Patents

Literature

48results about How to "No lateral offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

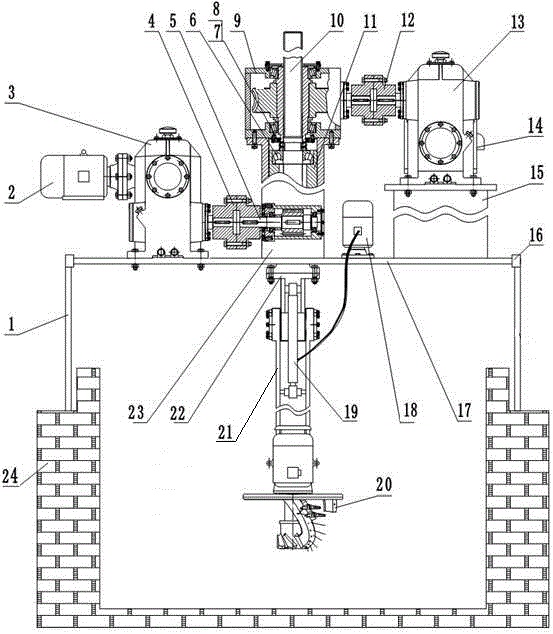

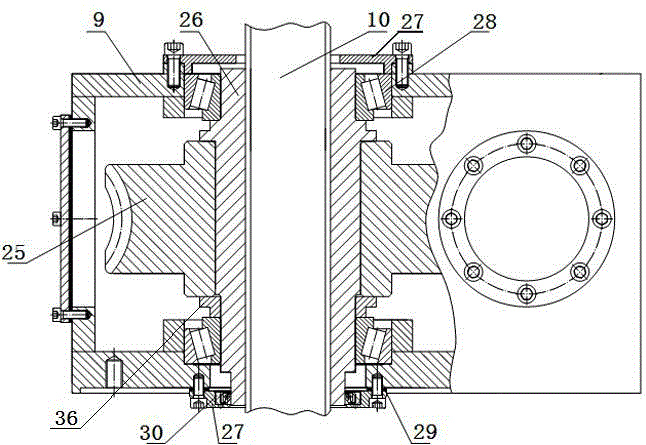

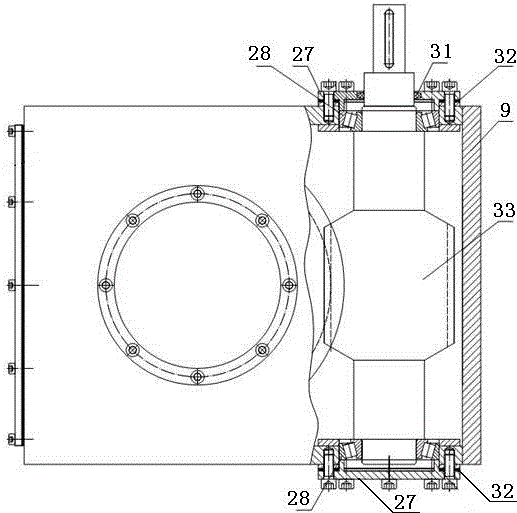

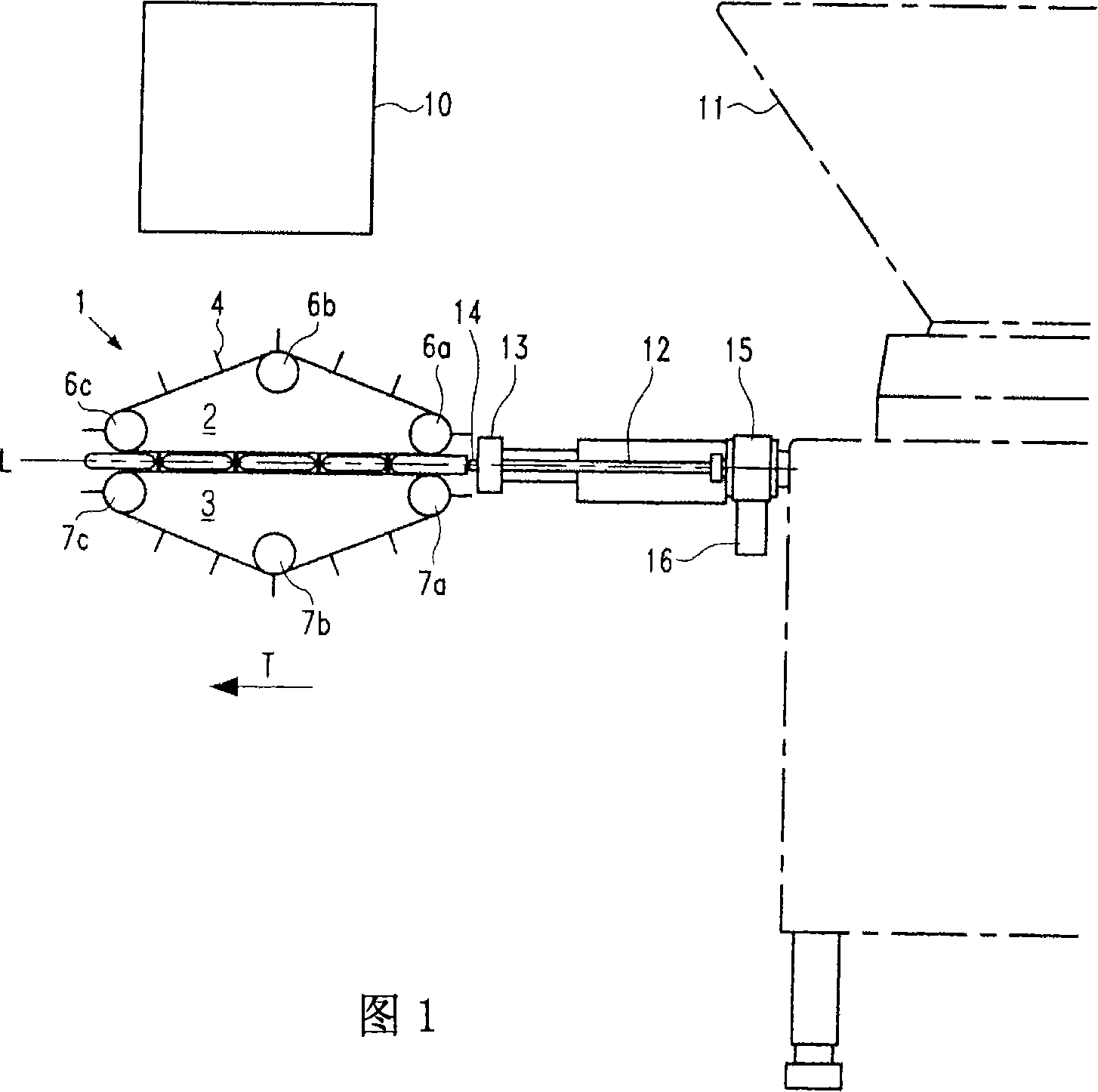

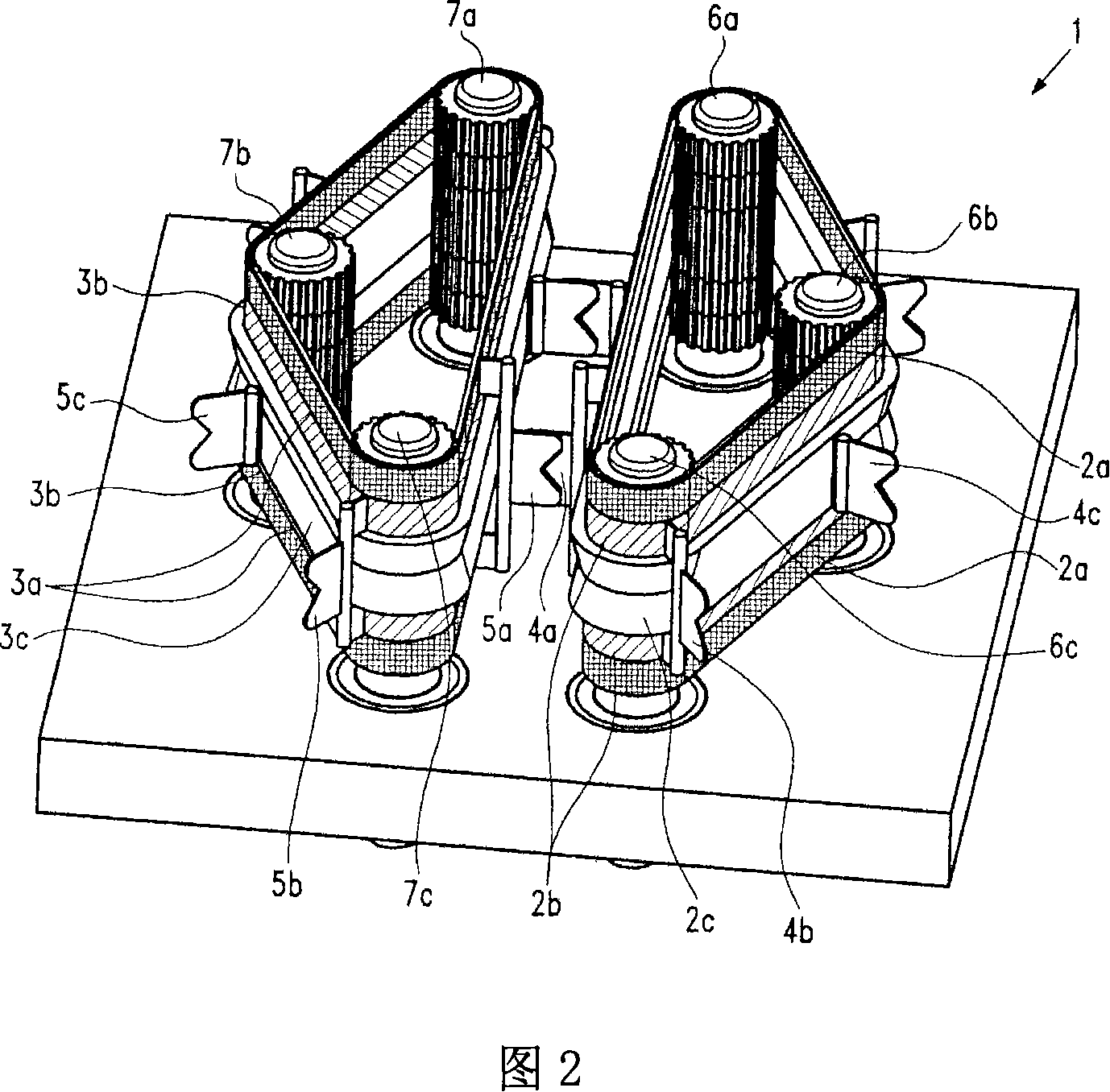

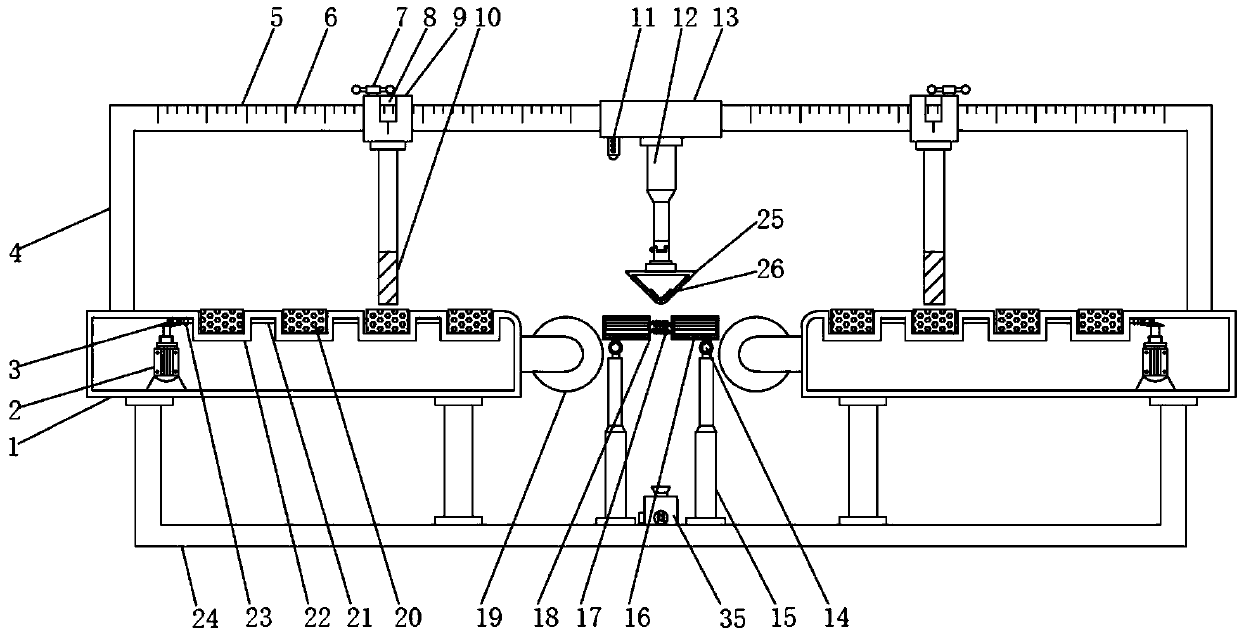

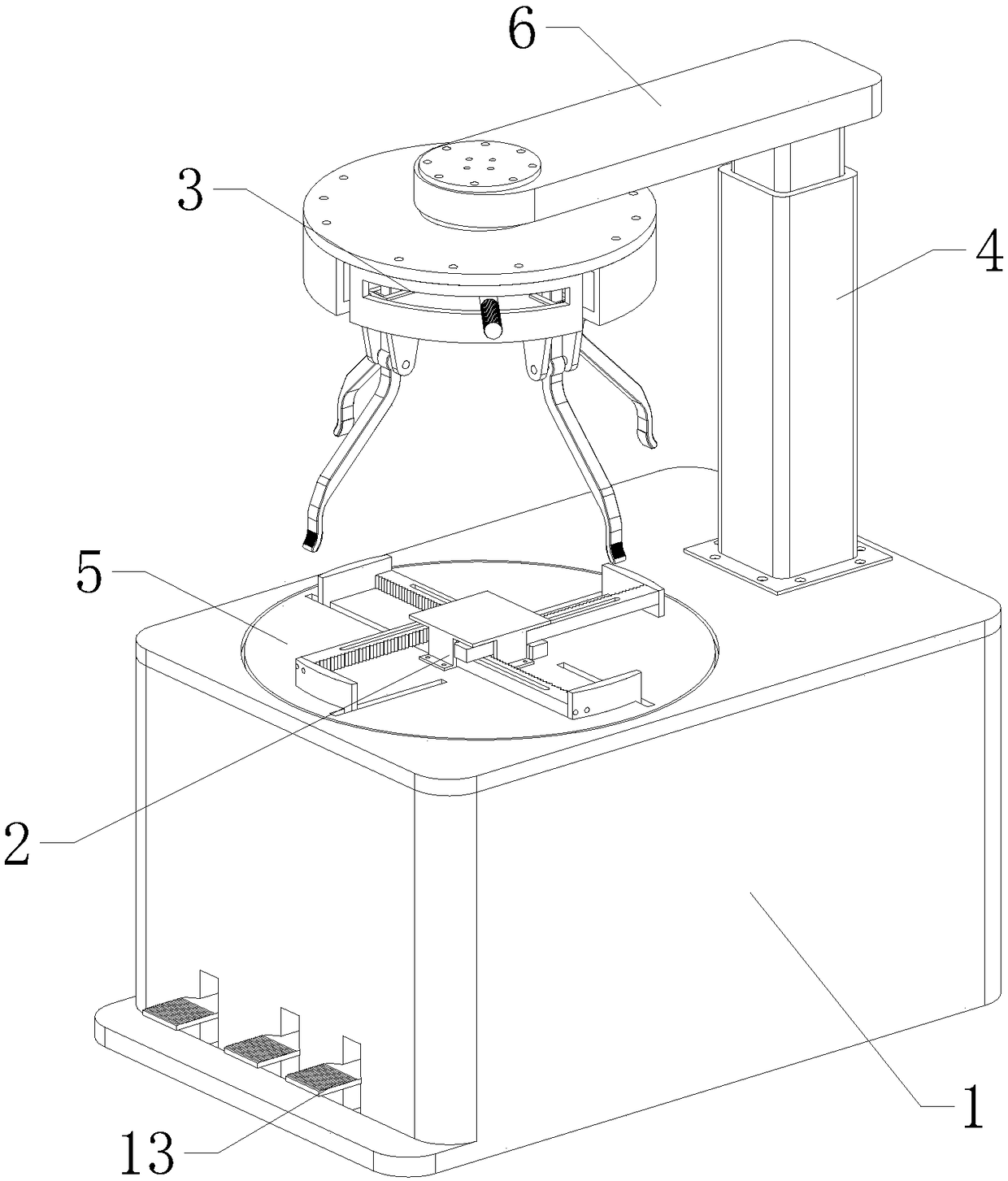

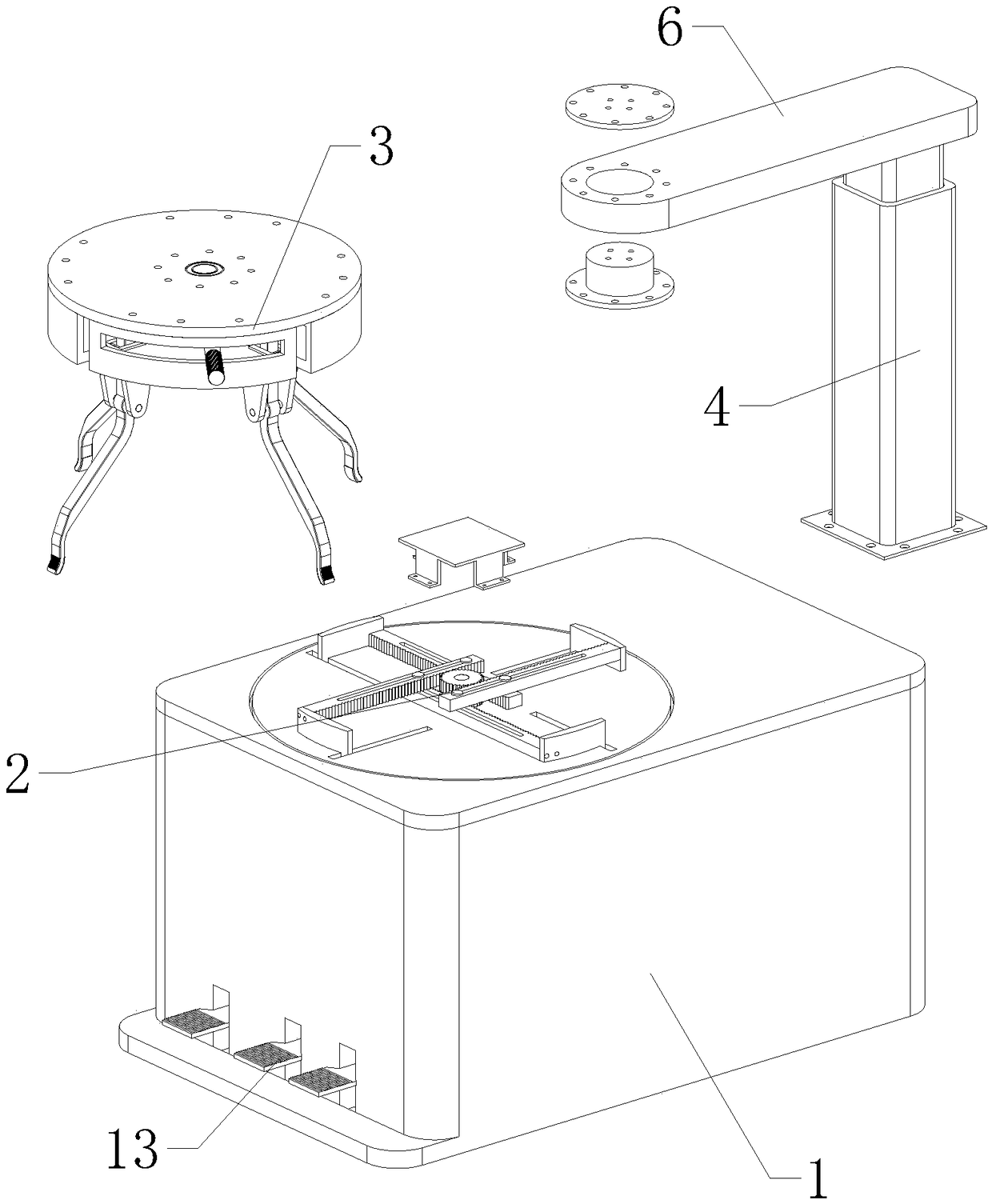

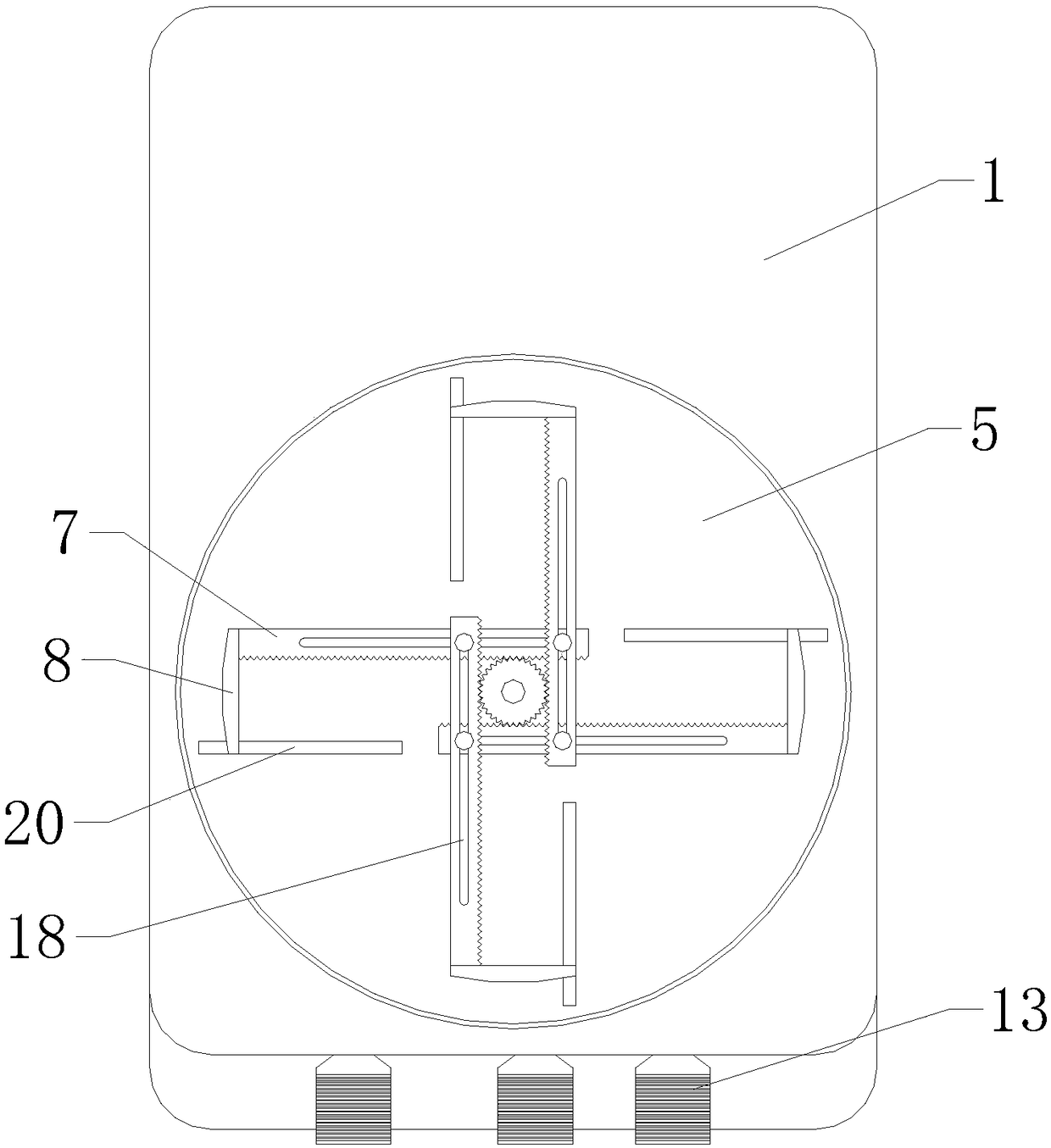

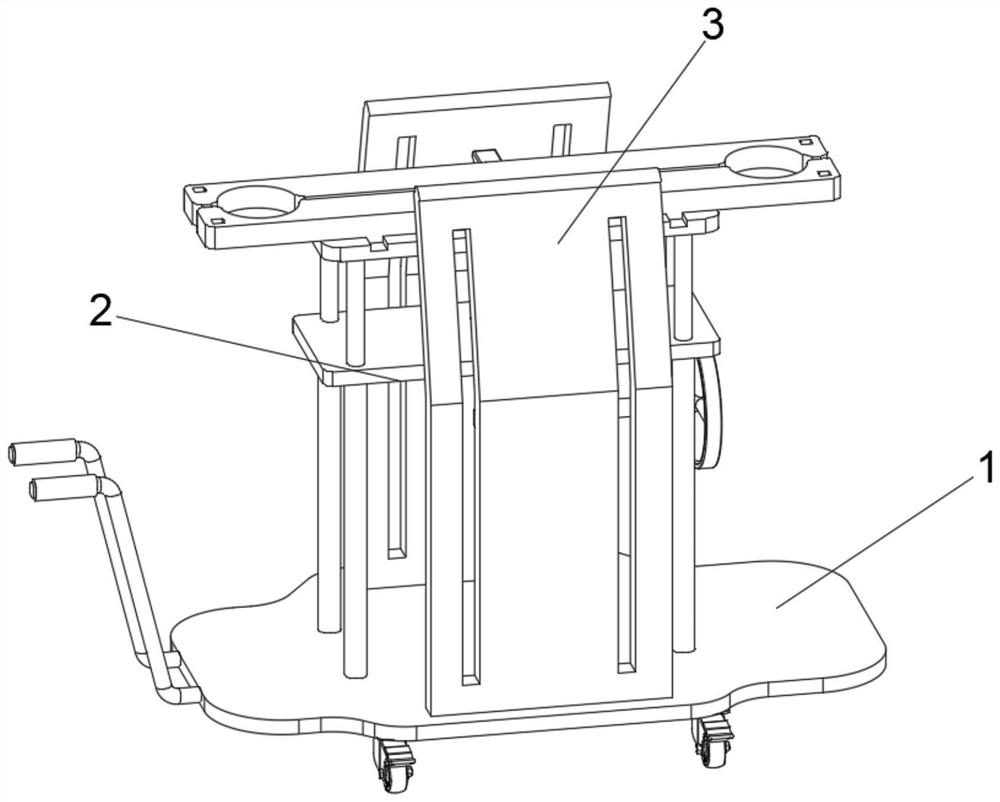

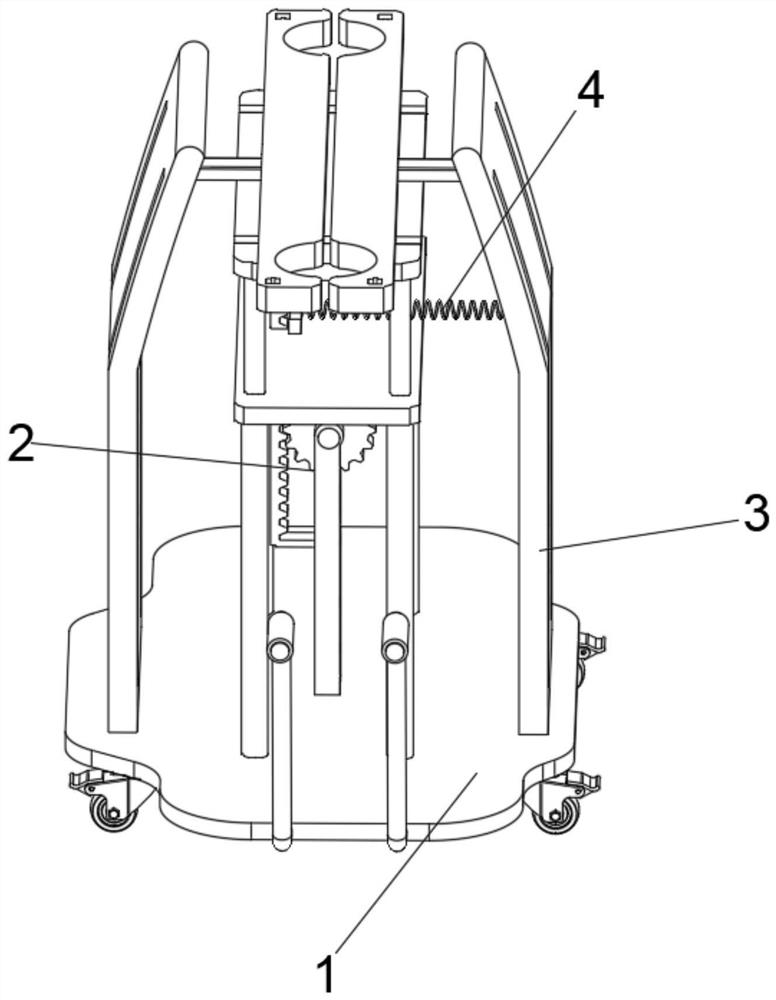

Dredging operation simulation device

InactiveCN106157778AChange in angular velocityAdjustable swing speedEducational modelsSoil propertiesEngineering

The invention relates to a dredging operation simulation device, which comprises a dredging pool, guide rails and a machine frame, wherein the guide rails are arranged at the two sides of the top of the dredging pool; the machine frame transversely spans above the guide rails positioned at the two sides and can move along the guide rails; a vertical main shaft, a rotating mechanism and an ascending and descending mechanism are arranged on the machine frame; the rotating mechanism can drive the main shaft to rotate; the rotating speed of the rotating mechanism is adjustable; the ascending and descending mechanism can drive the main shaft to ascend and descend; the bottom of the main shaft is connected with a dredging reamer through an angle regulating mechanism; the angle regulating mechanism can drive the dredging reamer to swing around the main shaft, and the swinging speed is adjustable during swinging. The device can be used for simulating the stepping, rotation and ascending and descending during the operation of a dredging boat; the simulation can be realized on different operation modes in practical construction; the dredging operation simulation device is suitable for the dredging of various different soil properties.

