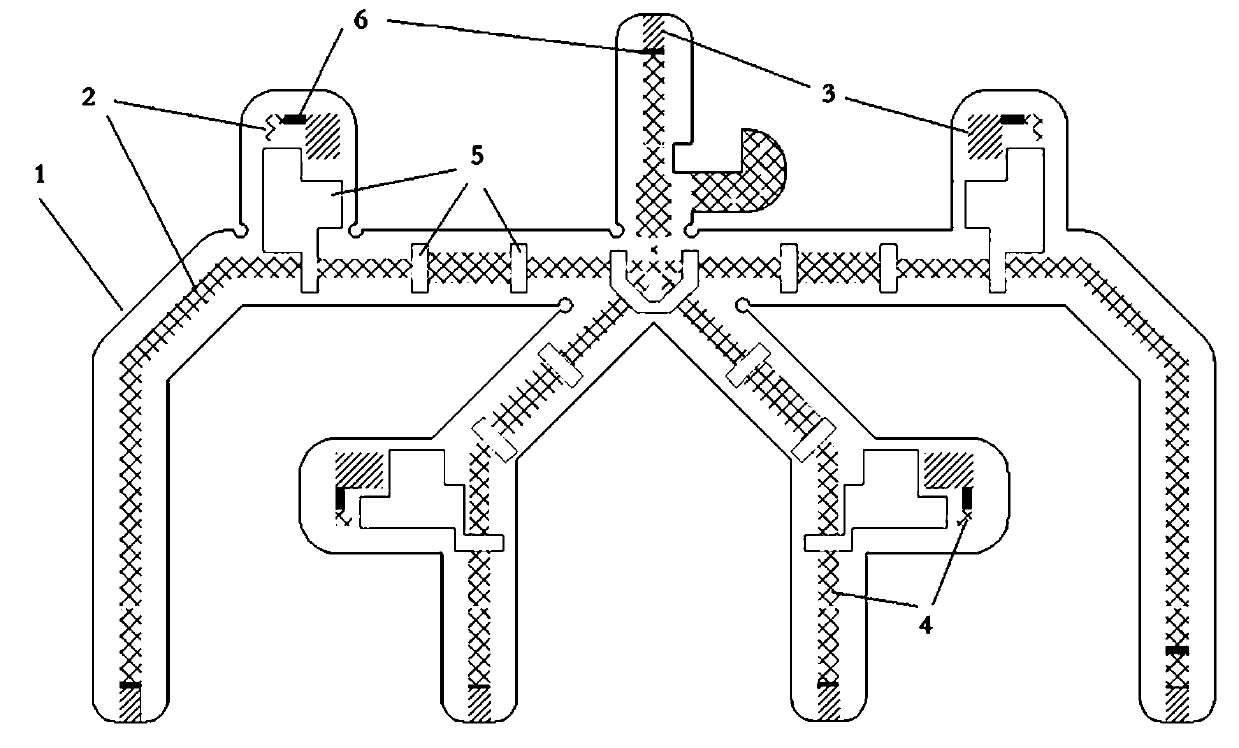

Semi-automatic tin dipping machine

InactiveCN102259223AGuaranteed levelConsistent immersion tin depthSolder feeding devicesSemi automaticEngineering

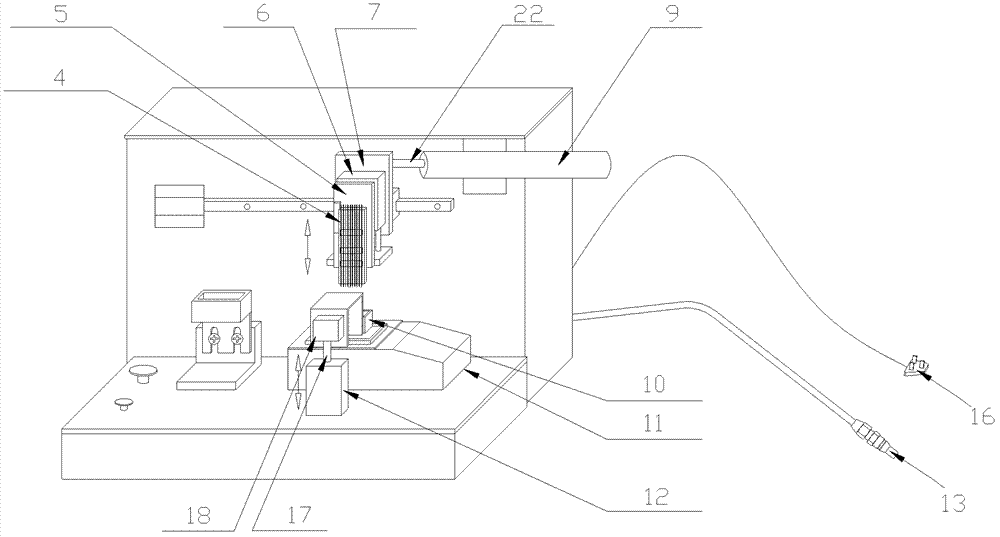

The invention discloses a semi-automatic wicking machine comprising a workbench, a fixing plate and a tin melting furnace. The semi-automatic wicking machine is characterized by further comprising a wicking groove, a soldering flux groove, a wiring plate, a guide rail, a first up-and-down moving device, a horizontal driving device and a second up-and-down moving device. The wicking groove is arranged above an opening of the tin melting furnace, the first up-and-down moving device is connected with the wicking groove, the soldering flux groove is arranged above the workbench, the second up-and-down moving device is connected with the wiring plate, the back end of the second up-and-down moving device is connected with the guide rail arranged on the fixing plate, and the horizontal driving device arranged on the fixing plate is connected with the second up-and-down moving device. The invention solves the problem that woven flare opening and bulging usually generate, the wicking length isinconsistent, and the sizes of finished produces are unstable due to the hard guarantee of the appearance and the quality of products because wire rods are wicked manually in prior art, and provides a semi-automatic wicking machine with unity in wicking, order appearance and good size consistency.

Owner:雷特威连接系统(苏州工业园区)有限公司

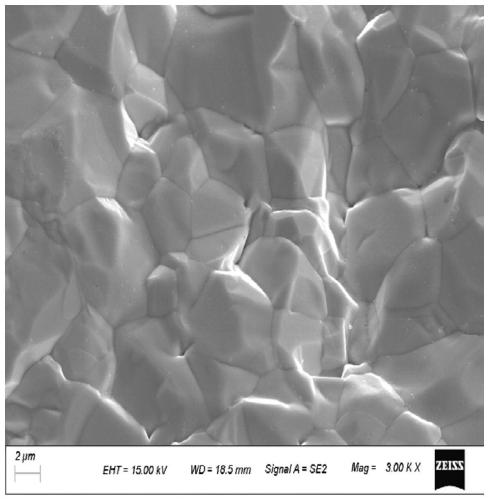

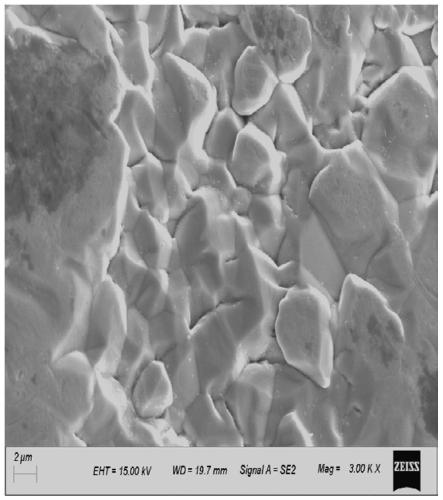

Neutral tin-plating addition agent

The invention discloses a neutral tin-plating addition agent. The neutral tin-plating addition agent is characterized by being prepared from the following raw materials in percentage by weight: 20%-30% of a complexing agent, 1%-3% of a wetting agent, 1%-5% of a surfactant, 10%-20% of a pH regulator and the balance of water. According to the neutral tin-plating addition agent, dangerousness and pollution caused by an acidic addition agent in the prior art are avoided, stable performance can be maintained at different temperatures, the storage life of products is prolonged, the stability of tin-plating liquid containing the neutral tin-plating addition agent is good while the uniform plating capability and the penetration capability are ensured, and a good tin-plating effect can be realizedwithin the large electroplating temperature range.

