High heat-resistance organic solder ability preservative

An organic solder retention technology, applied in the field of high heat resistance organic solder retention flux, to achieve the effects of inhibiting oxidation, excellent tinning performance, and preventing discoloration and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

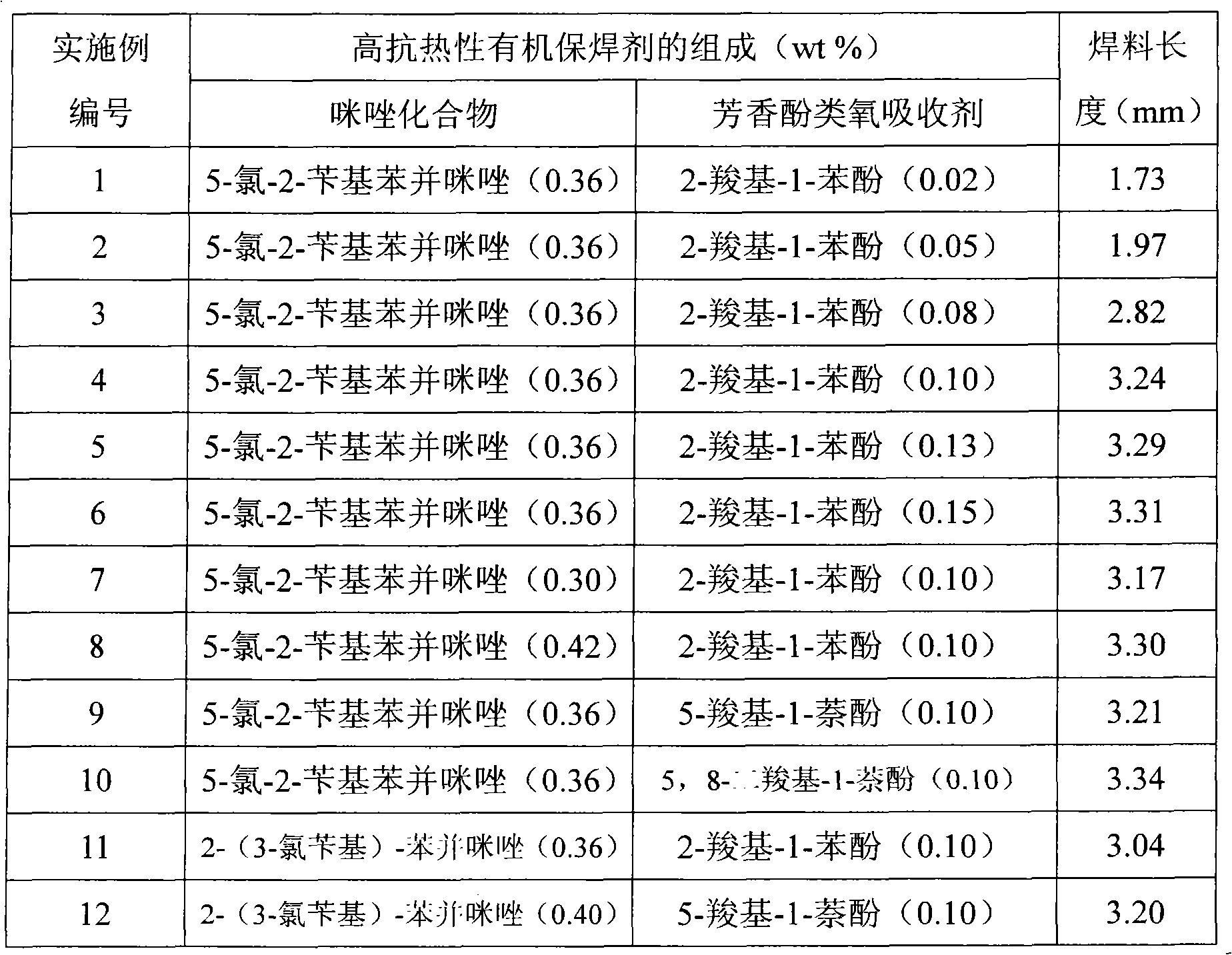

[0039] In Examples 1 to 12, except that the contents of imidazole compounds and aromatic phenol oxygen absorbers are as listed in Table 1, the composition of the high heat-resistant organic soldering flux is as follows: the content of acetic acid is 15.6%, The content of isopropanol is 1.2%, copper chloride is 0.1%, zinc acetate is 0.05%, and the balance is deionized water.

[0040] Preparation method: Add 2-carboxy-1-phenol and acetic acid into a clean enamel stirring tank at room temperature, add 5-chloro-2-benzylbenzimidazole during the stirring process, and after stirring for half an hour, the solid substance is basically Dissolve completely above, then add deionized water, isopropanol, copper chloride and zinc acetate in sequence, continue to stir for one hour until the solid raw materials are completely dissolved, mix evenly, stop stirring, stand and filter, and obtain a solution with a pH value of 3.40. Heat-resistant organic flux products. If the pH is lower than 2.5 ...

