Automatic tin cutting machine

A tin-cutting and automatic technology, applied in the directions of tin-feeding devices, auxiliary devices, metal processing equipment, etc., can solve the problem of not having the function of tin-cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

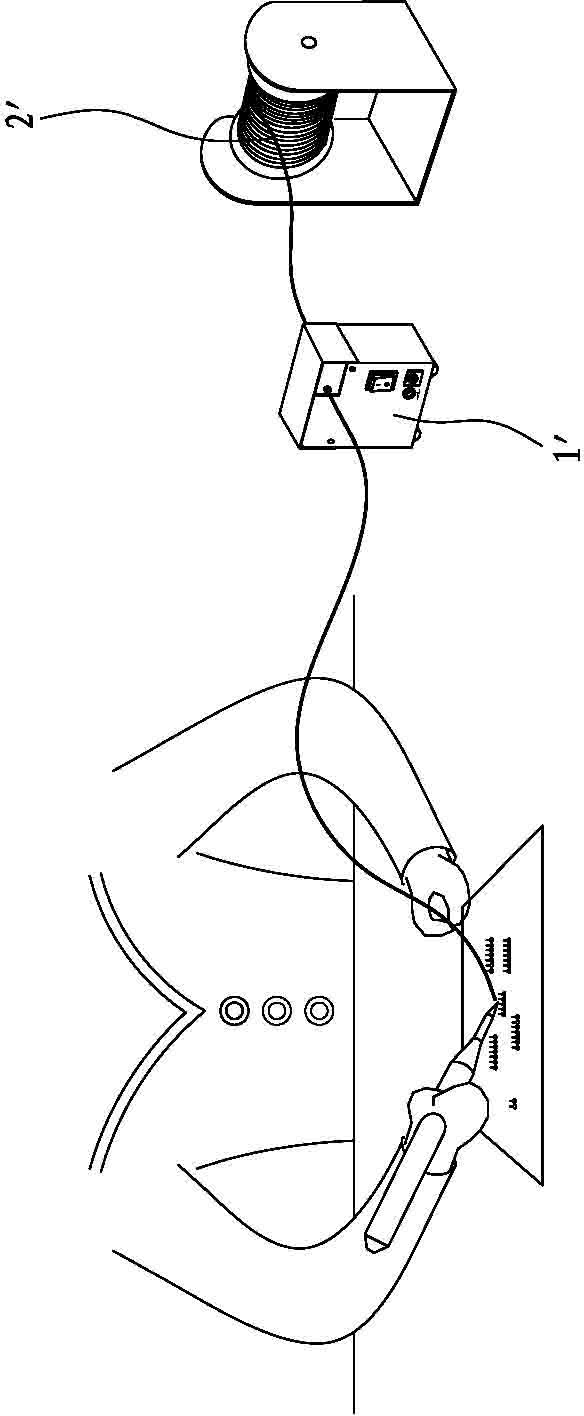

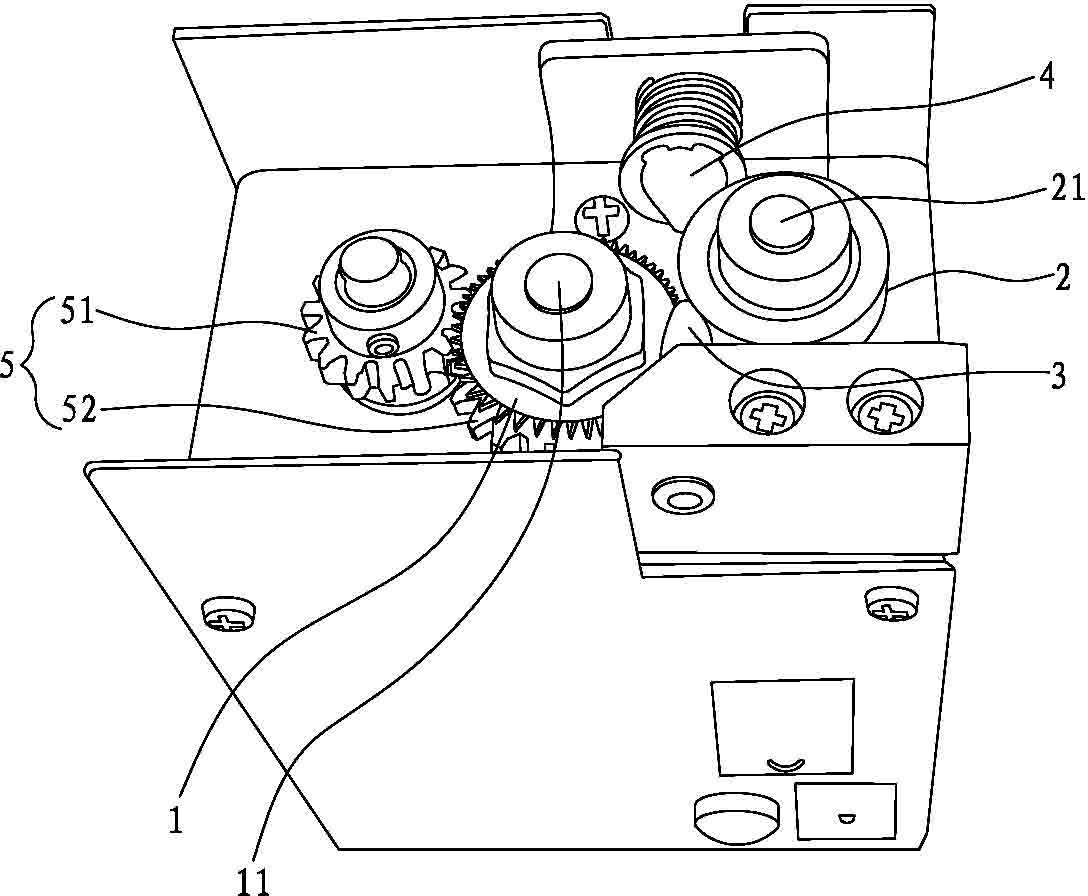

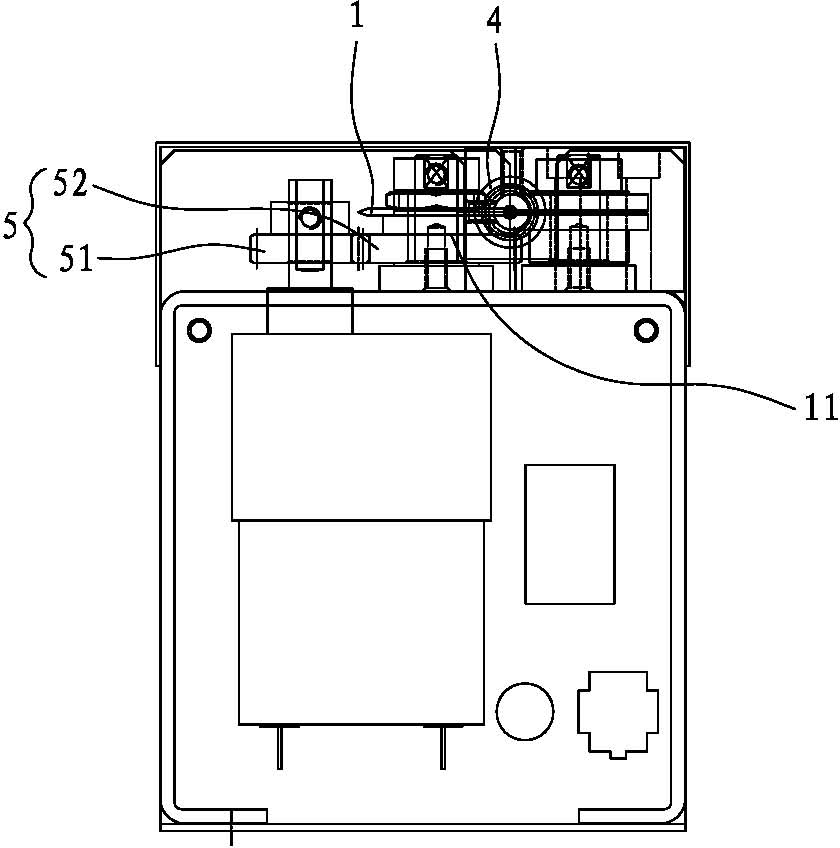

[0019] Such as figure 2 As shown, the present invention is an automatic tin cutting machine, which is mainly composed of a cutting gear blade 1, a guide wheel 2, a tin nozzle pipe 3, a tin feeding head 4, and a transmission mechanism 5.

[0020] Such as figure 2 , Figure 6 As shown, the cutting gear blade 1 is set opposite to the guide wheel 2, and is respectively rotatably sleeved on the gear blade rotating shaft 11 and the guiding wheel rotating shaft 21. The circumference of the guide wheel 2 is provided with a shallow groove 22 around the entire circumference, and the radial line of the shallow groove 22 is on a horizontal plane with the radial line of the cutting gear blade 1, so that the cutter teeth of the cutting gear blade 1 are aligned. To the shallow groove 22 on the guide wheel 2, and the gap between the cutter tooth of the cutting gear blade 1 and the shallow groove 22 on the guide wheel 2 is smaller than the tin wire diameter, so that the cutter teeth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com