Owner:广东比格莱科技有限公司

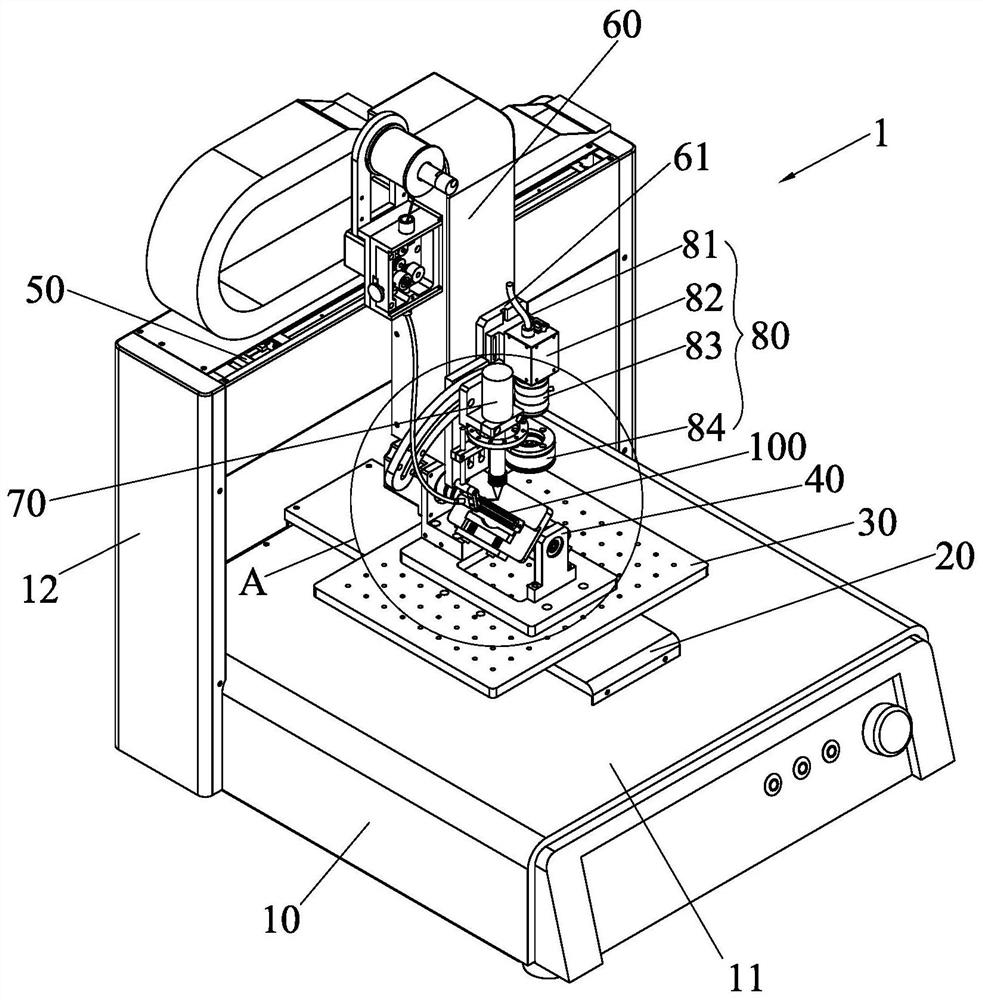

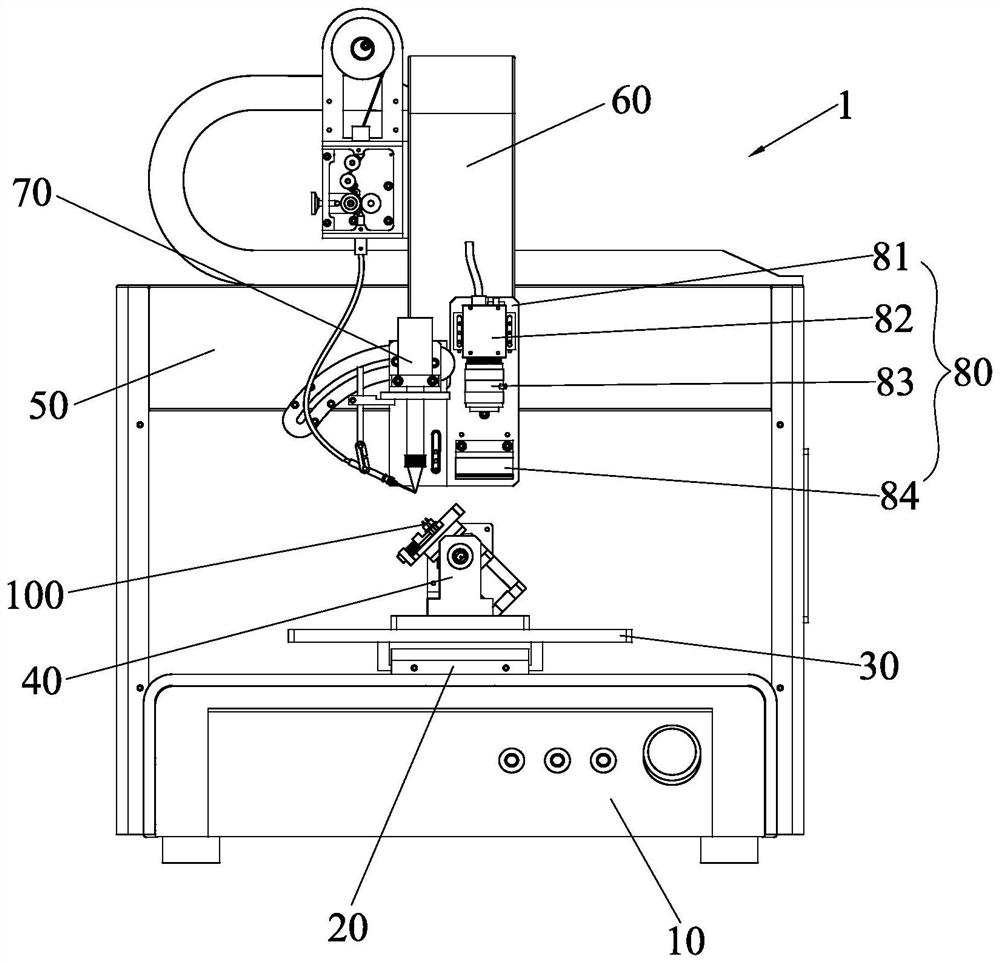

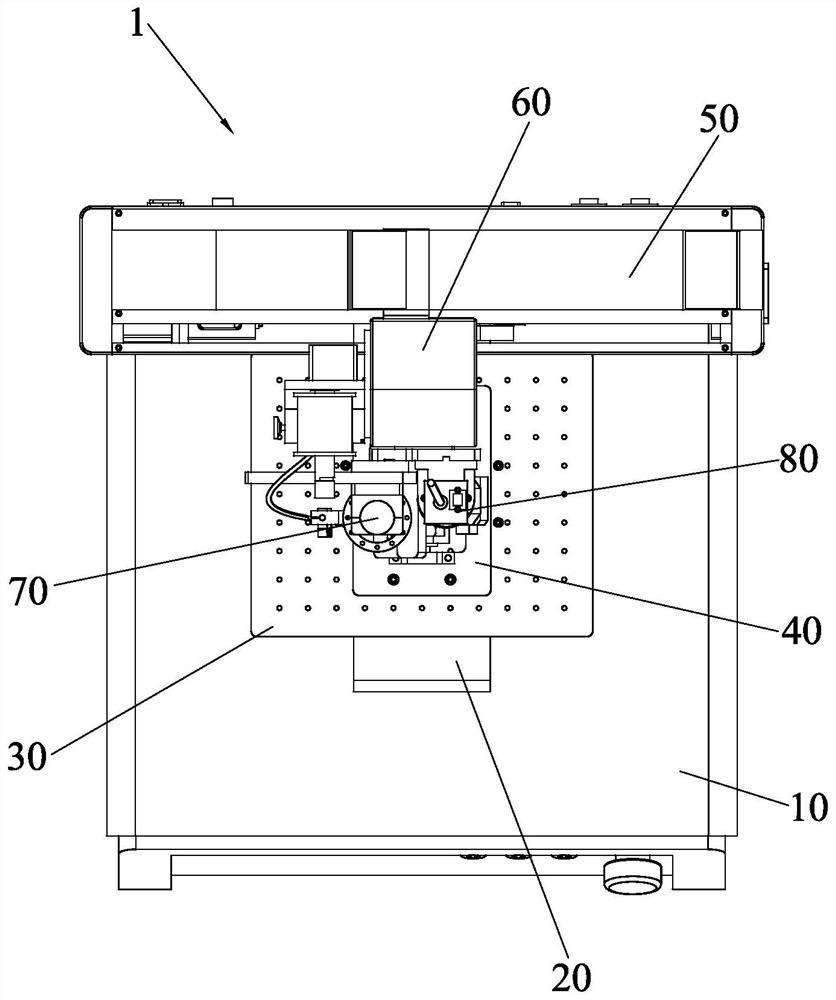

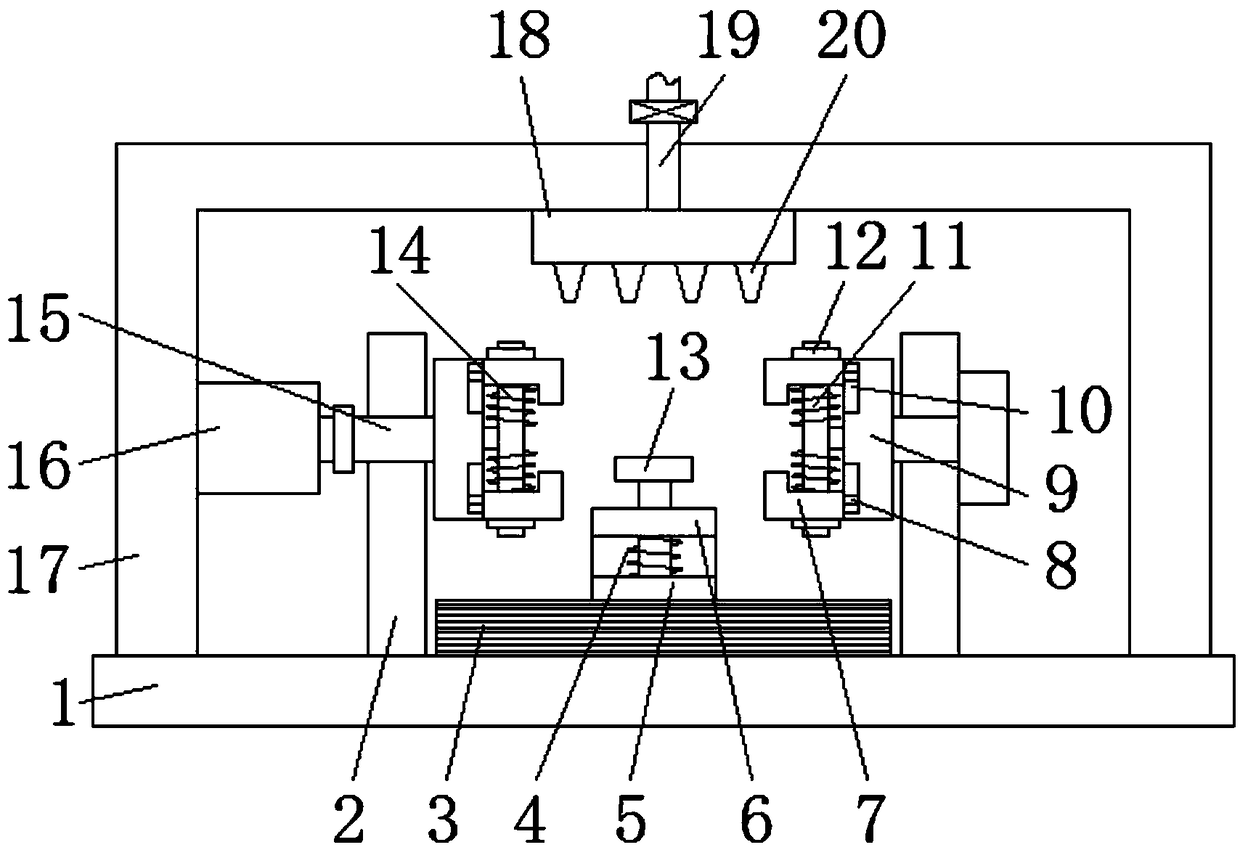

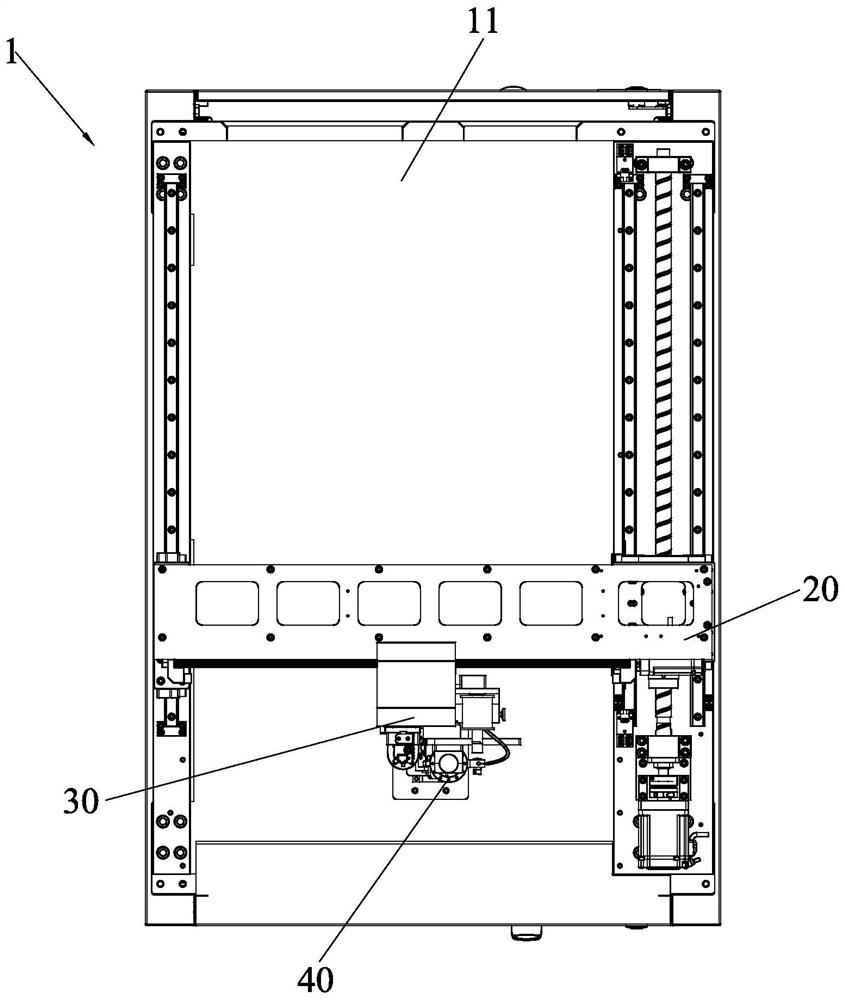

Table type soldering iron tin soldering equipment

PendingCN112170999AReduce use costReduce maintenance costsMetal working apparatusSolder feeding devicesEngineeringCamera module

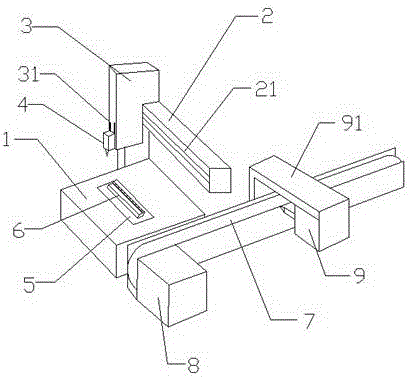

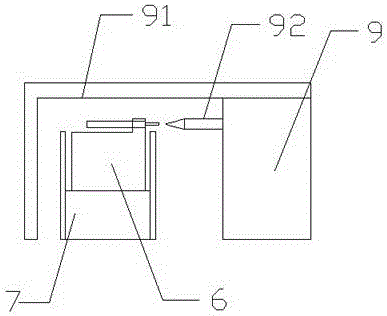

The invention discloses table type soldering iron tin soldering equipment. The equipment comprises a machine box, a Y-axis linear module, a movable carrying table, a positioning and rotating mechanism, an X-axis linear module, a Z-axis linear module, a soldering iron tin soldering assembly and a camera module, the Y-axis linear module is arranged on a workbench of the machine box, the movable carrying table is arranged on the Y-axis linear module and can move forwards and backwards along with the Y-axis linear module, the positioning and rotating mechanism is arranged on the movable carrying table, the X-axis linear module is arranged above the workbench, the Z-axis linear module is arranged on the X-axis linear module, and the soldering iron soldering tin assembly and the camera module are arranged on the Z-axis linear module. A convenient table type structure is adopted, the equipment cost is low, and the placement position can be flexibly adjusted according to the layout of a plant;and a soldering iron soldering process is adopted, the process is mature, soldering iron use and maintenance cost is low, and tin soldering quality of products can be well guaranteed by replacing soldering iron according to the service life of the soldering iron.

Owner:厦门柔性电子研究院有限公司 +2

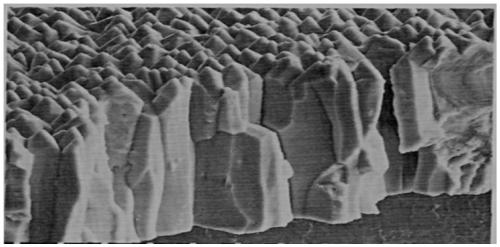

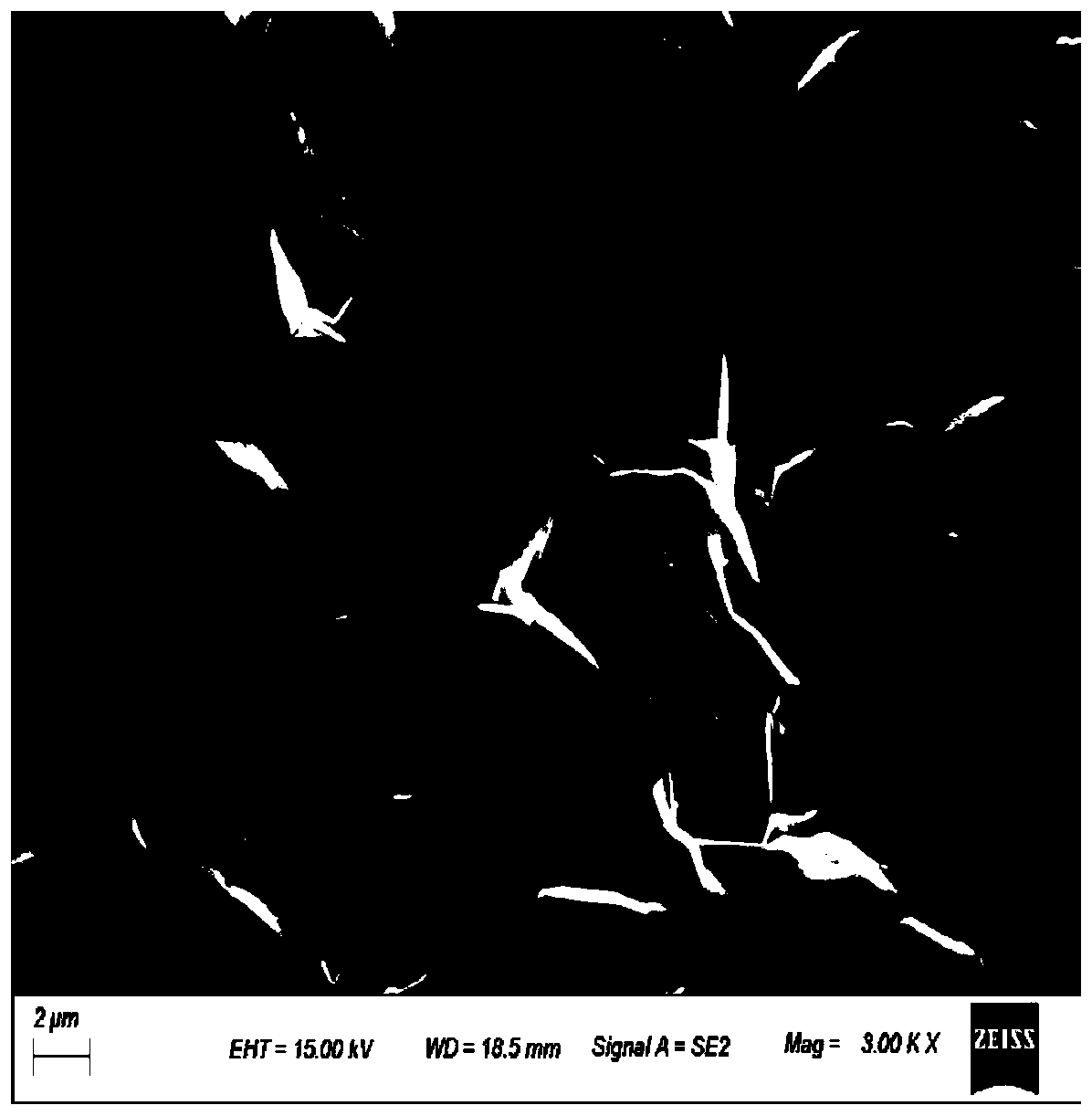

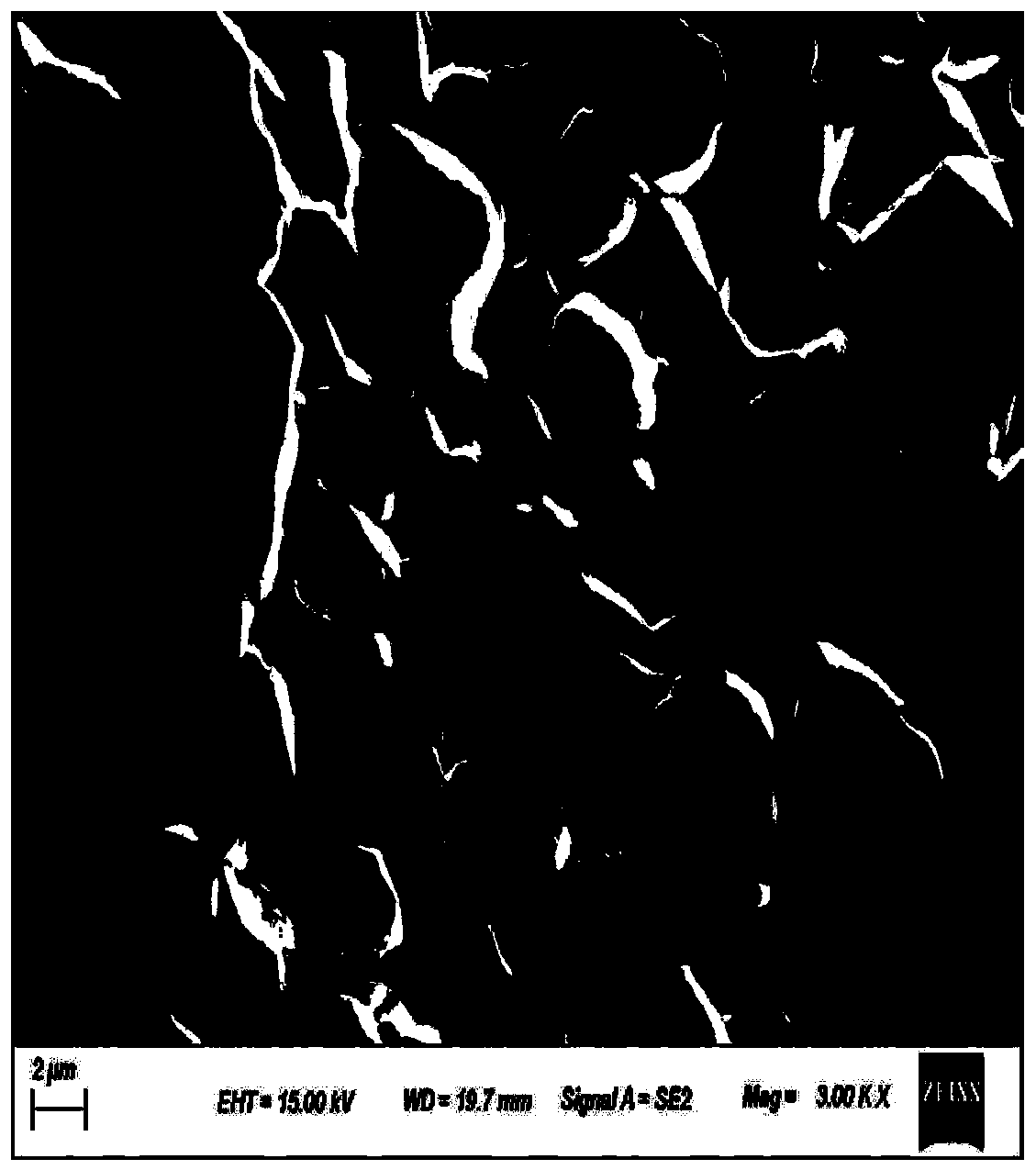

Organic metal shielded welding film and preparation method thereof

ActiveCN106413275AImprove the convenience of appearance visual inspectionGood tinning effectDouble resist layersNon-metallic protective coating applicationTinningVisual inspection

The invention provides an organic metal shielded welding film and a preparation method thereof. A novel surface treatment mode is an innovative process technology between an organic shielded welding film and metalized surface treatment; namely, a physical isolation protective layer is created; the protective layer is composed of a main clad layer and an organic protective layer; the main clad layer comprises silver metal and organic metal; the main clad layer is positioned on the surface of a circuit board; and the organic protective layer is positioned on the surface of the main clad layer. The organic metal shielded welding film has all performances of an OSP film, and simultaneously, has type chemical silver surface treatment performances; the preparation process is simple; the appearance visual inspection convenience is greatly improved; the tinning effect can be effectively improved; and the galvanic effect in the production process can be inhibited.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

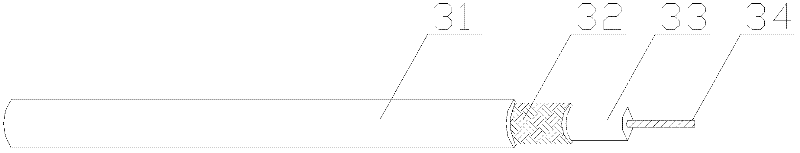

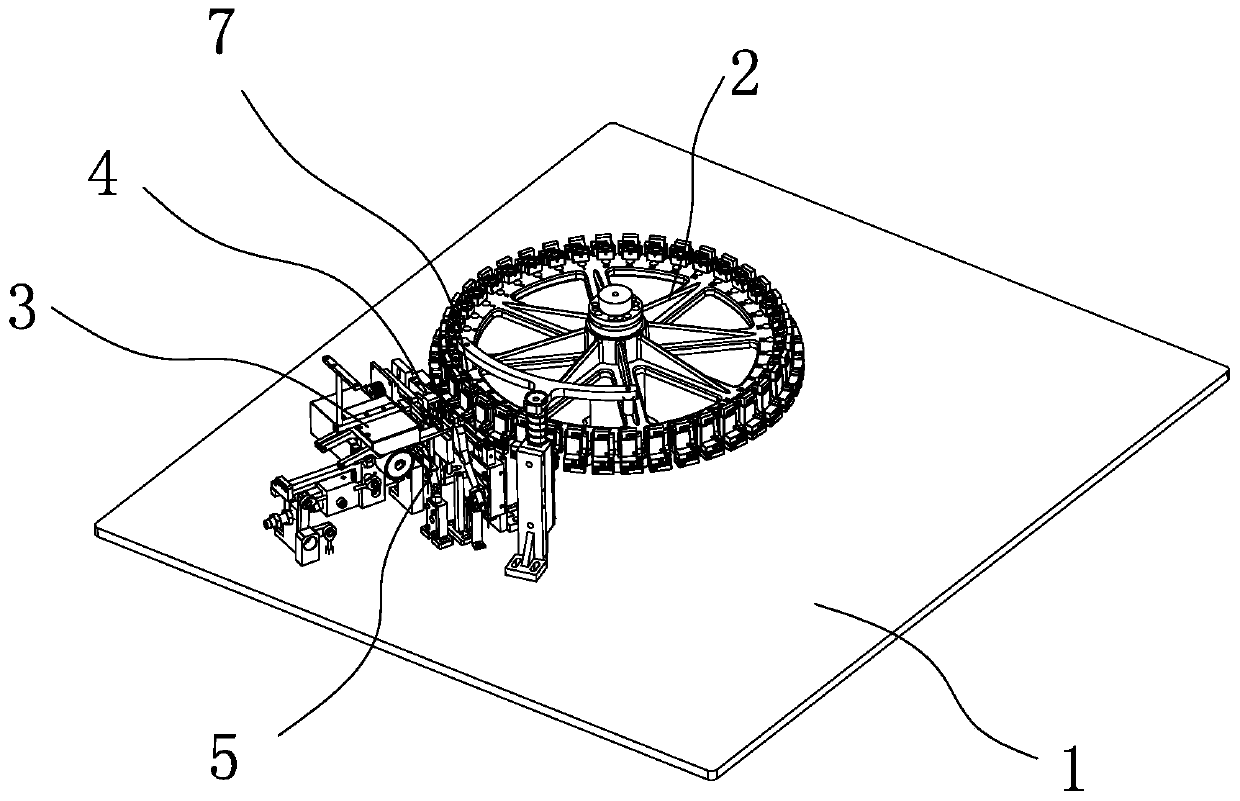

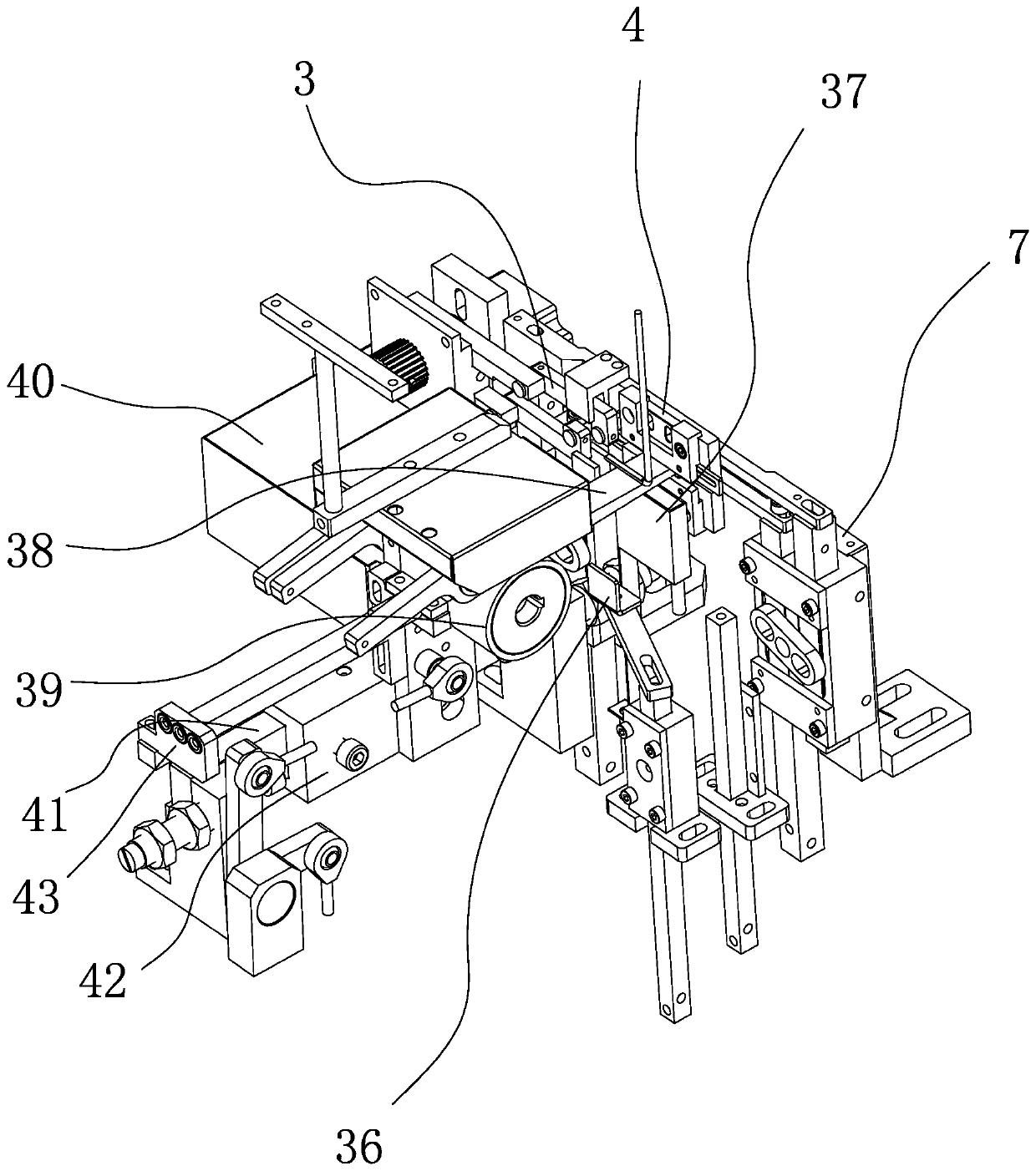

Lead cutting, stripping and twisting device and lead cutting, stripping and twisting method

