Tin furnace with liquid level lifting device, high-speed tinning machine and method

A liquid level and tin furnace technology, applied in the field of tin furnace and high-speed tin-clad machine, can solve the problems of insufficient tin-coated wire production speed, unfavorable high-speed production, increased resistance, etc., to achieve good tin plating effect and good tin plating quality. , the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

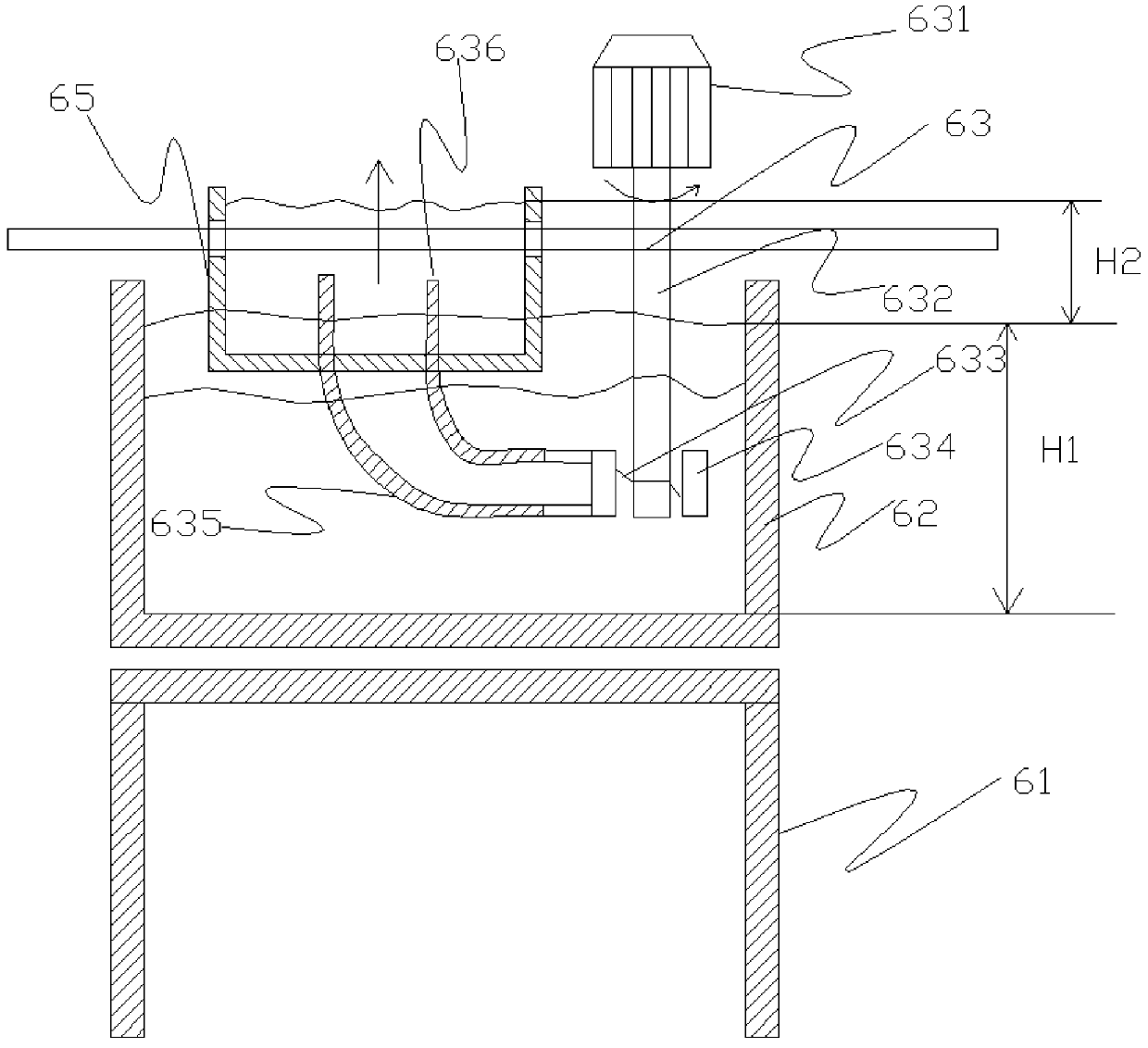

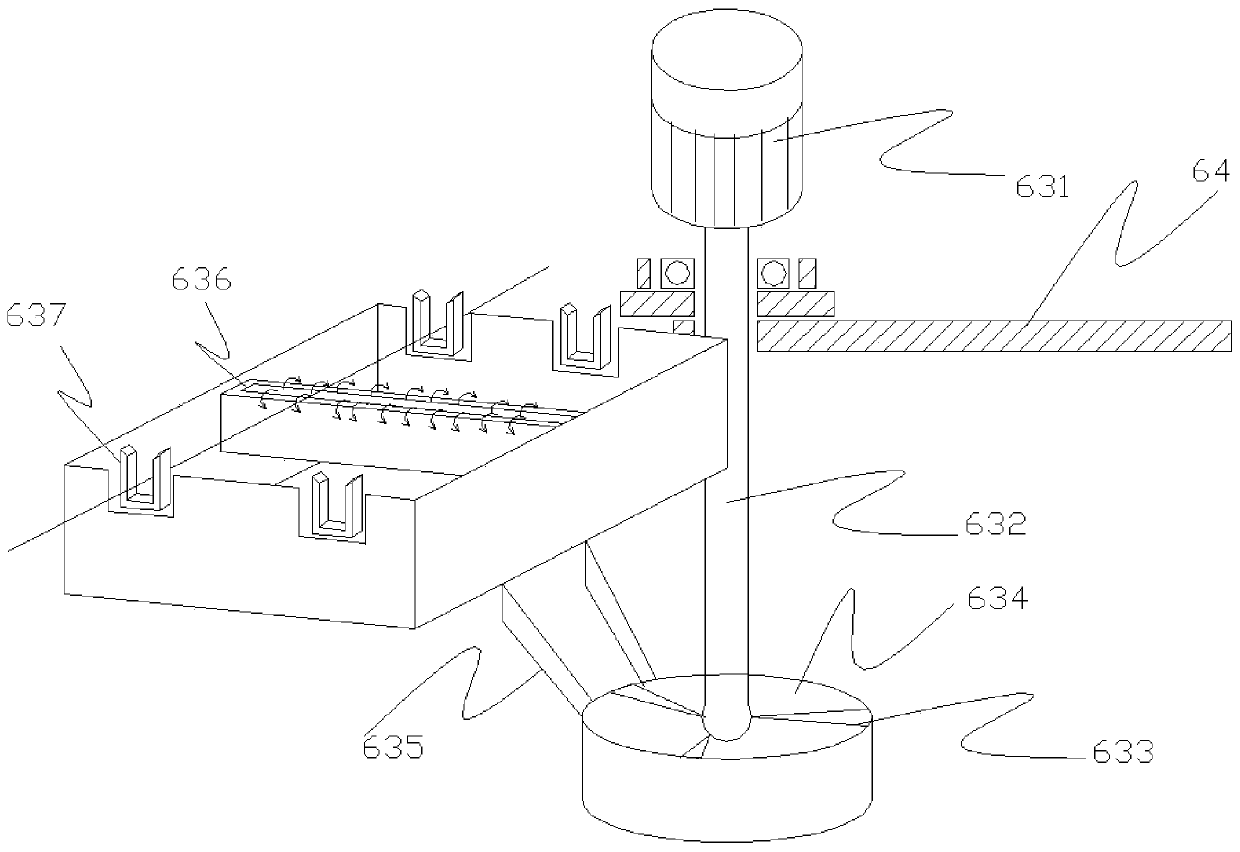