Owner:WUHAN UNIV OF TECH

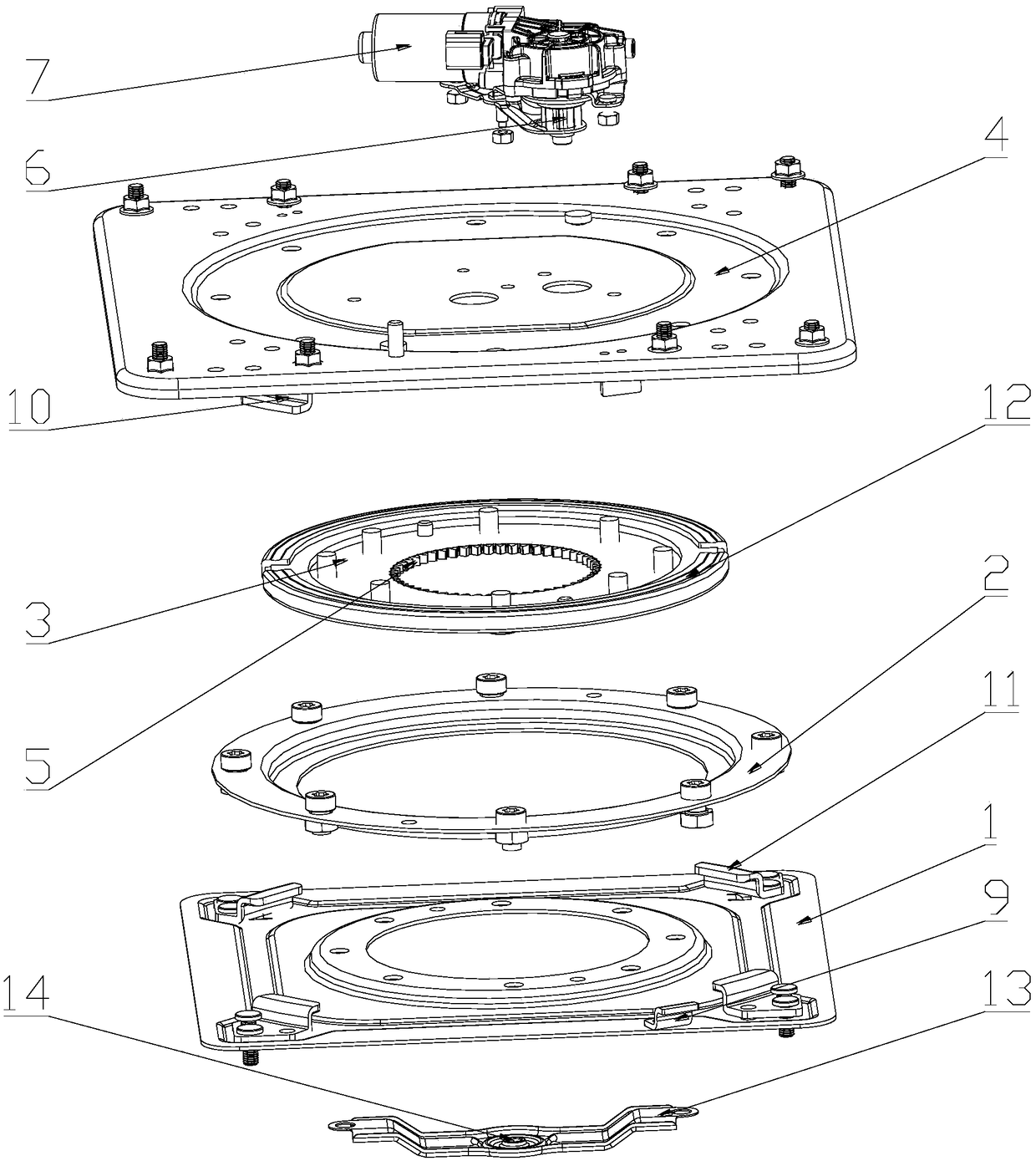

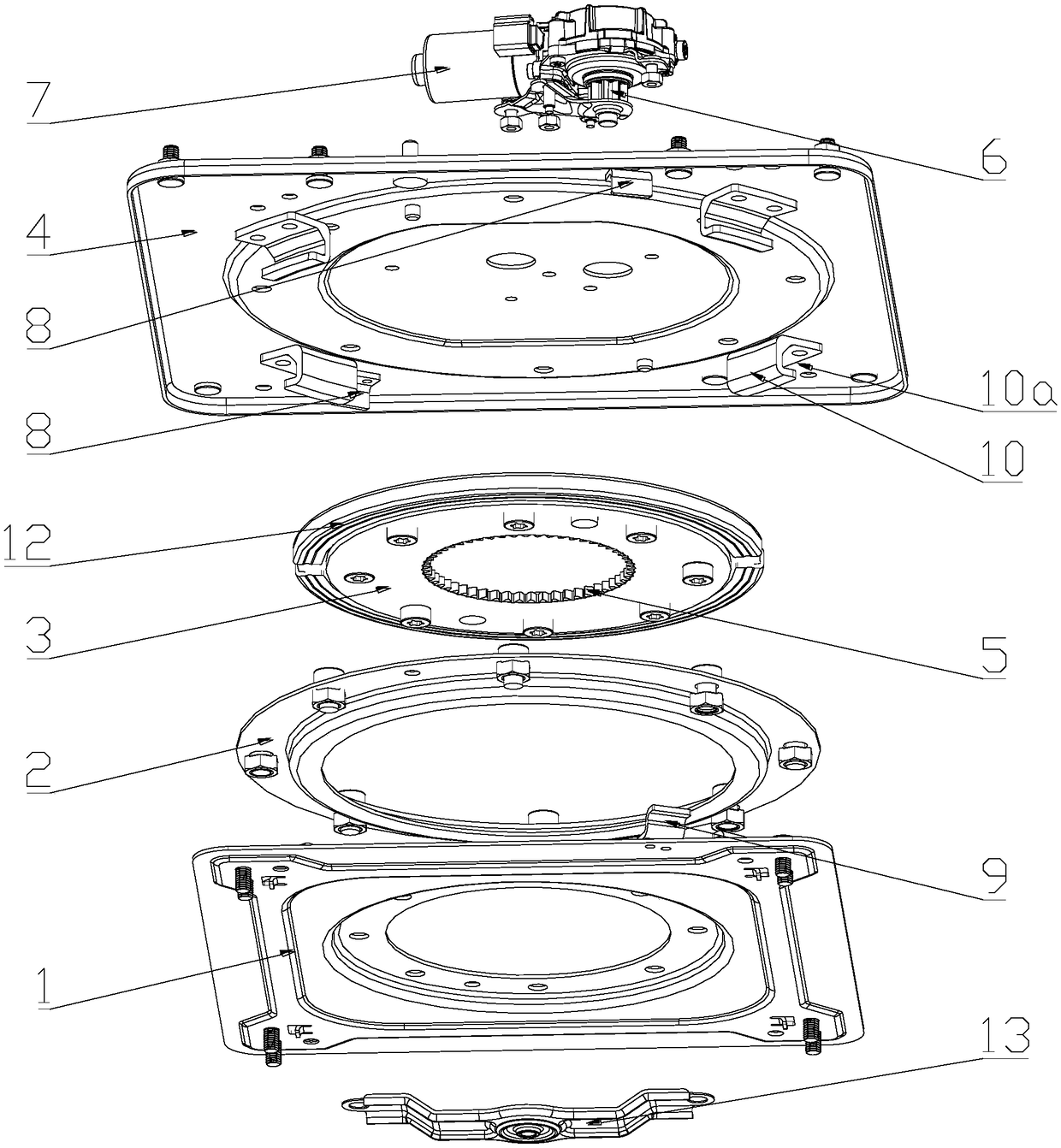

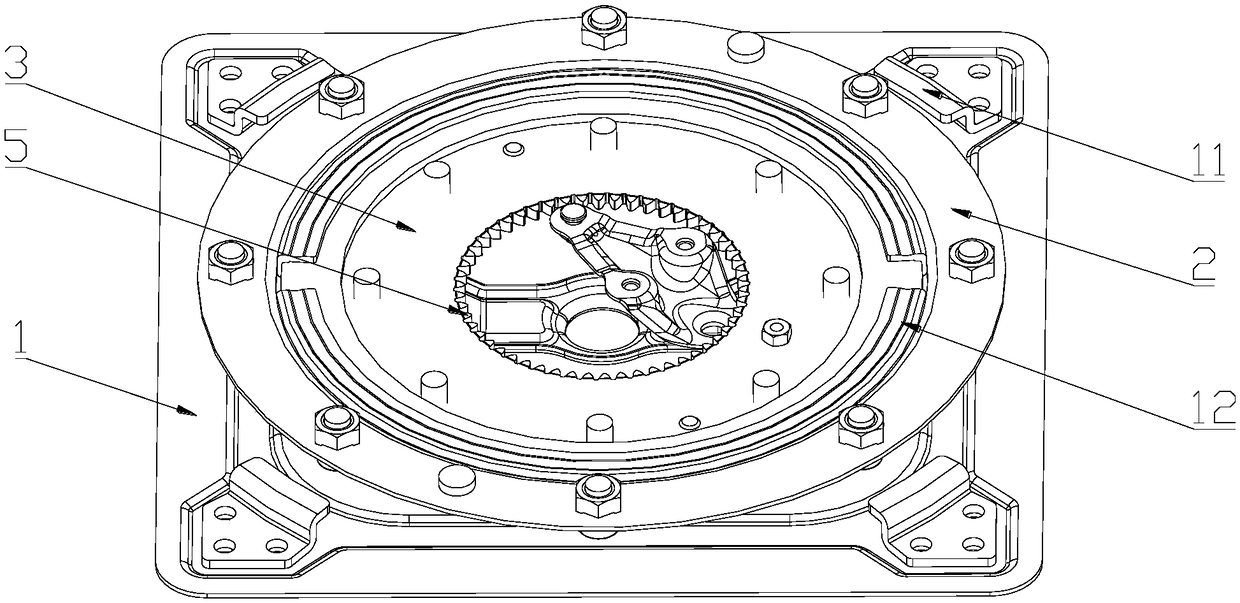

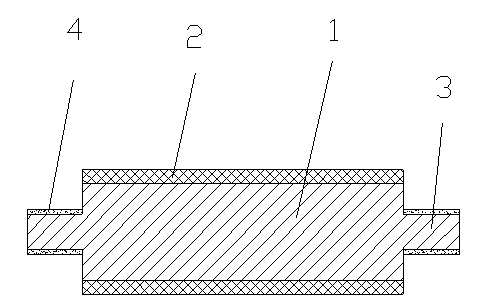

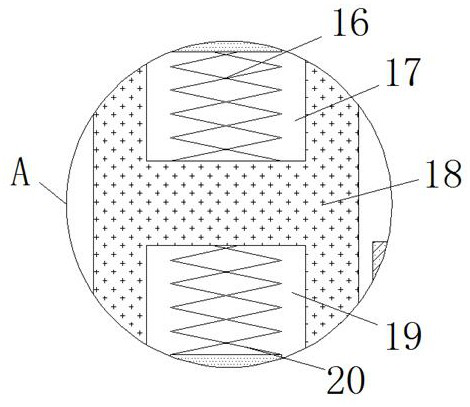

Automobile seat rotation mechanism

An automobile seat rotation mechanism comprises an upper rotary disk and a lower chassis arranged opposite to each other, the upper surface of the lower chassis is provided with a fixed plate, the lower surface of the upper rotating disk is provided with a holding disk, A hold plate is provided with an accommodating space, the lower part of the fixing plate is clamped in the accommodating space, An upper portion thereof extend out of that accommodating space, An upper rotary disk is seat on an upper portion of that stationary disk, the fixed disk is provided with an annular ring gear, An upperrotary disk is provide with a gear, gear meshes with ring gear, the gear is connected with a driving device. The beneficial effect of adopting the invention is that between the rotating part of the upper part and the fixed part of the lower part, the structure form of nesting and tightening is adopted, when the upper rotating disk rotates, the gripping disk is driven to rotate together, and the gripping disk is limited by the fixed disk, so that lateral deviation does not occur, so that the rotation of the upper rotating disk is more stable.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

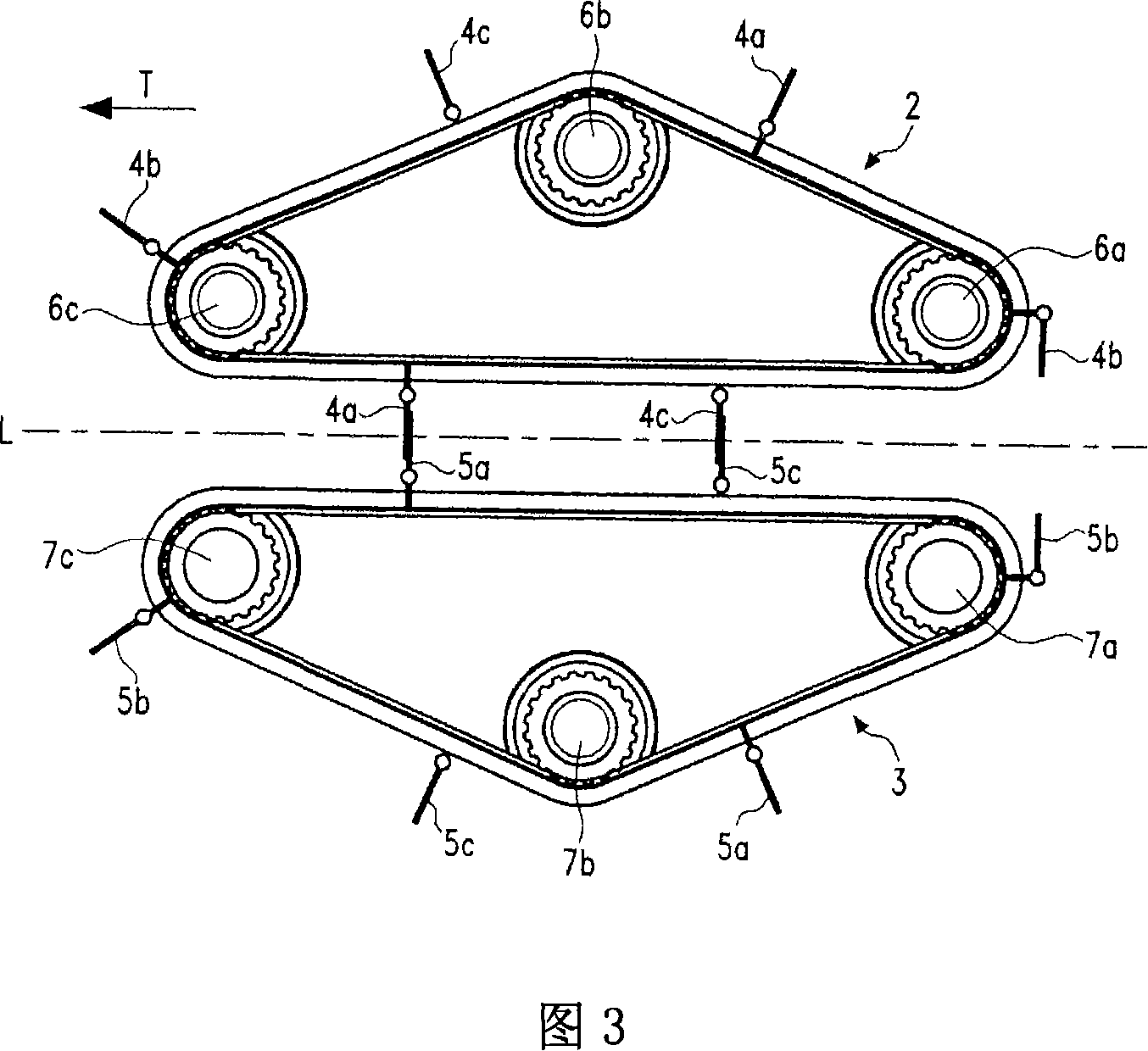

Apparatus and method for dividing a stuffed sausage skein

An apparatus and a method for dividing a stuffed sausage skein, wherein a transport element pair is provided, including rotating opposite transport elements between which the stuffed sausage skein is conveyed in a transport direction and each of which include at least one dividing element. To be able to configure the length of the portions flexibly without mechanical adaptation, the apparatus comprises several adjacently arranged transport element pairs drivable independently of each other with corresponding dividing element pairs. The speed of the transport element pairs is adjusted such that the spacing between the points of separation corresponds to a predetermined length of the divided sausage skein.