PendingCN110311288AShort operating timeImprove processing efficiencyLine/current collector detailsElectronic waste recyclingEngineeringMechanical engineering

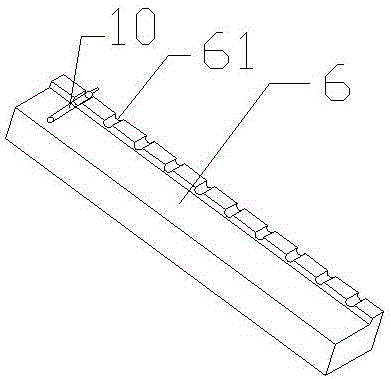

The invention provides a lead cutting, stripping and twisting device and a lead cutting, stripping and twisting method, belongs to the mechanical technical field, and solves the problems of cumbersomeoperation steps and poor effect of the existing lead cutting, stripping and twisting and the problems of lack of leg tension and stability of eyeglasses. The lead cutting, stripping and twisting device comprises a lead feeding mechanism and a lead cutting and stripping mechanism. The lead cutting, stripping and twisting device is characterized by further comprising a lead twisting mechanism. Thelead cutting and stripping mechanism comprises a cutter assembly and a stripping cutter assembly. The lead twisting mechanism comprises a lead twisting driving assembly and a lead twisting assembly. The lead twisting assembly is positioned between the cutter assembly and the stripping cutter assembly. The lead cutting, stripping and twisting operation can be realized, the operation time is short and the tinning effect after lead cutting, stripping and twisting is good.

Owner:TAIZHOU HAORAN MACHINERY MFG

Cylinder seat tinning device for refrigerator

InactiveCN109261397ASputtering will notGood tinning effectSpraying apparatusTinningElectric machinery

The invention relates to the technical field of tinning devices, in particular to a cylinder seat tinning device for a refrigerator. Support plates are fixed at both ends on the upper side of a workbench, and the two support plates are respectively provided with a rotating shaft in the penetration mode. The corresponding sides of the two rotating shafts are respectively fixedly provided with a rotating plate, and the corresponding sides of the two rotating plates are respectively provided with a threaded rod by welding through a connecting rod. The upper and the lower ends of the correspondingsides of the two rotating plates are respectively provided with an L-shaped clamping plate through a sliding mechanism, and the two ends of the threaded rods respectively penetrate the two L-shaped clamping plates. The outsides of the upper and lower ends of the two threaded rods are respectively provided with a knob, a U-shaped frame is fixed on the upper end of the workbench, a motor is mountedon the inner side of the U-shaped frame, an output shaft of the motor is connected with one rotating shaft, and the other end of the other rotating shaft is fixedly provided with a limiting block. Aconnecting pipe is fixed on the upper side of the U-shaped frame, and a plurality of nozzles are evenly arranged at the lower end of the connecting pipe, and a feeding pipe with a valve is connected to the upper end of the connecting pipe. The tinning device is simple in structure and high in tinning efficiency and causes no pollution to the workbench.

Owner:黄石市金雀电气股份有限公司

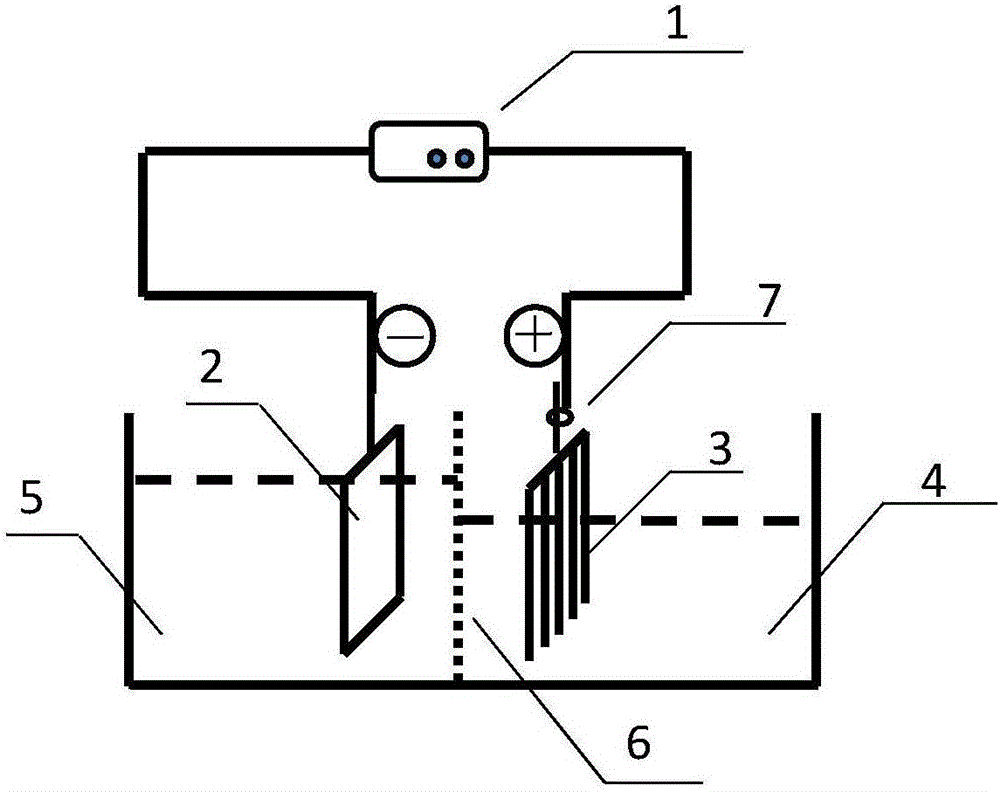

Method and device for cleaning and separating various components and parts and recycling tin from waste circuit boards

ActiveCN106216792AHigh stripping rateHigh puritySoldering auxillary devicesPre treatmentPrinted circuit board

The invention provides a method and device for cleaning and separating various components and parts and recycling tin from waste circuit boards. The method comprises the following steps of: adding the waste circuit boards into a mixture of tin stripping liquor methylsulfonic acid and SnCl4; and stripping tin through pulsed ultrasonic treatment and vibrating treatment to obtain tin-stripped liquor; and a proportion, in the mixture, of the methylsulfonic acid is 1.0wt.%-20.0wt.%. The method is short in period, is high in efficiency, is short in flow, can realize cleaning and separating of the various components and parts on the waste circuit boards, also realizes efficient recycling of tin, realizes cleaning pre-treatment of the waste circuit boards, does not cause damages on the various components and parts, and can achieve the purpose of reducing emission and increasing income. The device is simple and practical, and can comprehensively obtain good tin stripping effect and good tin extracting effect.

Owner:CENT SOUTH UNIV

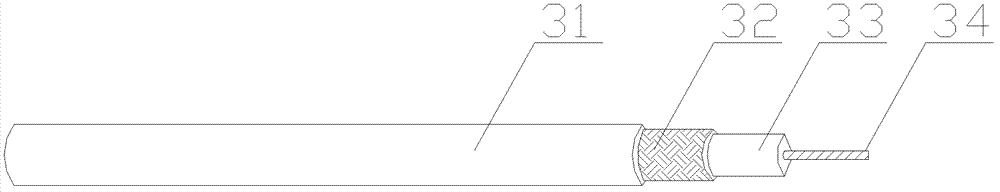

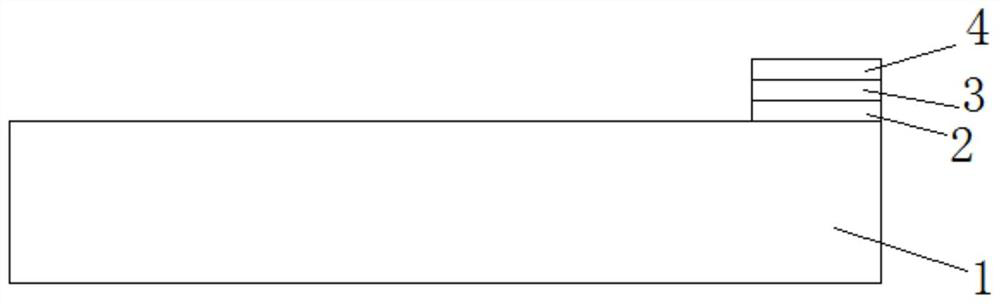

Copper alloy wire

InactiveCN104882198AGood flexibilityImprove ductilityFlexible cablesMetal/alloy conductorsCopper alloyNickel

The invention relates to a copper alloy wire. The copper alloy wire comprises, by weight, 94.7036% or higher of copper, 0.2% or higher of tin, 0.00038% or less of nickel, 0.000475% or less of ferrum, 0.00095% or less of antimony, 0.00019% or less of zinc, 0.0057% or less of oxygen, 0.000475% or less of manganese, 0.000475% or less of phosphorus, 0.0019% or less of bismuth, 0.000475% or less of arsenic, 0.000475% or less of gold and more than 5% of electroplating silver. The flexibility and the ductility of the copper alloy wire are improved.

Owner:LUXSHARE PRECISION INDUSTRY (CHUZHOU) CO LTD

Automatic tin cutting machine

InactiveCN102059425APrevent sticking phenomenonPrevent deviationSolder feeding devicesSoldering auxillary devicesKnife bladesNozzle

The invention discloses an automatic tin cutting machine which mainly comprises a cutting gear blade, a guide wheel, a tin outlet nozzle pipe and a tin inlet head, wherein the cutting gear blade is arranged opposite to the guide wheel, a shallow groove surrounding the circumference is arranged on the circumference of the guide wheel, cutter teeth of the cutting gear blade are arranged opposite to the shallow groove arranged on the guide wheel, the tin outlet nozzle pipe is opposite to the tin inlet head, a half-edge groove is arranged on the mesopore wall of the tin outlet nozzle pipe along the longitudinal direction, and the cutter teeth of the cutting gear blade cuts over the half-edge groove so as to split a tin wire in the tin outlet nozzle pipe. Because the tin wire between the cutting gear blade and the guide wheel is cut through the cutting gear blade, and a cutter tooth angle of the cutting gear blade is reasonably designed, the automatic tin cutting machine can well drive the tin wire to move forwards and can also efficiently prevent the wire adhesion phenomenon caused by the cutter teeth of the cutting gear blade, which excessively cut over the tin wire, therefore, the invention has the advantages of high automation degree and good tin cutting effect.

