Method and device for cleaning and separating various components and parts and recycling tin from waste circuit boards

A technology for discarded circuit boards and components, applied in the field of comprehensive recycling of electronic waste resources, can solve the problems of low efficiency, long processing cycle, poor operation effect, etc., and achieve high quality, smooth surface, good tin removal and improvement The effect of the tin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

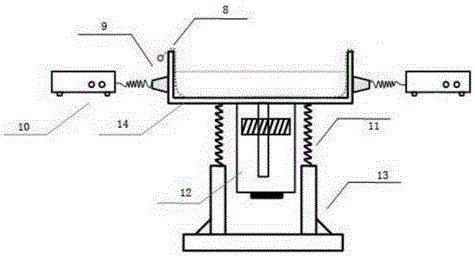

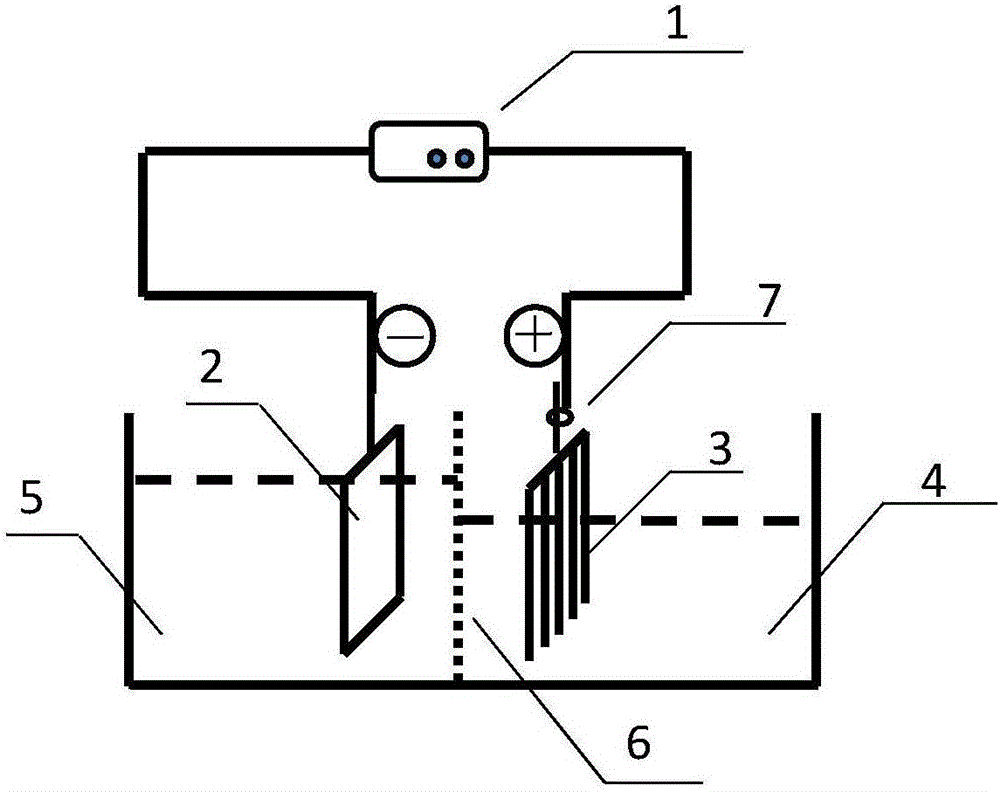

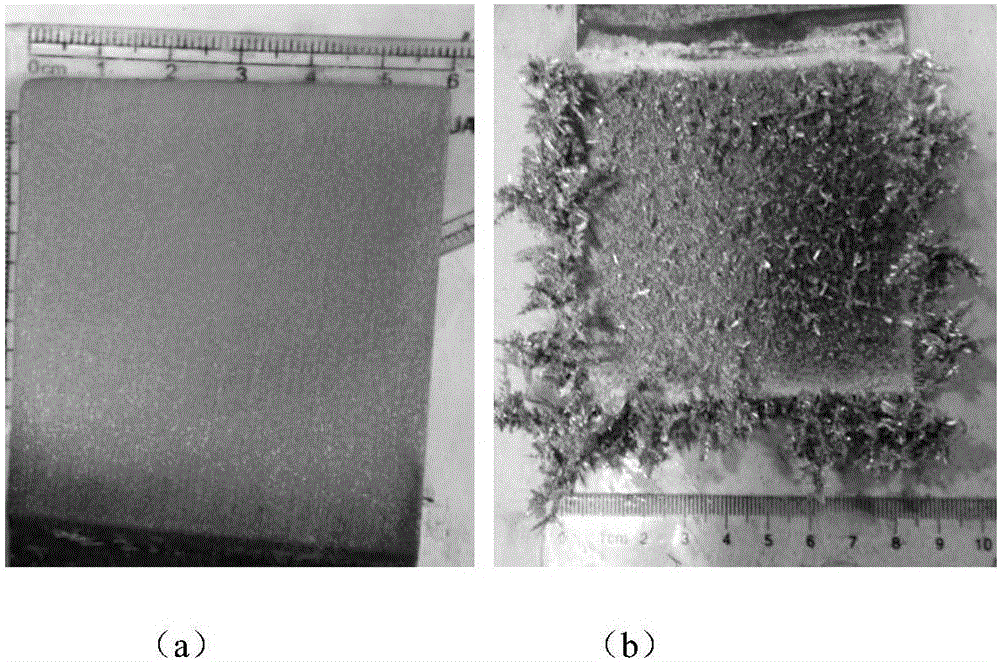

[0044]A method and device for cleaning and preprocessing waste circuit boards. Firstly, place the discarded circuit board in a desoldering device for oscillating desoldering treatment, and remove all the solder in the pins of components and through-holes on the discarded circuit board under certain conditions. After that, remove the components and light boards (bare boards) on the discarded circuit board after stripping the tin out of the tin stripping device. Mechanically or manually sort the components and light boards after tin stripping to obtain light boards, integrated circuit chips, capacitors, resistors and other components. The tin stripping liquid in the tin stripping device remains in the tin stripping tank and continues to be used for stripping tin from waste circuit boards. When the tin stripping liquid in the tin stripping tank reaches a certain condition (that is, when the concentration of stannous ions is greater than or equal to 100g / L, or the concentration o...

Embodiment 2

[0048] A method and device for cleaning and preprocessing waste circuit boards. Firstly, place the discarded circuit board in a desoldering device for oscillating desoldering treatment, and remove all the solder in the pins of components and through-holes on the discarded circuit board under certain conditions. After that, remove the components and light boards (bare boards) on the discarded circuit board after stripping the tin out of the tin stripping device. Mechanically or manually sort the components and light boards after tin stripping to obtain light boards, integrated circuit chips, capacitors, resistors and other components. The tin stripping liquid in the tin stripping device remains in the tin stripping tank and continues to be used for stripping tin from waste circuit boards. When the tin stripping liquid in the tin stripping tank reaches a certain condition, the tin stripping liquid is pumped into the "non-uniform electric field diaphragm electrodeposition" devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com