Owner:ALBERT HANDTMANN MASCHFABRICK

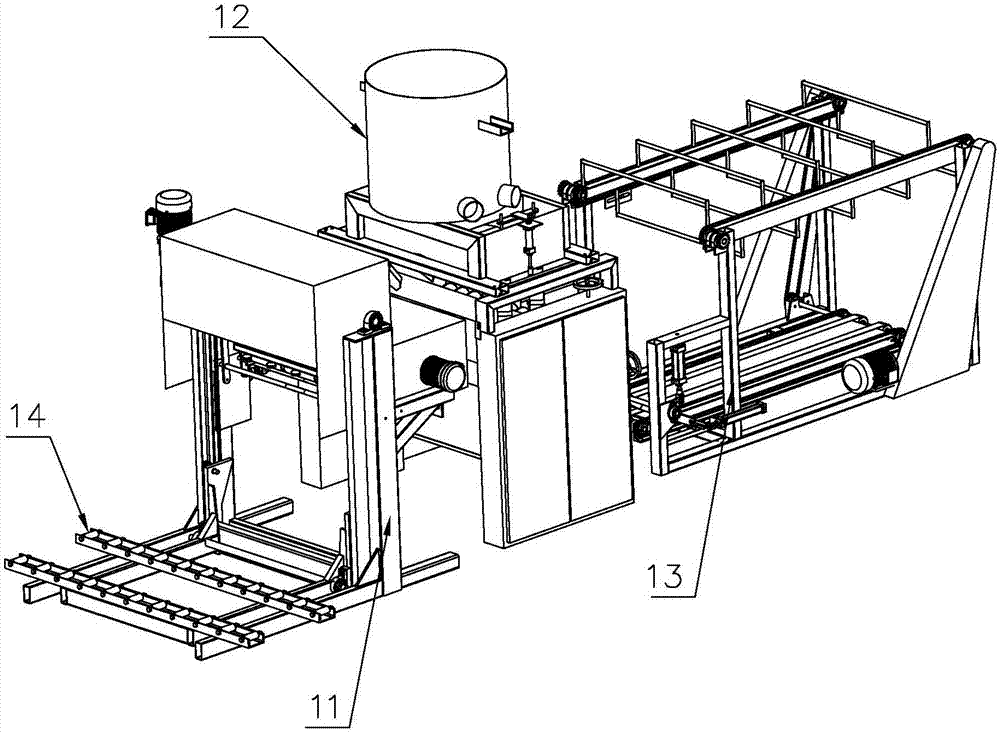

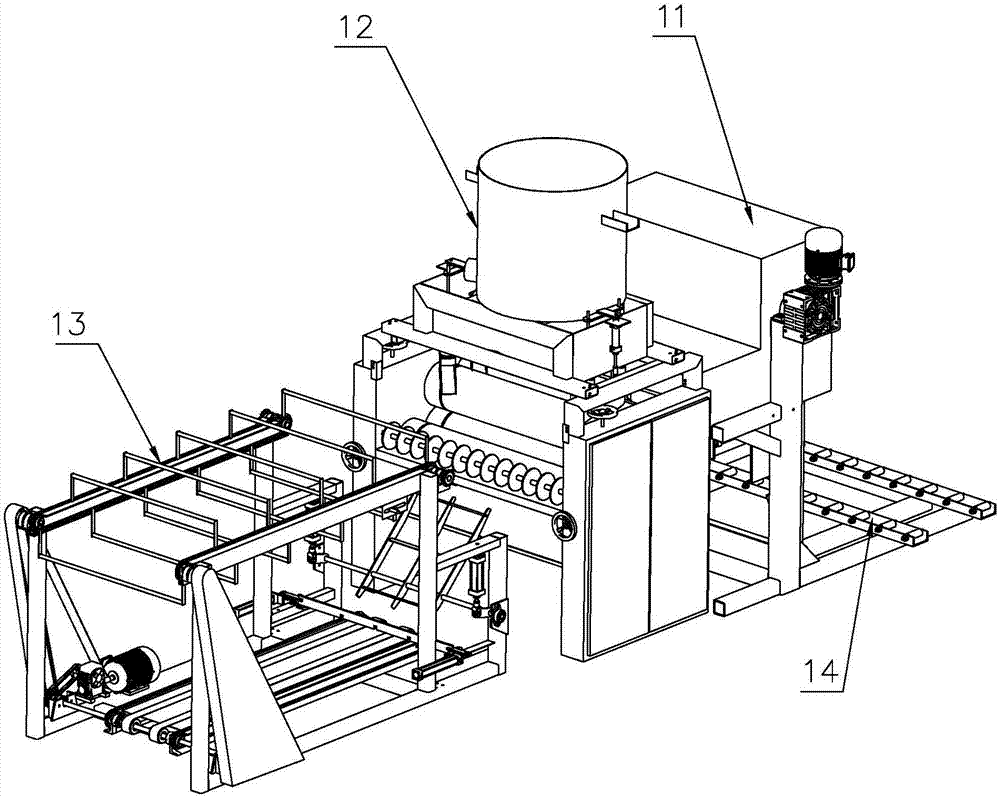

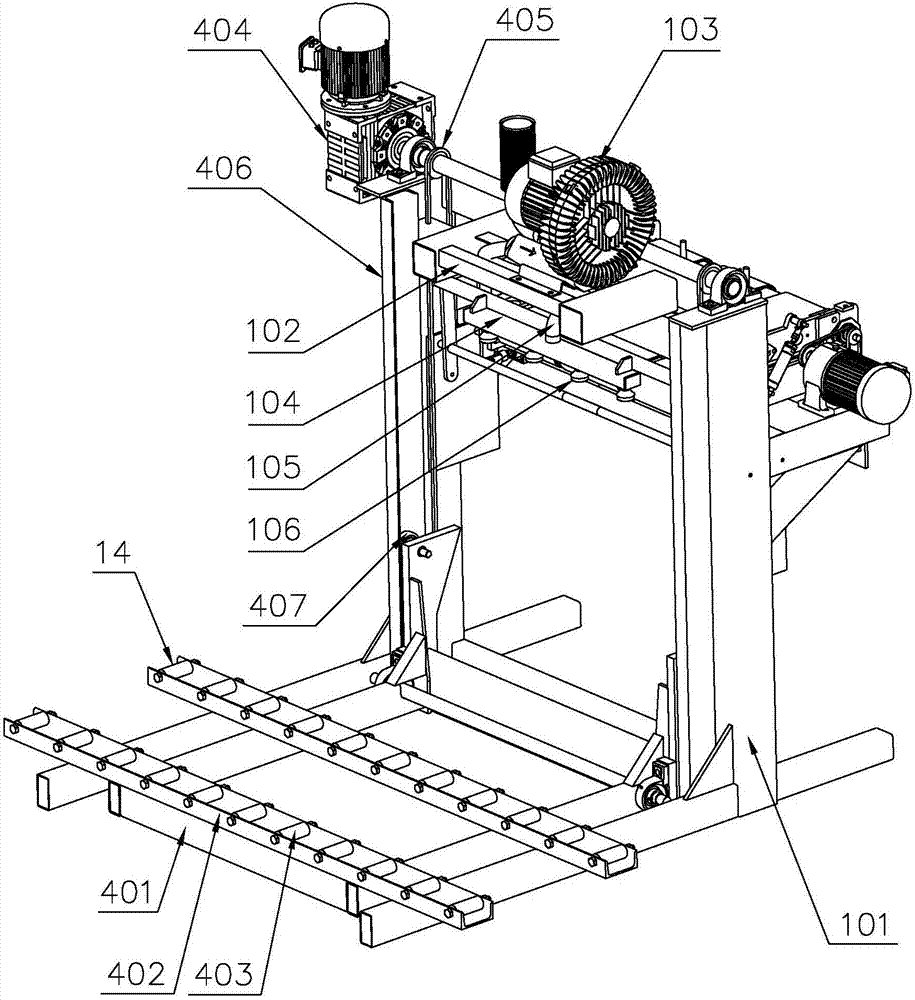

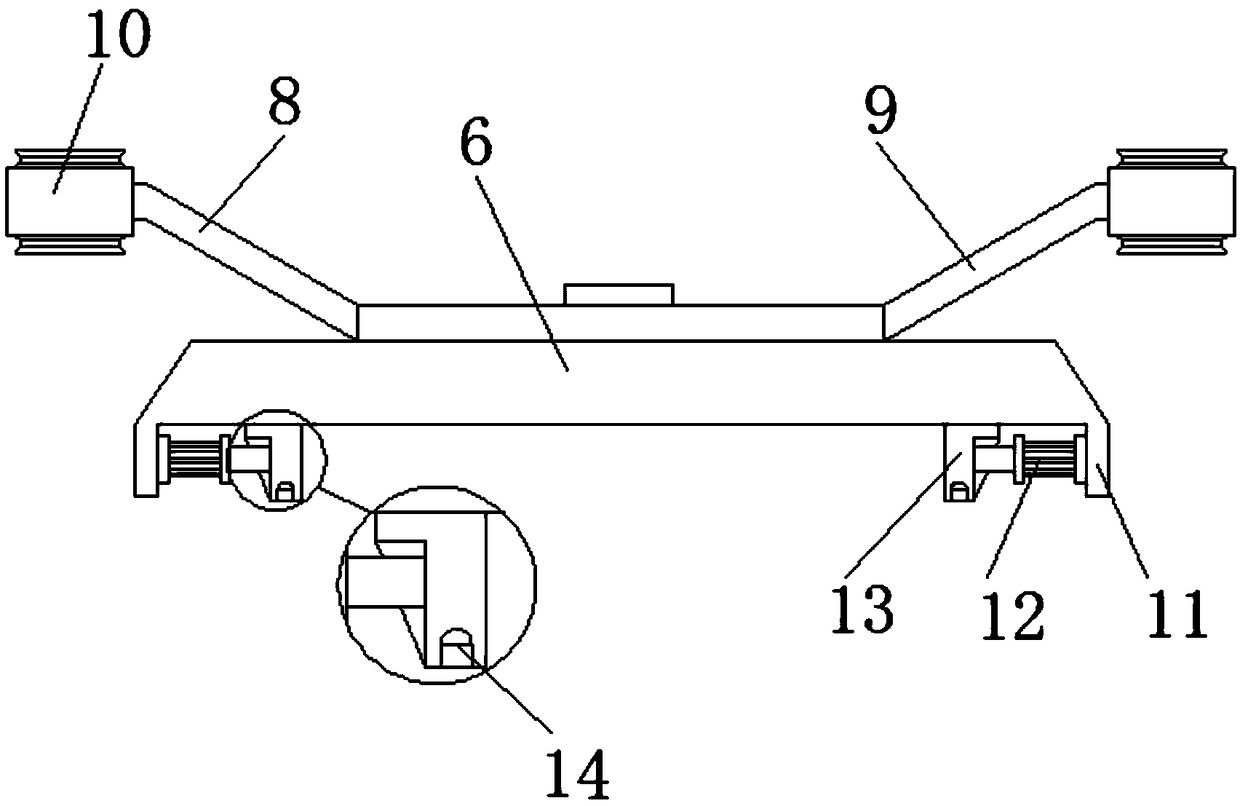

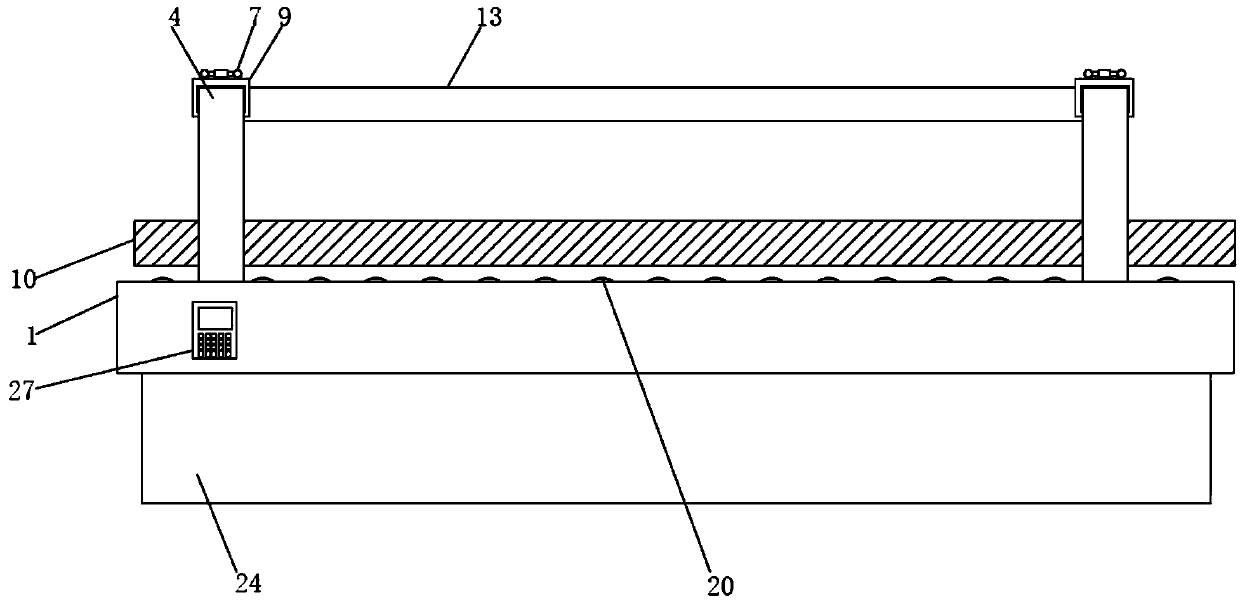

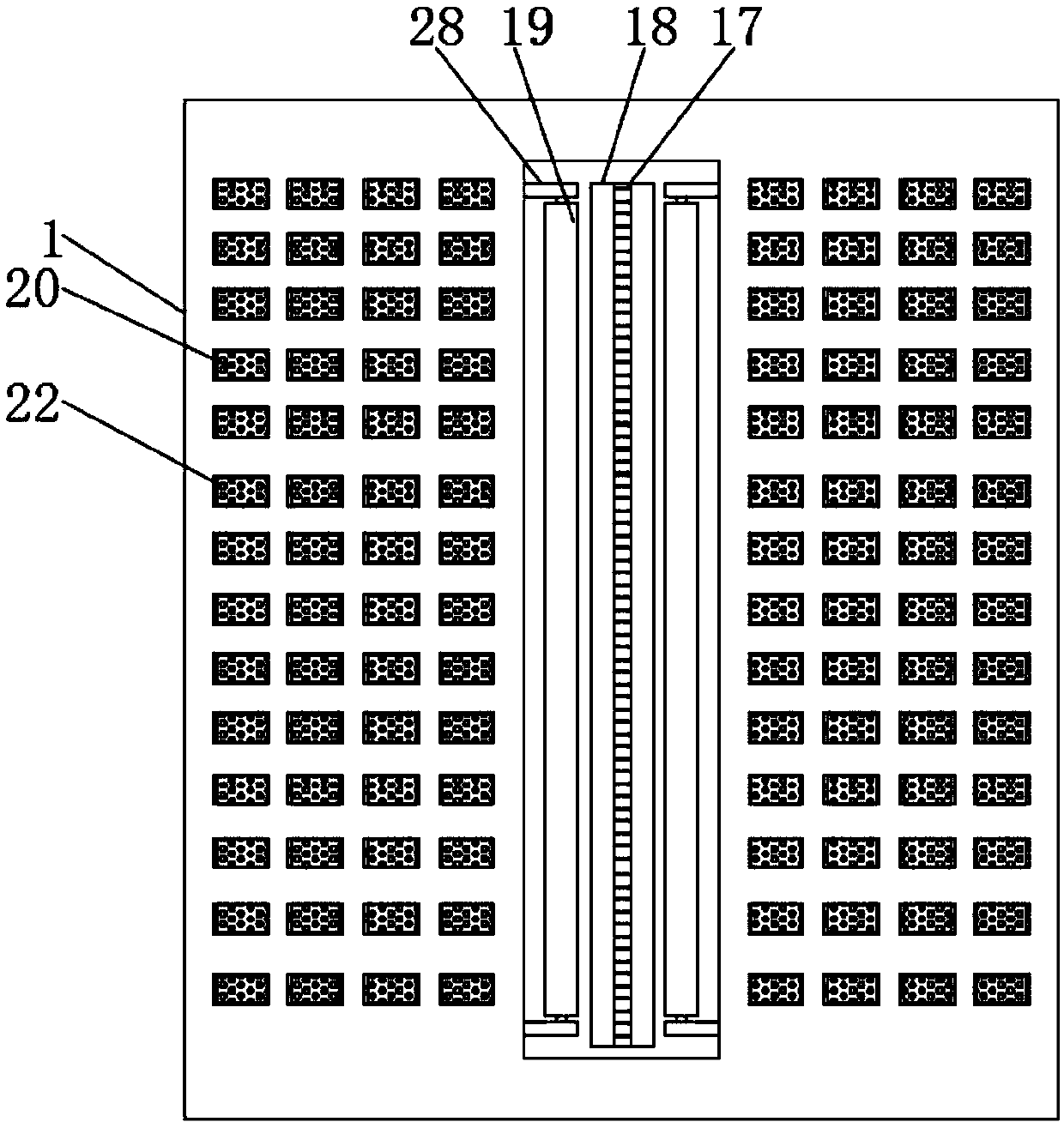

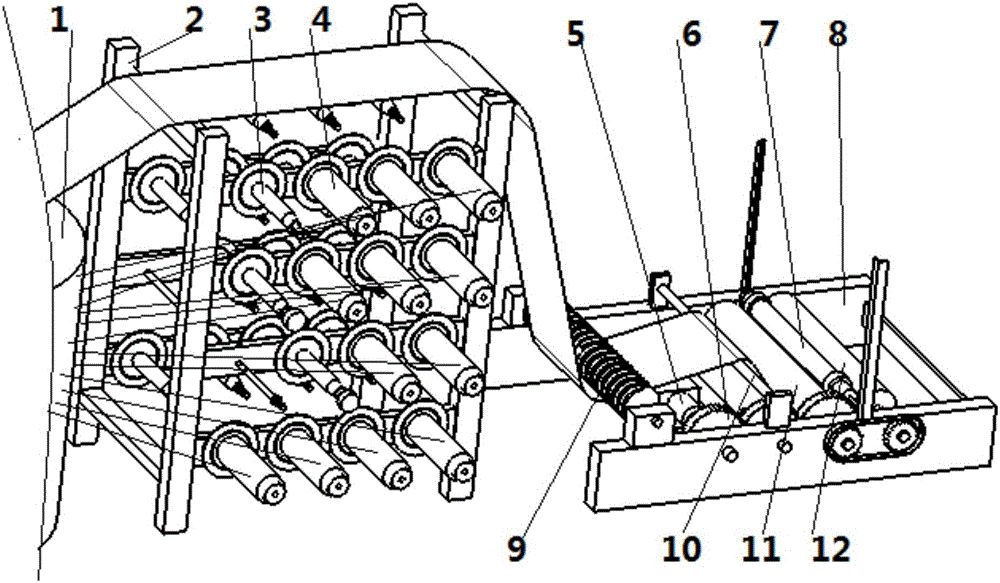

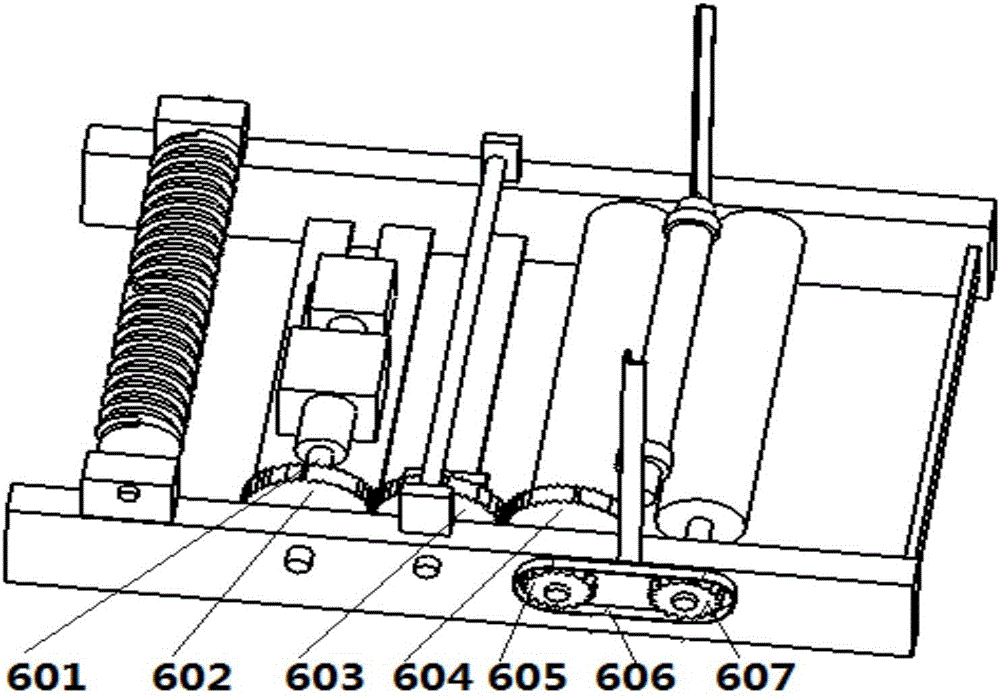

Full-automatic intelligent single-board gluing production line

PendingCN107282360AEasy to sendTimely adjustment of friction pressureLiquid surface applicatorsCoatingsTransfer mechanismAgricultural engineering

The invention discloses a full-automatic intelligent single-board gluing production line. The full-automatic intelligent single-board gluing production line comprises an adsorption transfer mechanism, a gluing mechanism and a receiving mechanism; the gluing mechanism is arranged on one side of the adsorption transfer mechanism, the receiving mechanism is arranged on one side of the gluing mechanism, the adsorption transfer mechanism comprises a lower transmission set, an upper transmission set, a feeding rack, a fixing frame, a vortex blower, a ventilation pipe, a pipeline and suction cups, the vortex blower is arranged on the fixing frame, and is communicated with the ventilation pipe through the pipeline, the multiple suction cups are arranged on the lower portion of the ventilation pipe, the upper transmission set is arranged on the upper portion of the lower transmission set, the lower transmission set is movably connected to a transfer support through a bearing pedestal, a supporting arm is arranged on one side of the transfer support, and a motor I is arranged on one side of the transfer support. Rotary cut veneer is rapidly fed, in the veneer conveying process, transverse shifting is avoided, feeding is rapid, double-face gluing is carried out, automatic receiving after gluing is carried out, work environment of a worker is improved, and labor amount of the worker is greatly reduced.