Owner:厦门顺拓电子有限公司

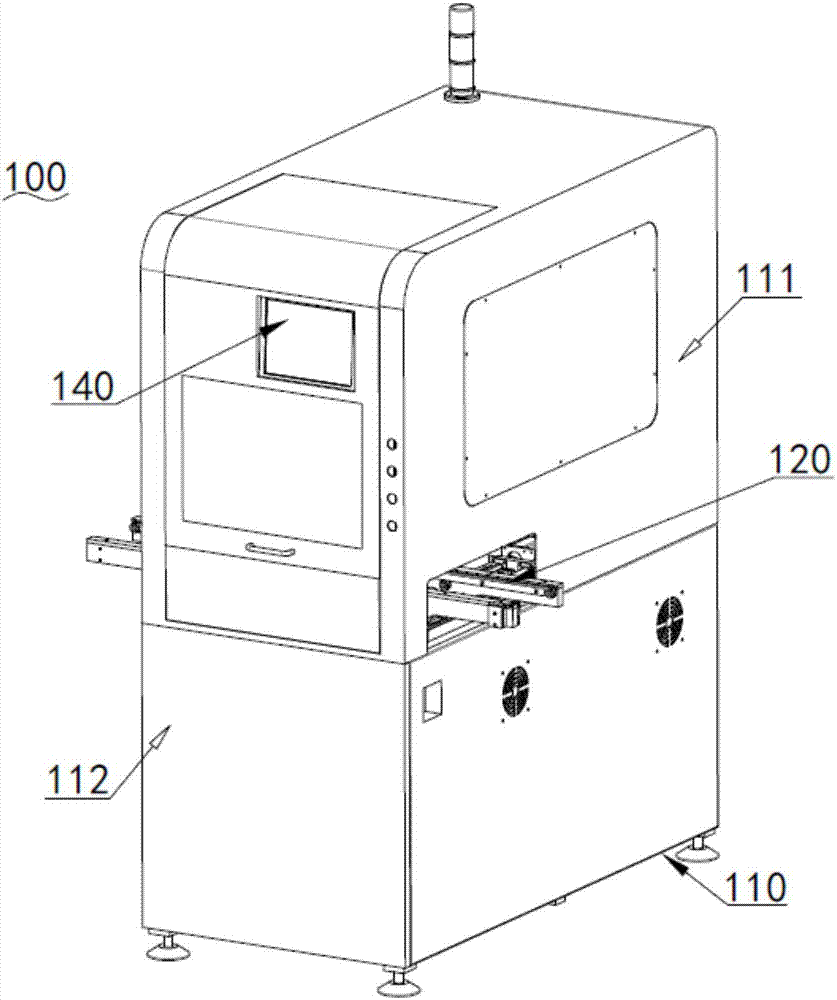

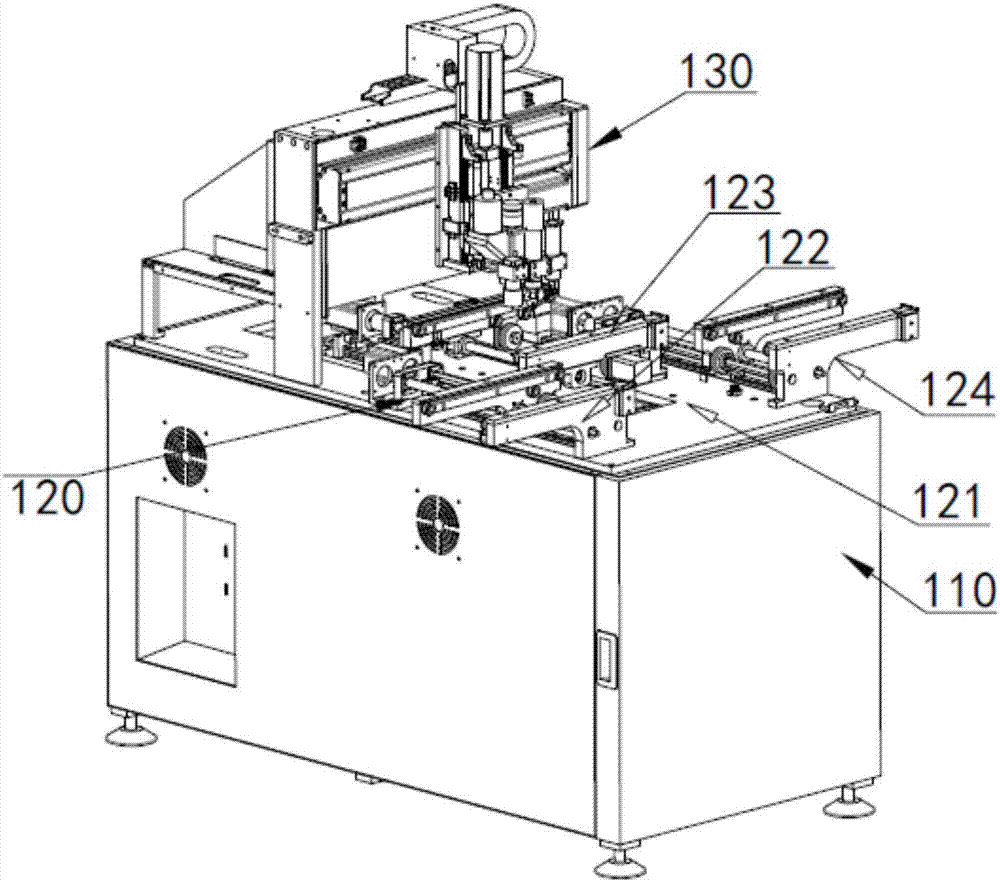

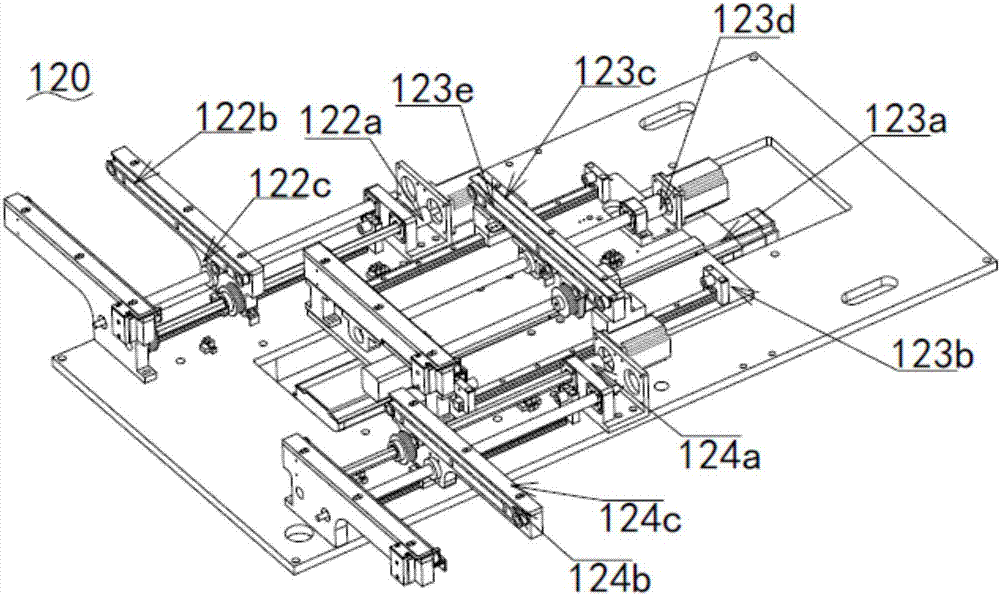

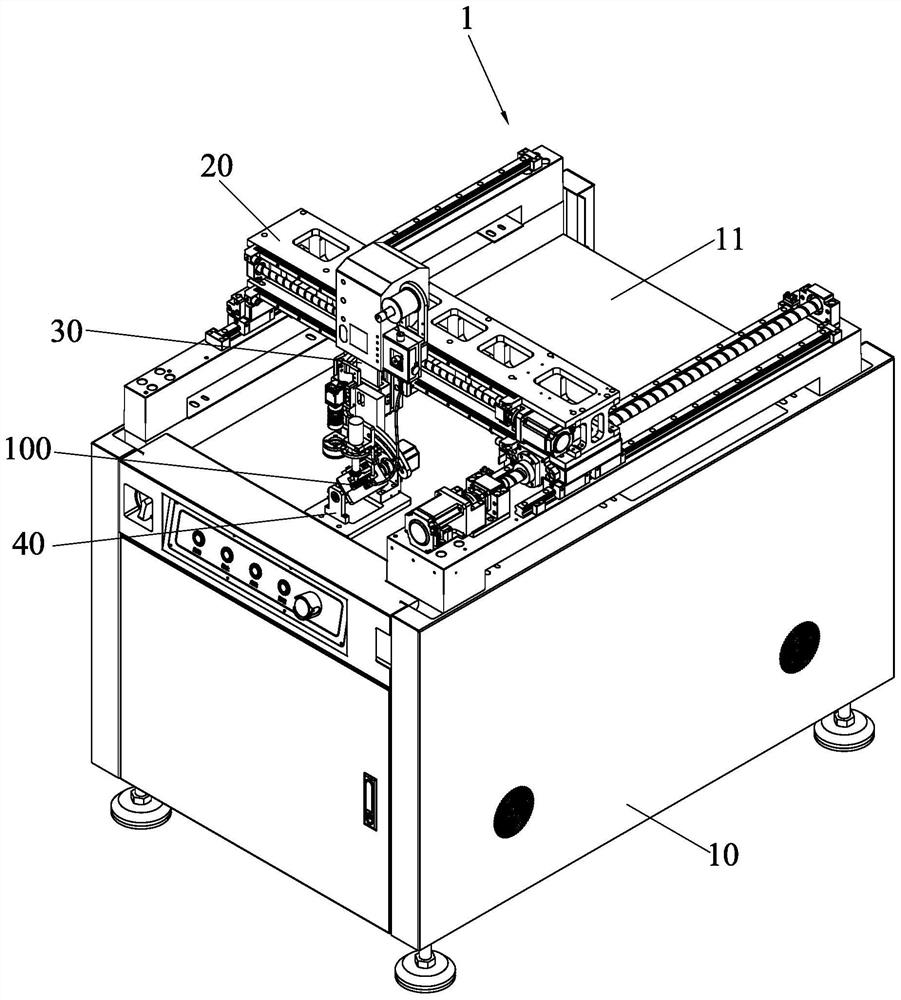

Automatic online tin paste dispensing equipment and working method thereof

PendingCN107088689AEasy to transportPlay a dynamic effectMetal working apparatusSoldering auxillary devicesEngineeringSpot welding

The invention relates to the technical field of tin dispensing equipment, in particular to automatic online tin paste dispensing equipment and a working method thereof. The automatic online tin paste dispensing equipment comprises a rack, a workbench, a tin dispensing device and a control device. The rack comprises an upper rack body and a lower rack body. The upper rack body is installed on the lower rack body and covers the workbench and the tin dispensing device. The control device is electrically connected to the workbench and the tin dispensing device. The workbench comprises an installation plate, a feeding assembly, a fixing assembly and a discharging assembly. The tin dispensing device comprises a supporting frame, a driving sliding platform, a detection assembly, a tin smearing assembly and a tin welding assembly. The automatic online tin paste dispensing equipment is high in working efficiency and automation degree and good in spot welding effect. The working method of the automatic online tin paste dispensing equipment comprises the steps that a program is written in the control device at first; a plate is fixed to the workbench, detected through the detection assembly, and smeared with tin paste through the tin smearing assembly; spot welding is conducted in the position where the tin paste is smeared through the tin welding assembly; and after spot welding is completed, the plate is detected again through the detection assembly. The working method is high in tin dispensing quality, automation degree and working efficiency.

Owner:VECTRON TECH ELECTRONICS EQUIP

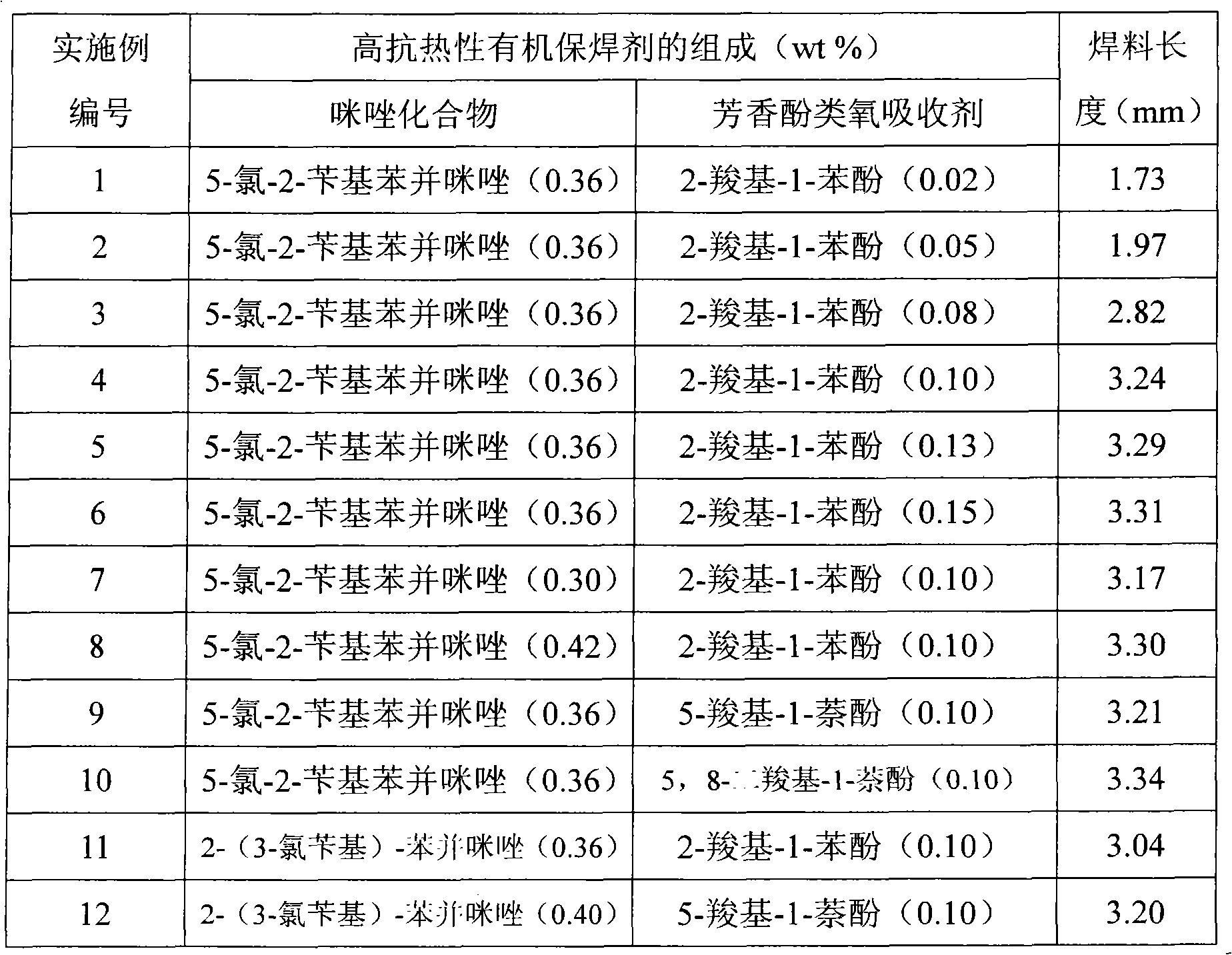

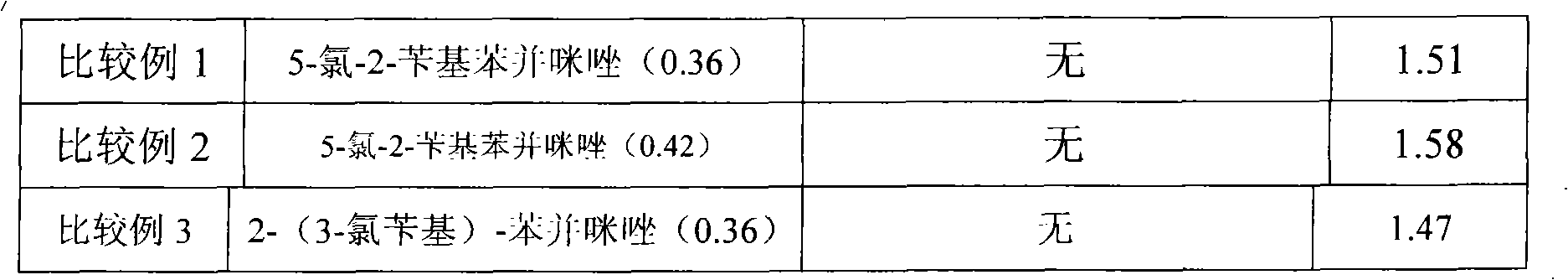

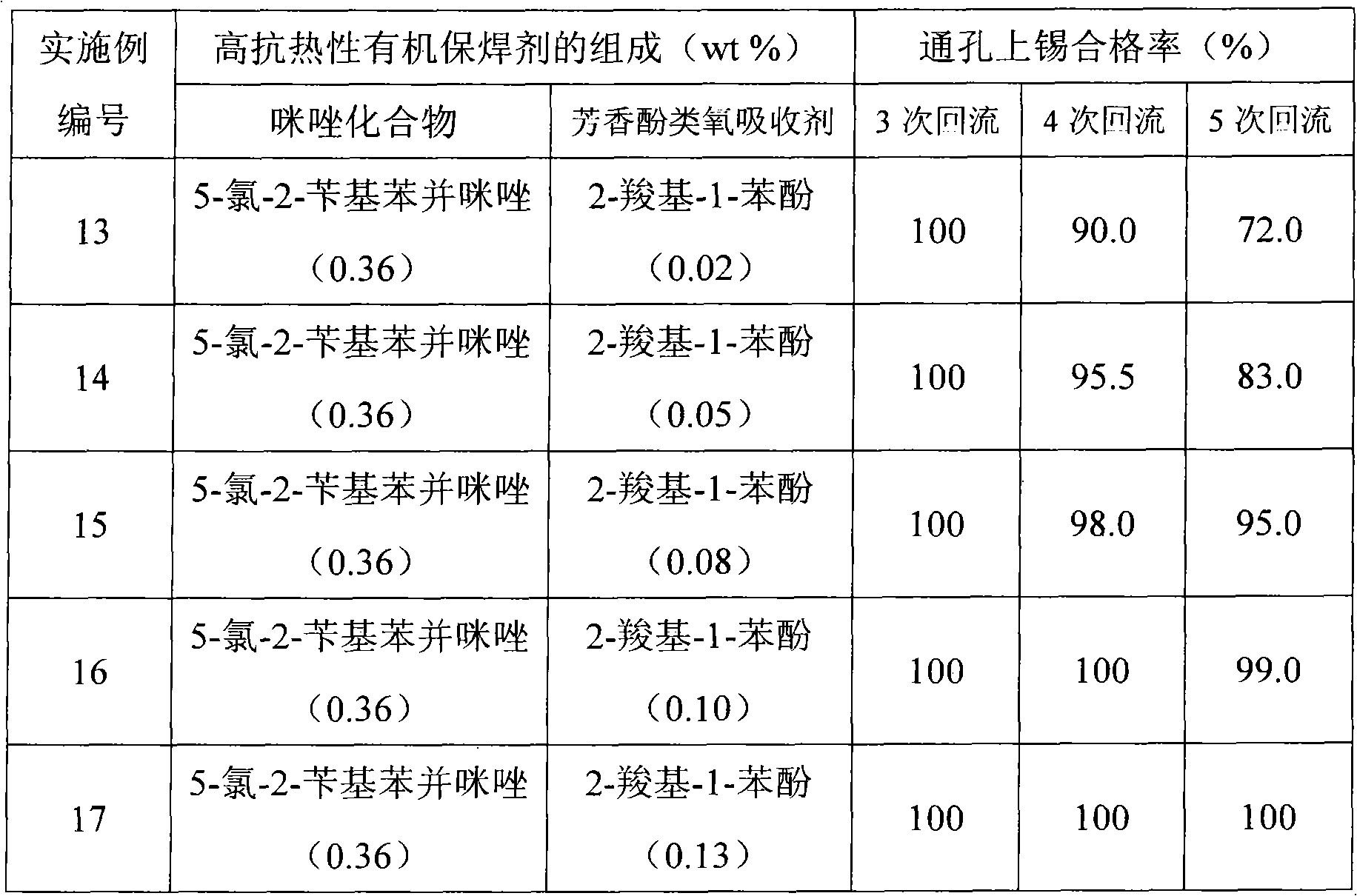

High heat-resistance organic solder ability preservative

ActiveCN101697662BPrevent oxidationGood tinning effectNon-metallic protective coating applicationColor changesOxygen

The invention discloses a high heat-resistance organic solder ability preservative. It is characterized by consisting of an aromatic phenol oxygen absorbent, an imidazole compound, an organic acid, a solubilizer, a metallic compound and deionized water. After being coated on the surface of a copper plate, the heat-resistance organic solder ability preservative can inhibit the oxidation of the copper surface of a circuit board, particularly can avoid the color-changing oxidation of copper surface during multiple high-temperature treatments, and can keep the excellent solderability of copper surface of the circuit board, improve weldability and guarantee the successful follow-up welding.

Owner:深圳市唯特偶新材料股份有限公司

Novel lead-free halogen-free hot air leveling scaling powder

ActiveCN103252598AGood tinning effectWon't connectWelding/cutting media/materialsSoldering mediaButanedioic acidActive agent

The invention relates to novel lead-free halogen-free hot air leveling scaling powder. By the weight percent, the scaling powder is prepared by components as follows: 10-70% of polyether, 10-70% of polyethylene glycol, 0.1-0.5% of special perfluorinated surfactant, 10-50% of de-ionized water, 0.1-10% of butanedioic acid, 0.1-10% of adipic acid, 0.1-10% of suberic acid, 1-20% of absolute ethyl alcohol, 1-20% of methyl alcohol and 0.1-10% of benzotriazole. The novel lead-free halogen-free hot air leveling scaling powder is used and can obviously strengthen soldering performance of small pads and small holes in the surface of a circuit board. The situation that integrated circuits (ICs) can not be interconnected is guaranteed. Moreover, residuals on the surface of the board are easy to clean. Residuals of a solder machine are high temperature resistant, smoke is very small, odor is light, and in comparison with other products, the working environment is better cleaned.