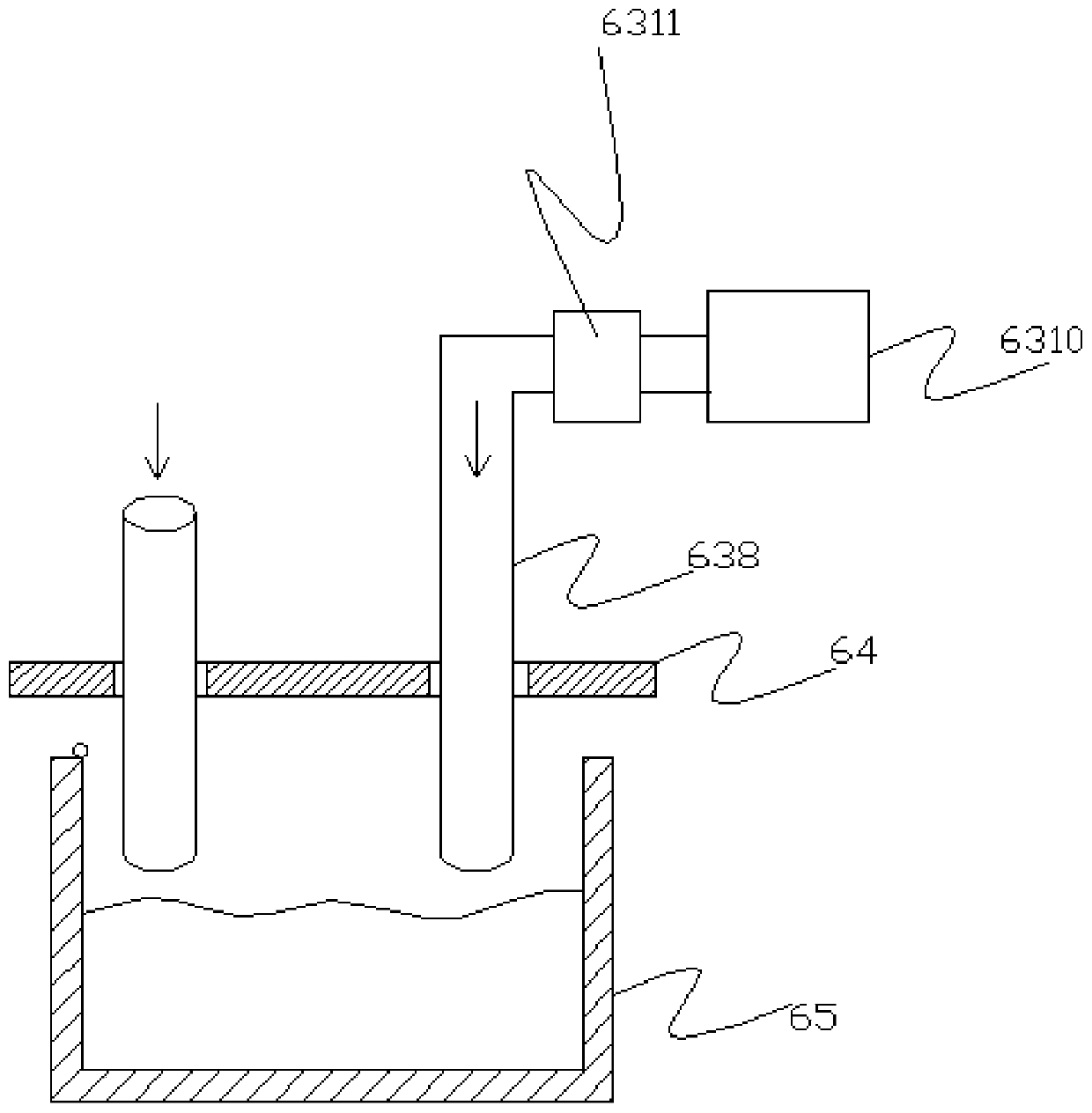

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention has a tin furnace with a liquid level lifting device 63, which includes a frame 61, a tin liquid pool 62 fixedly installed on the frame 61, and an inner upper end of the tin liquid pool 62 for dissolving the tin liquid pool 62 The liquid level raising device 63 that internal liquid level raises. That is, the liquid level of the tin liquid is partially raised to a certain height, which is used to tin-plate the copper wires that pass through in a straight line, so as to avoid the bending of the copper wires, reduce a lot of resistance, and greatly increase the startup speed.

[0022] The liquid level lifting device 63 is fixedly installed on the upper end of the tin liquid pool 62, or is fixedly installed on the upper end of the frame 61, or is arranged on the upper end of the tin liquid pool 62 through a support leg. Preferably, it is fixedly installed on the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com