Owner:SHANDONG CHANGXING WOOD MACHINERY CO LTD

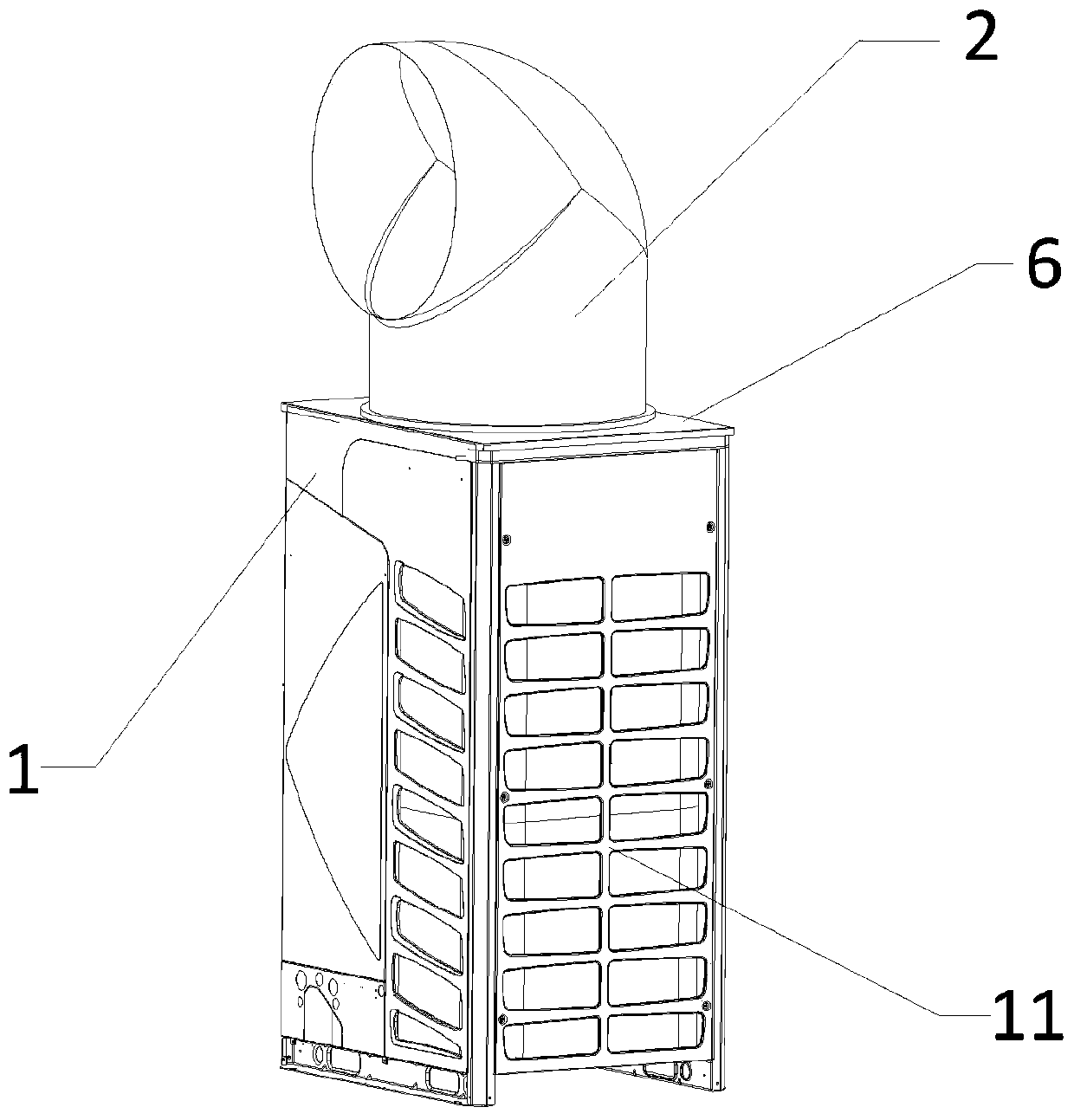

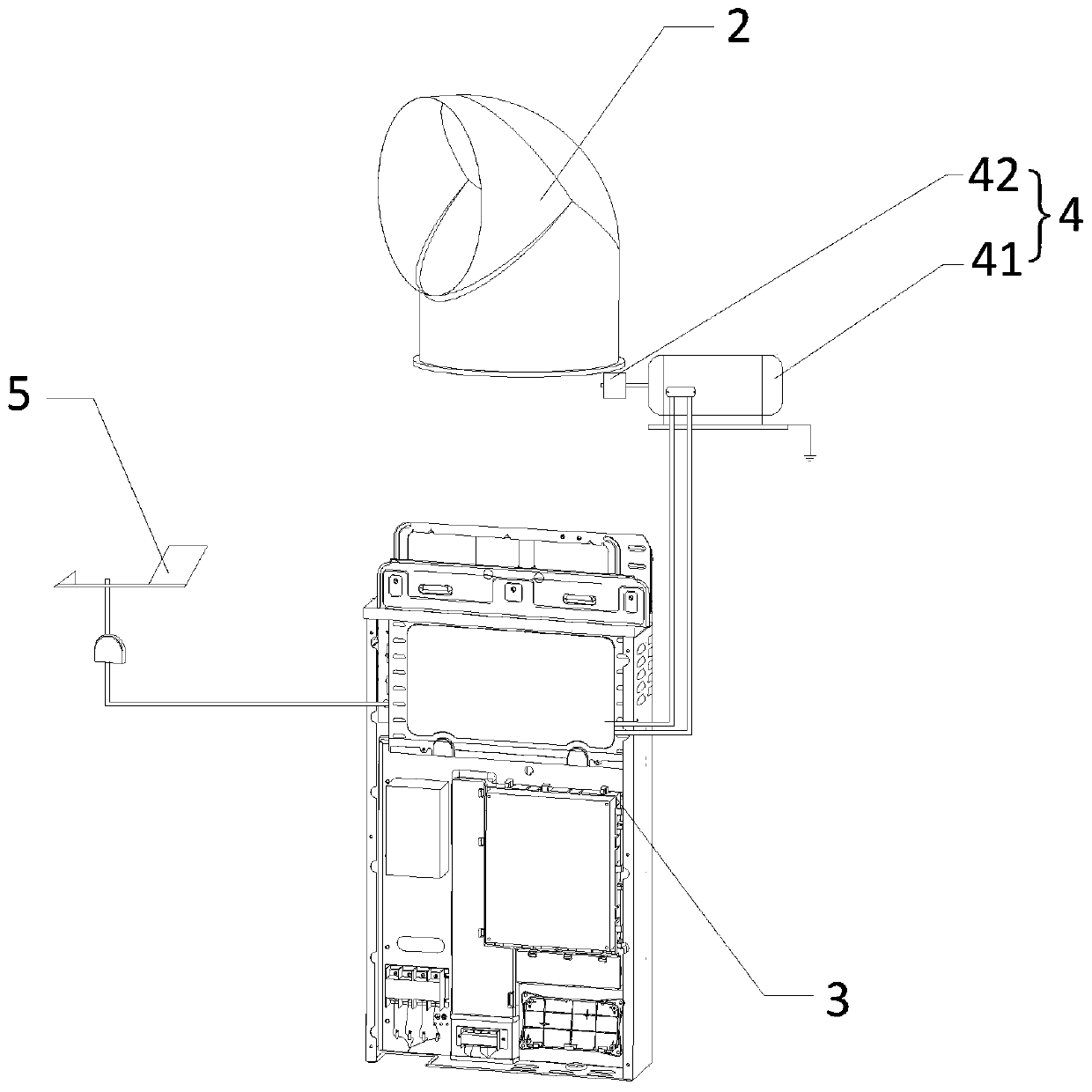

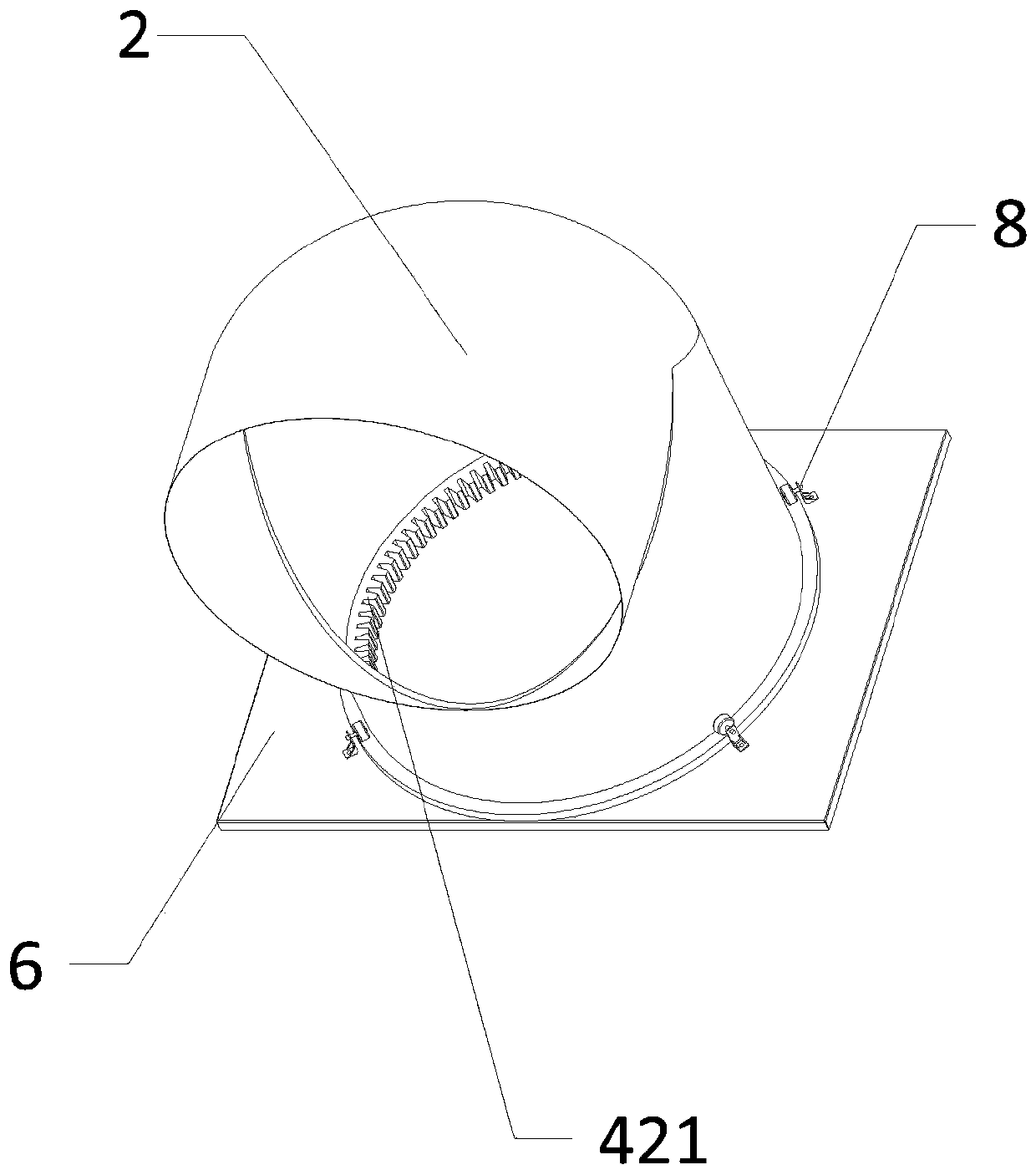

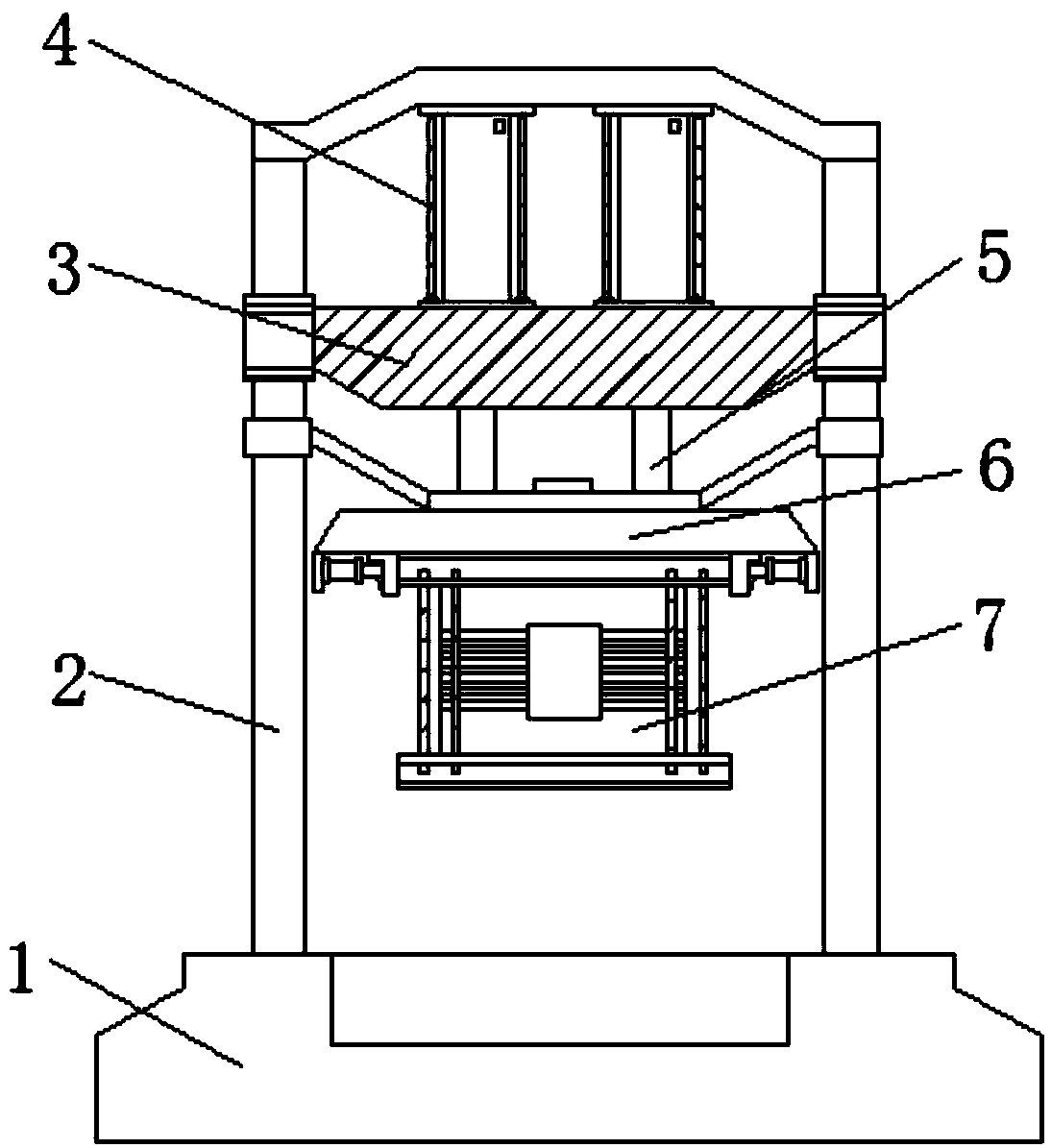

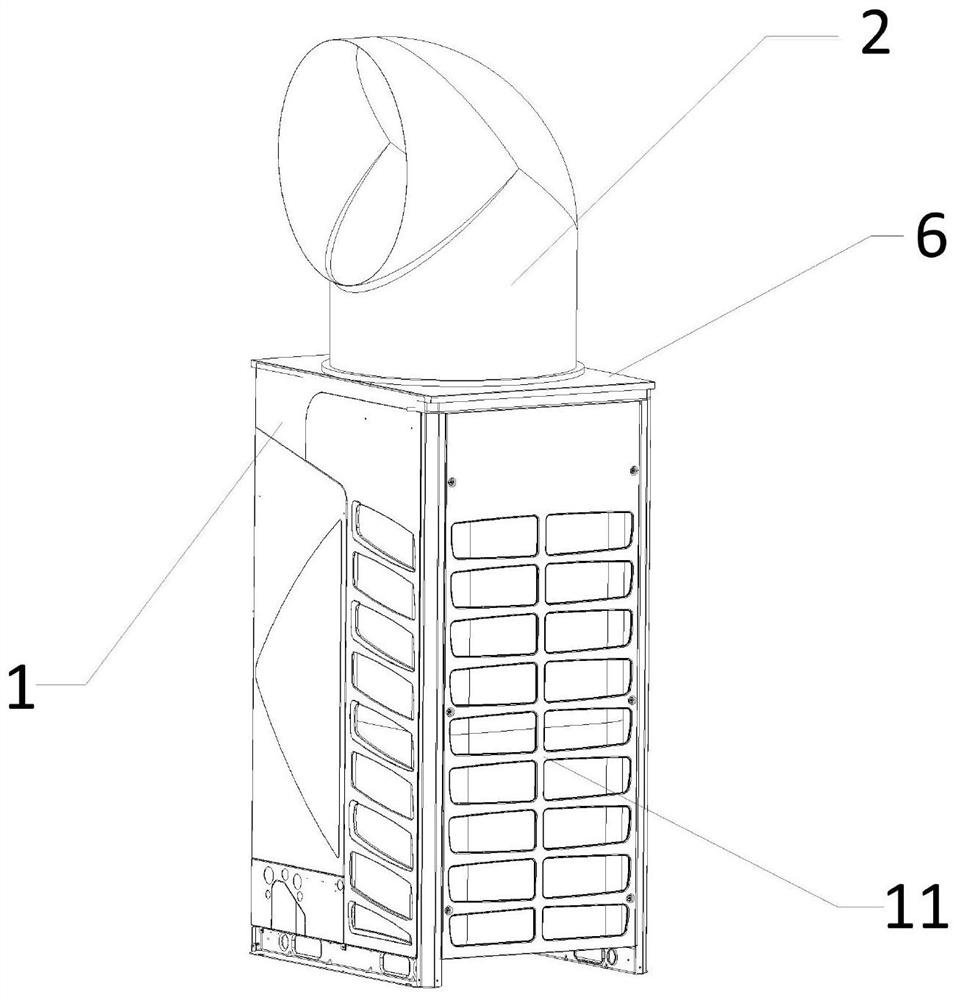

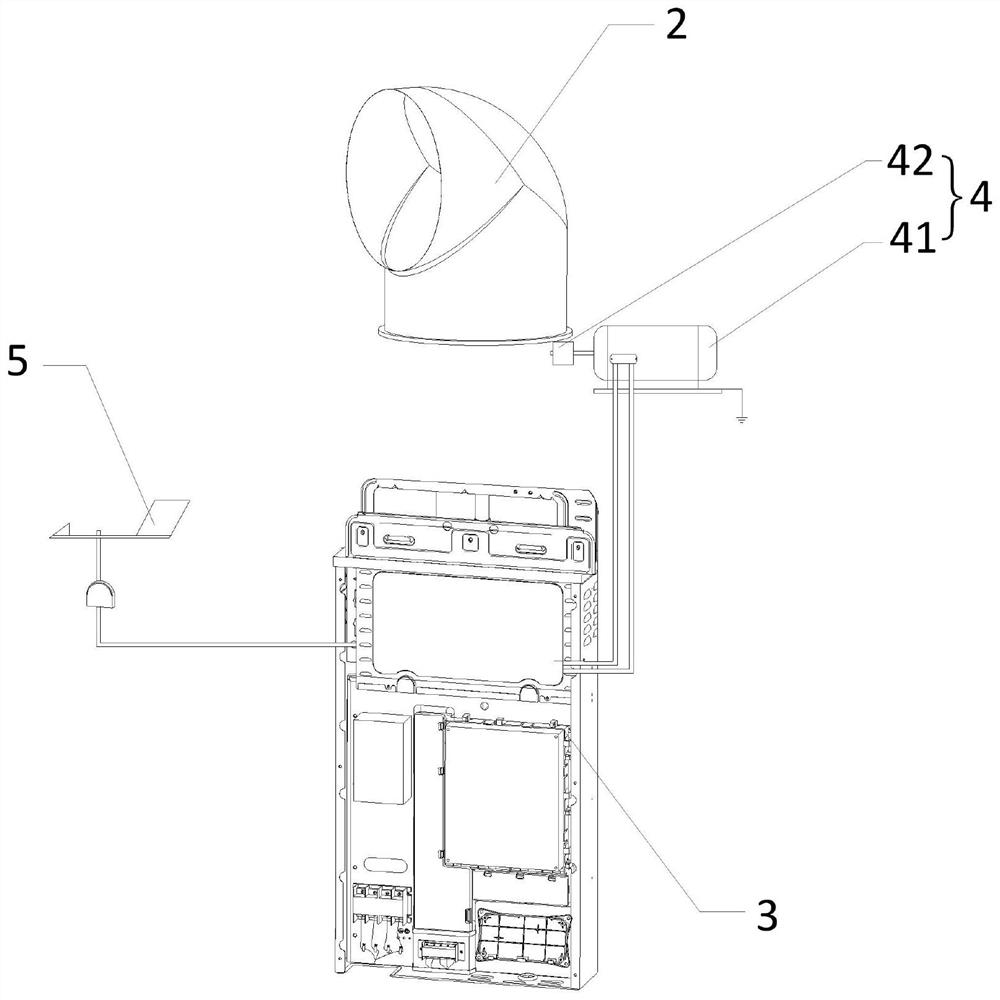

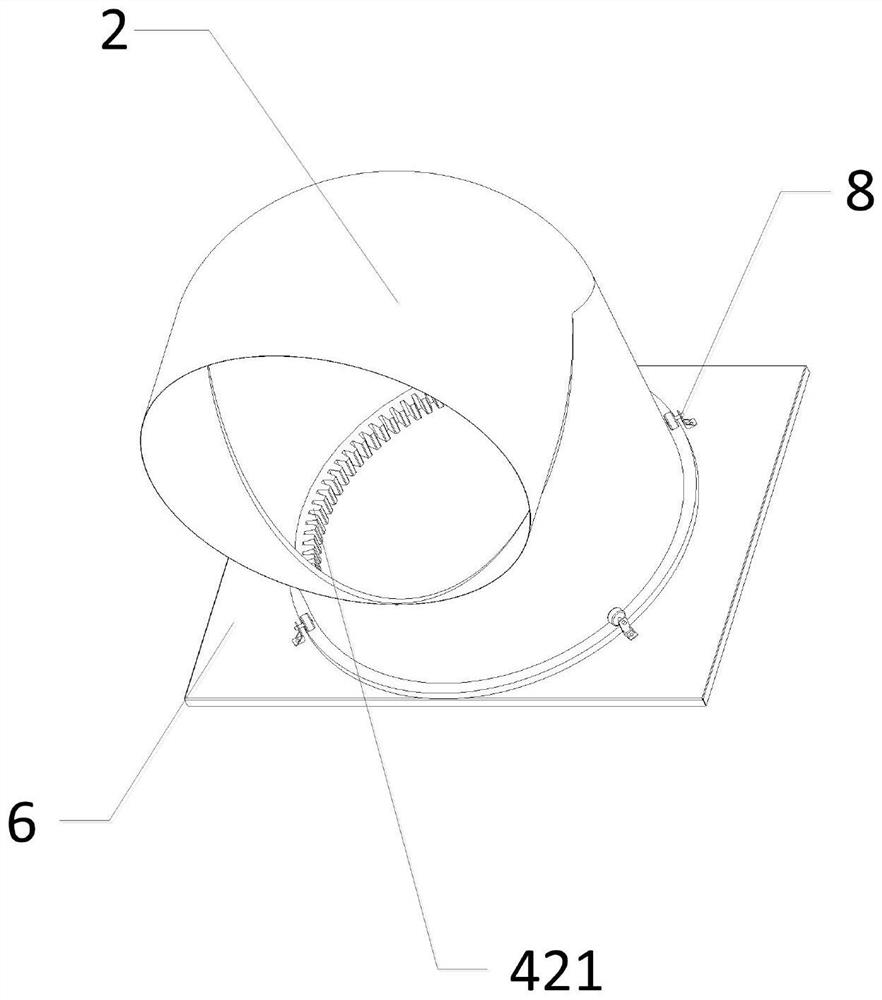

Air conditioner and control method thereof

ActiveCN110107962AExtended service lifeExtended maintenance cycleMechanical apparatusLighting and heating apparatusEngineeringControl system

The invention belongs to the technical field of air conditioners, and particularly provides an air conditioner and a control method thereof. The invention aims to solve the problems that an outlet direction of an existing snow protection cover is fixed and cannot be adjusted according to a wind direction change so as to easily cause the backward blowing of wind and snow and influence a ventilationeffect. Therefore, the air conditioner provided by the invention comprises an outdoor unit and a control system, wherein an air outlet is formed in the top part of a tank of the outdoor unit. The airconditioner further comprises a snow protection cover communicating with the air outlet, a rotary drive device connected with the snow protection cover, and a wind direction detection device arrangedon the tank, wherein the snow protection cover and the top part of the tank are rotatably arranged; and the rotary drive device and the wind direction detection device are in communication with the control system. According to the air conditioner and the control method thereof provided by the invention, an outlet direction of the snow protection cover can be adjusted according to the wind direction change, and the outlet direction and the wind direction keep consistent or keep within a small included angle, so that the backward blowing of wind and snow can be effectively prevented, and the ventilation efficiency is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

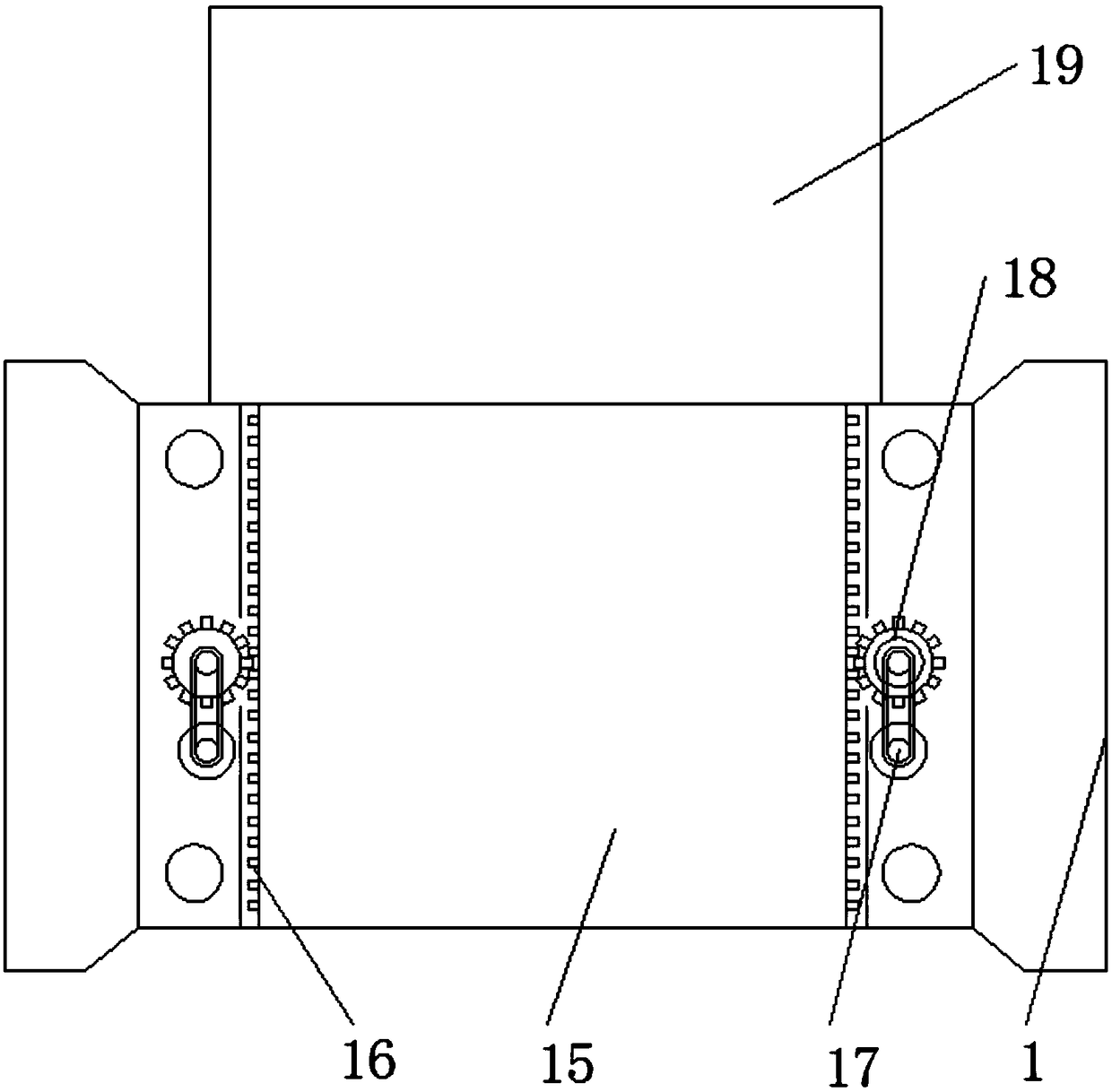

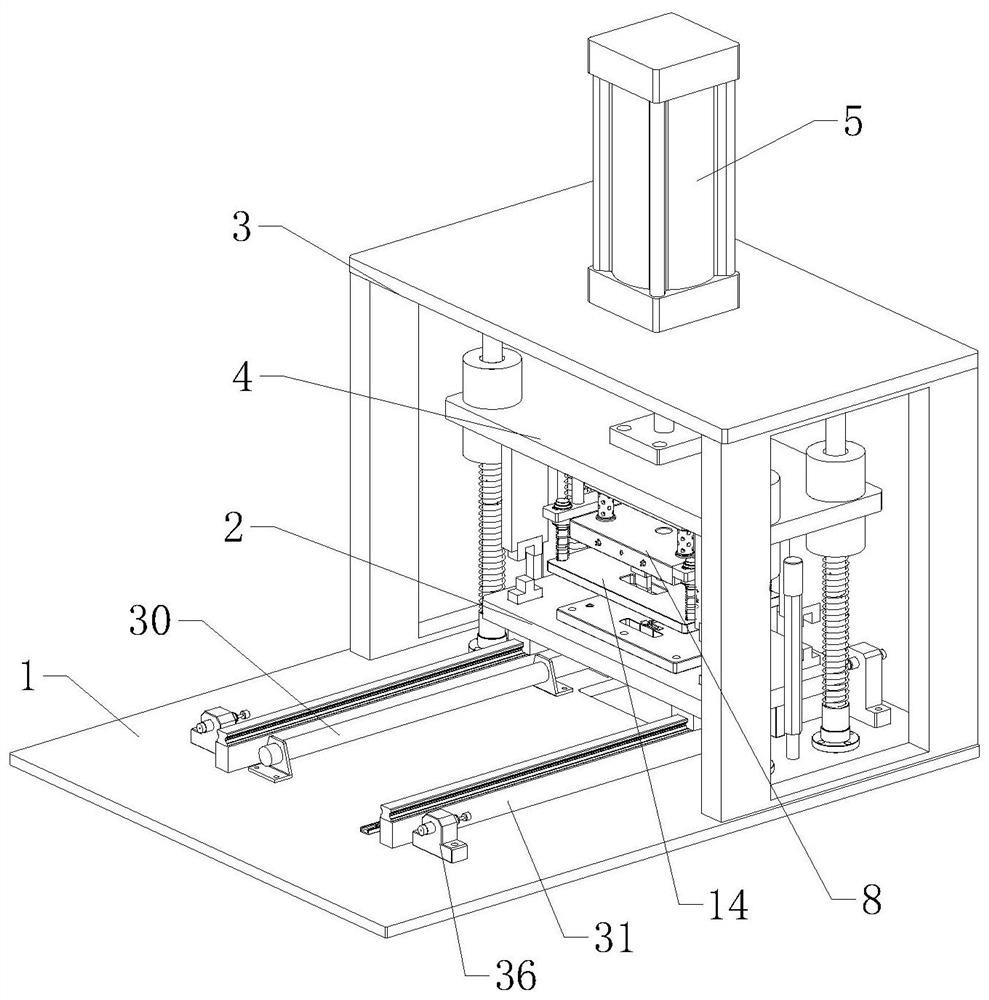

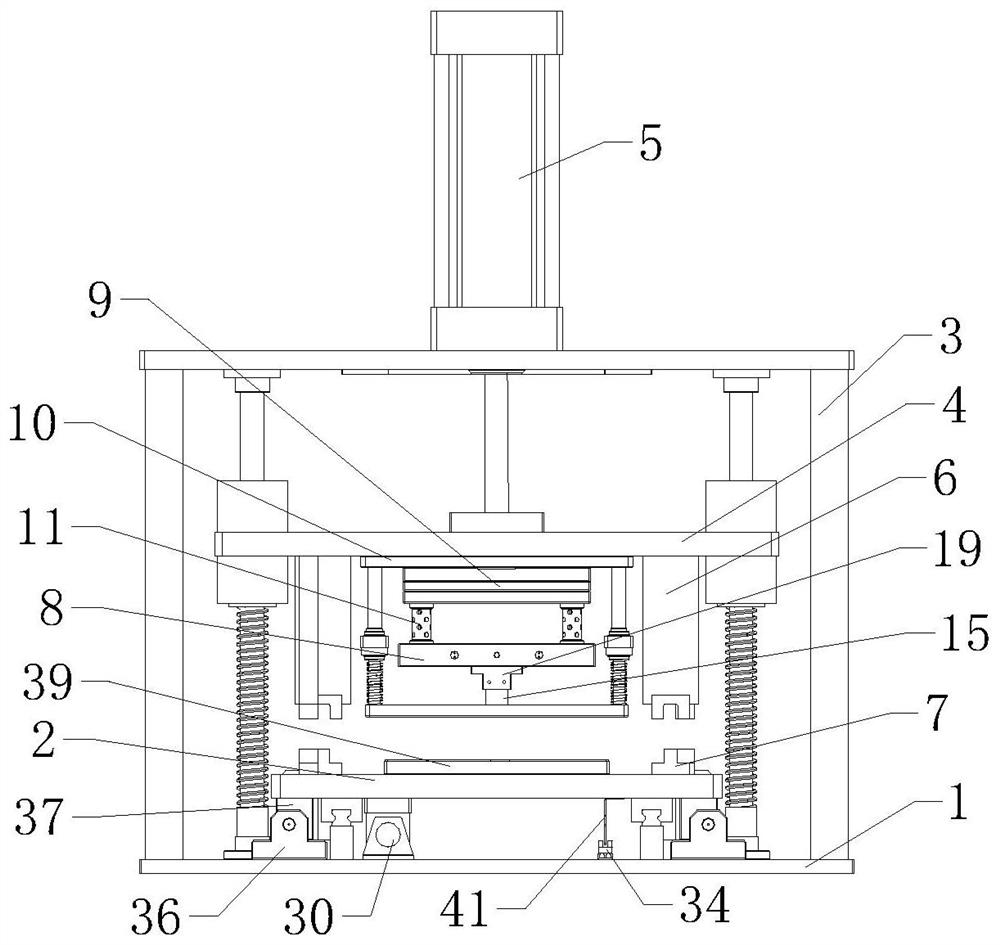

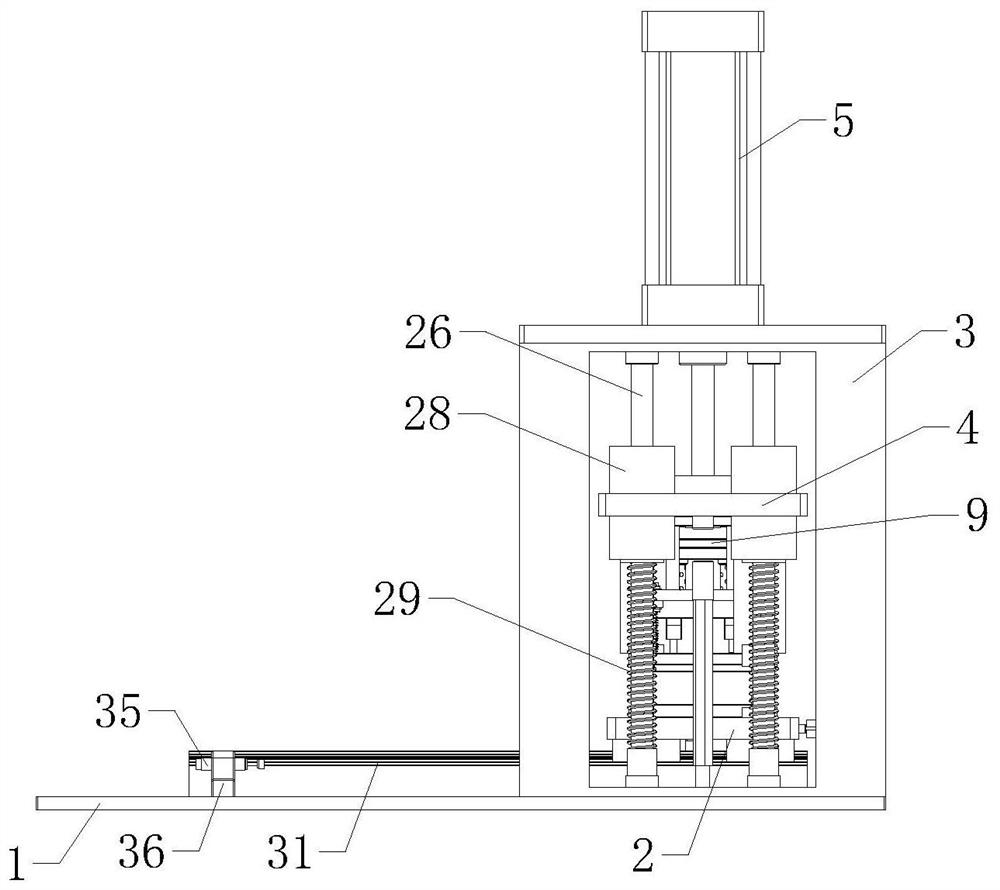

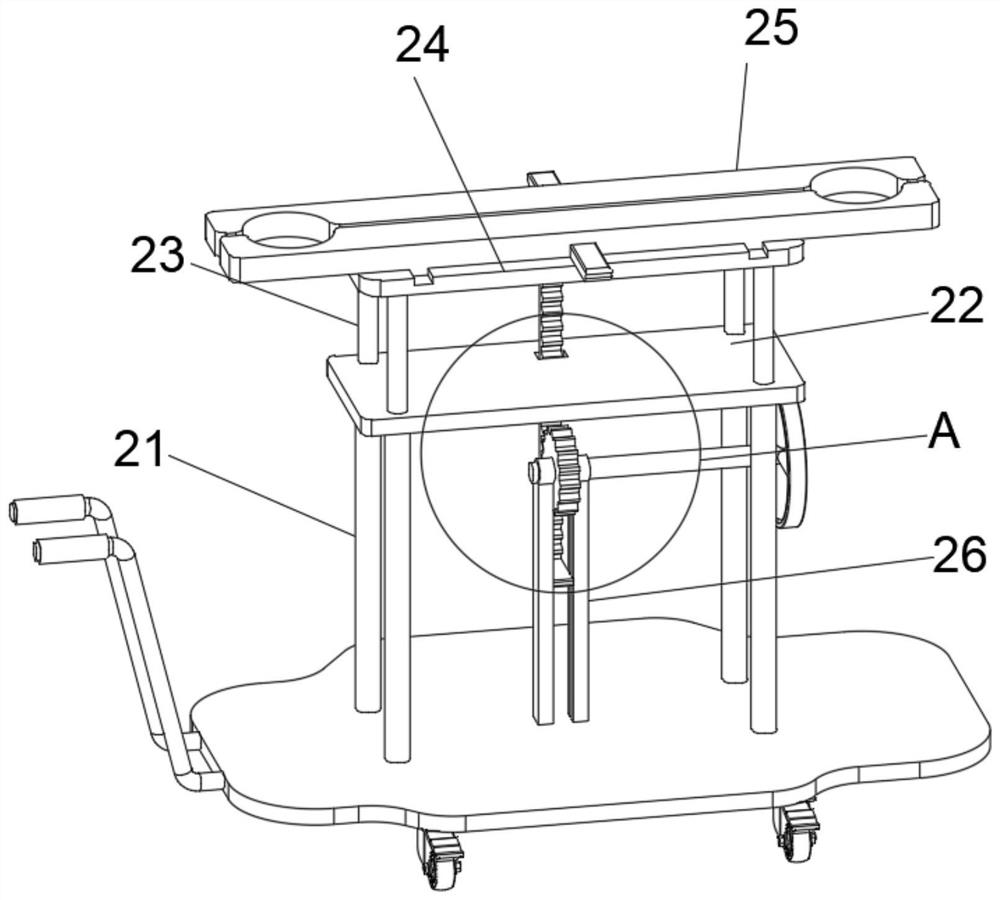

Tool clamp table for assembling transformer core

PendingCN109396791AThe installation position is accurateNo lateral offsetWork holdersMetal working apparatusTransformerEngineering

The invention creatively discloses a tool clamp table for assembling a transformer core. The tool clamp table comprises a fixed base. Four supporting rods are welded to four corners of the top of thefixed base and hydraulic oil cylinders are spirally fixed to the top ends of the four supporting rods through a connecting upper frame. According to the tool clamp table for assembling the transformercore, limiting side racks are symmetrically welded to two sides of a hanging rack, and sliding sleeves are welded to the tops of the limiting side racks. By connecting the sliding sleeves to a supporting rack, the hanging rack which is lifted can be limited, so that the hanging rack is kept in vertical lift without lateral deviation, and therefore, the mounting precision is improved. Then, by arranging a sliding limiting rack, the sliding limiting rack can limit a transformer core group, and meanwhile, a laser positioning lamp at the bottom of the sliding limiting rack can position the transformer core group, so that the mounting position of the transformer core group is more precise.