Owner:GUANGDONG HAFU SCI & TECH

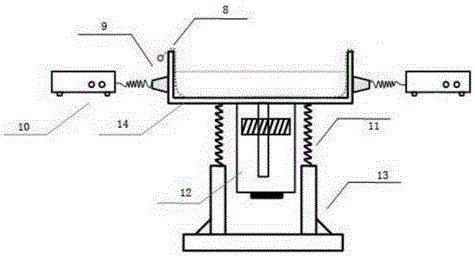

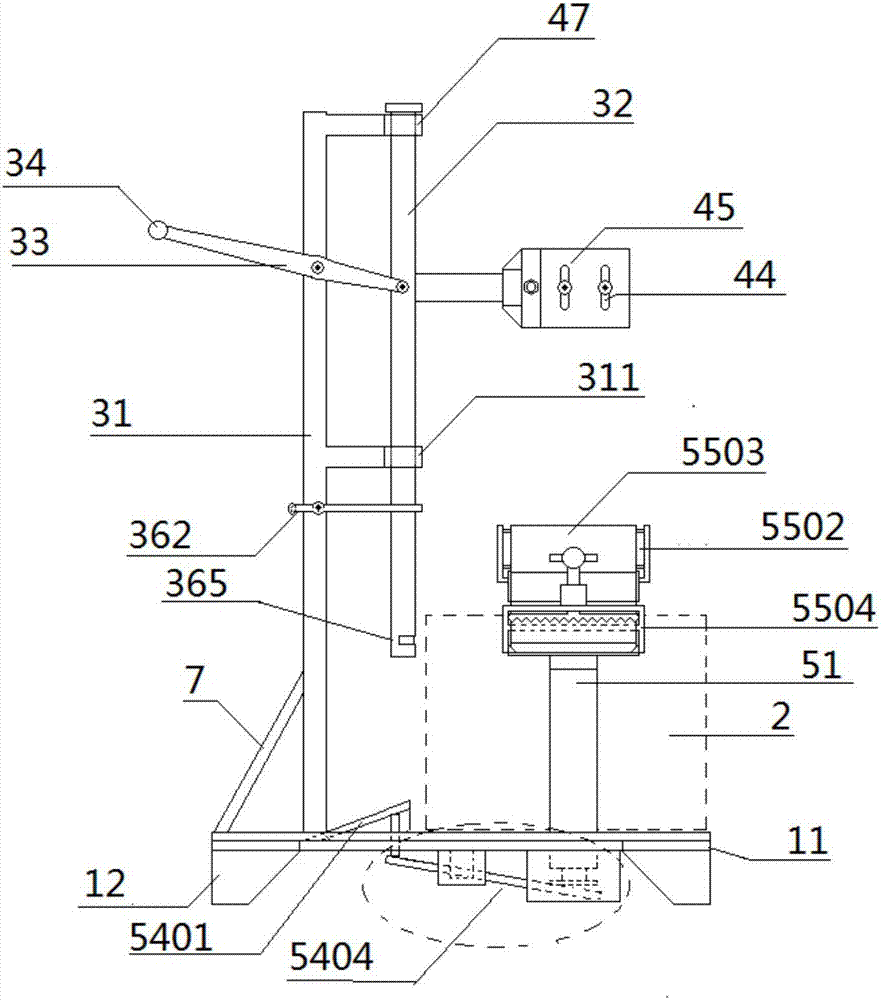

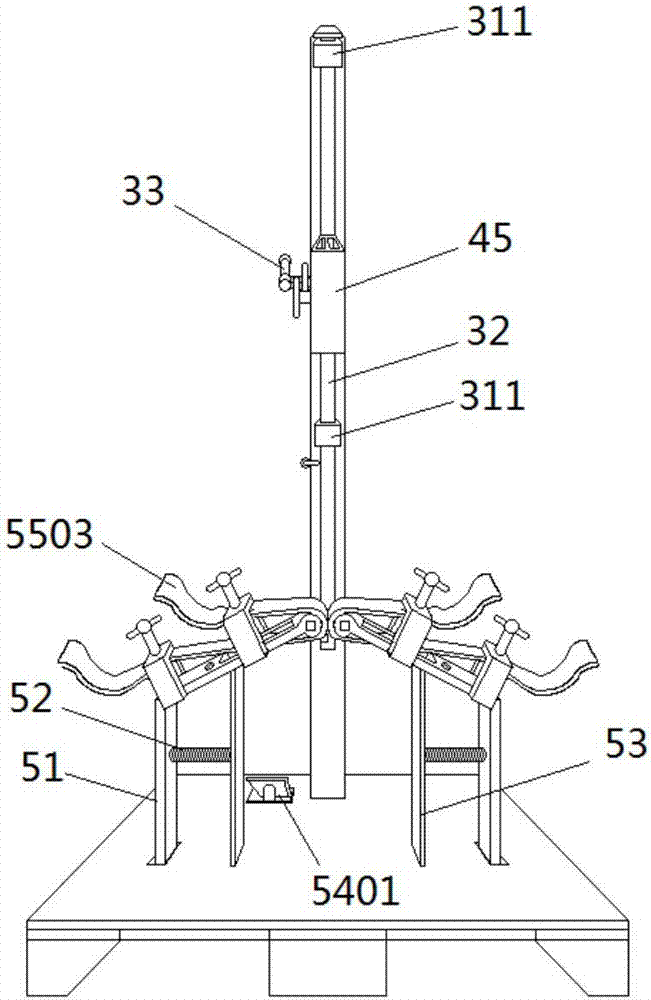

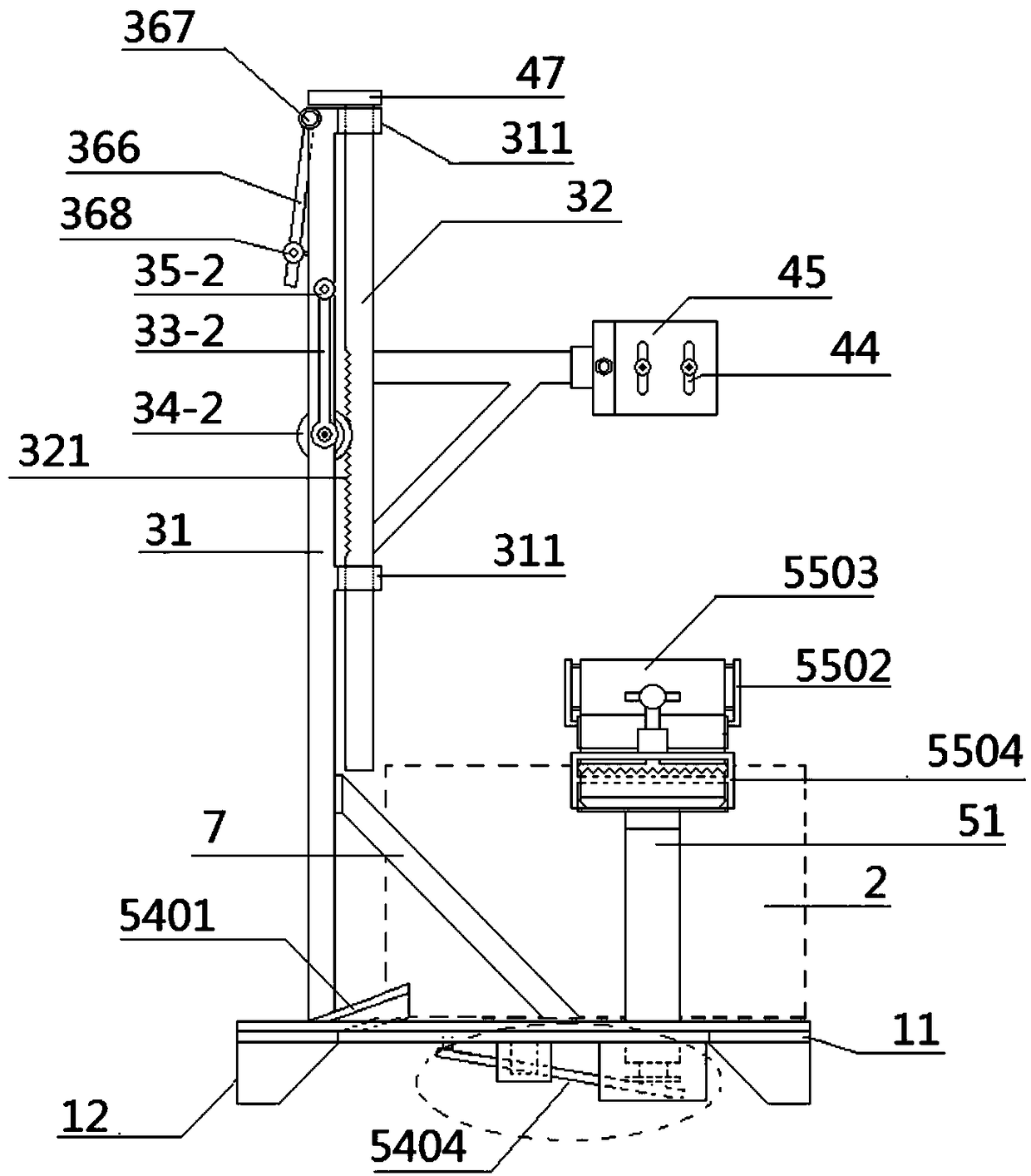

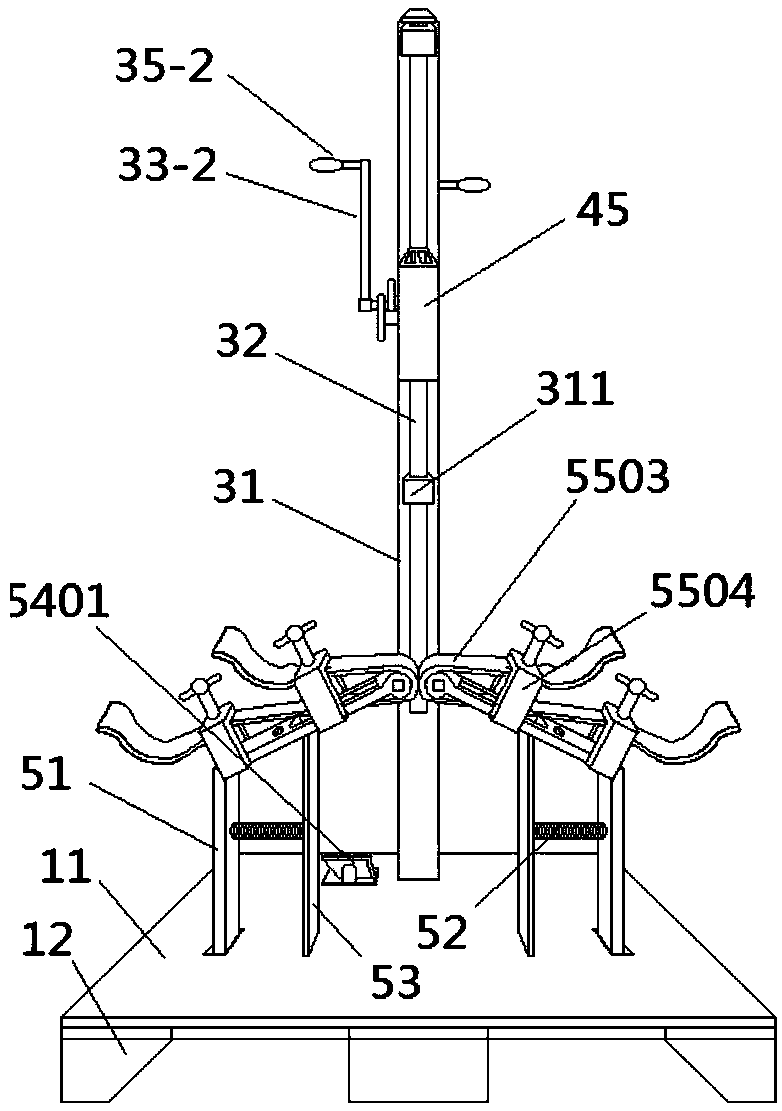

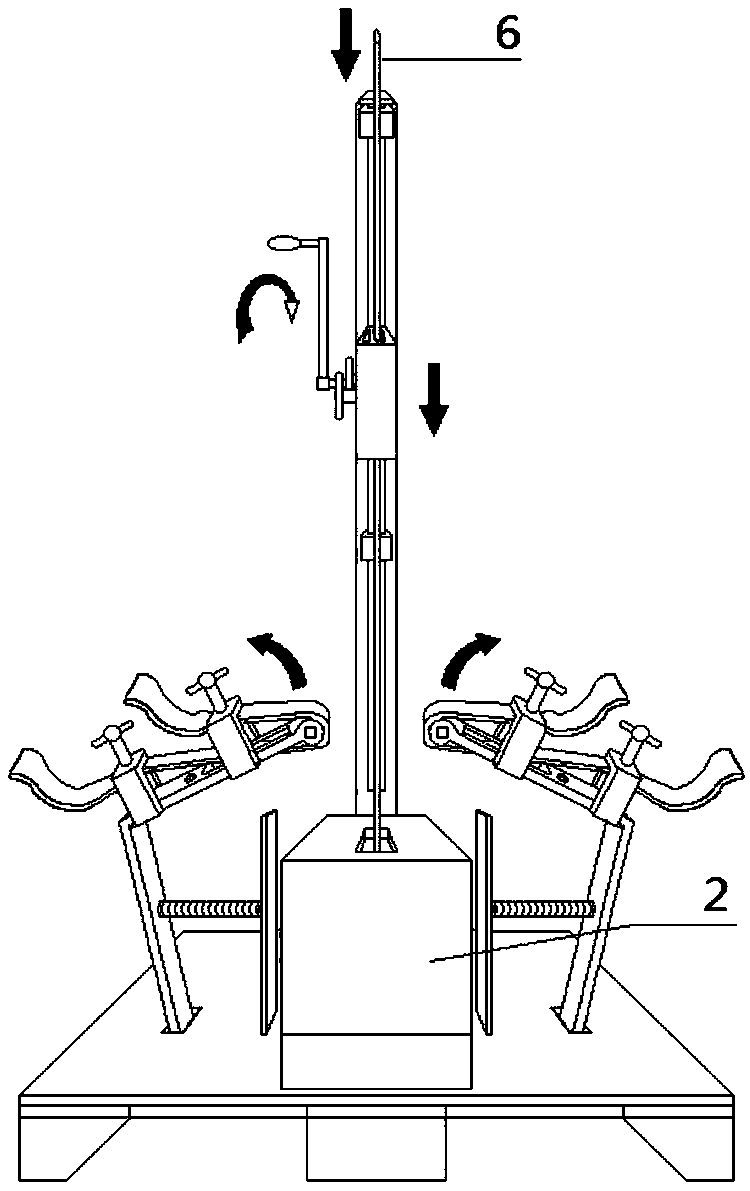

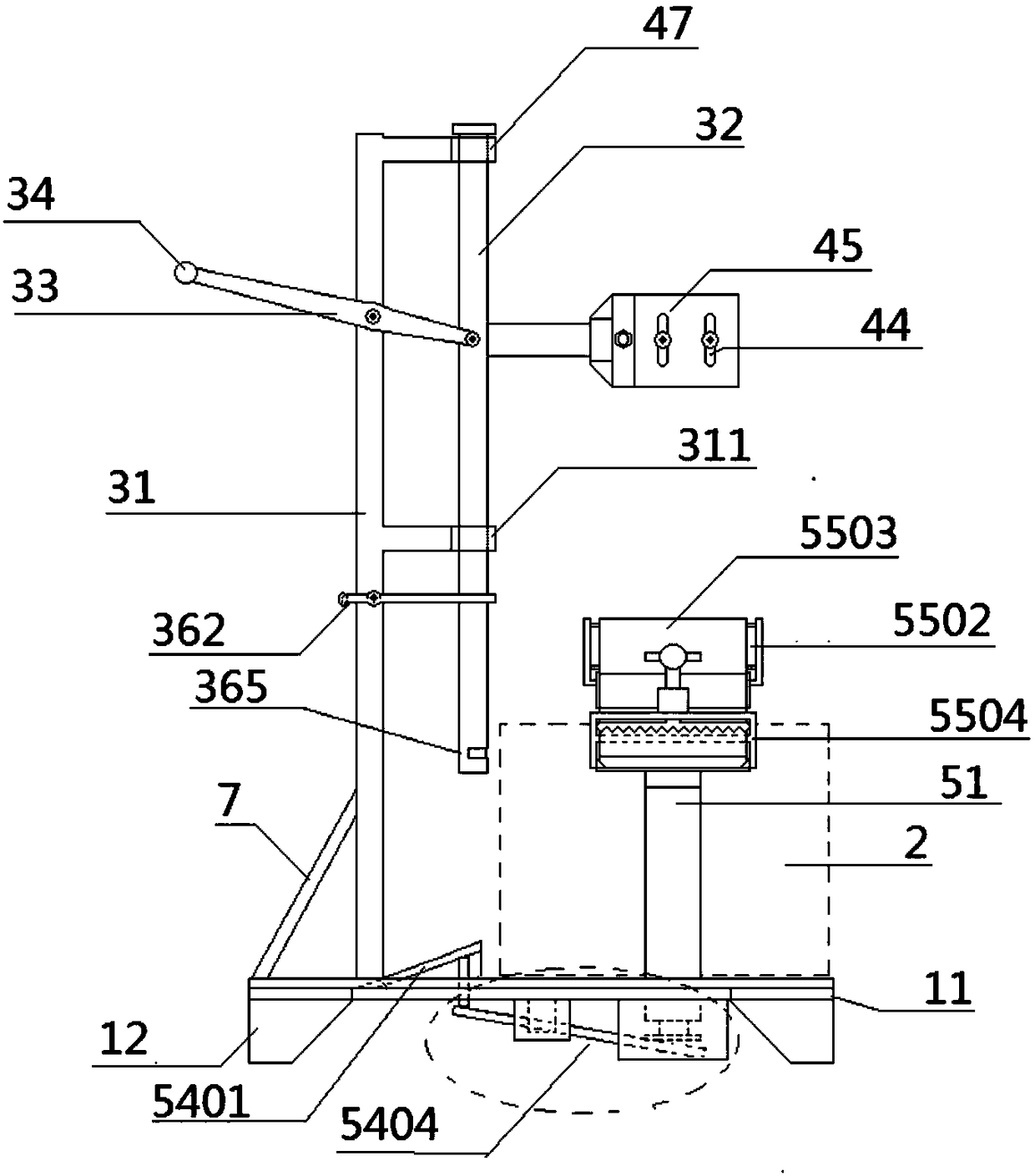

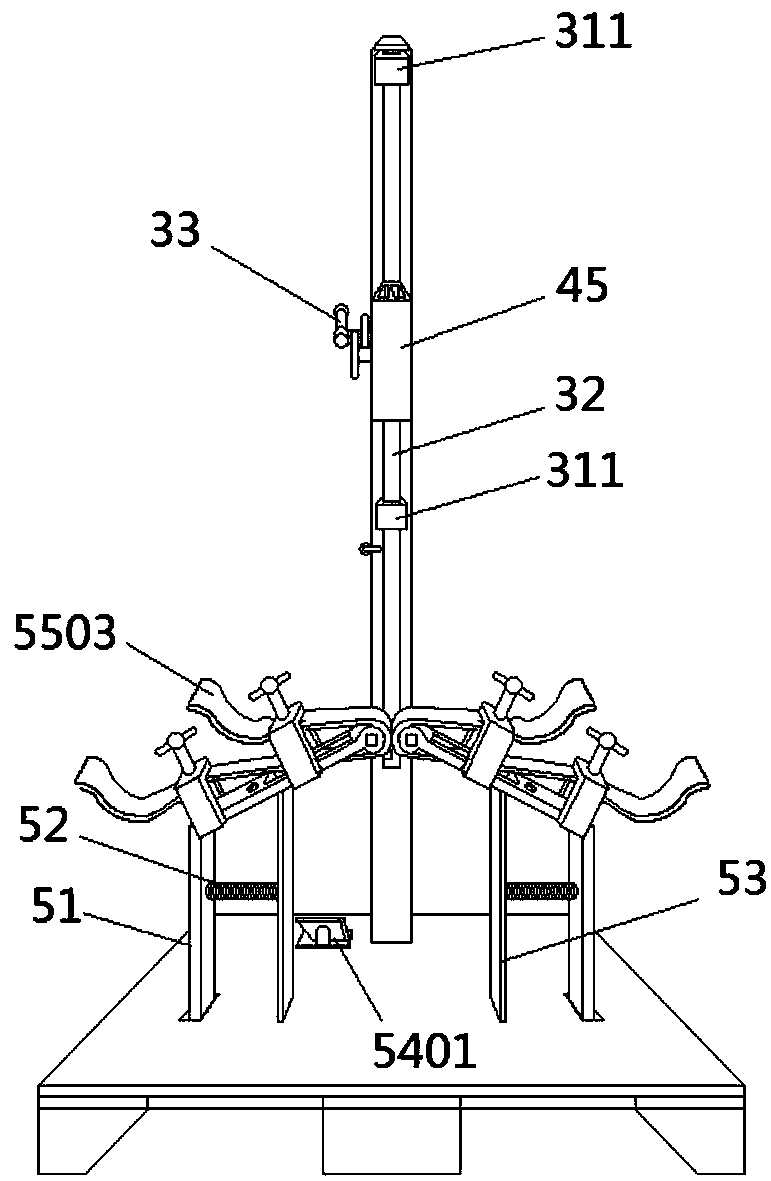

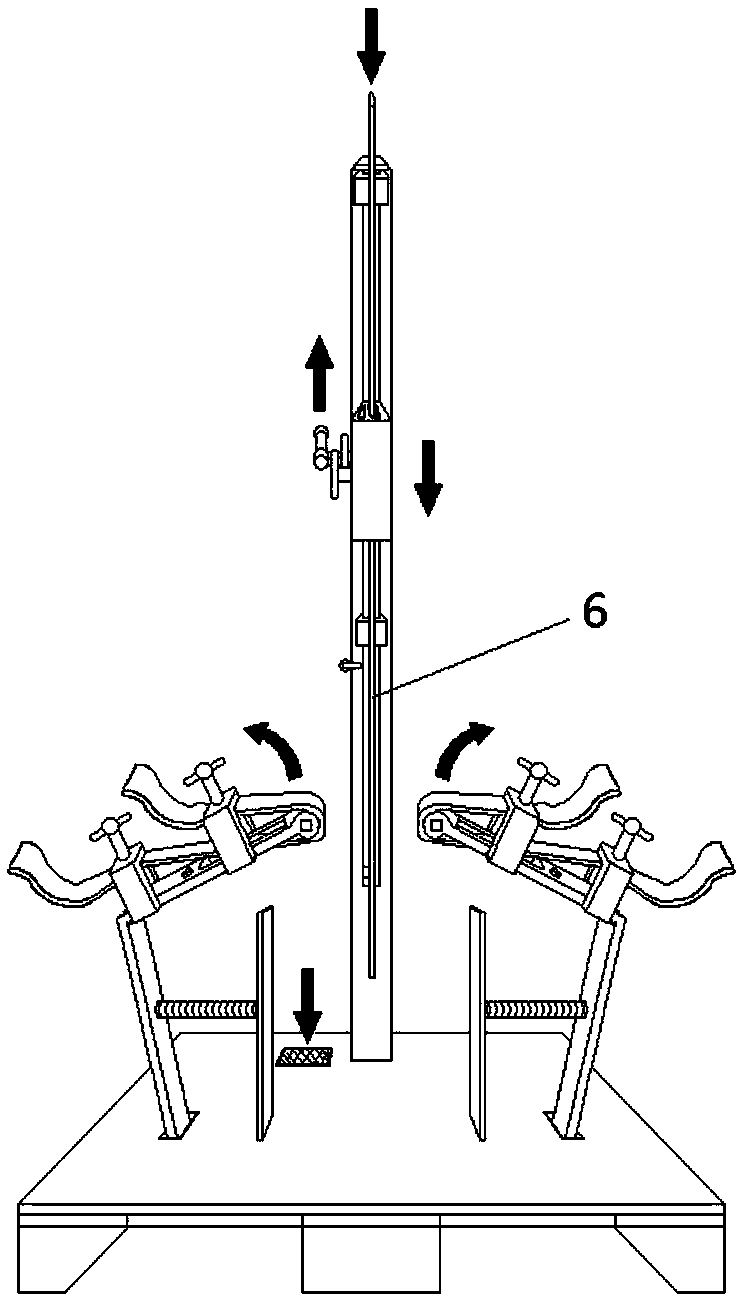

Lever lifting type copper bar busbar joint tinning device

The invention relates to the field of electrical machining equipment and discloses a lever lifting type copper bar busbar joint tinning device. The lever lifting type copper bar busbar joint tinning device comprises a base, a tin melting mechanism, a lever type copper bar lifting mechanism, a copper bar fixing mechanism and a copper bar wiping mechanism. The lever type copper bar lifting mechanism comprises a main bearing pillar, a lifting type main supporting frame and a lever type lifting adjusting mechanism. The main bearing pillar is vertically arranged on the base, and the lifting type main supporting frame is fixed in a clamping groove of the main bearing pillar. The lever type lifting adjusting mechanism comprises a lifting operation lever, a fulcrum of the lifting operation lever is connected to the main bearing pillar in a pivotal manner, and the tail end of the lifting operation lever is connected to the lifting type main supporting frame in a pivotal manner. The copper bar fixing mechanism is fixed to the lifting type main supporting frame. The tin welding mechanism is arranged on the base. By means of the lever lifting type copper bar busbar joint tinning device, tinning work can be semi-automatically conducted on a copper bar busbar joint, the work efficiency is high, the tinning effect is good, safety is good, in addition, the manufacturing cost is low, and popularization is facilitated.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

