High-reliability hybrid circuit printed board and production method thereof

A hybrid circuit and production method technology, applied in printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of difficult operation, reduced solder joint strength, thick intermetallic compounds, etc., and achieves low process complexity. , The effect of improving product reliability and reducing reliability risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

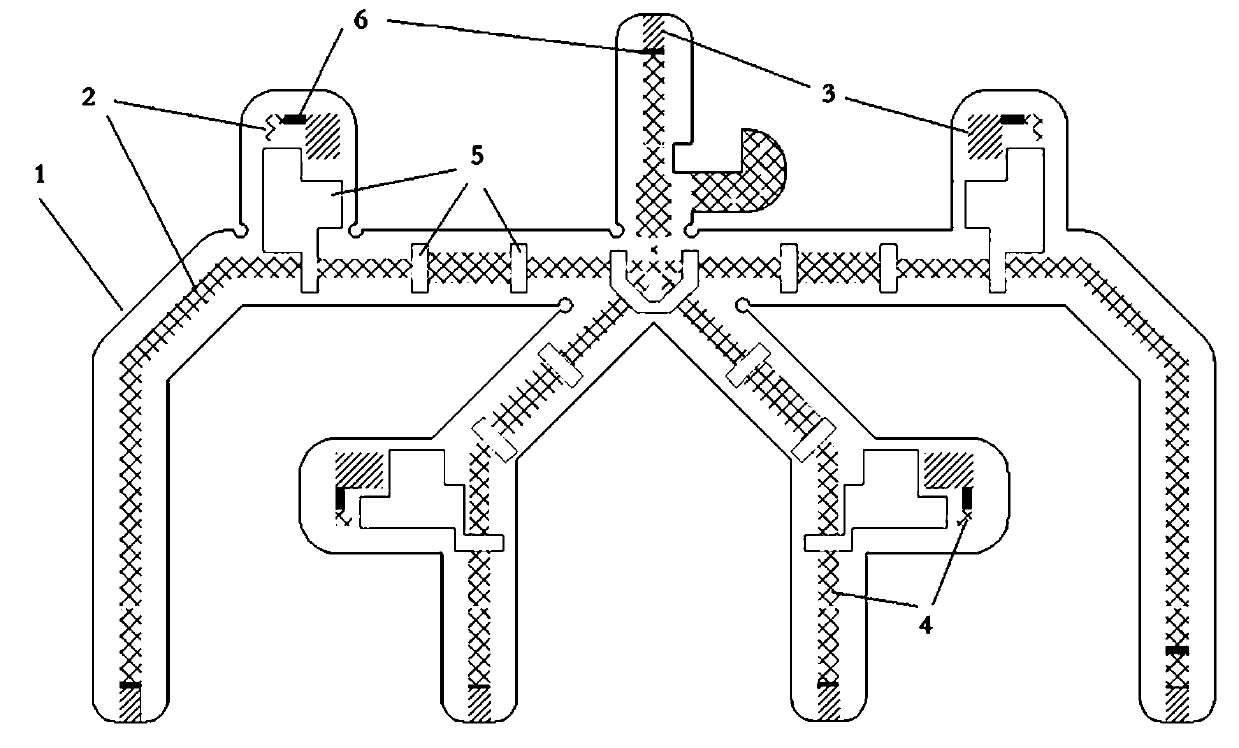

[0031] Such as figure 1 As shown, a high reliability hybrid circuit printed board has a graphic circuit area 2, a chip mounting area 5 and a green oil group soldering area 6, and the graphic circuit area is composed of a brazing area 3 and a gold-plated area 4,

[0032] The brazing area 3 is composed of an insulating substrate layer, a copper layer and an OSP film layer arranged in sequence from bottom to top and bonded together,

[0033] The gold-plated area 4 is composed of an insulating substrate layer, a copper layer and a gold-plated layer that are arranged sequentially from bottom to top and bonded together,

[0034] The chip mounting area 5 is a through hole that runs through the high-reliability hybrid circuit printed board,

[0035] The green oil group welding area 6 is composed of an insulating base material layer, a copper layer and a solder resist adhesive lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com