Owner:TAIZHOU TIANLI IRONCORE MFG

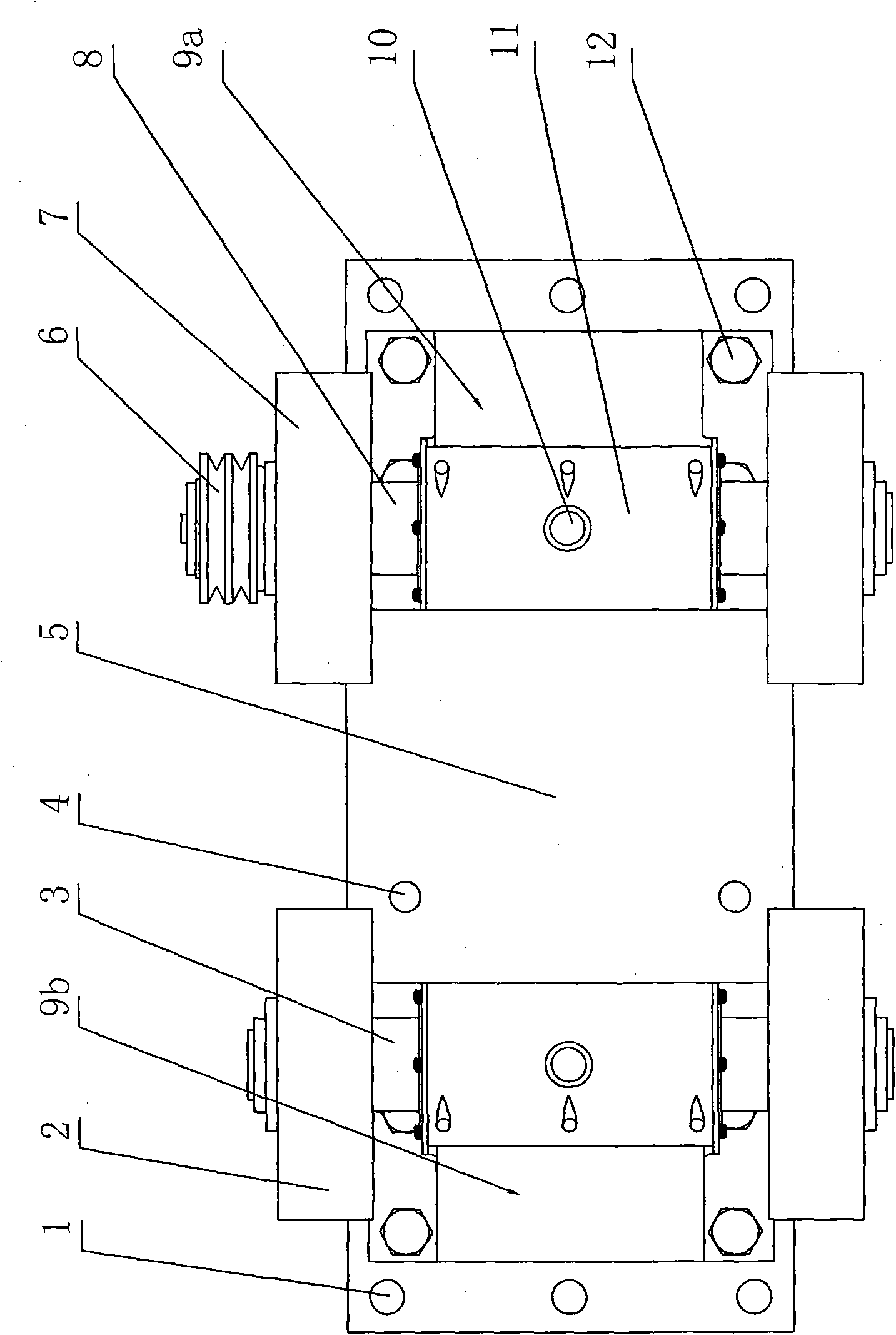

Rolling type centrifugal casting machine

The invention relates to a rolling type centrifugal casting machine. A first supporting seat and a second supporting seat which are used for supporting shafts are oppositely arranged on a base; a rotating shaft which extends horizontally is arranged on each of the two supporting seats; the two rotating shafts are parallel, and the heights of the two rotating shafts in the horizontal position are same; the rotating shafts are supported on the supporting seats through bearings; rollers for holding a cylinder casting mold for rotating are respectively installed at two extending ends of the rotating shaft; a driven wheel for receiving power transmission is installed at one end of the rotating shaft on the first supporting seat so as to enable the roller on the first supporting seat to be an active roller, and the roller on the second supporting seat to be a driven roller; and the spacing distance between the active roller and the driven roller is greater than the radius of the cylinder casting mold and is less than the diameter of the cylinder casting mold, thereby forming a raceway for the cylinder casting mold to rotate. The invention can enable the cylinder casting mold of which the axial length is greater than 400mm to be held by the rollers on the two supporting seats for rotating, overcomes the rotary swing of a cantilever type casting mold, realizes the purpose of carrying out centrifugal casting by using a longer cylinder casting mold, improves the production efficiency, has simple structure, and reduces the manufacturing cost of the centrifugal casting machine.

Owner:武胜县锦雄机械有限责任公司

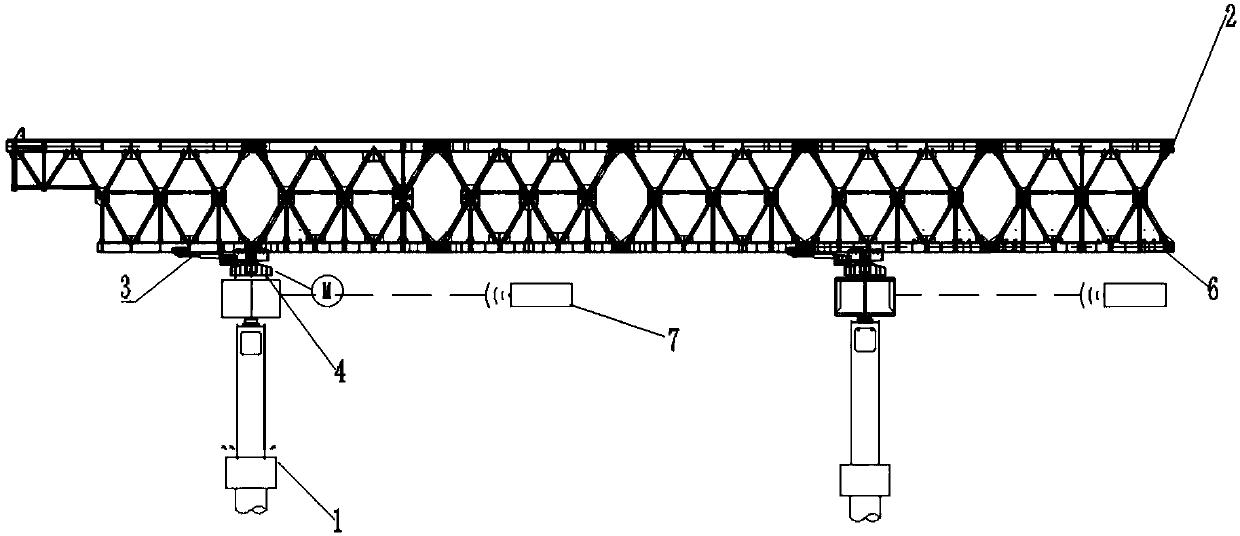

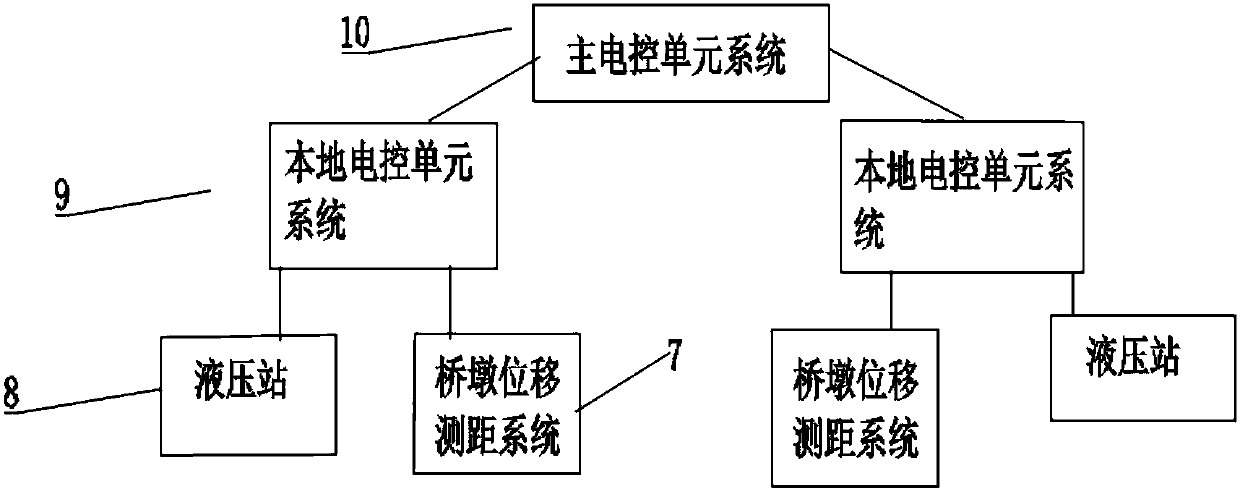

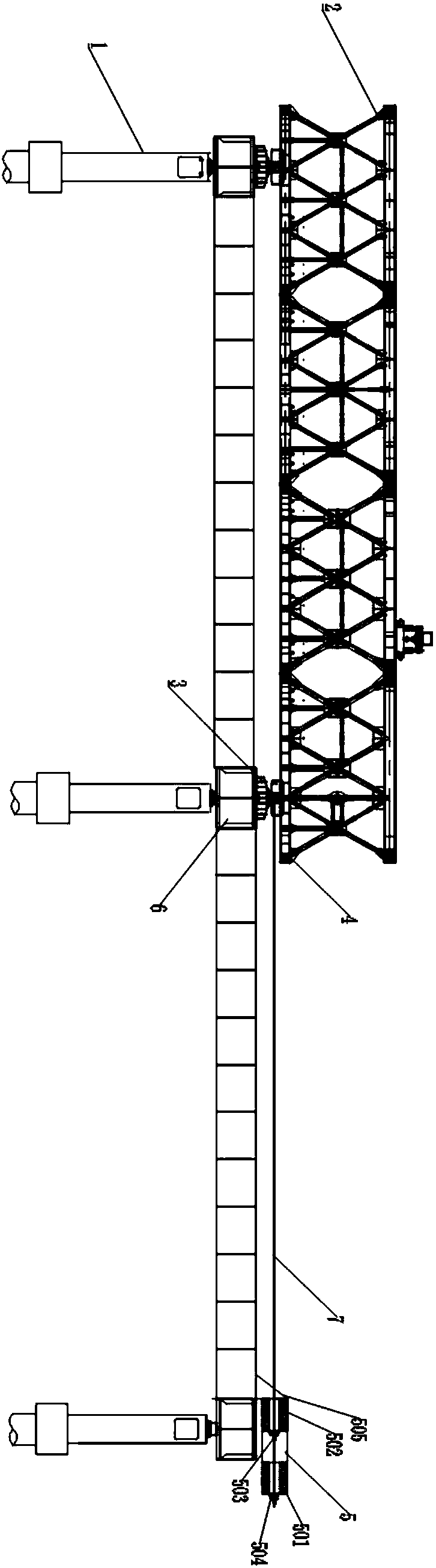

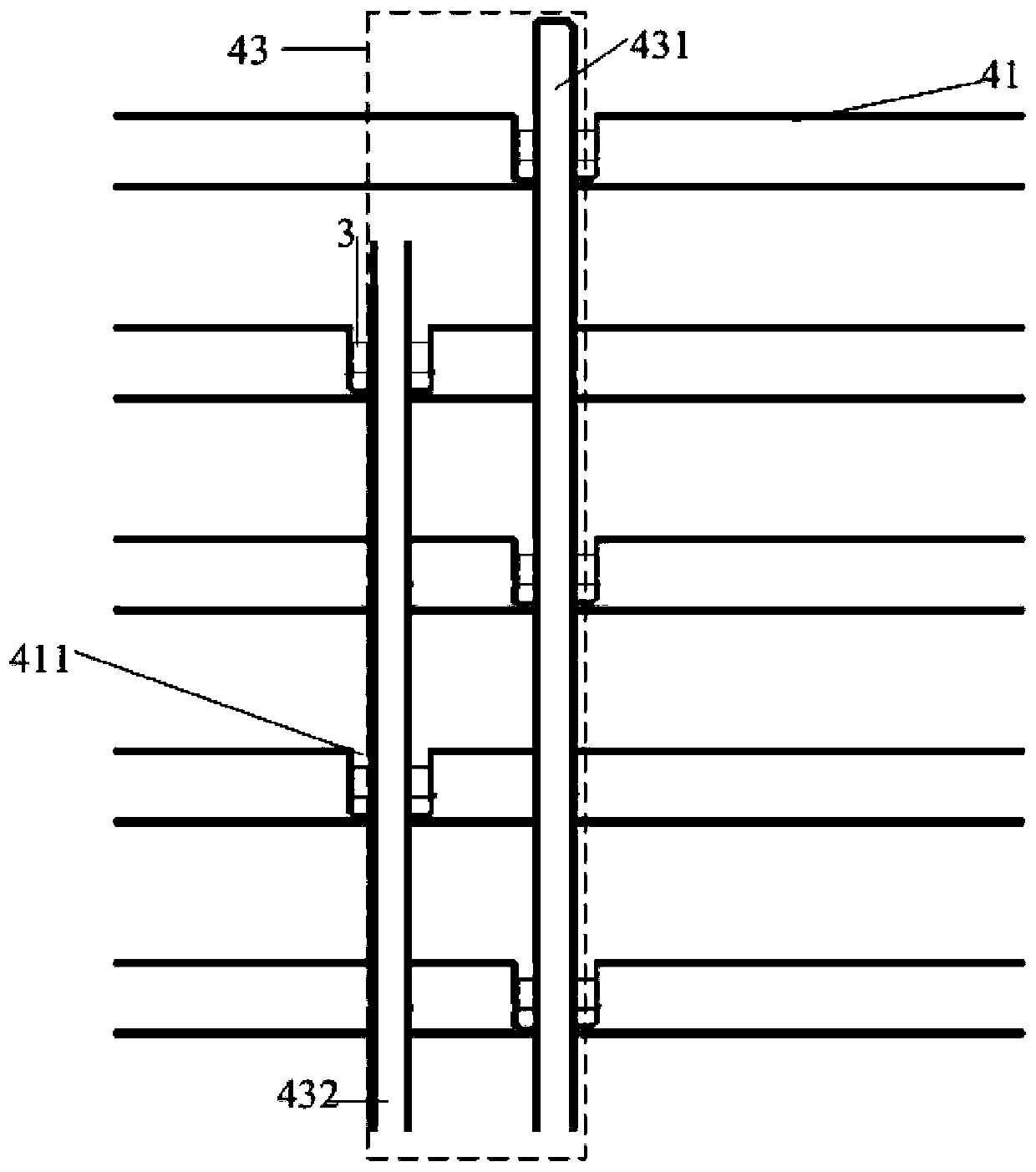

Independent non-rigid pier-based multipoint synchronous jacking device of multi-union multi-span steel beam, and construction method

PendingCN107815975AImprove construction quality and speedAddress the risk of damageBridge erection/assemblyPierJackscrew

The invention discloses an independent non-rigid pier-based multipoint synchronous jacking device of a multi-union multi-span steel beam. A hydraulic jacking unit is arranged on each pier, a continuous jacking sliding structure is arranged at the hydraulic jacking unit, the hydraulic jacking unit and the continuous jacking sliding structure are connected with the steel beam through a jacking counter force track, the jacking counter force track is distributed along with a bridge direction, a pin insertion and extraction system is arranged between the hydraulic jacking unit and the jacking counter force track, and a pier displacement ranging system is arranged between the continuous jacking sliding structure and the pier; and the invention further discloses a construction method of the device. The independent non-rigid pier-based multipoint synchronous jacking device of multi-union multi-span steel beam has the beneficial effects of being capable of controlling all independent piers to be synchronously jacked within the allowable displacement deviation range, so as to guarantee that the pier is not destroyed by jacking force, and the construction quality and speed of the steel beam can be improved.

Owner:江西乔田重工有限公司

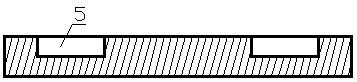

Automatic bending machining equipment for plate

ActiveCN109570287AAvoid crackingAvoid wrinklesMetal-working feeding devicesPositioning devicesThermal stateEngineering

The invention discloses automatic bending machining equipment for a plate. The automatic bending machining equipment for the plate comprises two conveying frames (1) which are arranged at the left side and right side in parallel, wherein a base (24) is arranged on the bottom surfaces of the conveying frames (1), and two groups of lower telescopic rods (15) which are arranged at the left side and right side in parallel are connected between the two conveying frames (1) and to the inner top surface of the base (24); heating plates (18) are hinged to the top surfaces of each group of the lower telescopic rods (15) through rotary shafts (14), and the heating plates (18) at the left side and the right side are connected through springs (17); an upper drive rod (12) is connected to the top surface of each conveying frame (1); a bending head (25) with a heating assembly is connected to the bottom surface of each upper drive rod (12); and a plate detector (11) is arranged at one side of each upper drive rod (12). The equipment is provided with a limit plate (10), a conveying roll (20) and an auxiliary cooling device (35), the limit plate (10) guarantees an accurate position of the plate, the conveying roll (20) guarantees the conveying accuracy, and the auxiliary cooling device (35) greatly avoids the risk of resilient deformation of a thermal-state bent product during die release.

Owner:QILU INST OF TECH

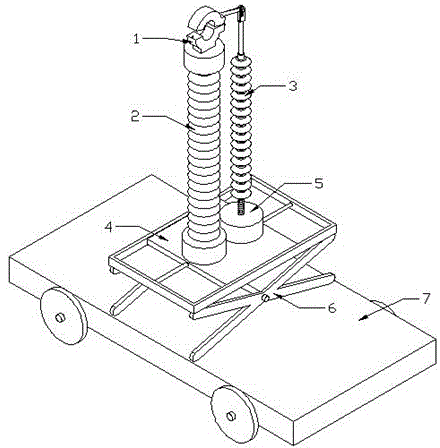

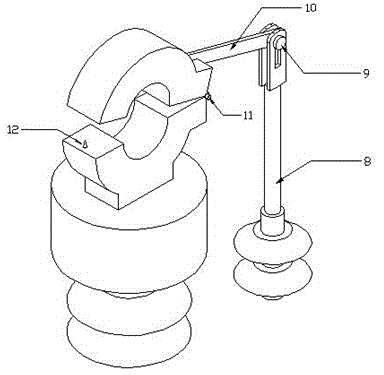

High-voltage live access apparatus for current transformer

ActiveCN103336261AEasy accessPlay a buffer roleElectrical measurementsPower flowElectric power equipment

The invention relates to the field of calibration, verification and detection of electric power equipment, and especially relates to a high-voltage live access apparatus for a current transformer. The high-voltage live access apparatus comprises an opening CT, a main insulator and an opening on-off apparatus. The opening on-off apparatus is used for opening or closing the opening CT, and measurement of primary bus current or an online calibration test of the current transformer is conducted by connecting the current transformer which is relatively large in weight into a primary high-voltage bus in the case that the system is not powered off and the primary bus is not disconnected. Therefore, the workload is substantially reduced and economic loss caused by a power outage of the system is prevented.

Owner:STATE GRID CORP OF CHINA +1

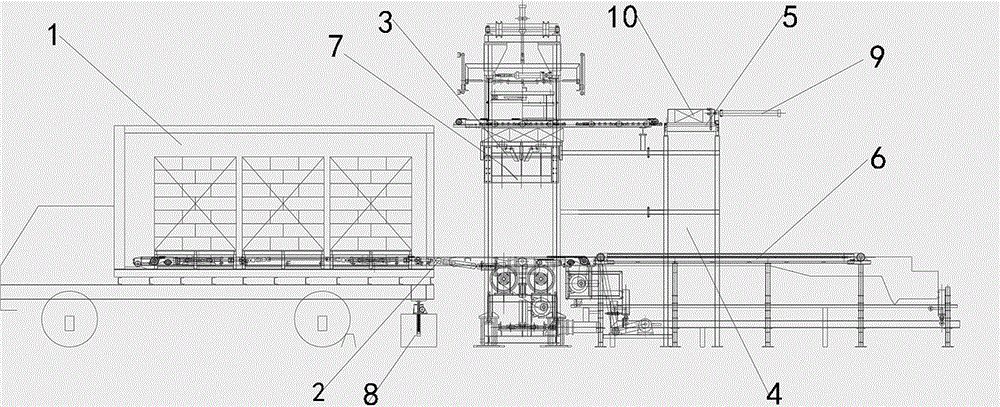

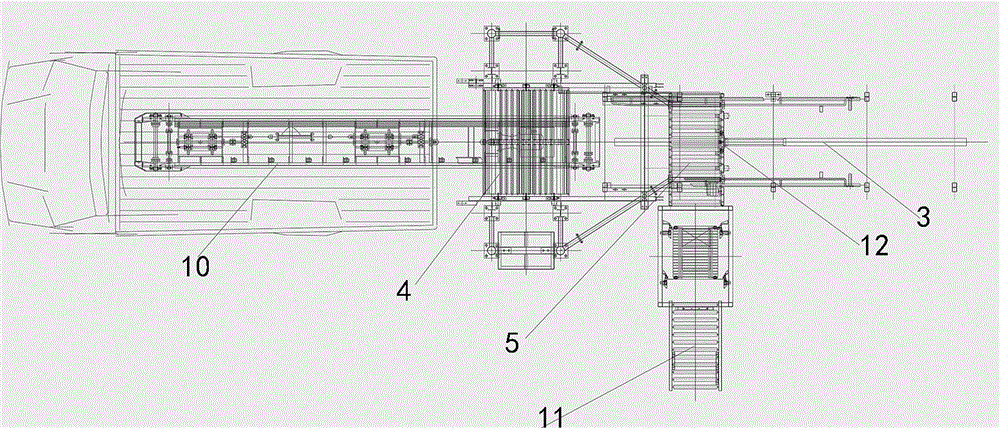

Automatic stacking and loading device for industrial explosive products

The invention discloses an automatic stacking and loading device for industrial explosive products. The automatic stacking and loading device comprises a load vehicle; a stacking tray is arranged in a compartment of the load vehicle; a conveying device is arranged at the bottom of the stacking tray; the rear end of the conveying device is arranged on a lifting frame; a conveying line truss is arranged close to the conveying device; an elevator is arranged above the part, close to the conveying device, of the conveying line truss; the conveying line truss is provided with a drive device for driving the conveying line truss; the lifting frame is provided with a tray lifting drive device; a stacking is arranged on the tray lifting drive device; clamping boards used for tidying goods are arranged around the upper portion of the stacking; a pushing device of the elevator adjoins the elevator; and the pushing device comprises a pushing layer and a pushing drive device used for driving the pushing layer. The automatic stacking and loading device for industrial explosive products can achieve automatic and continuous stacking and loading and is high in loading efficiency.

