Press-fetching type liquid suction bottle

A liquid and aspirator technology, which is applied in the field of push-and-take liquid suction bottles, can solve the problems of waste, time-consuming, and user inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

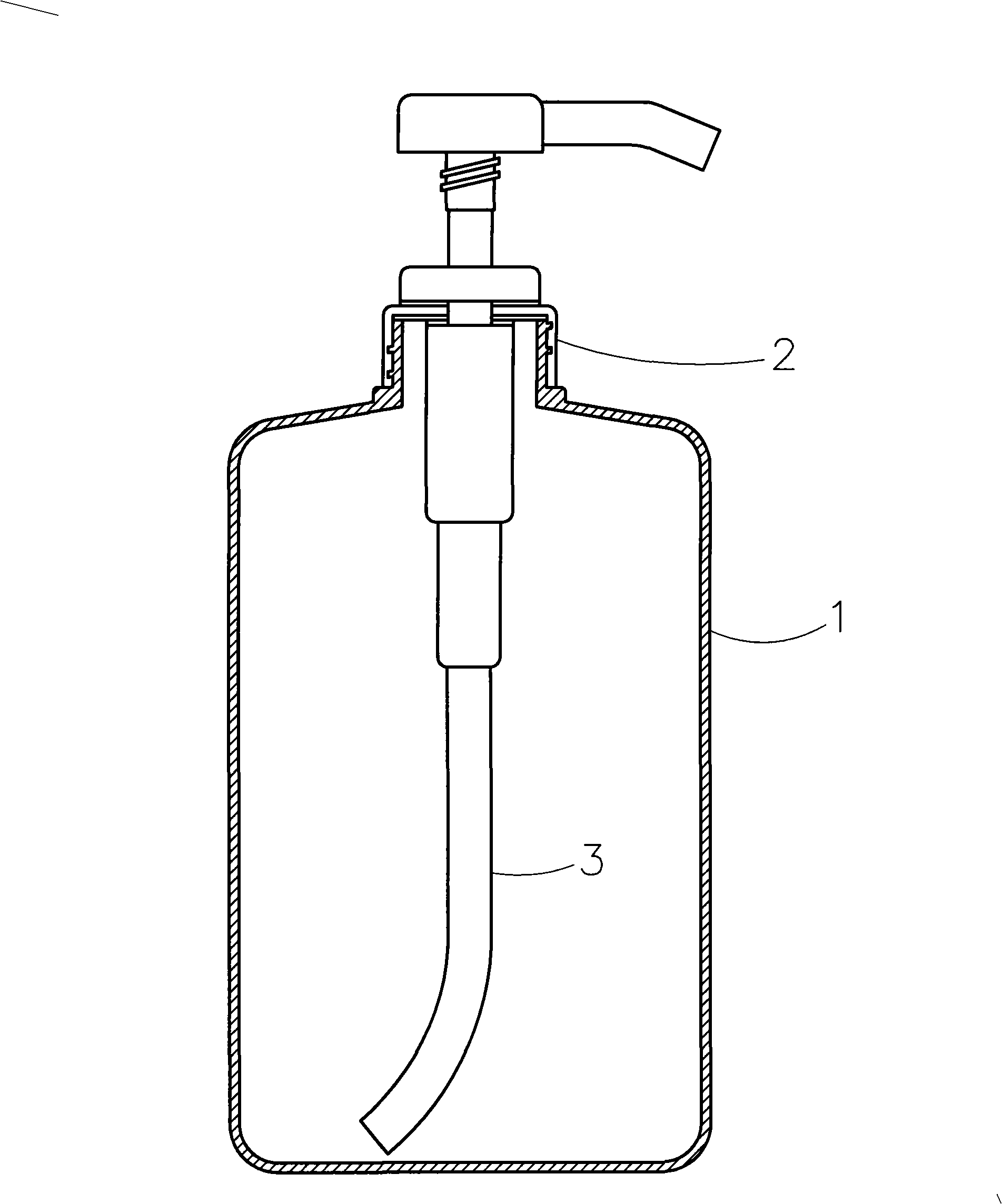

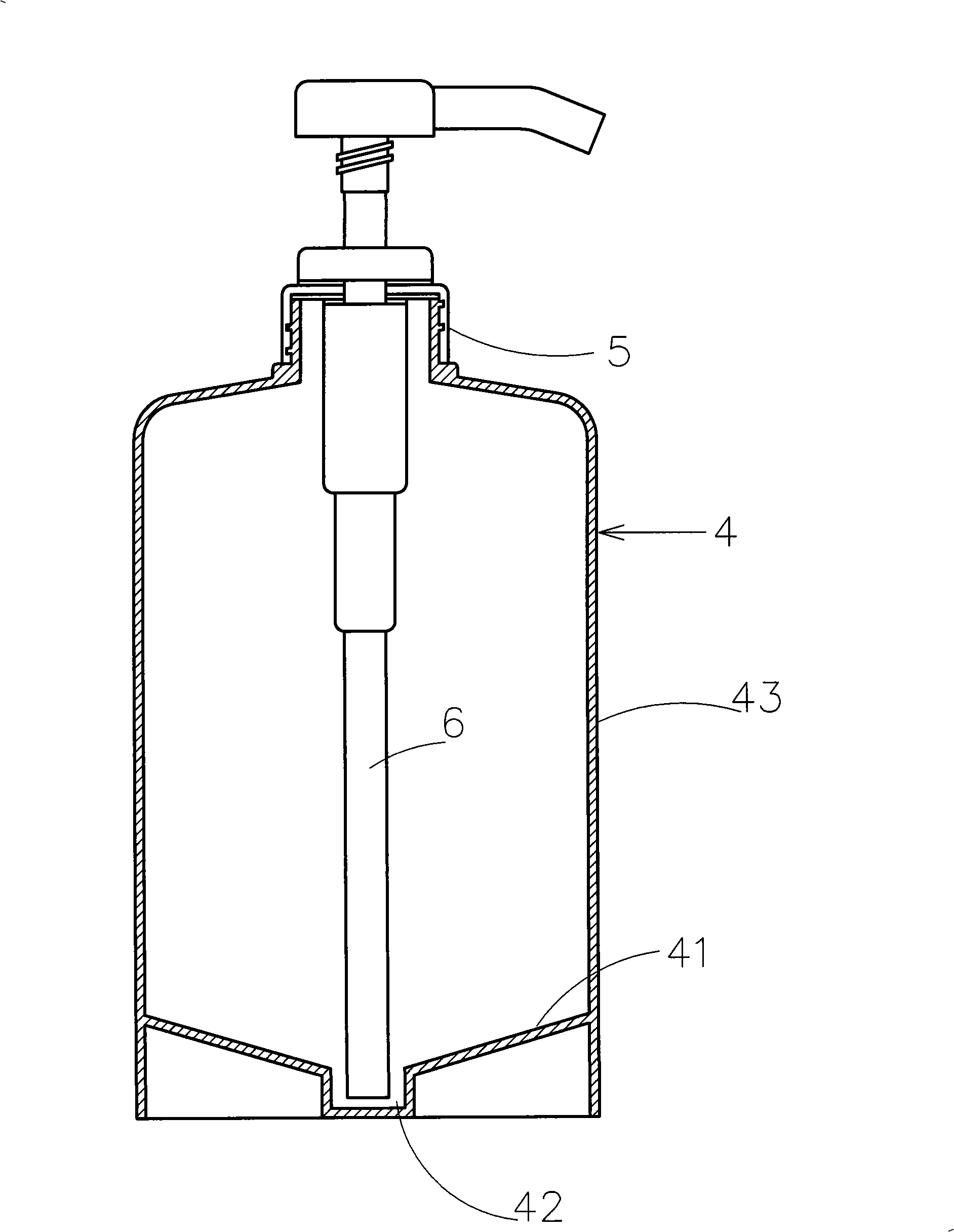

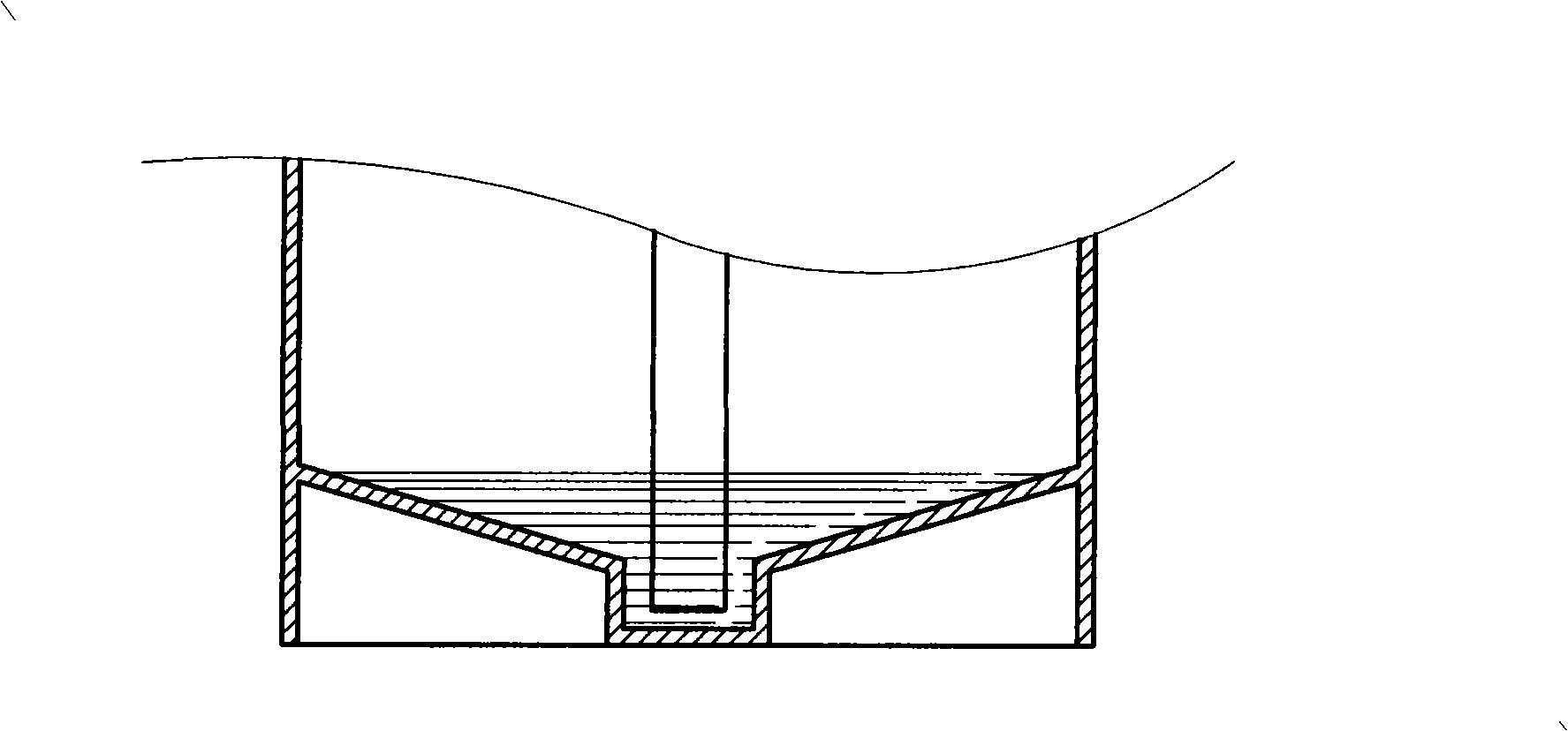

[0020] See first figure 2 , is a cross-sectional view of the present invention, and it can be seen that the pressure-taking type liquid suction bottle of the present invention is mainly composed of a bottle body 4, an aspirator 5 located at the mouth of the bottle, and a downward extension of the aspirator 5. Its basic principle and structure are all the same as those known in the art, but it is characterized in that the bottom surface 41 of the bottle body 4, the central part of the bottom surface 41 is a downwardly recessed container 42, and its notch is upward and parallel. Connecting the bottom surface 41, the diameter of the container 42 is slightly larger than the diameter of the straw 6, and the length of the straw 6 is just enough to extend into the container 42, and the bottom surface 41 of the bottle body 4 is downward from the side wall 43 of the bottle body 4. Extending obliquely to the notch of the container 42 , that is, the bottom surface 41 forms an inverted c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com