Embodiment 13~18

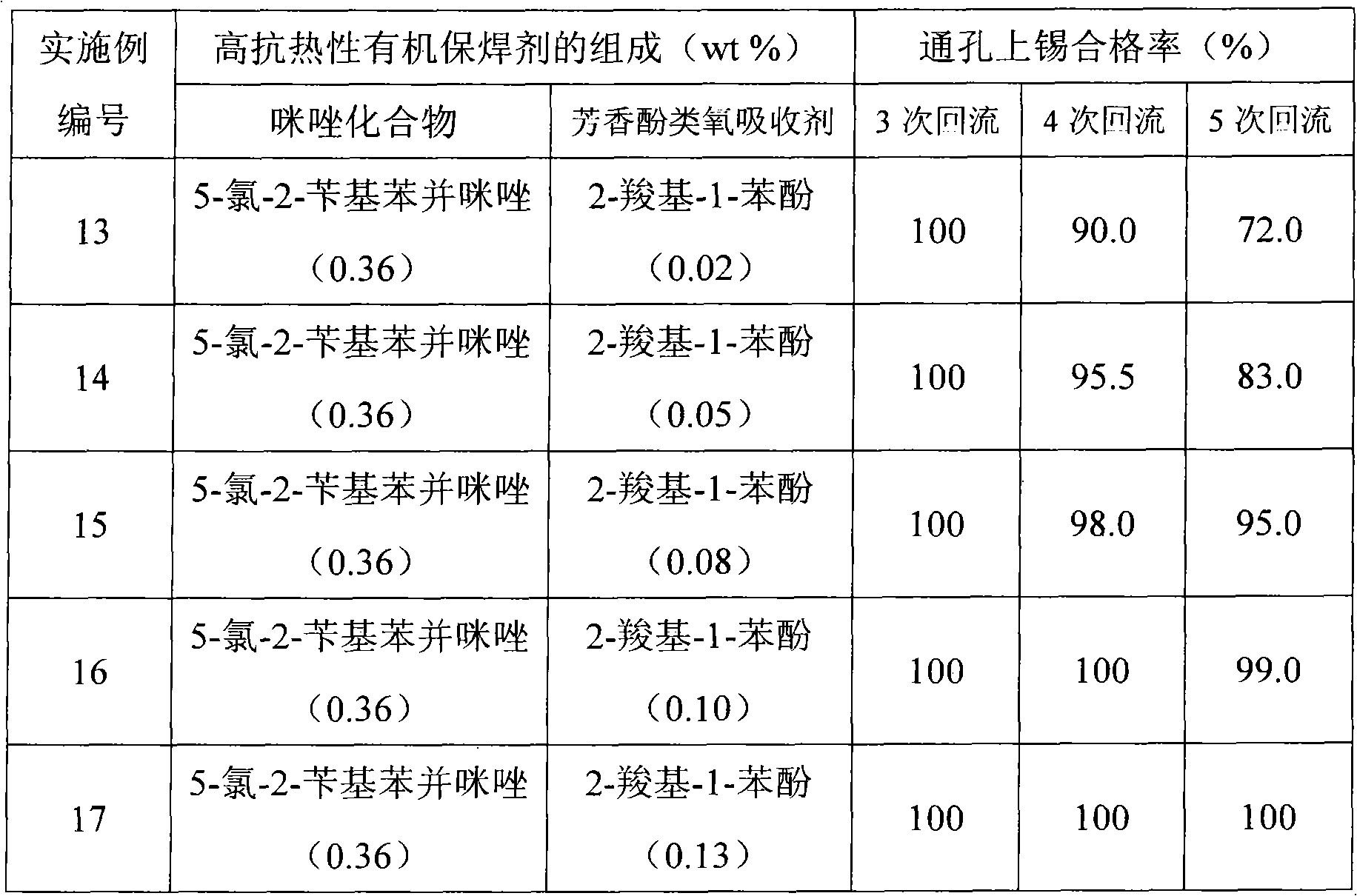

[0051] In Examples 13-18, except that the aromatic phenolic oxygen absorber content is listed in Table 2 in the composition of the high heat-resistant organic flux, the other components are: 3-chloro-2-benzylbenzimidazole 0.36%, the content of acetic acid is 15.6%, the content of isopropanol is 1.2%, copper chloride is 0.1%, zinc acetate is 0.05%, and the balance is deionized water.

[0052] Preparation method is identical with embodiment 1~12.

[0053] Table 2 is a comparison of the results of the tin test on the through hole of the weldment using the high heat-resistant organic fluxes of Examples 13-18 and the heat-resistant organic fluxes of Comparative Examples 4 and 5:

[0054] The high heat-resistant organic fluxes of Comparative Examples 4 and 5 are all prepared from imidazole compounds, organic acids, solubilizers, metal compounds, and deionized water, and do not contain aromatic phenol oxygen absorbers.

[0055] A copper-clad laminate base material with a length, wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com