Owner:雅化集团三台化工有限公司

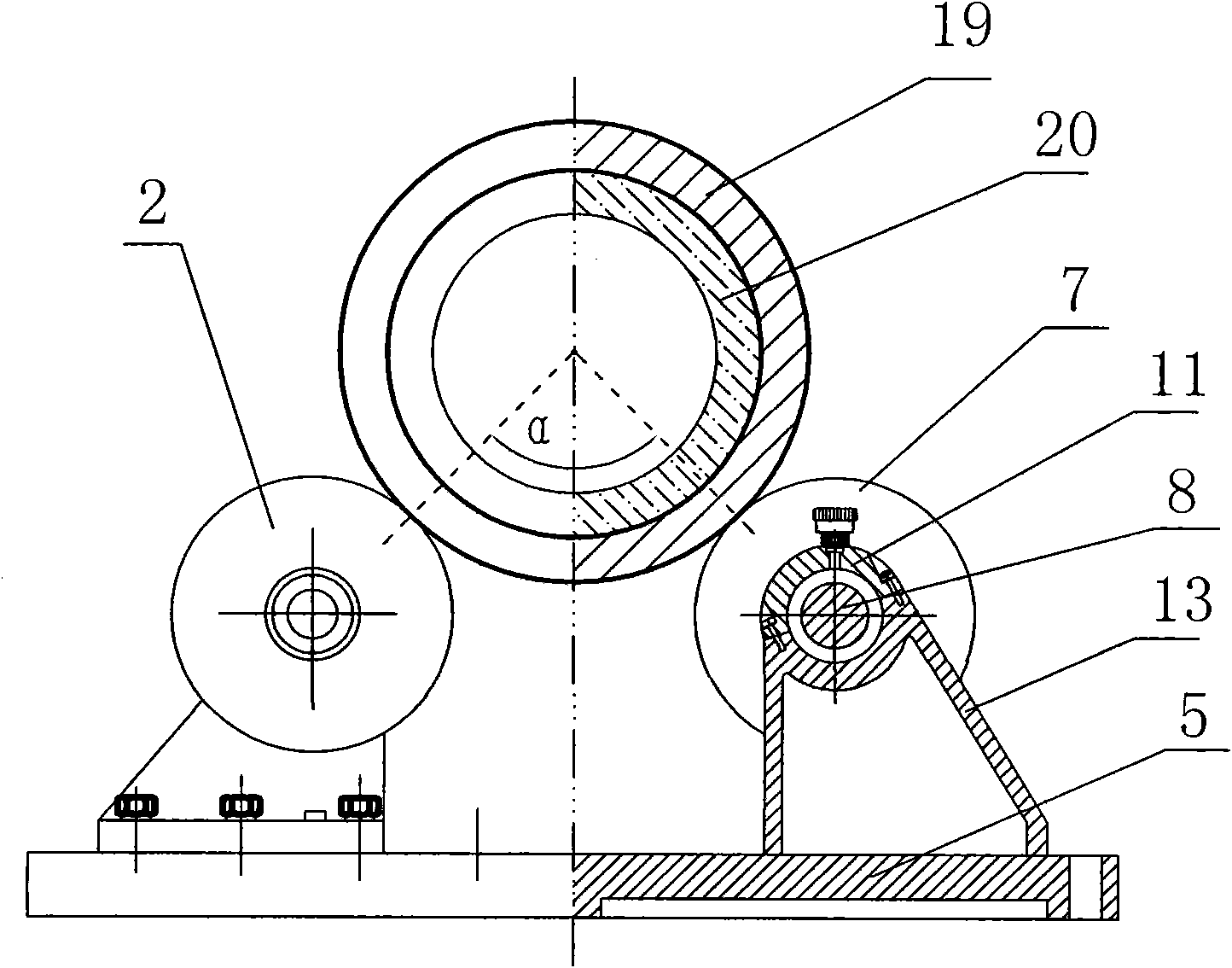

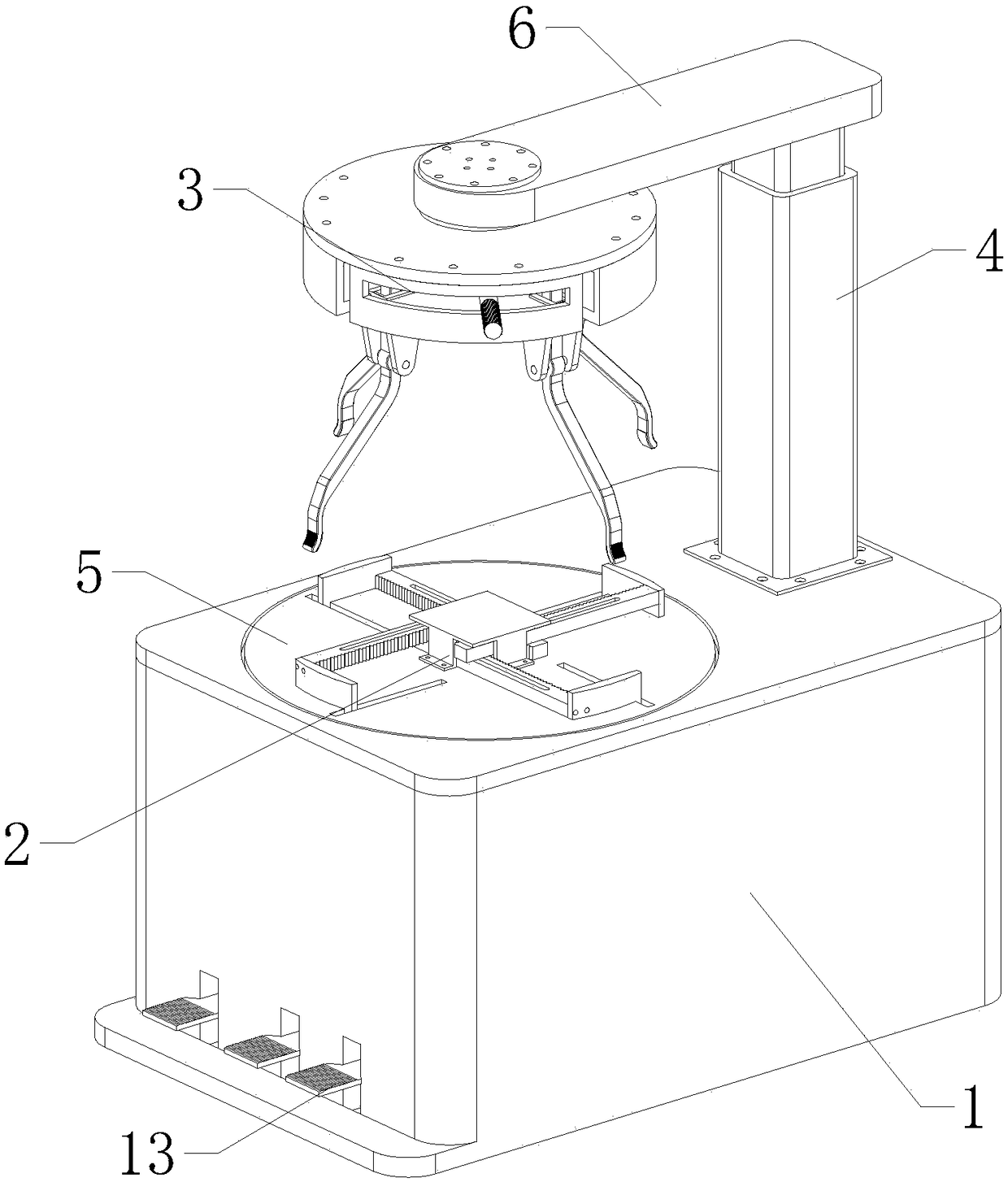

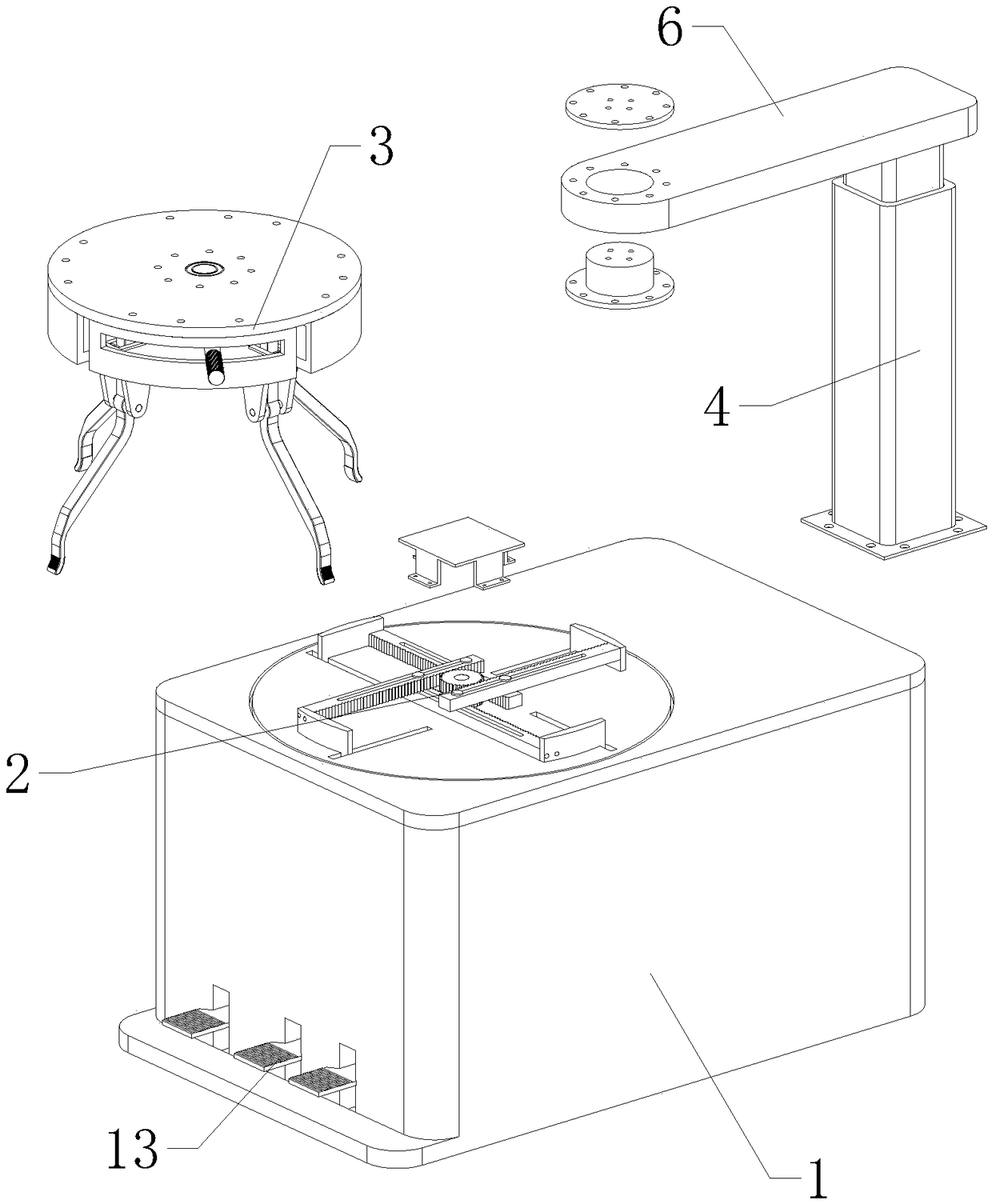

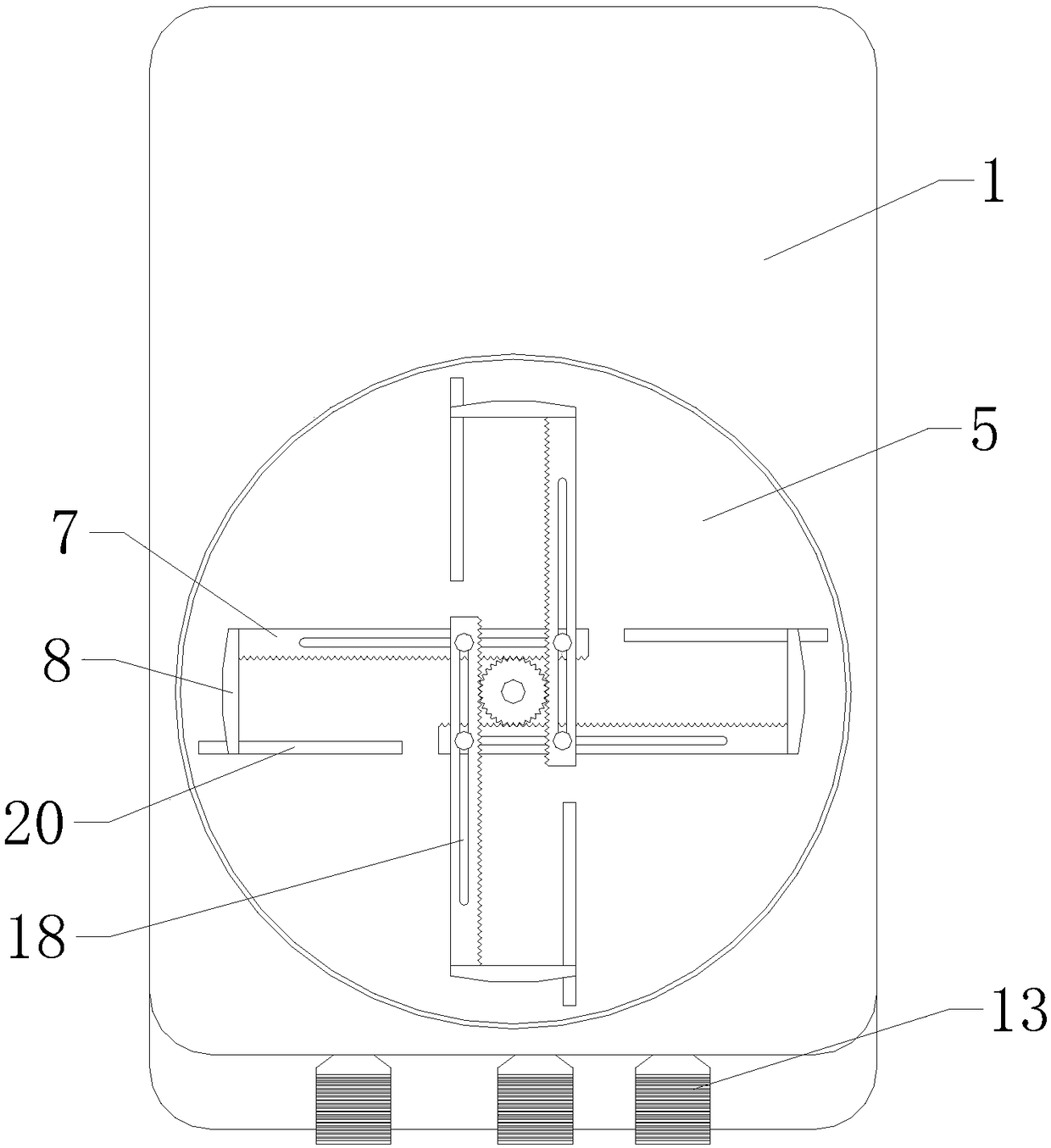

Protective dismounting machine for tires

The invention relates to the field of tire dismounting tools, in particular to a protective dismounting machine for tires. The protective dismounting machine for the tires comprises a working table, alocating mechanism, a trimming mechanism and a hydraulic lifting arm, wherein a hydraulic swivel plate is horizontally arranged on the top of the working table; the locating mechanism comprises fourcontact rods and a rotating motor; the outer end of each contact rod is connected with an abutting block; the trimming mechanism comprises a circular containing plate and four derrick masts; the circular containing plate is internally provided with a shifting plate used for shifting the derrick masts; the side face of the shifting plate is connected with a push rod extending out of the circular containing plate; a plurality of pedal switches are arranged at the bottom of the lateral part of the working table. The protective dismounting machine for the tires can quickly perform the tire mounting operation of the low flatness ratio tire in a labor-saving way, avoids the situation that the low flatness ratio tire collides with a tire pressure sensor during installation, so that the tire pressure sensor is damaged, and effectively protects the rim from damage.

Owner:HEFEI CAREER TECHNICAL COLLEGE

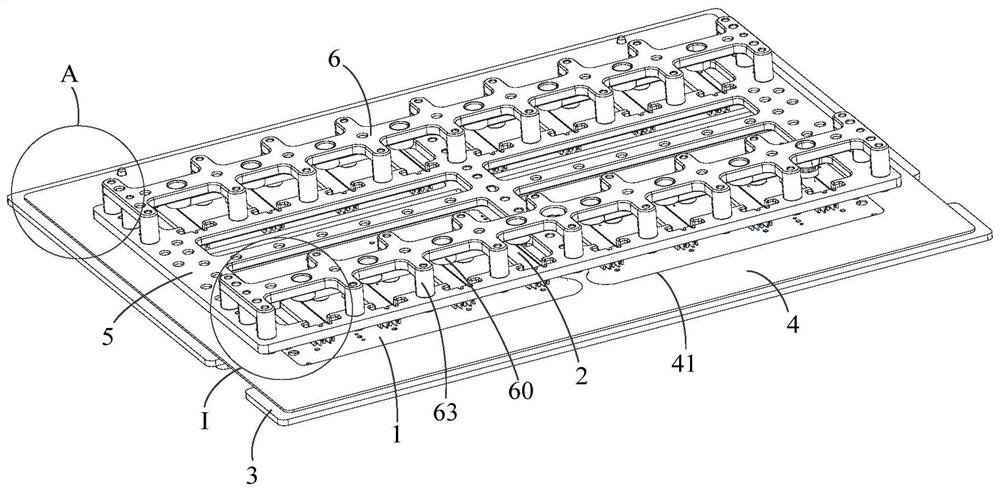

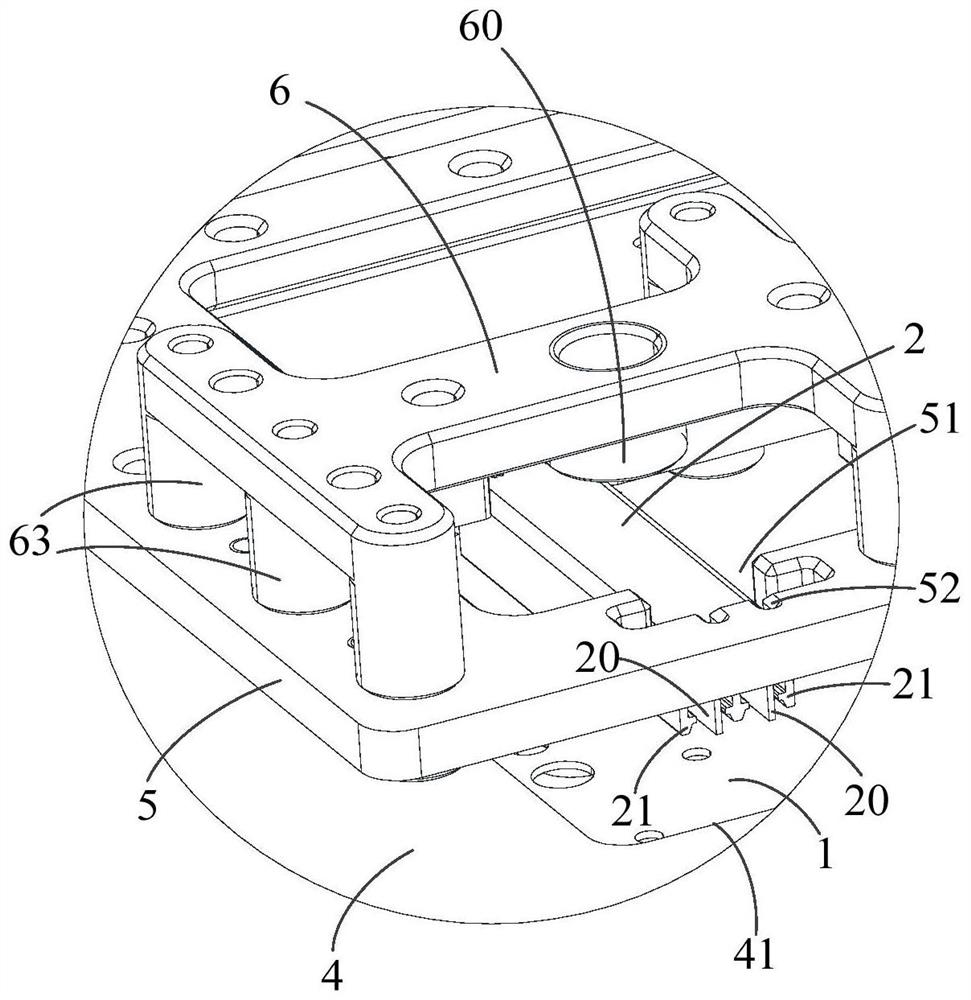

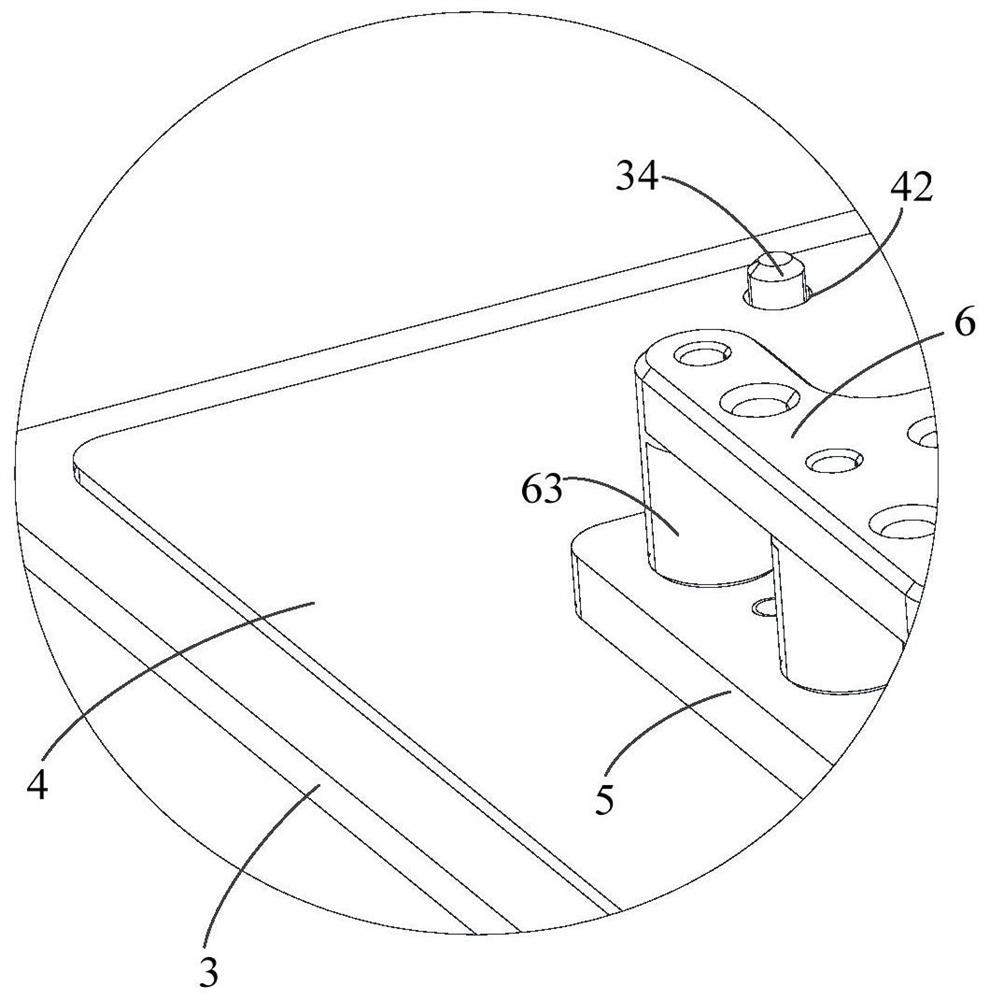

Positioning device for phase shifter welding and method for positioning phase shifter by using positioning device

PendingCN112157387ANo lateral offsetPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl theory

The invention relates to a positioning device for phase shifter welding and a method for positioning a phase shifter by using the positioning device. The positioning device comprises a power dividingplate positioning bottom plate and a phase shifter limiting plate which are oppositely arranged. A limiting hole used for limiting the phase shifter is formed in the phase shifter limiting plate; thephase shifter is located in the limiting hole; the surface, facing the phase shifter limiting plate, of the power dividing plate positioning bottom plate forms a bearing surface used for bearing a power dividing plate; and a first positioning column used for being connected with a first positioning hole in the power dividing plate in a matched mode is arranged on the power dividing plate positioning bottom plate. The positioning device for phase shifter welding further comprises a pressing structure arranged on the phase shifter limiting plate, wherein the pressing structure is used for pressing the phase shifter on the power dividing plate, so that the bottom face of the cavity wall of the phase shifter can be attached to a first bonding pad on the face, facing the phase shifter, of the power dividing plate, a positioning effect on the phase shifter is improved, and gaps generated by contact between the phase shifter and the power dividing plate can be effectively eliminated.

Owner:COMBA RF TECH GUANGZHOU LTD +1

Protective dismounting equipment for low-flatness-ratio tyre

The invention relates to the field of tyre dismounting tools, in particular to protective dismounting equipment for a low-flatness-ratio tyre. The protective dismounting equipment comprises a workbench, a positioning mechanism, an edge holding mechanism and a hydraulic lifting arm, wherein a hydraulic rotary disc is horizontally arranged on the top of the workbench; the positioning mechanism comprises four collision rods and a rotary motor; the outer end of each collision rod is connected with a resisting block; the edge holding mechanism comprises a circular accommodating disc and four holding rods; a pulling disc for pulling the holding rod is arranged in the circular accommodating disc; the side surface of the pulling disc is connected with a pushing rod which extends to the outside ofthe circular accommodating disc; and a plurality of pedal switches are arranged on the bottom of the side of the workbench. The low-flatness-ratio tyre protective dismounting equipment can quickly mount the low-flatness-ratio tyre in a labor-saving mode, avoids the condition that the low-flatness-ratio tyre is damaged as a tyre pressure sensor is collided in a mounting process, and effectively protects a rim from being damaged at the same time.

Owner:HEFEI CAREER TECHNICAL COLLEGE

Glass twitch roller structure

InactiveCN103253540ANo lateral offsetLight in massWebs handlingPulp and paper industryLateral deviation

The invention discloses a glass twitch roller structure which comprises a central roller body and a twitch roller cylinder arranged on the external of the central roller body, two ends of the central roller body are respectively provided with an end shaft, the central roller body and the end shafts are made of rigid plastics and are of an integrated structure, the twitch roller cylinder is a silica glass roller cylinder, a dull polish layer is arranged on the outer surface of the silica glass roller cylinder, and abrasion-resisting layers are arranged on outer surfaces of the end shafts. Through the mode, the glass twitch roller structure is light in weight, the outer surface has definite roughness, and lateral deviation of cloth cannot be caused.

Owner:虞伯林

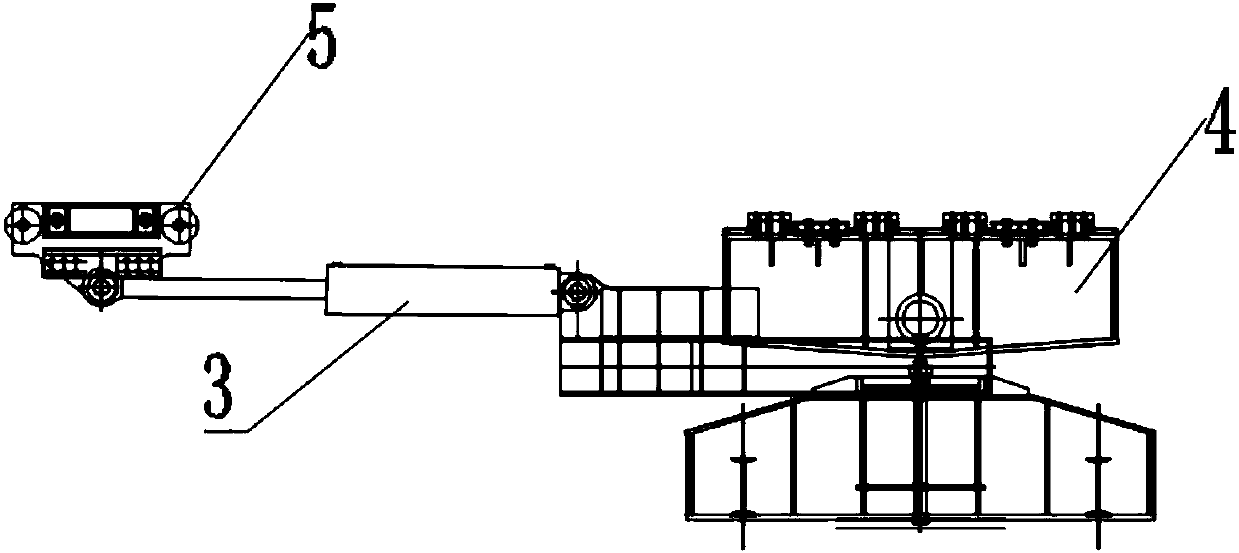

Dragging device and construction method of large steel beams based on finely rolled deformed steel bars and continuous hydraulic jacks

PendingCN107858932AImprove construction quality and speedRealize the erection problemBridge erection/assemblyFluid-pressure actuator componentsCross channelEngineering

The invention relates to a dragging device of large steel beams based on finely rolled deformed steel bars and continuous hydraulic jacks. Dragging slide structures are arranged at dragging points between bridge piers and steel beams; the dragging slide structures are connected with continuous dragging structures through the finely rolled deformed steel bars; the dragging slide structures are in slide connection with the steel beams through dragging counterforce rails; the dragging counterforce rails are arranged along the bridge direction; displacement, pressure and distance measurement sensing components are arranged between each dragging slide structure and each bridge pier; each dragging slide structure communicates with a hydraulic station; each hydraulic station communicates with a field control unit; and each field control unit communicates with a main control unit and corresponding displacement, pressure and distance measurement sensing components. The invention also disclosesa construction method of the device. The dragging device and the construction method have the beneficial effects that erection of the steel beams across channels, railways and expressways in complex environments can be realized, dragging devices arranged on a plurality of bridge piers can be controlled simultaneously, and the dragging displacement can be ensured to be equal to the actual displacement of the steel beams.