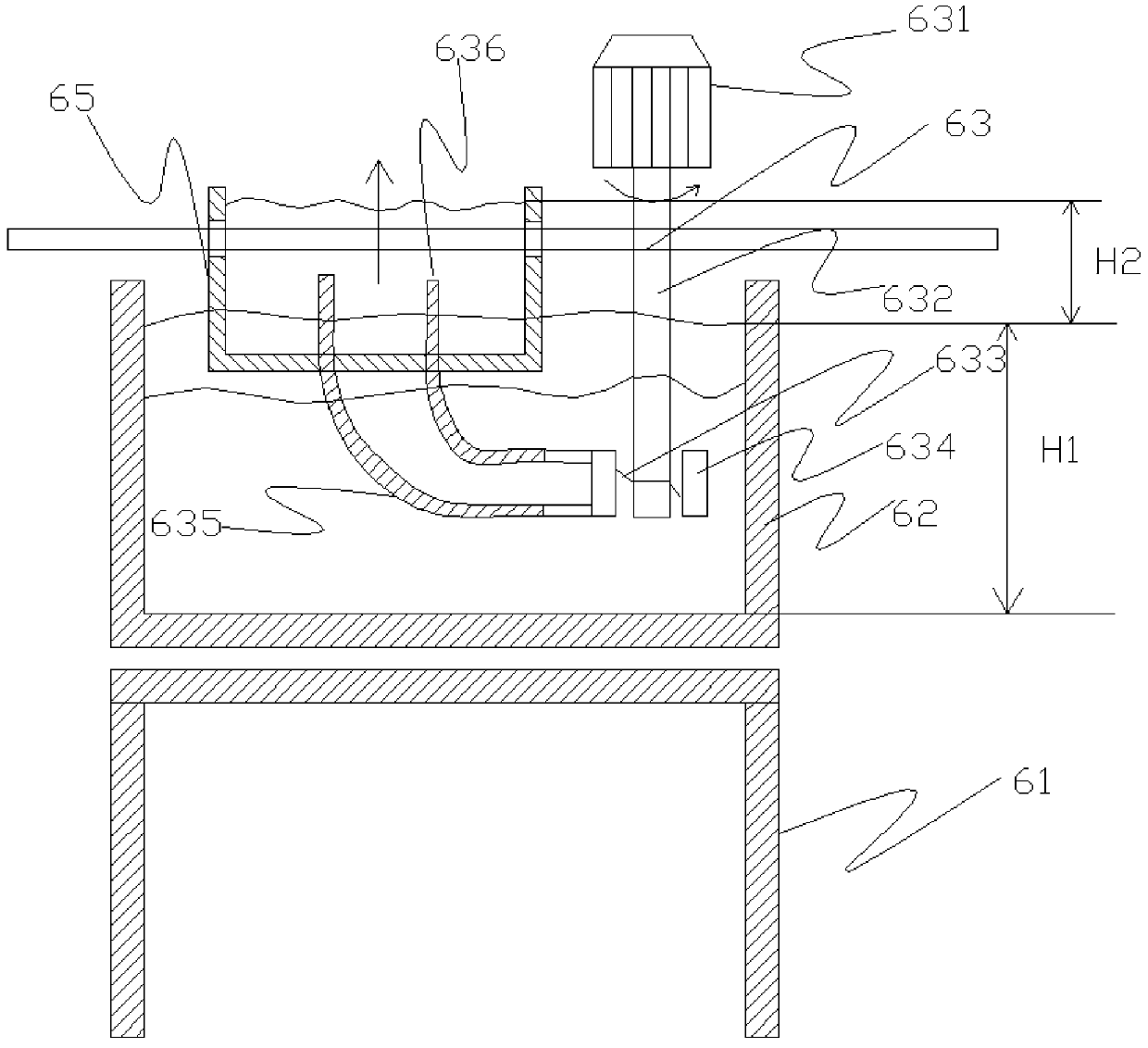

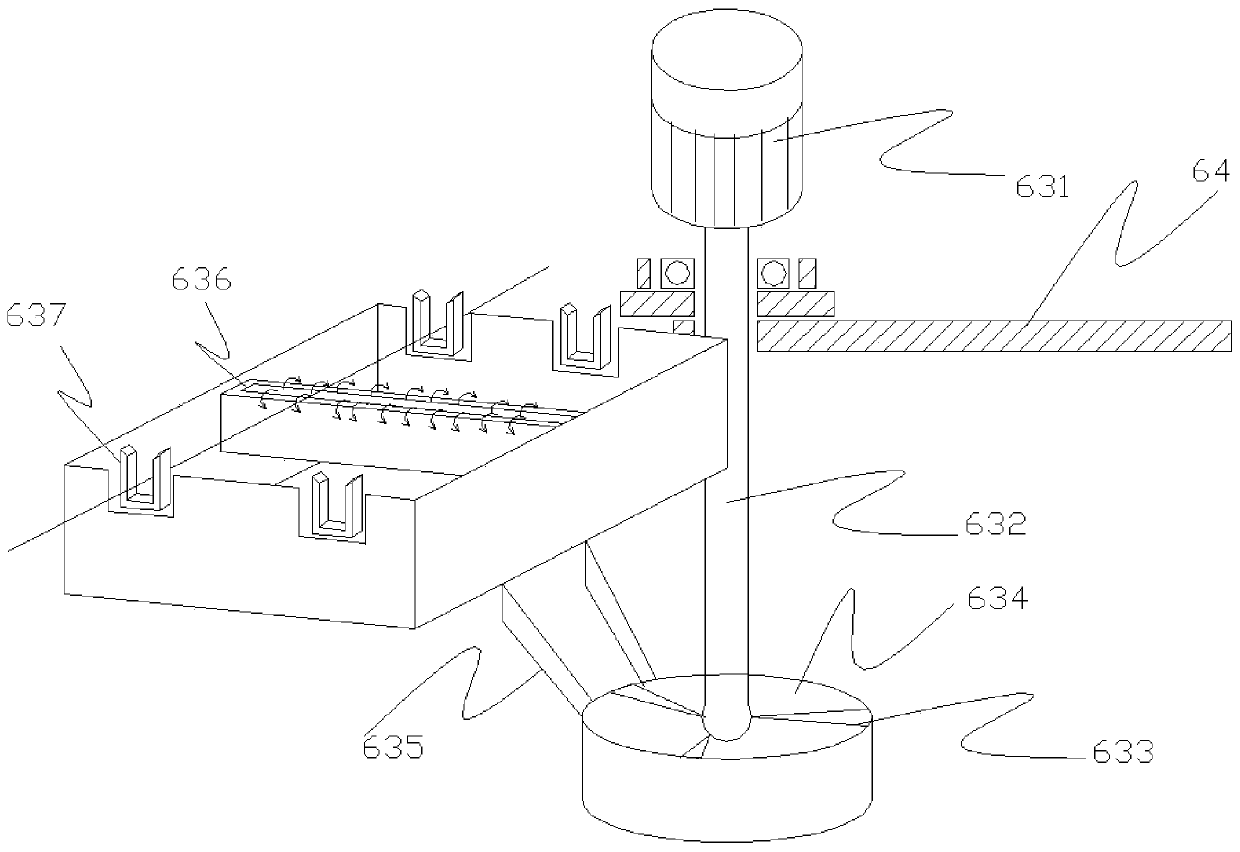

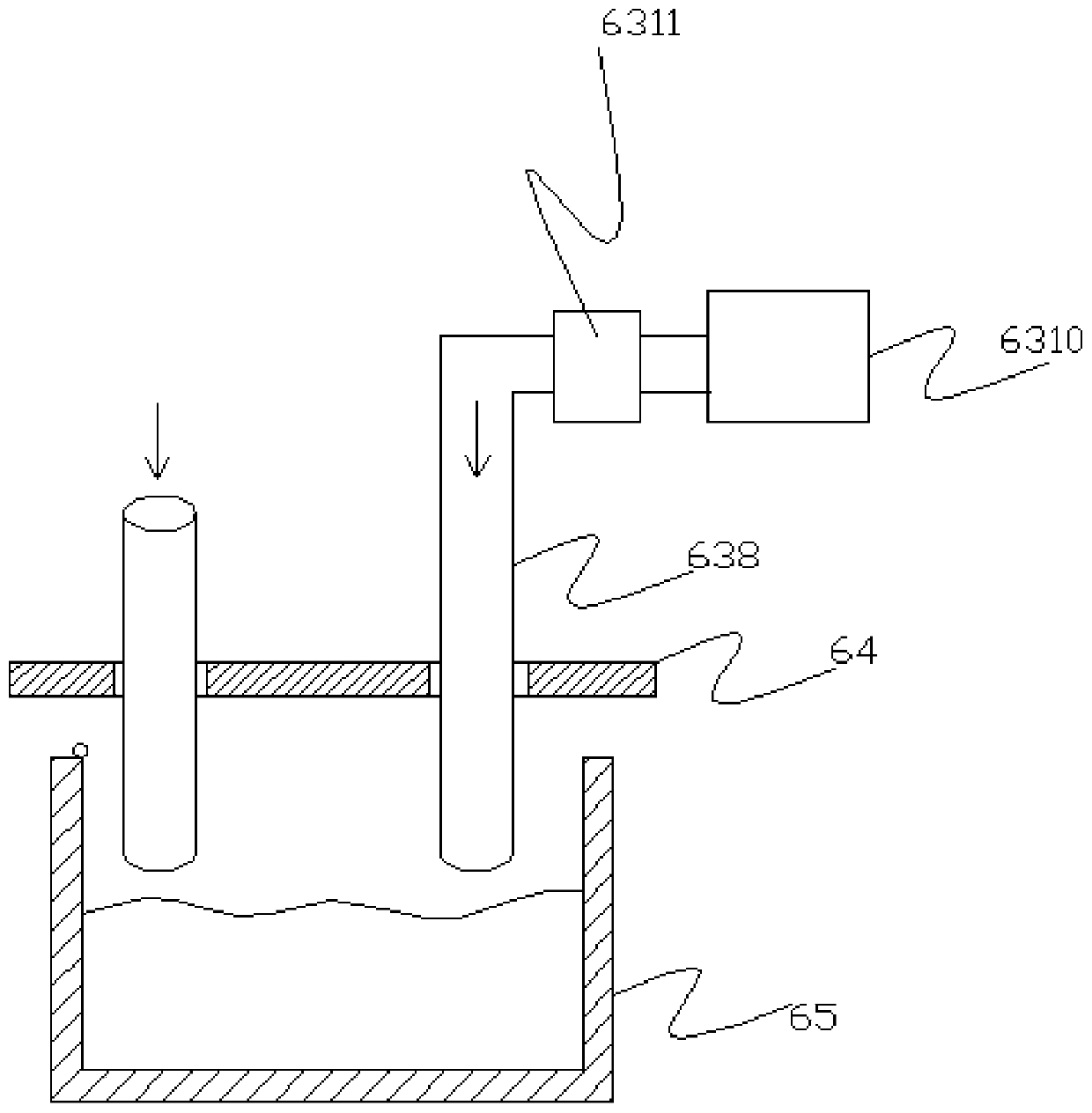

Tin furnace with liquid level lifting device, high-speed tinning machine and method

InactiveCN109972069ARaise the liquid levelReduce contact widthHot-dipping/immersion processesTinningCopper wire

The invention discloses a tin furnace with a liquid level lifting device, a high-speed tinning machine and a method. The tin furnace with the liquid level lifting device comprises a rack, a tin liquidbath and the liquid level lifting device. The high-speed tinning machine comprises a pay-off device, a guiding device, an acid pickling device, an ultrasonic cleaning device and a high-temperature annealing and drying device. The high-speed tinning machine further comprises a take-up device. The method is applied to the tin furnace with the liquid level lifting device and comprises the steps thata copper wire straightly passes through the tin furnace; and the liquid level lifting device works, the liquid level of the tin liquid bath is lifted to a liquid level lifting area, so that tin plating is conducted on the surface of the copper wire. By means of the tin furnace with the liquid level lifting device, the high-speed tinning machine and the method, the liquid level of tin liquid can be lifted; the copper wire can straightly passes without turning; the contact width of the tin liquid is decreased, the resistance is small, and the production speed can be guaranteed; the production cost is lowered; the tin furnace and the high-speed tinning machine have the advantages of being stable in operation, good in tin plating quality and long in service life; and the method is simple in procedure and good in tin plating effect.

Owner:珠海蓉胜电子材料研究院有限公司

A neutral tin plating additive

The invention discloses a neutral tin-plating addition agent. The neutral tin-plating addition agent is characterized by being prepared from the following raw materials in percentage by weight: 20%-30% of a complexing agent, 1%-3% of a wetting agent, 1%-5% of a surfactant, 10%-20% of a pH regulator and the balance of water. According to the neutral tin-plating addition agent, dangerousness and pollution caused by an acidic addition agent in the prior art are avoided, stable performance can be maintained at different temperatures, the storage life of products is prolonged, the stability of tin-plating liquid containing the neutral tin-plating addition agent is good while the uniform plating capability and the penetration capability are ensured, and a good tin-plating effect can be realizedwithin the large electroplating temperature range.

Owner:广东比格莱科技有限公司

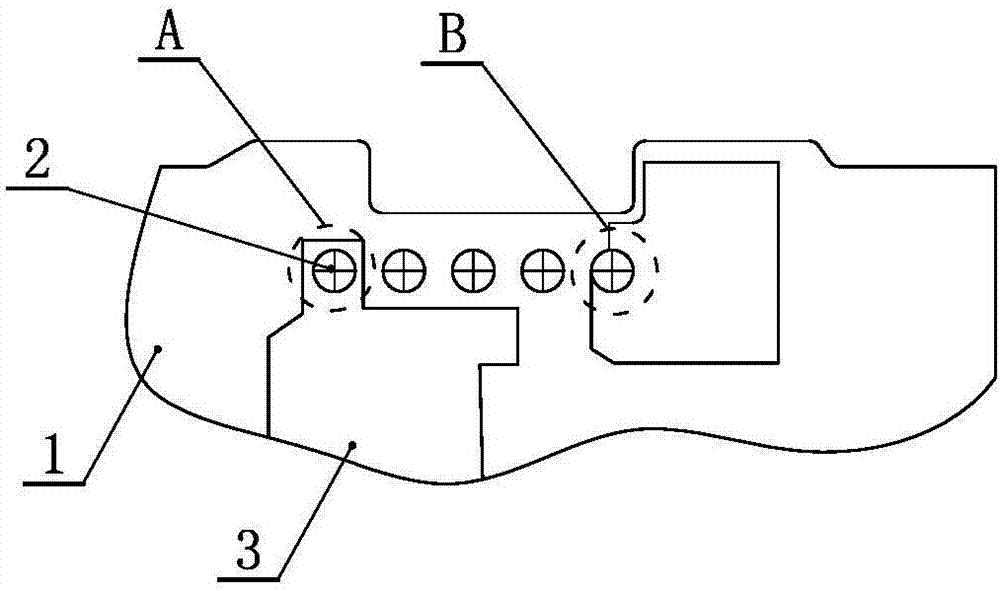

Battery connector for solving poor welding, and manufacturing method thereof

InactiveCN107172811AReduce heat gainGood tinning effectPrinted circuit assemblingLine/current collector detailsCopper platingEngineering

The invention discloses a battery connector for solving poor welding, and a manufacturing method thereof. The battery connector comprises a PCB, wherein copper foil is arranged between Pins and the PCB, the copper foil outside Pin jacks is line-shaped, one end of the line-shaped copper foil is in contact with each Pin, and the rest part of the copper foil is attached to and fixed on the PCB. The manufacturing method comprises the steps of: S1, drilling through holes / blind holes in the PCB, wherein part of the through holes serve as the Pin jacks; S2, plating copper to form in-hole copper foil; S3, plating copper to form outer-hole copper foil; S4, and inserting the Pins into the Pin jacks subjected to copper plating. According to the battery connector and the manufacturing method thereof, the area of the copper foil is reduced while other parts remain unchanged, and the original surface-type copper foil is changed into the line-shaped copper foil, thus the reduction of heat absorbed by the cooper foil in a welding region is realized, the tin soldering effect is improved, and the welding quality is ensured. That is, the large copper foil area in the welding region is reduced to decrease the heat absorbed by the cooper foil, the absorption ability of the copper foil is decreased when the area of the copper foil is reduced, and the heat dissipation of the Pins welded on the connector is slowed down, thereby achieving the effect of satisfying the tin soldering requirement.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

