Neutral tin-plating addition agent

An additive and tin-plating technology, applied in the field of neutral tin-plating additives, can solve the problems of strong acidity and pollution of the plating solution, and achieve the effects of prolonging the storage period, good stability of the plating solution, and avoiding danger and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

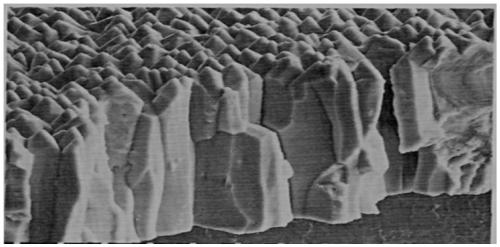

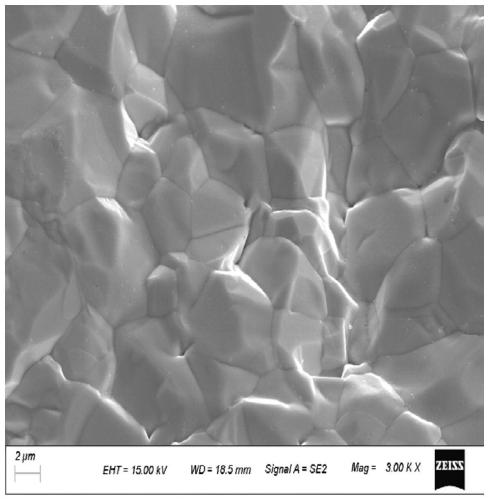

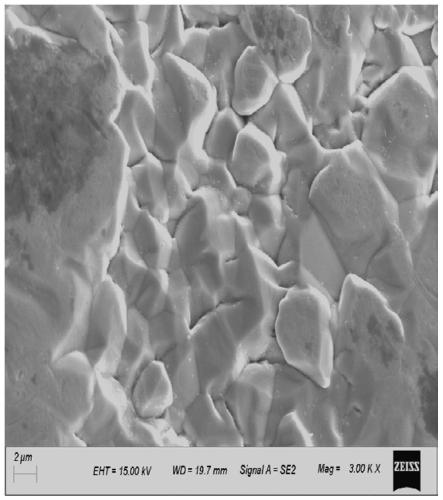

Image

Examples

preparation example Construction

[0065] In some preferred embodiments, taking the preparation of 1 kg of additive solution as an example, the preparation method of the neutral tin plating additive comprises the following steps: weighing complexing agent, wetting agent, and surfactant according to the proportion, and wetting Agent, surfactant, and complexing agent were added into 0.4kg of water, and after the pH regulator was added to adjust the pH of the solution to 6-8, water was added to make up to 1kg.

[0066] The second aspect of the present invention provides a tin plating solution, the preparation raw materials of which include: 30-50 mL / L of stannous methanesulfonate, 275-325 mL / L of the above-mentioned neutral tin plating additive, and water as a solvent.

[0067] In some preferred embodiments, the raw materials for the preparation of the tin plating solution include: 40 mL / L of stannous methanesulfonate, 300 mL / L of the above-mentioned neutral tin plating additive, and the solvent is water.

[0068]...

Embodiment 1

[0076] Embodiment 1 provides a kind of neutral tin-plating additive, prepares 1kg additive solution: take complexing agent 25.8%, wetting agent 1.5%, surfactant 3% by weight percentage, under room temperature, wetting agent, surface Activator and complexing agent are added into 0.4kg of water, and the pH regulator is added to adjust the pH of the solution to 7.5. The amount of the pH regulator is 16.5% of the solution weight, and water is added to make up to 1kg.

[0077]The complexing agent is organic acid and organic acid salt; the organic acid is sulfamic acid, and the organic acid salt is sodium gluconate; the weight ratio of sodium gluconate and sulfamic acid is 1:1.1.

[0078] The wetting agent is polyethylene glycol.

[0079] The surfactants are Plurafac SL-62 and Synfac 8216, and the weight ratio of Plurafac SL-62 and Synfac8216 is 2:1.

[0080] The pH regulator is ammonia water.

[0081] This example also provides a tin plating solution, prepare 1L tin plating solut...

Embodiment 2

[0083] Embodiment 2 provides a kind of neutral tin-plating additive, prepares 1kg additive solution: take complexing agent 25.8%, wetting agent 1.5%, surfactant 3% by weight percentage, under room temperature, wetting agent, surface Activator and complexing agent are added into 0.4kg of water, and pH regulator is added to adjust the pH of the solution to 7.2. The dosage of pH regulator is 16.0% of the solution weight, and water is added to make up to 1kg.

[0084] The complexing agent is organic acid and organic acid salt; the organic acid is sulfamic acid, and the organic acid salt is sodium gluconate; the weight ratio of sodium gluconate and sulfamic acid is 1:1.1.

[0085] The wetting agent is polyethylene glycol.

[0086] The surfactants are Plurafac S-305LF and Synfac 8120, and the weight ratio of Plurafac S-305LF and Synfac 8120 is 2:1.

[0087] Plurafac S-305LF in this application is produced by BASF and Synfac 8120 is produced by Milliken.

[0088] The pH regulator i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com