Owner:江西乔田重工有限公司

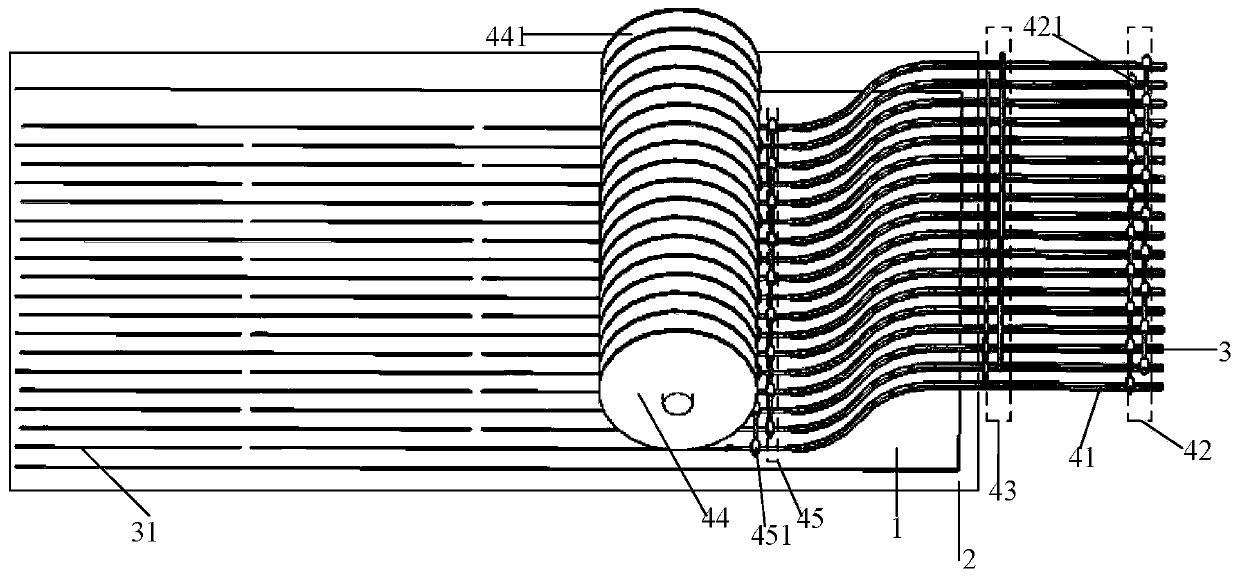

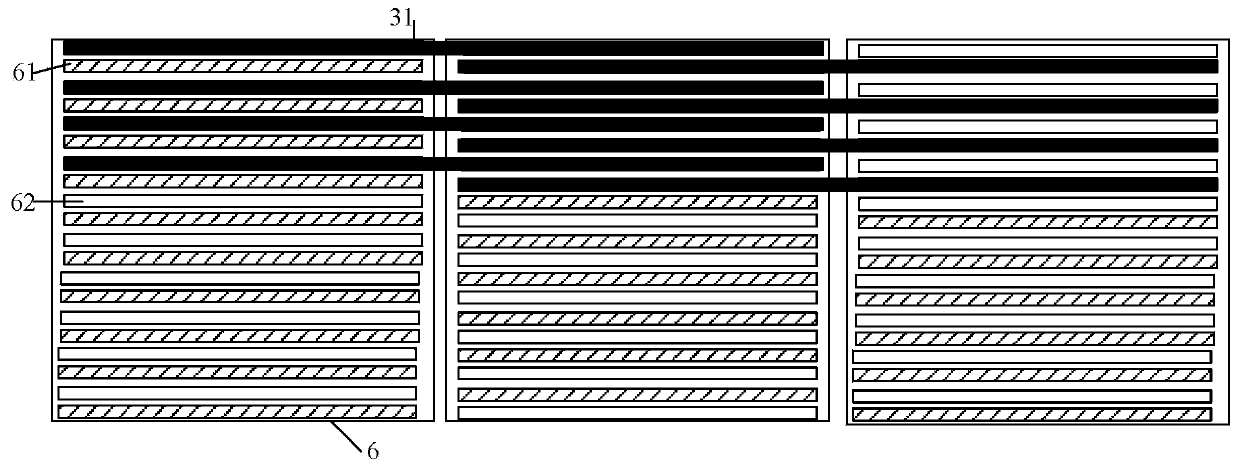

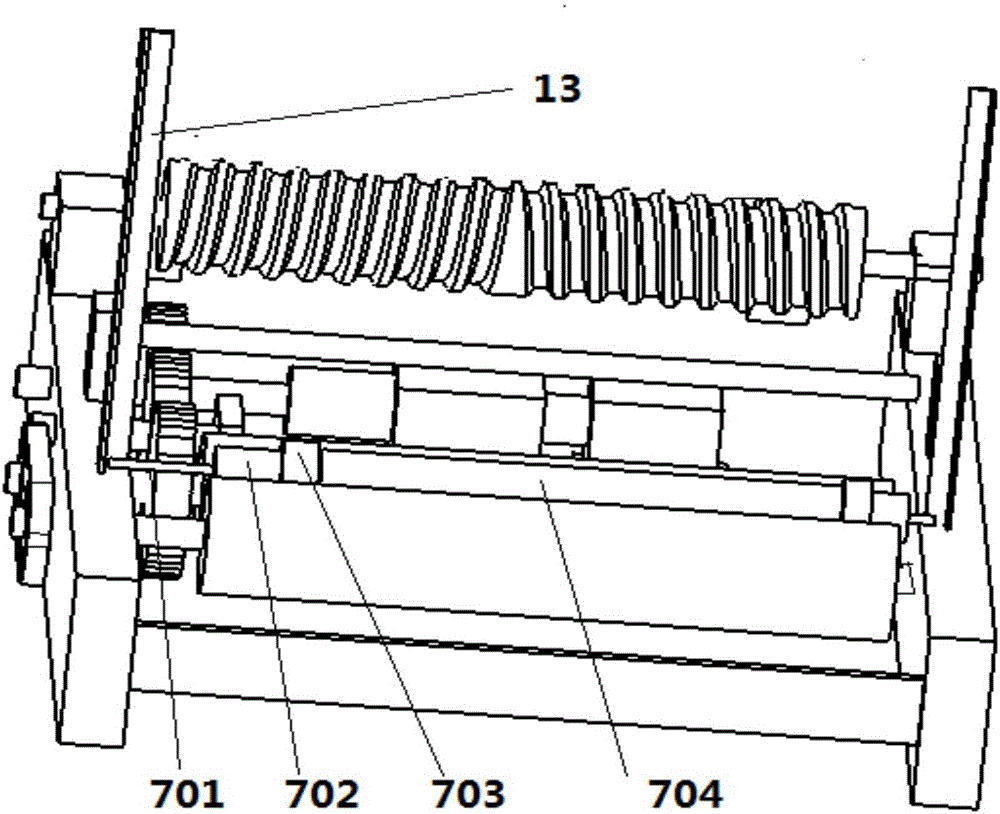

Production device and production method of conductive interconnection board, and conductive interconnection board

PendingCN111180549ANo lateral offsetPrecise positioningFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention provides a production device and a production method of a conductive interconnection board of a back contact battery and the conductive interconnection board, and relates to the technical field of solar photovoltaics. The device comprises a workbench used for bearing a substrate, a wiring unit used for arranging a conductive wire on the substrate, and a moving unit used for enablingthe wiring unit and the substrate to move relatively. The wiring unit comprises: a plurality of wire pipes which are arranged side by side; a first group of conveying mechanisms which are used for conveying a plurality of conductive wires into the wire tubes from the feeding positions from the inlets of the corresponding wire tubes; a cutting mechanism which is used for cutting off the conductivewire in the wire pipe to obtain a wire section; a heating and rolling mechanism which is used for rolling the wire section on a substrate to form a conductive interconnection board; and a second groupof conveying mechanisms which are used for respectively introducing the plurality of wire sections into the heating and rolling mechanism from the outlets of the corresponding wire pipes. The conductive interconnection board is low in production cost and high in production efficiency.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

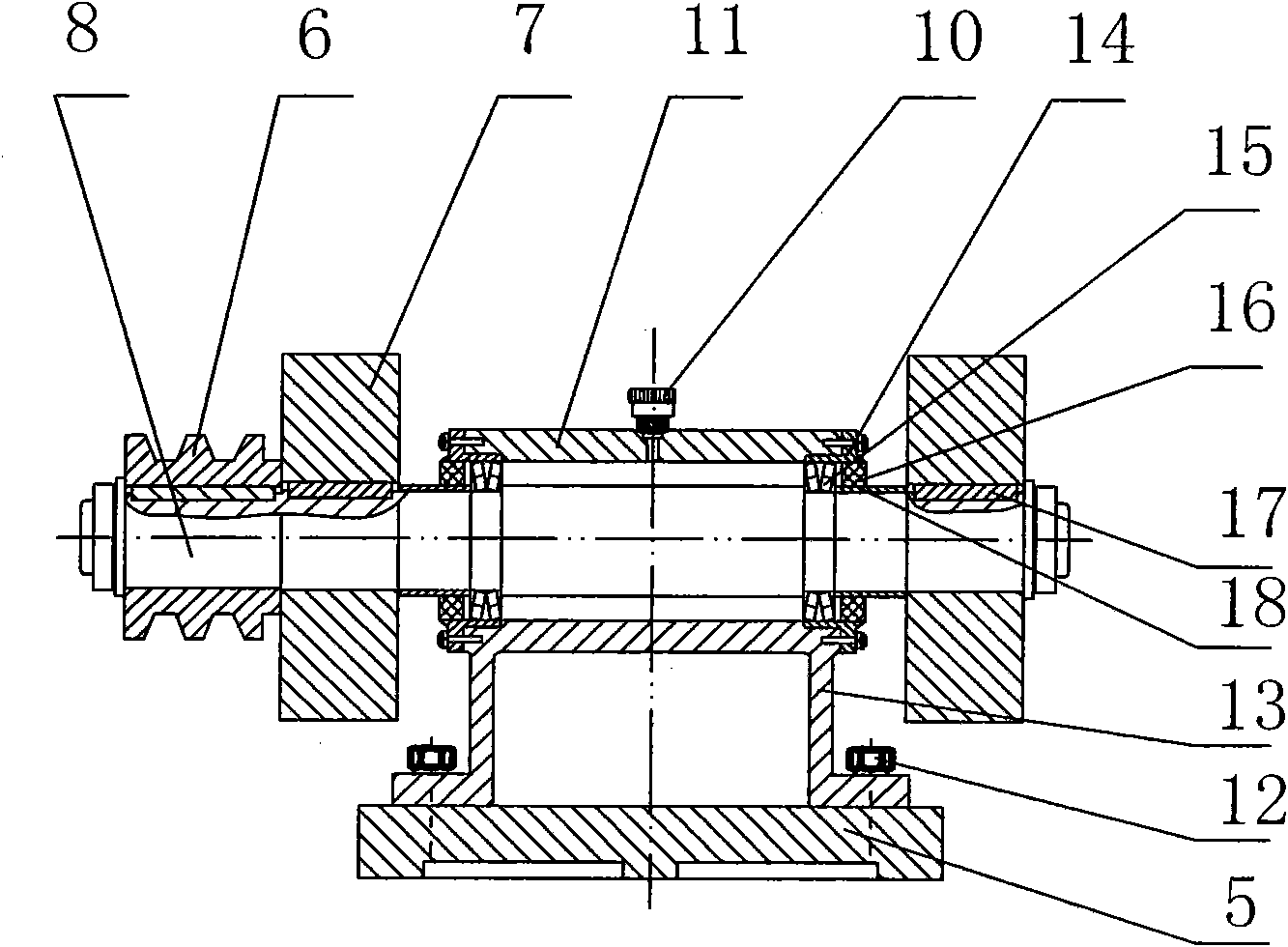

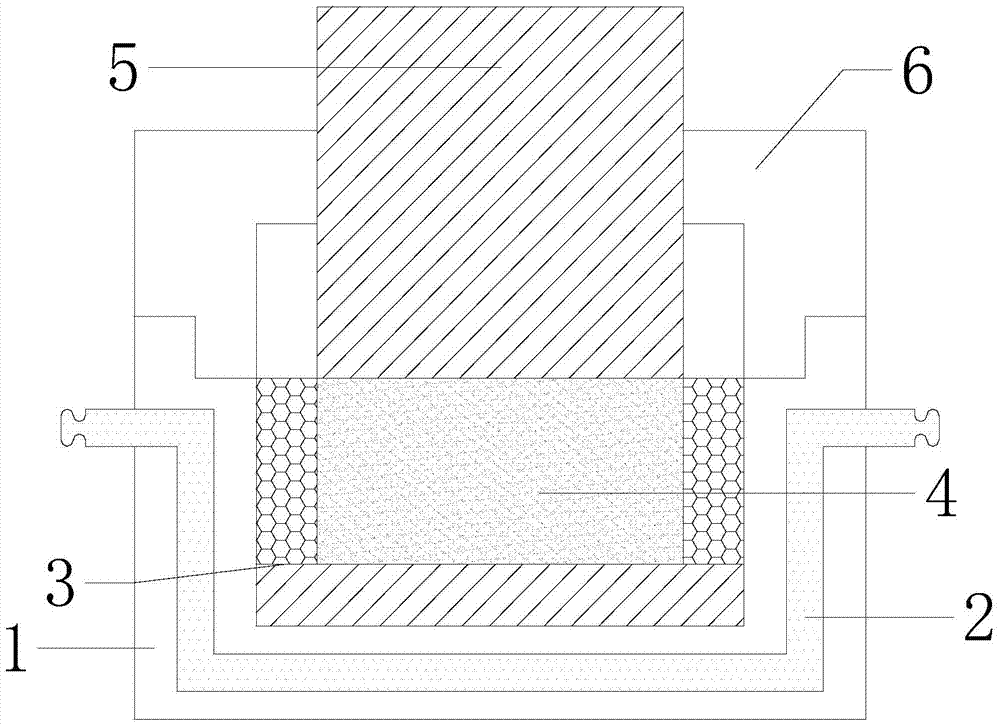

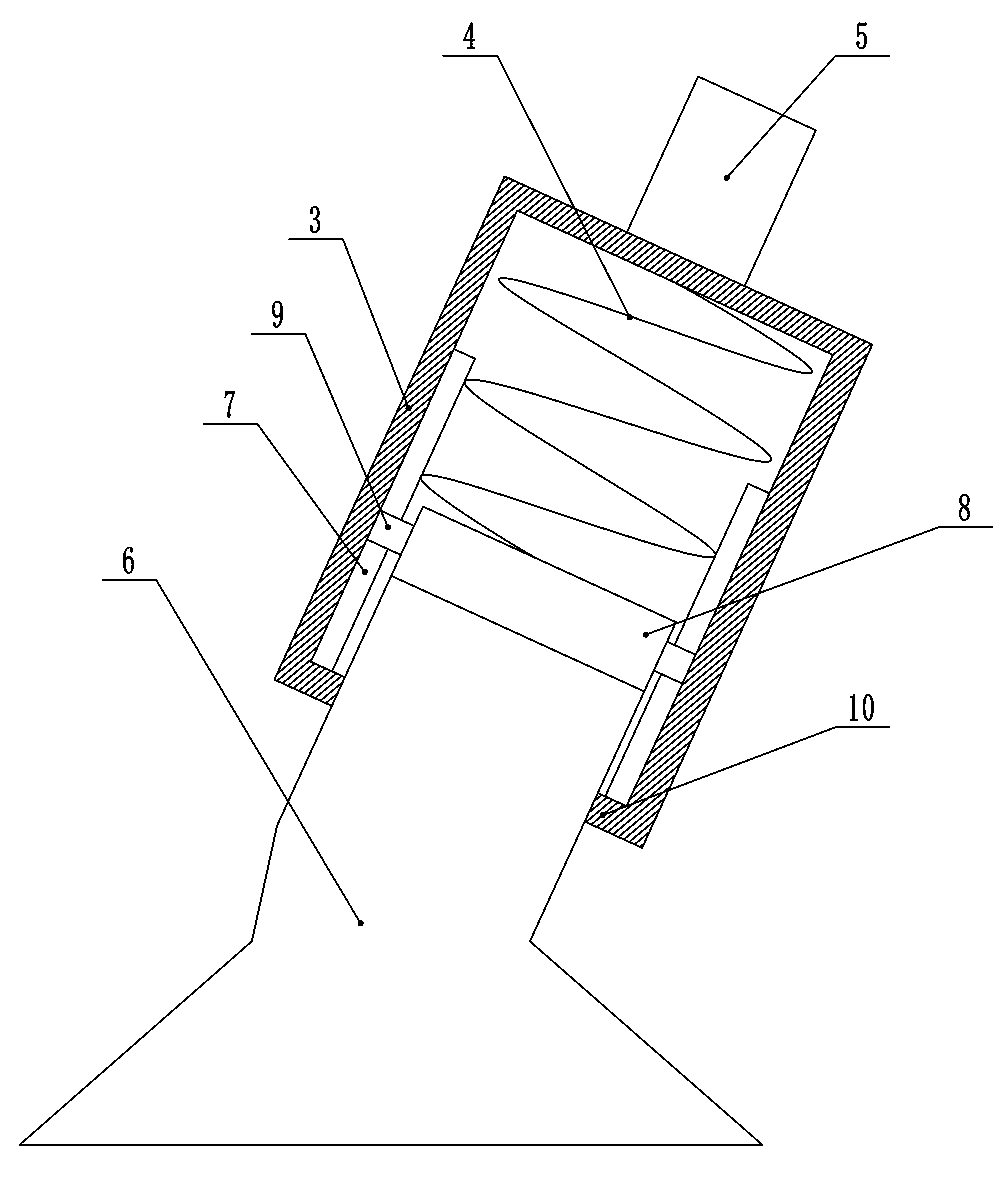

Device for testing compression resistance of aluminum ice solid propellant

InactiveCN103575594AWon't meltImprove accuracyMaterial strength using tensile/compressive forcesEngineeringResistance test

The invention provides a device for testing compression resistance of an aluminum ice solid propellant. The compression resistance testing device comprises a base (1), a chemical groove (3), a force bearing rod (5) and a limiter (6), wherein the chemical groove (3) is formed in the base (1); the limiter (6) is arranged above the base (1); the force bearing rod (5) is nested in the limiter (6) and acts on the surface of an aluminum ice solid propellant test block (4) in the chemical groove (3). When being used, the compression resistance testing device is applied to a material tester, the pressure of the material tester is transferred to the surface of the propellant test block through a mechanism, and the compression resistance of the propellant is tested. The compression resistance testing device can be applied to the field of solid propellant tests.

Owner:HARBIN ENG UNIV

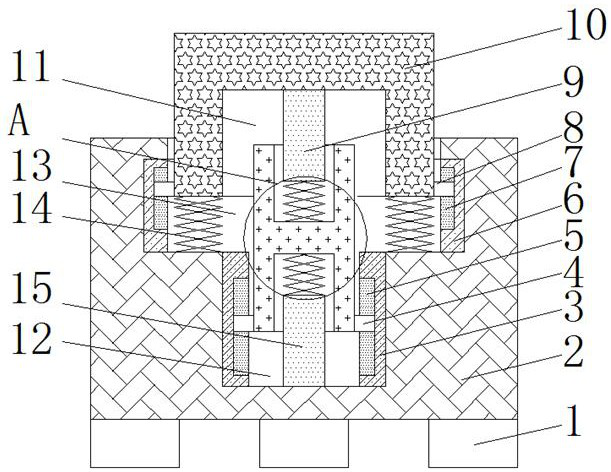

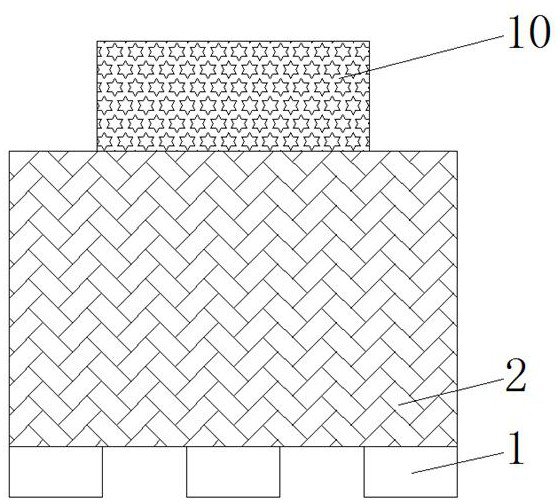

Radar base capable of absorbing shock

InactiveCN111812595ASolve the situation that cannot absorb multiple shocksNo lateral offsetWave based measurement systemsVertical planeRadar

The invention discloses a radar base capable of absorbing shock. The radar base comprises a base body. A cavity is arranged in the base body, a first groove is arranged in the upper surface of the base body, two symmetrical first fixing strips are fixedly connected to the inner side wall of the cavity, and first sliding grooves are arranged in side faces, close to each other, of the two first fixing strips. According to the radar base capable of absorbing shock, shock absorption columns can complete shock absorption again in a vertical direction; a secondary shock absorption effect of a foundation is improved; and lateral deviation of the shock absorption columns is avoided while shock absorption is achieved. A problem that the existing radar base cannot be damped for multiple times is solved; and the radar base has advantages that multiple shock absorption effects can be achieved, preliminary shock absorption of the fixing base can be completed on the vertical plane, the preliminary shock absorption effect of the radar base is improved, the fixing base does not deviate while shock absorption is performed on the vertical plane, the problem that an existing radar is poor in shock absorption effect is solved, and preliminary shock absorption is stabilized.

Owner:于浩

Anti-rollover metal vibration damping support

PendingCN110747730APrevent rolloverImprove the safety of useBridge structural detailsSingle supportClassical mechanics

The invention discloses an anti-rollover metal vibration damping support, and belongs to the technical field of viaducts. The anti-rollover metal vibration damping support comprises a guide sliding seat body composed of a transverse limiting part, a locking limiting part and a bearing part, a longitudinal sliding group composed of a longitudinal sliding lower plate, an annular oblique folding spring and a longitudinal sliding upper block or a longitudinal sliding group composed of a longitudinal sliding lower plate, a disk spring and a longitudinal sliding upper block, and a guide sliding groove on the guide sliding seat body; the sliding guide group is locked and limited not to move up and down by the locking limiting part in the guide sliding seat body, the sliding guide group is limitednot to slide to two sides by the transverse limiting part in the guide sliding seat body, so that the two sides of the beam body of the viaduct which locks the supporting beam body of a single pier single support do not swing up and down, the beam body of the viaduct which locks the supporting beam body of the single pier single support does not roll over to any side, the function preventing theviaduct of supporting beam body of the single pier single support from rolling over is integrated with the function of adapting to the change of thermal expansion and cold contraction of the viaduct,and the use safety and the use stability of the viaduct are improved.

Owner:唐缝梁

Rolling holder for cloth weaving machine

The invention provides a rolling holder for a cloth weaving machine. The rolling holder comprises a rolling machine body which is divided into a rolled yarn setting part and a cloth rolling part. The rolled yarn setting part and the cloth rolling part are connected by means of a circular weaving machine. The rolled yarn setting part comprises a support on which a plurality of rolled yarn supporting rods are arranged. The cloth rolling part comprises a pedestal, a driving mechanism, a transmission mechanism, and a rolling mechanism. A first guide roll and a second guide roll are arranged on the pedestal. The rolling mechanism is placed between the two guide rolls. A limiting device is arranged on the pedestal, and comprises L-shaped baffle plates. The rolling mechanism is located between and in clearance with two L-shaped baffle plates. According to the rolling holder for a cloth weaving machine proposed by the invention, further improvements are made for the defects of an existing spool fixing device, such that a spool can be fixed more stably during operating of the equipment, and cloth can be rolled more regularly; in addition, the rolling holder is strong and durable in own structure, and therefore, the probability of breakage thereof is reduced, and the maintenance cost of the equipment is reduced.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

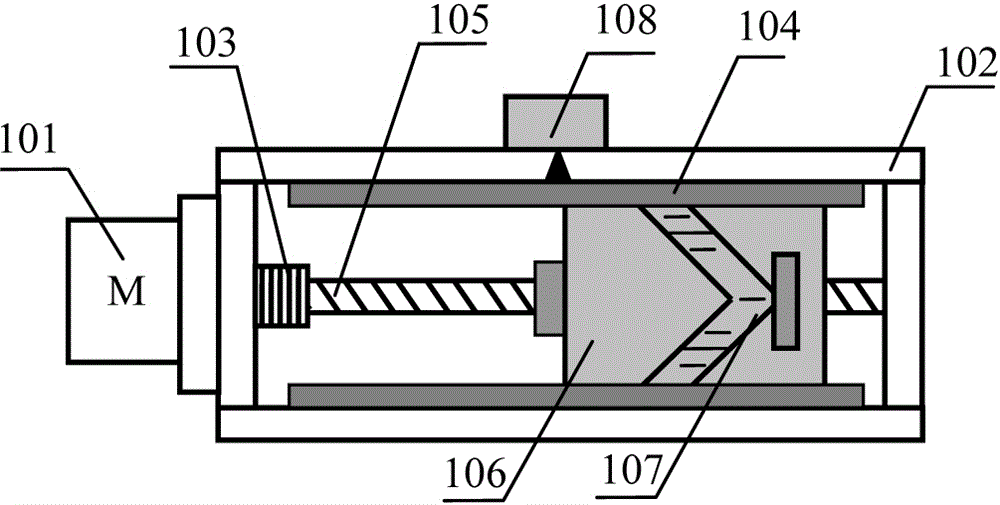

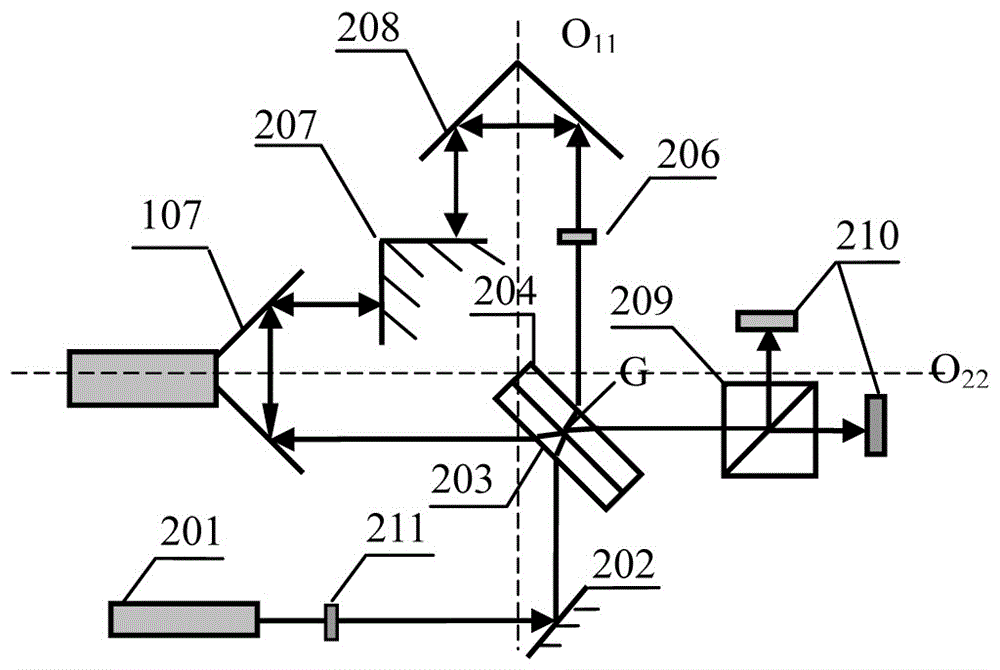

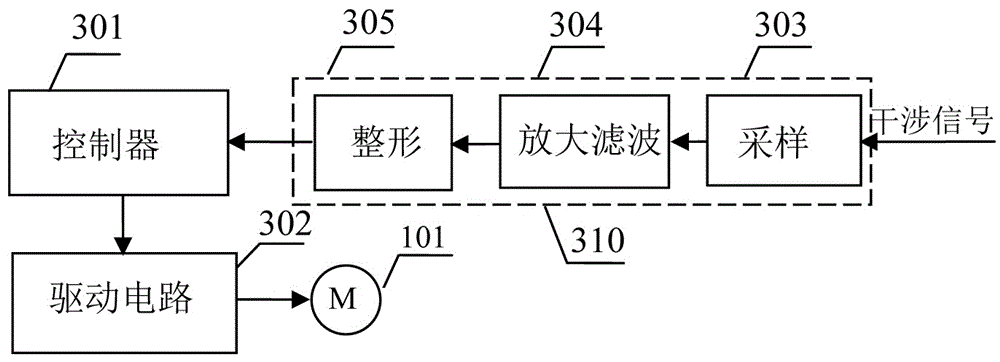

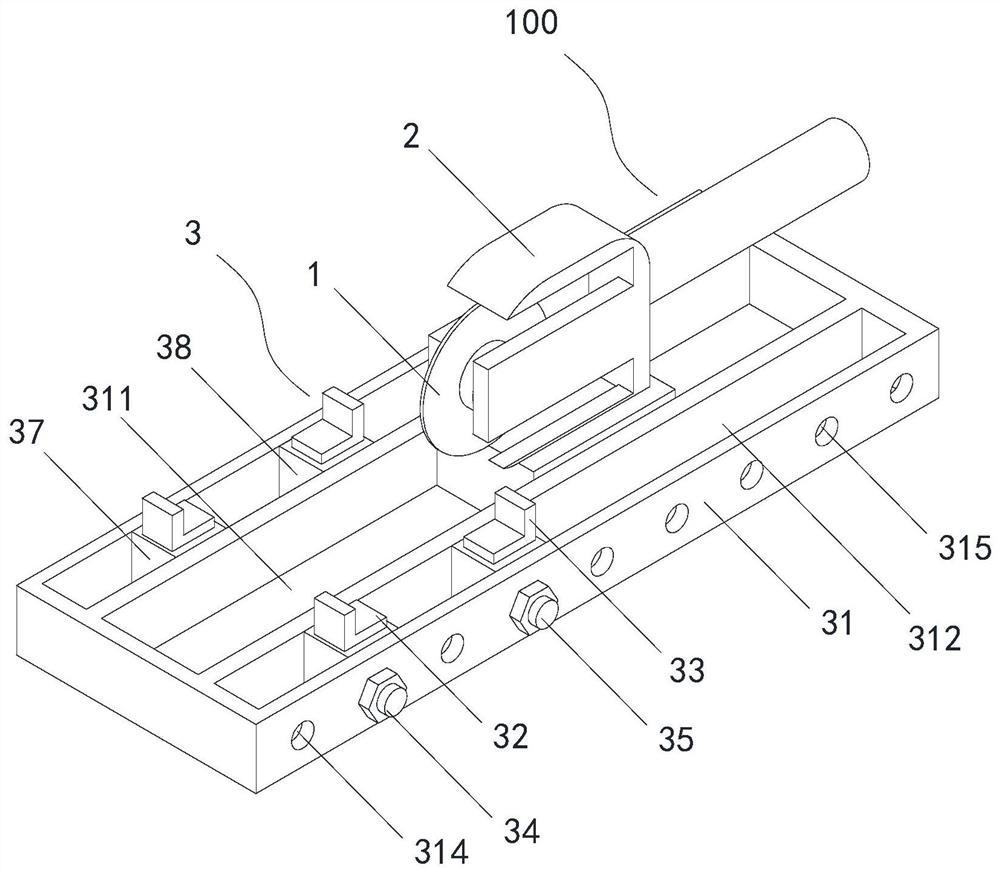

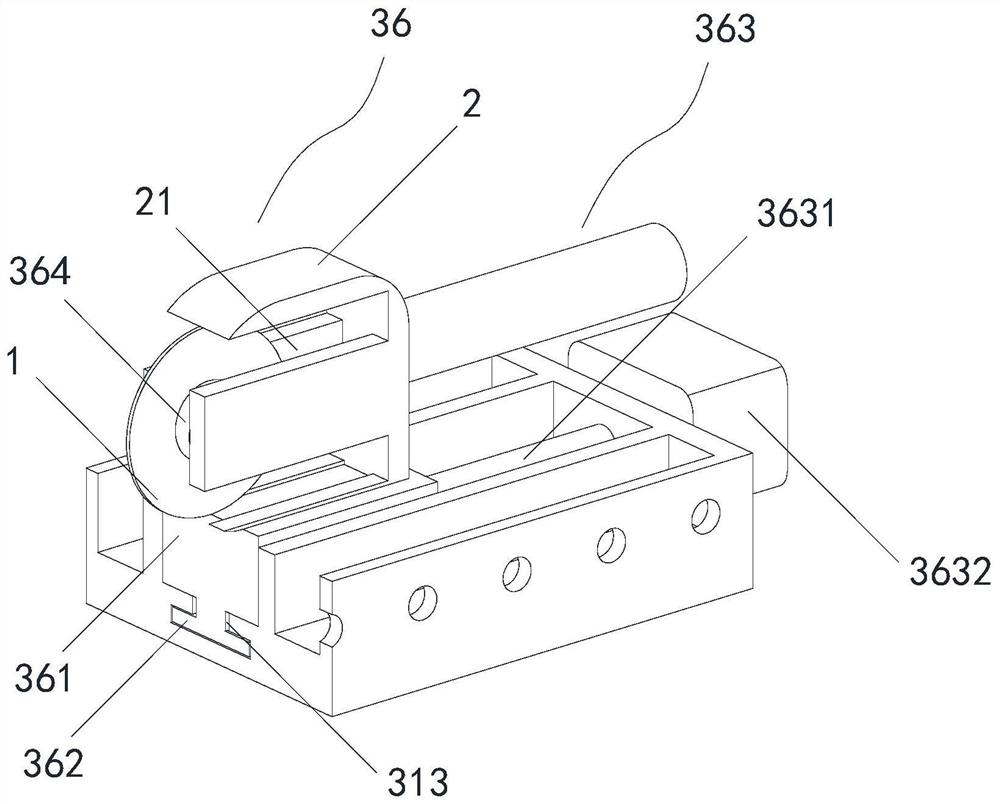

Infrared imaging spectrometer

InactiveCN105938014AGuaranteed uptimeNo lateral offsetInterferometric spectrometryInfraredBeam splitter