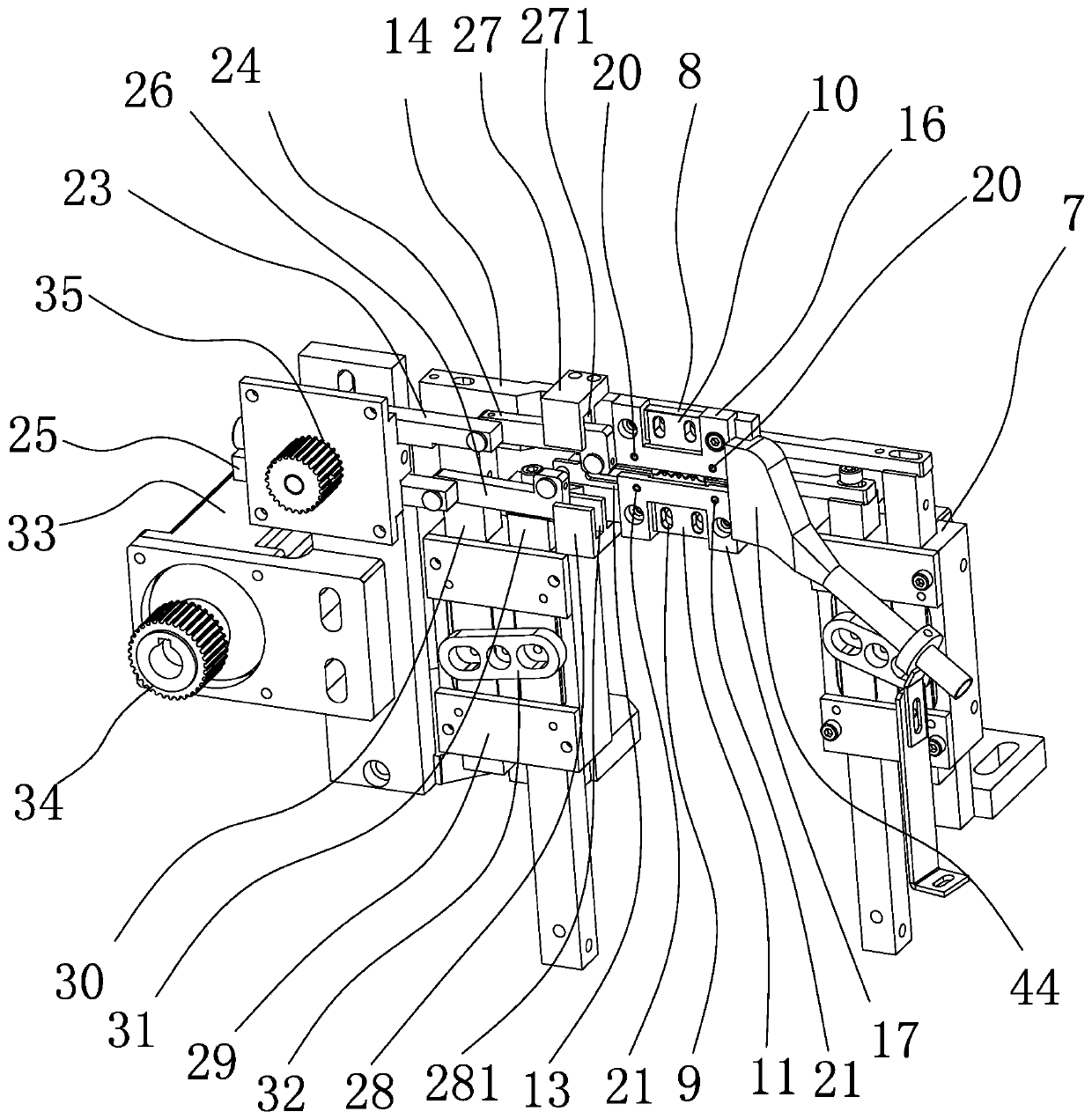

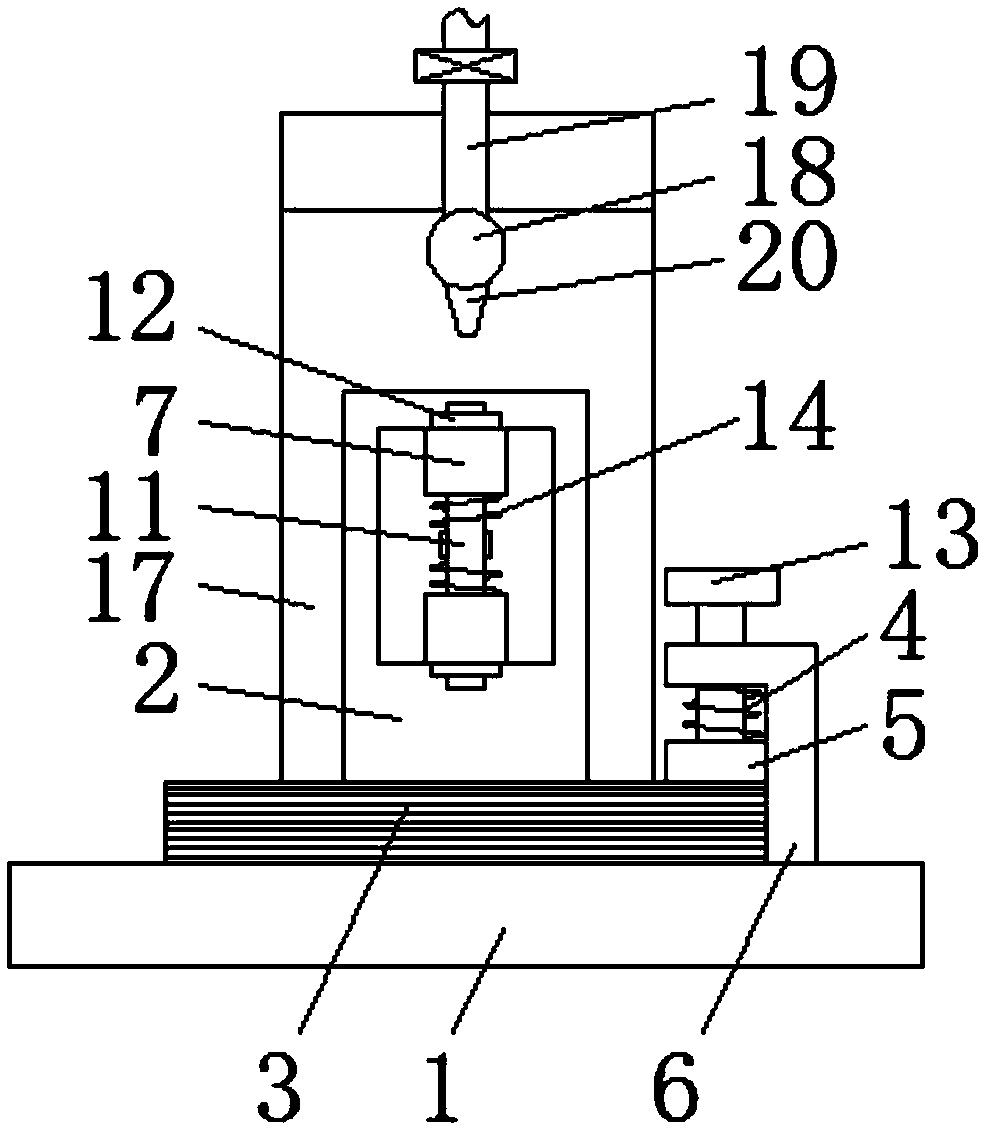

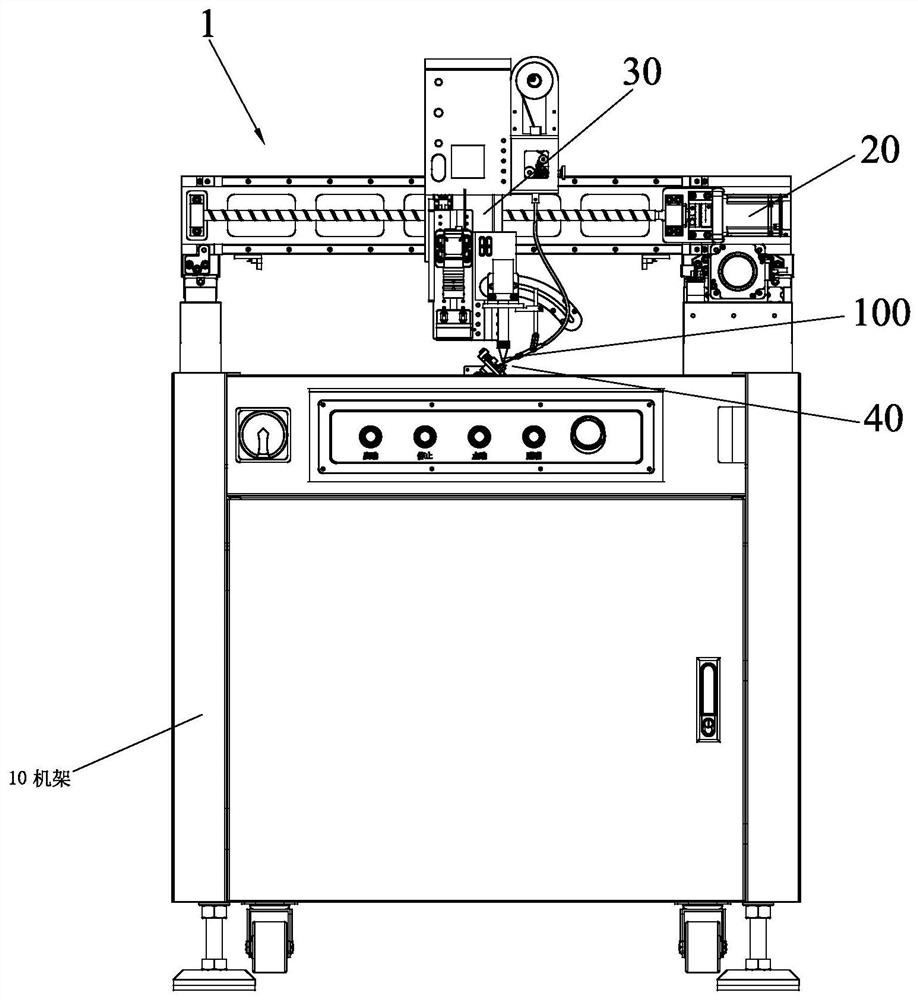

Soldering iron tin soldering equipment

PendingCN112191974AReduce use costReduce maintenance costsSoldering ironMetal working apparatusCamera moduleMaterials science

The invention discloses soldering iron tin soldering equipment which comprises a rack, an XY-axis moving module, a soldering iron tin soldering mechanism and a positioning and rotating mechanism. Thesoldering iron tin soldering mechanism comprises a module fixing plate, a Z-axis linear module, a soldering iron tin soldering assembly and a camera module. The positioning and rotating mechanism is arranged on a rack working table below the soldering iron tin soldering mechanism. The Z-axis linear module is arranged on the XY-axis moving module. The soldering iron tin soldering assembly is arranged on the Z-axis linear module, thus the soldering iron tin soldering assembly can move in the XYZ-axis direction in a reciprocating manner, the camera module recognizes and positions a product, and the soldering iron tin soldering assembly carries out preheating and tin soldering on the product. The positioning and rotating mechanism comprises a rotating device and a product positioning jig arranged at the rotating end of the rotating device. The rotating device drives the product positioning jig to rotate. According to the equipment, a soldering iron tin soldering technology is adopted, thetechnology is mature, the tin soldering position is precise, damage to the product is avoided, the product machining quality can be ensured, the product yield is increased, and the production efficiency is improved.

Owner:厦门柔性电子研究院有限公司 +2

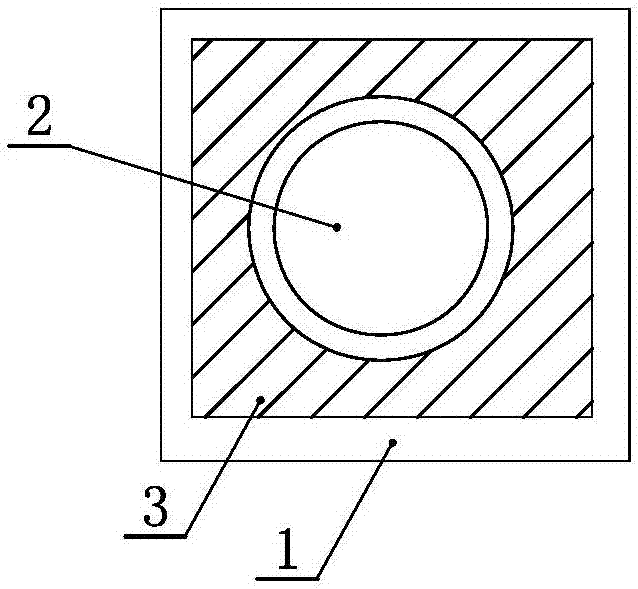

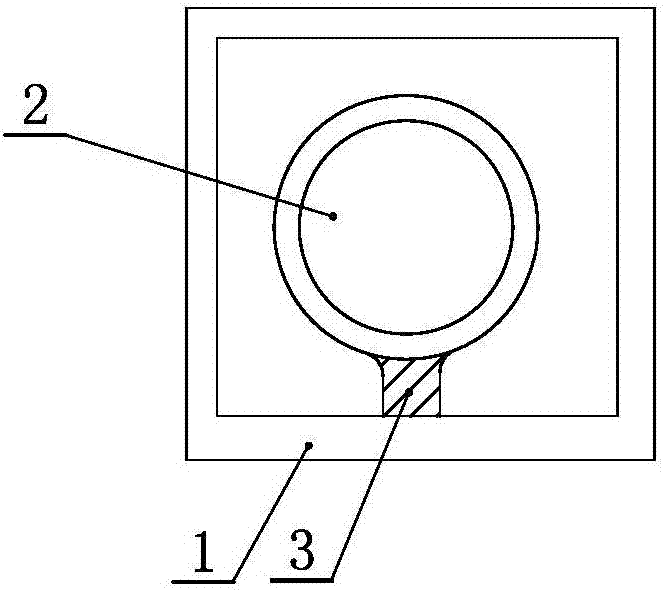

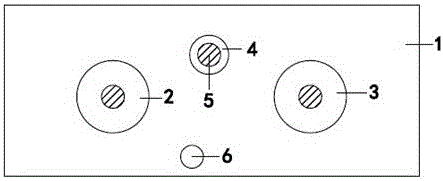

Tinning guide wheel

InactiveCN106435426AEasy to produceNot easy to damageHot-dipping/immersion processesTinningEngineering

The invention discloses a tinning guide wheel. The tinning guide wheel comprises a fixed plate, a fixed wheel, a first rotating wheel, a second rotating wheel and three bearings. The fixed plate comprises a hole. The three bearings penetrate through the circle center of the first rotating wheel, the circle center of the second rotating wheel and the circle center of the fixed wheel correspondingly. The circle center of the first rotating wheel is flush with the circle center of the fixed wheel, and the radius of the first rotating wheel is equal to the radius of the fixed wheel. The distance of the straight line where the circle center of the first rotating wheel and the circle center of the fixed wheel are located to the circle center of the second rotating wheel is smaller than the sum of the radius of the first rotating wheel and the radius of the second rotating wheel. According to the tinning guide wheel provided by the invention, compared with a traditional guide wheel, the second rotating wheel is additionally arranged, and a tensioning effect is achieved; in order to save materials, the radius of the second rotating wheel is smaller than that of the first rotating wheel; and meanwhile, the tinning guide wheel is practical, durable, easy to manufacture and produce and not prone to being damaged.

Owner:陈富强

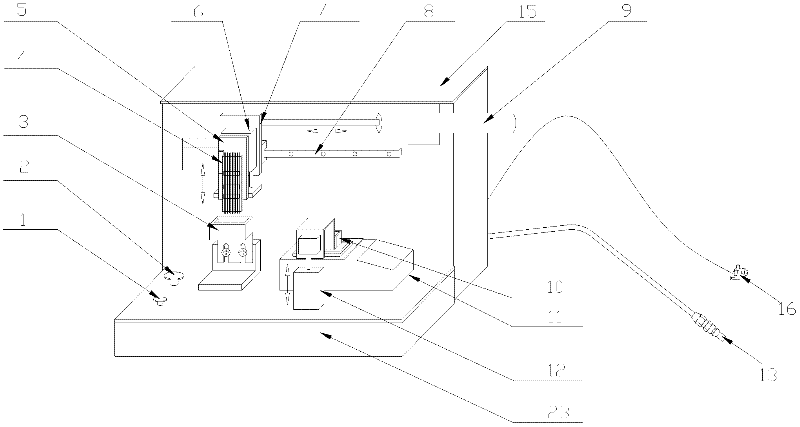

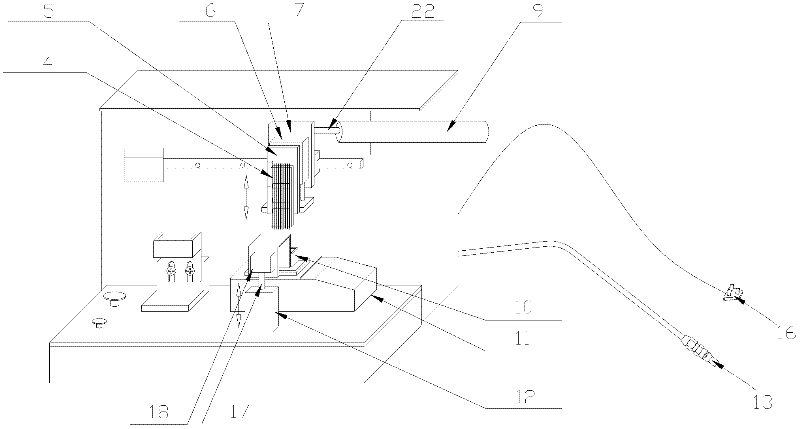

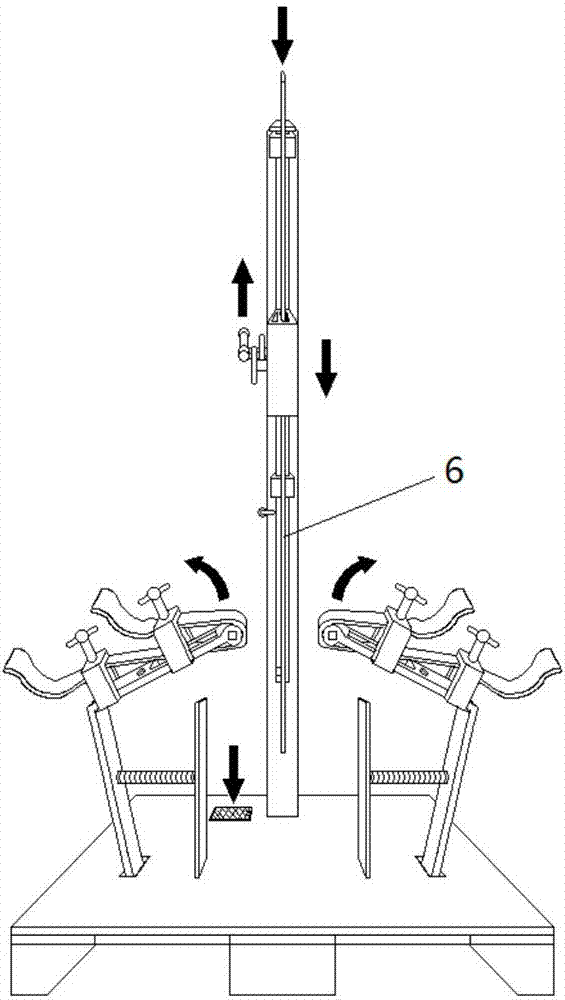

Semi-automatic wicking machine

InactiveCN102259223BGuaranteed levelConsistent immersion tin depthHot-dipping/immersion processesWire rodSemi automatic

The invention discloses a semi-automatic wicking machine comprising a workbench, a fixing plate and a tin melting furnace. The semi-automatic wicking machine is characterized by further comprising a wicking groove, a soldering flux groove, a wiring plate, a guide rail, a first up-and-down moving device, a horizontal driving device and a second up-and-down moving device. The wicking groove is arranged above an opening of the tin melting furnace, the first up-and-down moving device is connected with the wicking groove, the soldering flux groove is arranged above the workbench, the second up-and-down moving device is connected with the wiring plate, the back end of the second up-and-down moving device is connected with the guide rail arranged on the fixing plate, and the horizontal driving device arranged on the fixing plate is connected with the second up-and-down moving device. The invention solves the problem that woven flare opening and bulging usually generate, the wicking length isinconsistent, and the sizes of finished produces are unstable due to the hard guarantee of the appearance and the quality of products because wire rods are wicked manually in prior art, and provides a semi-automatic wicking machine with unity in wicking, order appearance and good size consistency.