The invention discloses an infrared imaging spectrometer. The infrared imaging spectrometer comprises a moving mirror driving apparatus, a laser interference calibration system and a moving mirror control circuit. The moving mirror driving apparatus comprises a support base, a stepping motor, a ball screw, an intersection roller guide rail and a slide block, wherein the slide block is provided with a moving stereo pyramid prism. The laser interference calibration system comprises a laser, a reflective mirror, a beam splitter mirror, a compensation mirror, a one-eighth wave plate, a right-angle reflector, a fixed solid angle mirror, a polarization beam splitting prism, a laser detector and a half-wave plate. The moving mirror control circuit comprises a controller, a detection circuit acting on orthogonal interference signals and a driving circuit connected with the stepping motor. According to the invention, the system load capacity is high, a large-volume solid angle mirror can be driven to perform heavy-load motion, and different requirements of different spectrum resolutions and different application environments for a moving mirror control speed can be satisfied.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

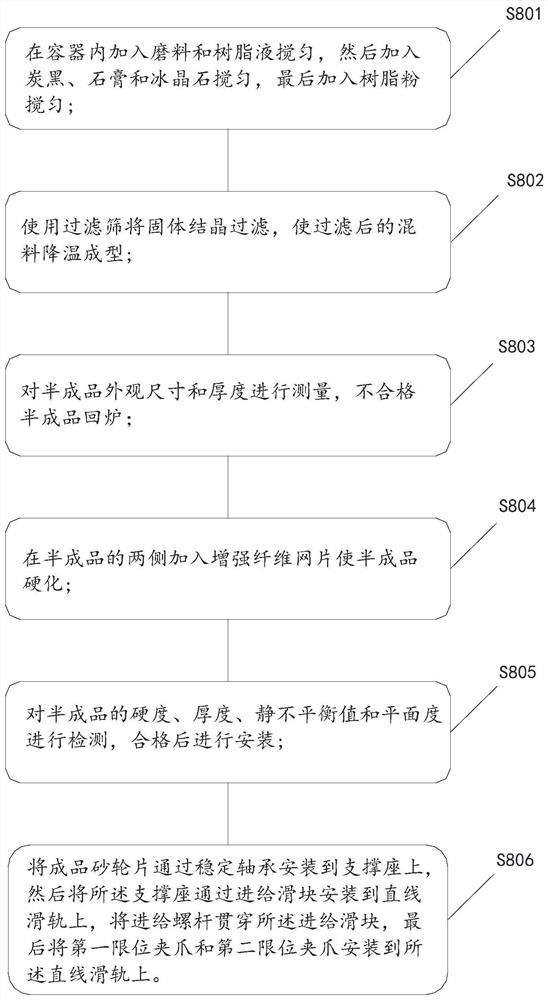

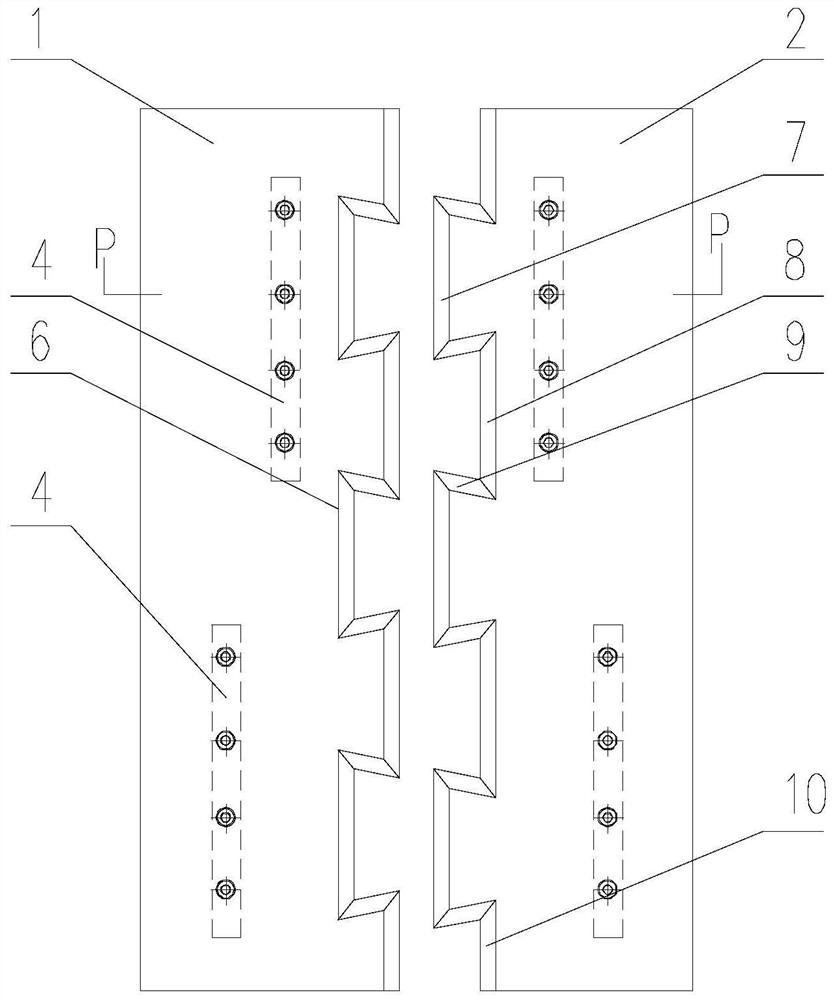

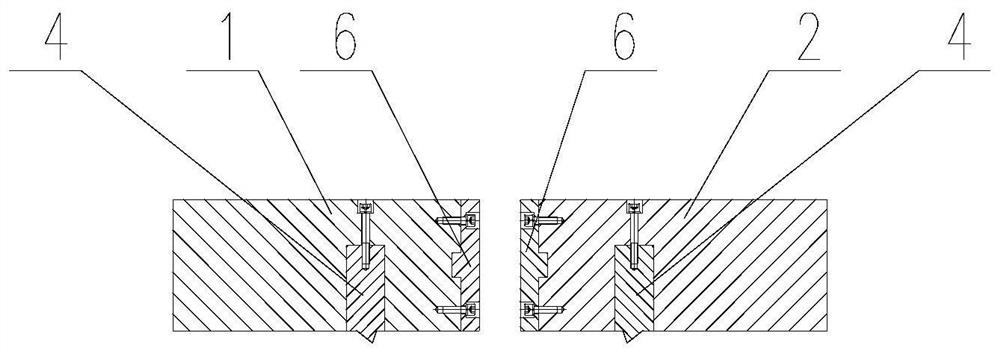

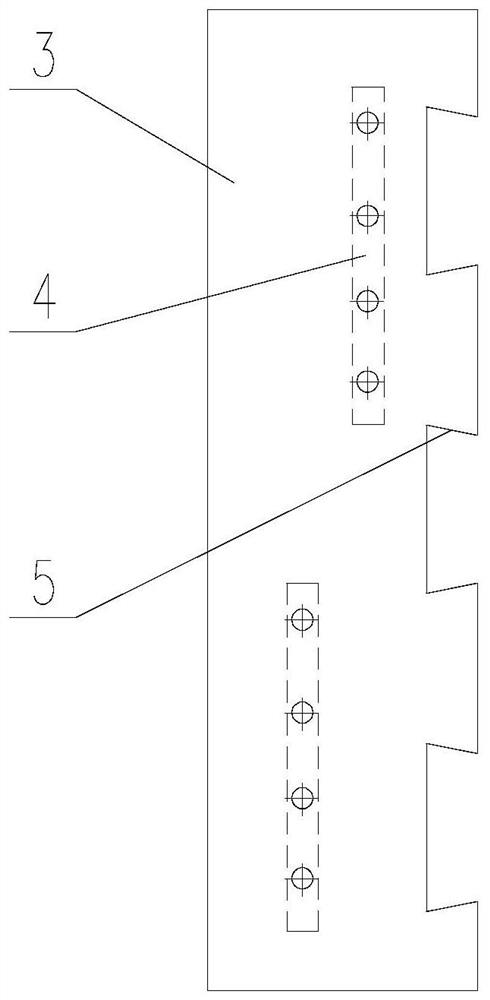

Rail cutting grinding wheel and preparation method

PendingCN112192416AImprove cutting effectSmooth slidingGrinding drivesGrinding devicesVertical angleBall screw

The invention discloses a rail cutting grinding wheel and a preparation method. A linear slide rail is mounted at the bottom of a rail, the linear slide rail and the length direction of the rail forman included angle of 90 degrees, the linear slide rail is buried into the ground, a first limiting clamping claw and a second limiting clamping claw are in threaded fixation through a first locking pin and a second locking pin respectively, the linear slide rail is kept perpendicular to the rail, a feeding sliding block and a T-shaped limiting block are installed at the bottom of a supporting basein a threaded mode, the T-shaped limiting block is matched with a T-shaped groove of the linear slide rail, so that sliding of the feeding sliding block and the linear slide rail is more stable, lateral deviation is avoided, therefore, through rotation of a feeding ball screw and the feeding sliding block, the feeding sliding block is driven to slide linearly, then a grinding wheel piece is driven to make contact with the rail at a vertical angle, feeding in the linear direction is kept, and the cutting effect of the grinding wheel piece on the rail is better.

Owner:徐州锦驰耐磨材料科技有限公司

Inclined carving and crimping shear blade device for hot-rolled intermediate billet

PendingCN112934970AReduce use costAffect the carrying capacityMetal rolling arrangementsStructural engineeringHot rolled

The invention belongs to the technical field of intermediate billet connection of endless rolling of hot rolled strips and provides an inclined carving and crimping shear blade device for a hot-rolled intermediate billet, and aims to solve the problem that the intermediate billet is poorly locked and positioned in the shearing process. The device comprises an inlet side shear blade and an outlet side shear blade with staggered slot buckled structures, wherein the inlet side shear blade and the outlet side shear blade are provided with apex blocks on the corresponding surfaces facing the intermediate billet. By arranging the apex blocks on upper half bodies of the inlet side shear blade and the outlet side shear blade, in the shearing process by the inclined carving and crimping shear blade device for the hot-rolled intermediate billet, the intermediate billet is clamped, such that the intermediate billet is prevented from deviating transversely.

Owner:CISDI RES & DEV CO LTD

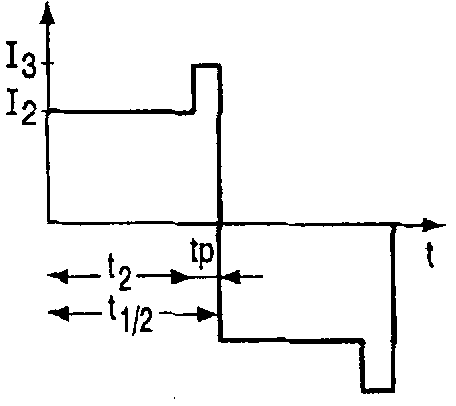

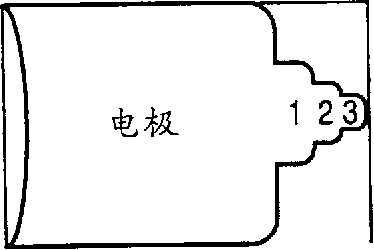

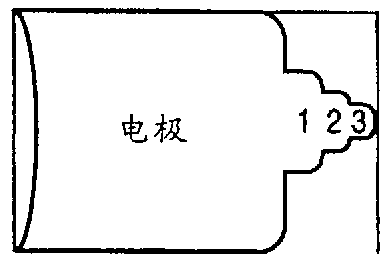

Method and arrangement for operating gas discharge lamp

InactiveCN1336783BSolution to short lifeNo lateral offsetElectric light circuit arrangementTube/lamp factory adjustmentGas-discharge lampEngineering

A method of and a device for operating a gas discharge lamp which is fed with an alternating voltage or an alternating current and wherein the instantaneous power of the lamp is increased at given time intervals are used to form the electrodes. The value of an operational datum of the lamp which varies in time is continuously or discontinuously measured and the frequency of the alternating voltage or the alternating current (operating frequency) is selected in dependence on the measured values.

Owner:SIGNIFY HLDG BV

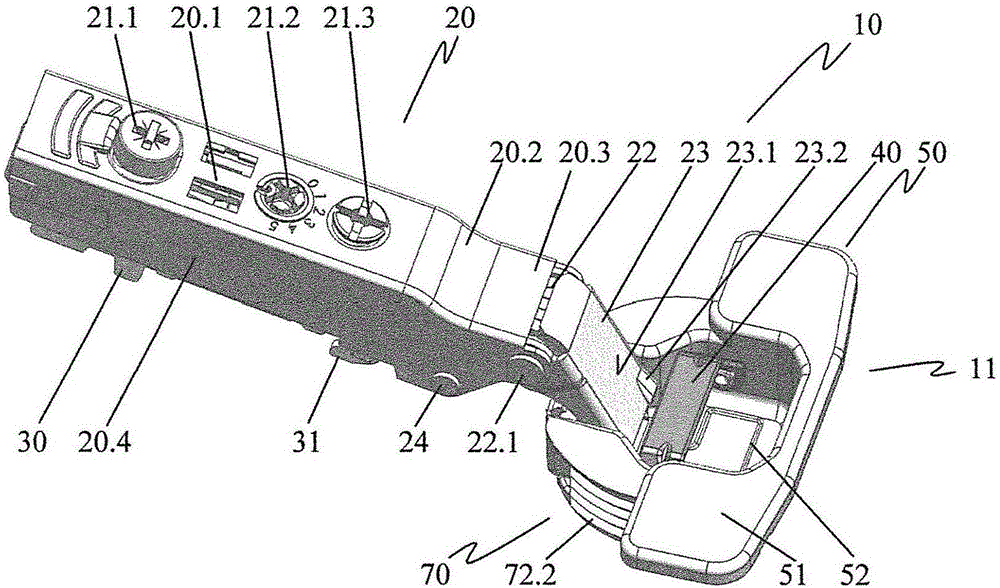

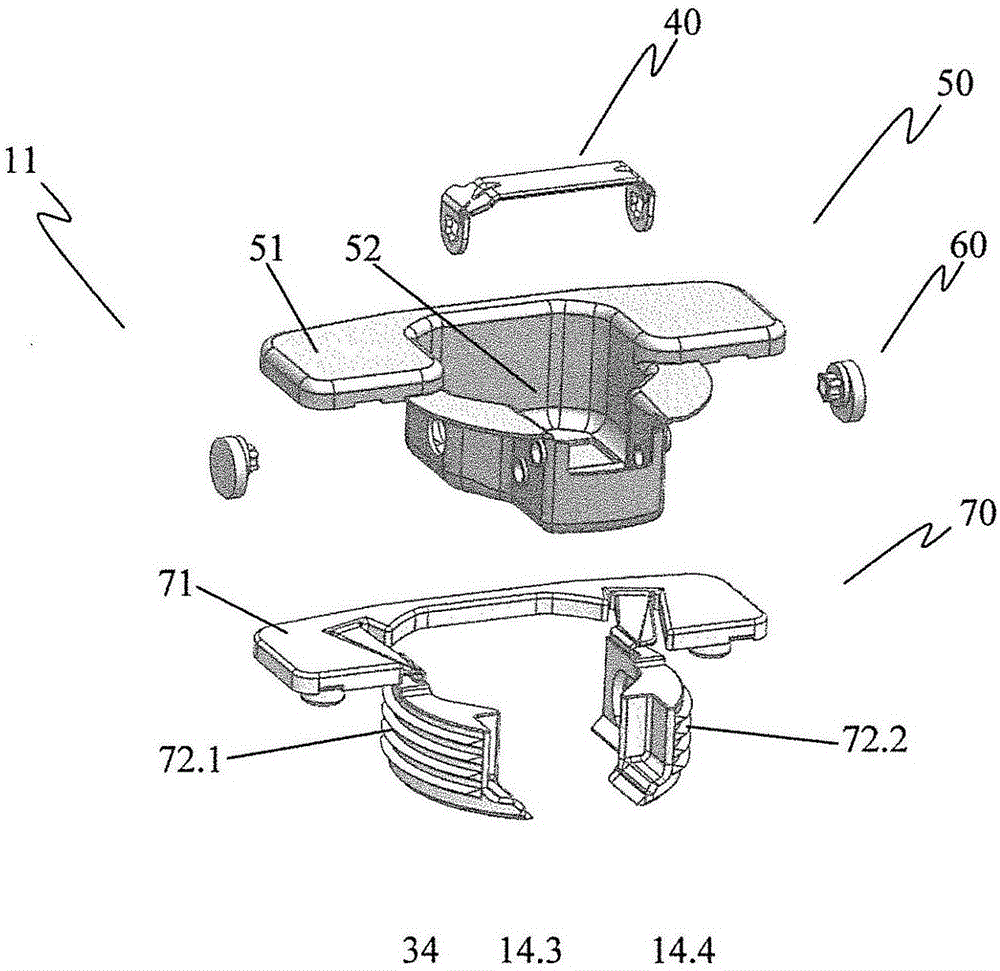

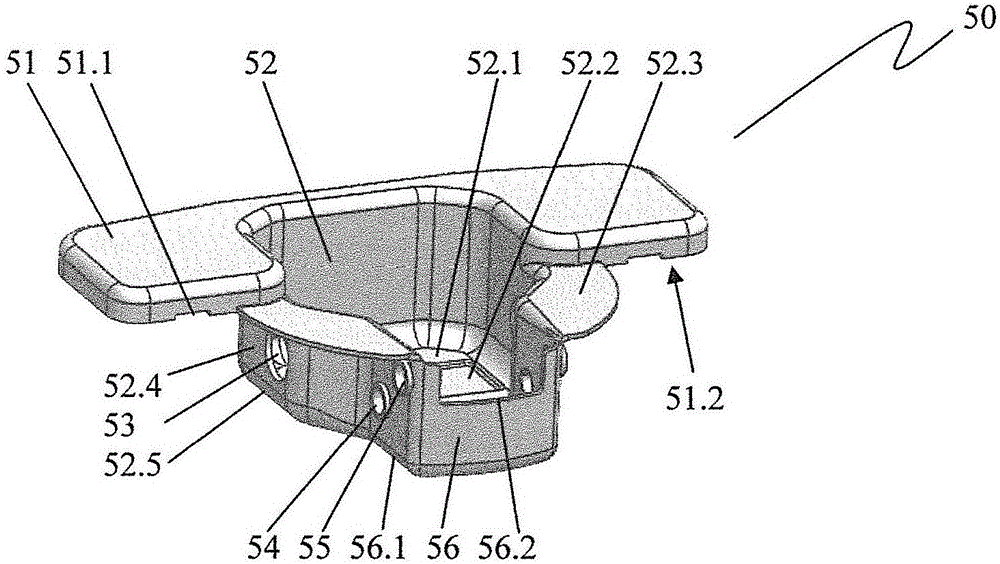

Furniture hinge

The invention relates to a furniture hinge (10) with a hinge cup (52) with cup side walls (52.4) which encircle a cup opening at least in certain regions, and with a cup base (52.1) which closes off the hinge cup (52) opposite to the cup opening at least in certain regions, with a spreading element (70) with two clamping jaws (72.1, 72.2) which at least partially radially enclose the cup side walls (52.4) of the hinge cup (52) and which are connected via a flange (71), and with a lifting arrangement for adjusting at least one of the clamping jaws (72.1, 72.2) between a first position and a second position. It is provided here that at least one of the clamping jaws (72.1, 72.2) has at least one integrally formed spreading extension (76, 78) which, during the transition from the first into the second position, interacts with the hinge cup (52) in such a way that the clamping jaws (72.1, 72.2) are spread. As a result, a furniture hinge which can be produced cost-effectively and can be fitted quickly and securely to a furniture part is provided.

Owner:土耳其萨麦提模子及矿物工商股份公司

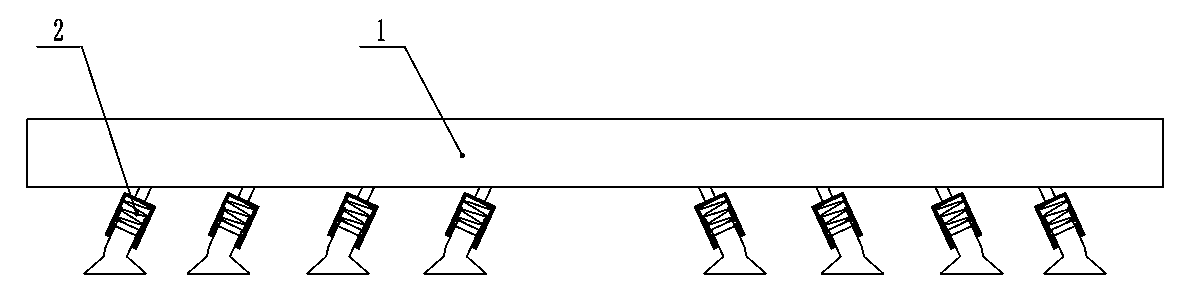

Quick-load cushioning chassis for mobile homes

ActiveCN107542311BEnsure normal restReduce vibrationProtective buildings/sheltersShock proofingCushioningEngineering

The invention provides a fast-assembly shock-relieving chassis for a mobile house. The fast-assembly shock-relieving chassis for the mobile house comprises a mounting bracket and a plurality of shock-relieving supports uniformly distributed on the mounting bracket, wherein each shock-relieving support comprises a spring cavity, a spring mounted in the spring cavity, an ejector pin fixed on the upper part of the spring cavity and a supporting leg connected with the spring; and the mouth of each spring cavity is provided with a stop for preventing the corresponding supporting leg from moving out. The fast-assembly shock-relieving chassis for the mobile house has the advantages of being scientific in design, high in shock-relieving capacity, and not prone to skew.

Owner:河南众联云科工程技术有限公司

An automatic punching device for sol forming

Owner:深圳金皇尚热熔胶喷涂设备有限公司

Air conditioner and its control method

ActiveCN110107962BNo lateral offsetDoes not affect rotationMechanical apparatusLighting and heating apparatusThermodynamicsControl system

The invention belongs to the technical field of air conditioners, and specifically provides an air conditioner and a control method thereof. The invention aims to solve the problem that the outlet direction of the existing snow cover is fixed and cannot be adjusted according to the change of the wind direction, and the snow cover is prone to backflow by wind and snow, which affects the ventilation effect. For this reason, the air conditioner of the present invention comprises an outdoor unit and a control system, the top of the casing of the outdoor unit is provided with an air outlet, and the air conditioner also includes a snow cover communicated with the air outlet, a rotating drive device connected to the snow cover and a set The wind direction detection device on the box body, the snow cover is rotated with the top of the box body, and the rotation drive device and the wind direction detection device are all in communication with the control system. The invention can adjust the outlet direction of the snow cover according to the change of the wind direction, so that the outlet direction and the wind direction can be kept consistent or within a relatively small angle, which can effectively prevent wind and snow backflow and improve ventilation efficiency.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Method for installing low-voltage cable transformation platform

PendingCN114038653AAchieve a fixed installationNo lateral offsetTransformers/reacts mounting/support/suspensionUtility poleTransformer

The invention relates to the technical field of transformer tables, in particular to a method for installing a low-voltage cable transformer platform. The method specifically comprises the following steps that a supporting element is pushed to the position between two telegraph poles; two single transformation tables are oppositely placed on a carrying block of the supporting element, and the transformation tables and the two telegraph poles are located between the two transformation tables; the supporting element is normally driven, the carrying block moves upwards to enable the transformation tables to be synchronously and upwards driven, the transformation tables are upwards along the surface of the telegraph poles, and when the supporting element reaches the adaptive height from the ground, the supporting element stops working; the two transformation tables are relatively pushed to be close to each other, arc openings in the surfaces of the transformation tables clamp the surface of the telegraph poles, then the two transformation tables are connected through bolt pieces, and bolts enter along the bolt piece holes to lock the two transformation tables. A top plate faces upwards, the guide blocks make contact with the inner walls of the side plates, the guide blocks extrude a platen body to get close after being limited by the inner walls of the side plates, the arc opening of the platen body is attached to the telegraph pole all the time, and manual secondary pushing is not needed.

Owner:广西中复工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com