Owner:雷特威连接系统(苏州工业园区)有限公司

A kind of organometallic solder protection film and preparation method thereof

ActiveCN106413275BImprove the convenience of appearance visual inspectionGood tinning effectDouble resist layersNon-metallic protective coating applicationTinningVisual inspection

The invention provides an organic metal solder protection film and its preparation method. The new surface treatment method is an innovative process technology between organic solder protection film and metallized surface treatment, that is, to create a layer of physical isolation protection layer , the protective layer is composed of a main plating layer and an organic protective layer, the main plating layer includes silver metal and organic metal, the main plating layer is located on the surface of the circuit board, and the organic protective layer is located on the surface of the main plating layer. This organometallic solder protection film not only has all the properties of OSP film, but also has the surface treatment performance of type chemical silver. Giovanni effect.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Lead-free solder environmental-protection scaling powder used for soldering capacitor with film adhered on surface

ActiveCN101745760BHigh activityReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh surfaceSurface-active agents

The invention discloses a lead-free solder environmental-protection scaling powder used for soldering a capacitor with a film adhered on a surface, which contains 4-17 percent of rosin and derivates thereof, 3-9 percent of organic acid activating agent, 1.5-3.5 percent of diethylamine hydrochloride and / or cyclohexylamine hydrochloride, 0.3-0.7 percent of surface active agent and 70-90 percent of dissolvant. Firstly, the rosin and the derivate thereof, the organic acid activating agent and the diethylamine hydrochloride and / or the cyclohexylamine hydrochloride are added to the dissolvant to bestirred evenly; then the surface active agent is added to be continuously stirred evenly; and finally, the solution is filtered by gauze so as to remove solid impurities, and finally, light yellow clear and transparent liquid is obtained. The solder has the advantages of strong wetting power and superior solderability and can improve the soldering performance of the lead-free solder; the solderedsoldering tin has even spreading, bright and smooth surface, high surface insulation resistance and superior electrical property and meets the environmental protection requirements.

Owner:XIAMEN FARATRONIC

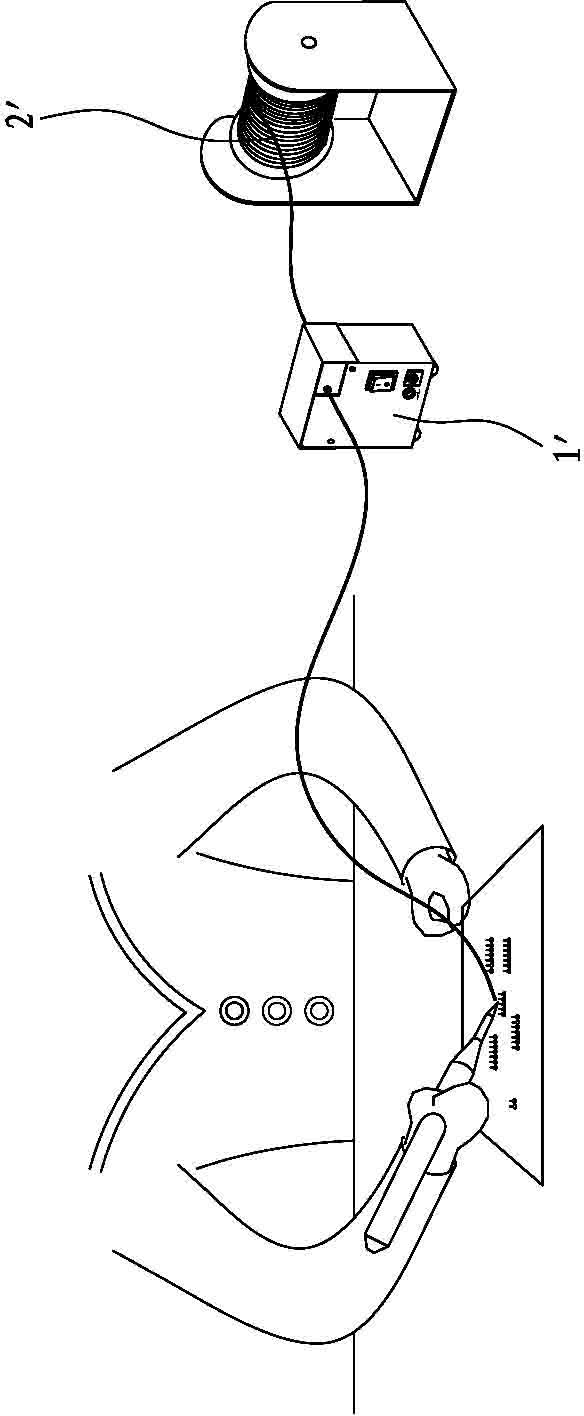

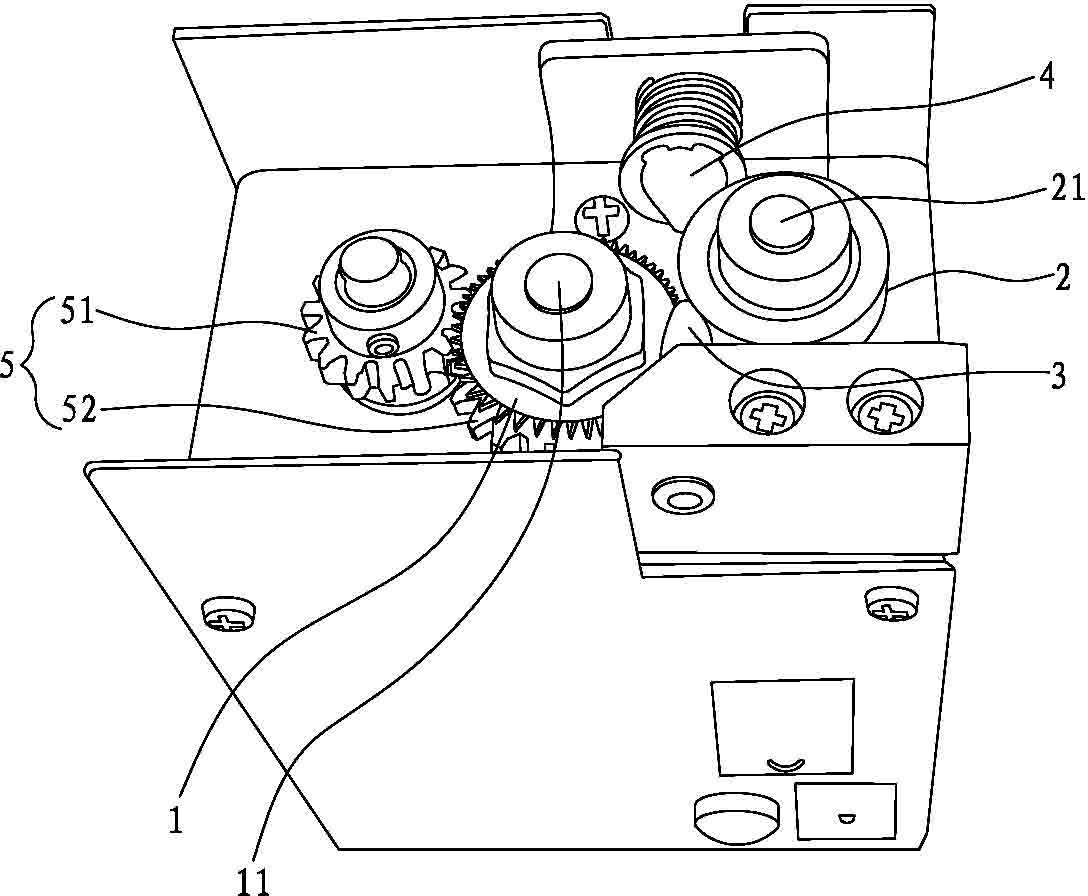

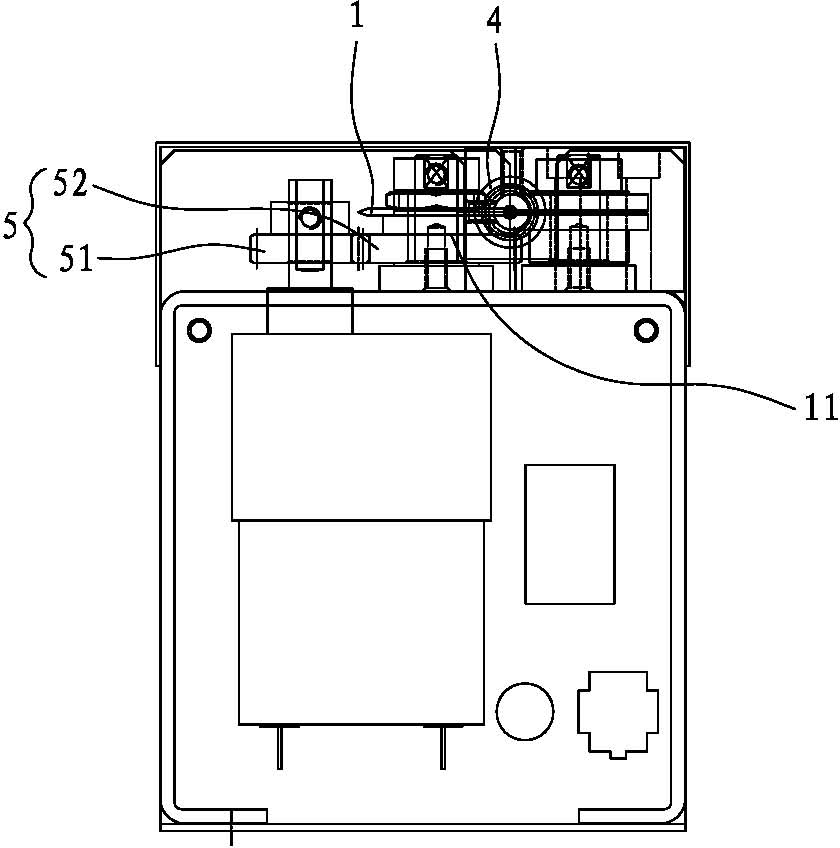

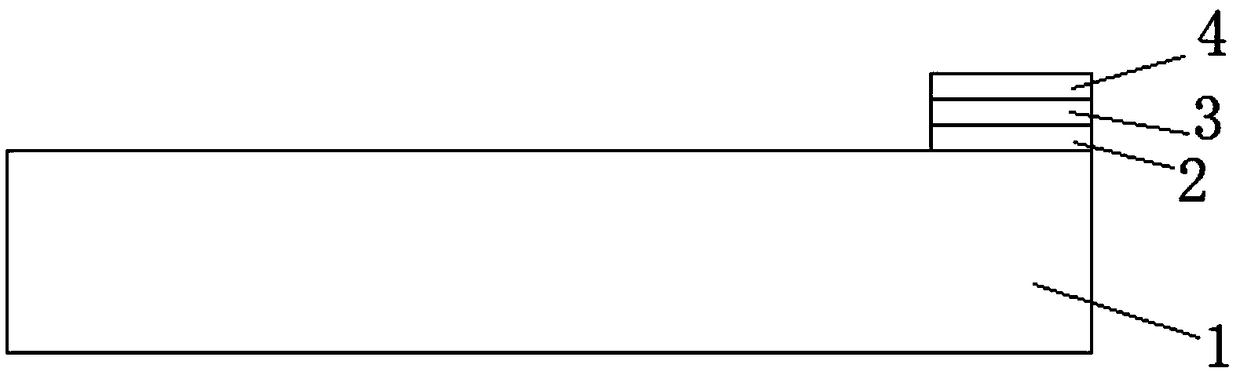

Wire riveting part tin adding device

InactiveCN106425006AShort heating timeWon't hurtHeating appliancesSolder feeding devicesMechanical engineeringTin

The invention belongs to the field of connectors. A wire riveting part tin adding device comprises a tin paste dispensing device, a heating device and a die. The wire riveting part tin adding device is characterized in that the tin paste dispensing device comprises a base, a supporting frame fixed to the base, a sliding table arranged on the supporting frame and a tin dispensing head fixed to the sliding table; a first sliding rail moving left and right is horizontally arranged on the supporting frame, and the sliding table is arranged on the first sliding rail; a second sliding rail moving up and down is arranged on the sliding table, the tin dispensing head is arranged on the second sliding rail, and the first sliding rail and the second sliding rail are driven through a stepping motor; and the heating device comprises a conveying mechanism, a motor controlling running of the conveying mechanism, and a heater providing heat, and the heater is located on the side wall of the conveying mechanism. According to the wire riveting part tin adding device, tin feeding is stable, the production efficiency is high, and the defective percentage is low.

Owner:HUIZHOU ZHENGHE ELECTRONICS

Electromagnetic maintaining type tin wiping device

ActiveCN112645582AEasy to adjustGood tinning effectGlass transportation apparatusMagnet coilMagnetic tension force

The invention discloses an electromagnetic maintaining type tin wiping device which comprises an electromagnetic device, an electric control assembly, a transition roller and graphite for wiping tin on the roller surface of the transition roller. The electromagnetic device comprises a magnetic rod and an electromagnetic coil; the magnetic rod is arranged in a magnetic field after the electromagnetic coil is electrified; when the magnetic force of the electromagnetic coil is changed, the magnetic rod moves in the direction perpendicular to the transition roller; the top end of the magnetic rod is fixedly connected with graphite; graphite is attached to the roller surface of the transition roller under the action of electromagnetic force on the magnetic rod; the electric control assembly comprises a wire and a power supply; the power supply is electrically connected with the electromagnetic coil through a wire; and a regulator for regulating the magnitude of circuit current is mounted on the wire. According to the tin wiping device, the regulator is arranged to change the magnitude of the circuit current, then the magnitude of the magnetic force of the electromagnetic coil is changed, the height of the magnetic rod is adjusted, graphite on the magnetic rod is attached to the surface of the transition roller, tin wiping is conducted, adjustment is convenient, and the tin wiping effect is good.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Novel optical heater and preparation method thereof

ActiveCN109375400AReduce heating powerFirmly attachedTransparent/reflecting heating arrangementsNon-linear opticsElectrical resistance and conductanceLow temperature curing

The invention discloses a novel optical heater and a preparation method thereof. The novel optical heater comprises ITO conductive glass, wherein two opposite sides of the ITO conductive glass are respectively provided with an electrode strip mechanism; the electrode strip mechanism comprises an A-type low-temperature curing conductive copper glue, a B-type low-temperature curing conductive copperglue and a tin-plated white copper sheet, wherein the A-type low-temperature curing conductive copper glue, the B-type low-temperature curing conductive copper glue and the tin-plated white copper sheet are fixed on the surface of the ITO conductive glass from bottom to top; the problems that when a prior electrode strip is solidified, the required temperature is high, the coating layer of the heating glass is easy to change, the square resistance value is shifted, the square resistance value is increased, the heating power of the heating glass is reduced, and the heating effect is insufficient to the effect of the expected design; and meanwhile, the deviation condition of the square resistance value has no effective linear rule for carrying out pre-judgment which seriously affect the quality reliability of the product are solved.

Owner:中航华东光电有限公司

High-reliability hybrid circuit printed board and production method thereof

InactiveCN110856369AGuaranteed reliabilityEnsure solderableElectrical connection printed elementsNon-metallic protective coating applicationBonding processHemt circuits

The invention discloses a high-reliability hybrid circuit printed board, which is provided with a pattern circuit area, a chip mounting area and a green oil assembly welding area, wherein the patterncircuit area is composed of a brazing area and a gold plating area, the brazing area is formed by bonding an insulating base material layer, a copper layer and an OSP film layer which are sequentiallyarranged in the direction from bottom to top, and the gold plating area is formed by bonding an insulating base material layer, a copper layer and a gold plating layer which are sequentially arrangedin the direction from bottom to top. The invention also discloses a production method of the printed board. The invention has the beneficial effects that thick gold is plated in a non-welding area toensure the reliability of gold wire bonding, OSP treatment is adopted for a brazing pad, the tin soldering property of the pad is ensured, the welding end of the printed board is free of a gold plating layer, gold removal is not required to be performed on the brazing pad, the bonding process and the brazing process are completely compatible, and printed board can be applied to high-reliability products; and the process difficulty of gold removal is effectively solved, the use amount of gold is reduced, the processing cost is reduced, and the welding end of the printed board is coated with OSP.

Owner:CHENGDU TIGER MICROWAVE TECH

Copper ecological tinplating water-based process material and tinplating method thereof

InactiveCN107460455AReasonable formulaUniform thicknessLiquid/solution decomposition chemical coatingTinningWater based

The invention discloses a copper ecological tinplating water-based process material, which is prepared from the following raw materials in percentage by mass: 0.1 to 3 percent of emulgator, 0.2 to 0.5 percent of dispersing agent, 1 to 3 percent of penetrating agent, 0.5 to 6 percent of organic acid, 0.2 to 8 percent of hexamethylenetetramine, 3 to 9 percent of stannous chloride, 0.3 to 5 percent of neutral salt, 1 to 11 percent of organic salt, and the balance pure water. According to the copper ecological tinplating water-based process material provided by the invention, a formula is reasonable, a direct-current power supply has no need to be added, a heating source is not needed, a copper piece to be plated is adopted as a cathode, and a tin ion of the copper ecological tinplating water-based process material is combined with the copper piece to be plated through an ion exchange manner by utilizing different electric potentials exited in the copper piece to be plated, so that a layer of compact tinplating layer with uniform thickness is formed on a surface of the copper piece to be plated, a tinplating effect is good, and the combination property and the service life of the product are effectively improved; and in addition, a tinplating method is concise in processing steps, easy to implement, high in tinplating efficiency, low in cost, energy-saving and environmentally-friendly, and beneficial to be widely popularized and applied.

Owner:东莞聚顺环保科技有限公司

A tinning device for gear-lifting bus bar joints

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

Novel optical heater and preparation method thereof

ActiveCN109375400BReduce heating powerFirmly attachedTransparent/reflecting heating arrangementsNon-linear opticsTinningCupronickel

The invention discloses a novel optical heater and a preparation method thereof. The novel optical heater comprises ITO conductive glass, and two opposite sides of the ITO conductive glass are respectively provided with electrode strip mechanisms; And the A-type low-temperature curing conductive copper glue, the B-type low-temperature curing conductive copper glue and the tin-plated copper sheet fixed on the surface of the ITO conductive glass; solve the problem that the traditional electrode strips need to be cured at a higher temperature, which is easy to make heating Changes in the coating layer of the glass lead to a deviation of the square resistance value, and the increase of the square resistance value reduces the heating power of the heater glass, and the heating effect is not as good as the expected design effect. At the same time, the deviation of the square resistance value has no effective linearity Prediction of the law seriously affects the quality and reliability of the product.

Owner:中航华东光电有限公司

A lever lifting type copper bar bus joint tinning device

The invention relates to the field of electrical machining equipment and discloses a lever lifting type copper bar busbar joint tinning device. The lever lifting type copper bar busbar joint tinning device comprises a base, a tin melting mechanism, a lever type copper bar lifting mechanism, a copper bar fixing mechanism and a copper bar wiping mechanism. The lever type copper bar lifting mechanism comprises a main bearing pillar, a lifting type main supporting frame and a lever type lifting adjusting mechanism. The main bearing pillar is vertically arranged on the base, and the lifting type main supporting frame is fixed in a clamping groove of the main bearing pillar. The lever type lifting adjusting mechanism comprises a lifting operation lever, a fulcrum of the lifting operation lever is connected to the main bearing pillar in a pivotal manner, and the tail end of the lifting operation lever is connected to the lifting type main supporting frame in a pivotal manner. The copper bar fixing mechanism is fixed to the lifting type main supporting frame. The tin welding mechanism is arranged on the base. By means of the lever lifting type copper bar busbar joint tinning device, tinning work can be semi-automatically conducted on a copper bar busbar joint, the work efficiency is high, the tinning effect is good, safety is good, in addition, the manufacturing cost is low, and popularization is facilitated.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

Lead-free solder low-smoke water-soluble tin spraying soldering flux

InactiveCN107553009AResidue reductionReduce pollutionPrinted circuit assemblingWelding/cutting media/materialsOrganic acidHalogen

The invention relates to lead-free solder low-smoke water-soluble tin spraying soldering flux. The lead-free solder low-smoke water-soluble tin spraying soldering flux is composed of, by weight, 0.5-10% of an organic acid activating agent, 1-5% of organic amine halogen acid salt, 40-70% of an nonionic surface active agent, 0.1-5% of a reducing agent, and the balance deionized water. The lead-freesolder water-soluble tin spraying soldering flux is reasonable in proportion, simple in manufacturing technique, good in wettability and weldability, little in smoke, easy to wash and low in ion contamination, and a tin surface is flat and bright.

Owner:湖北格志电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com