Full-automatic intelligent single-board gluing production line

A production line, fully automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., which can solve the problems of high scrap rate, lateral deviation of the board skin, and heavy labor of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

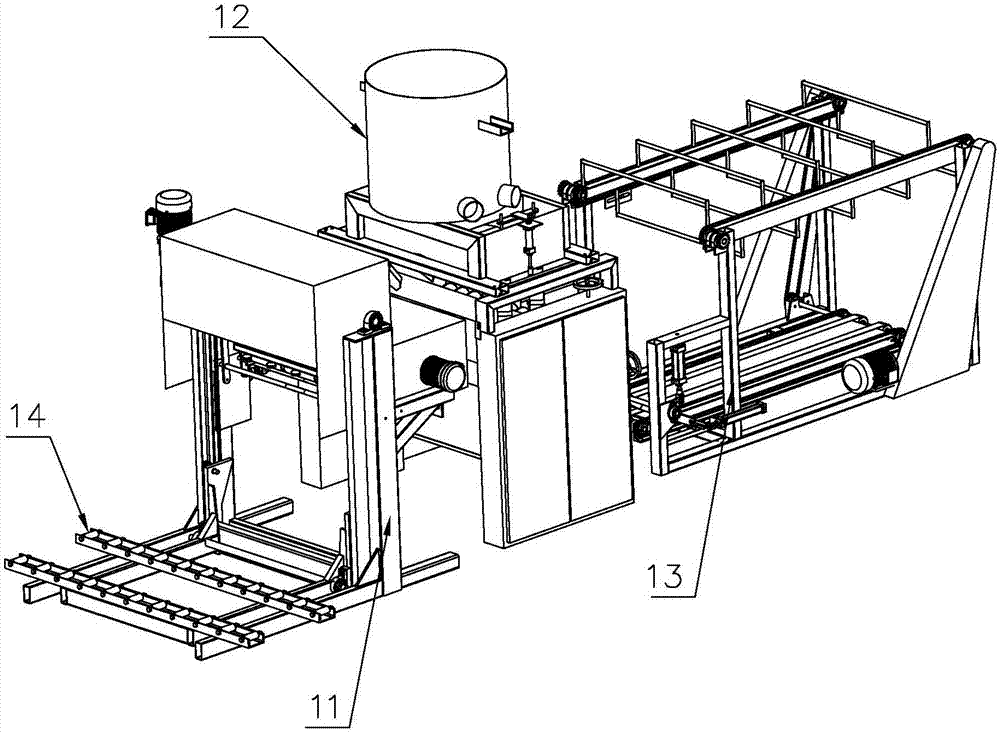

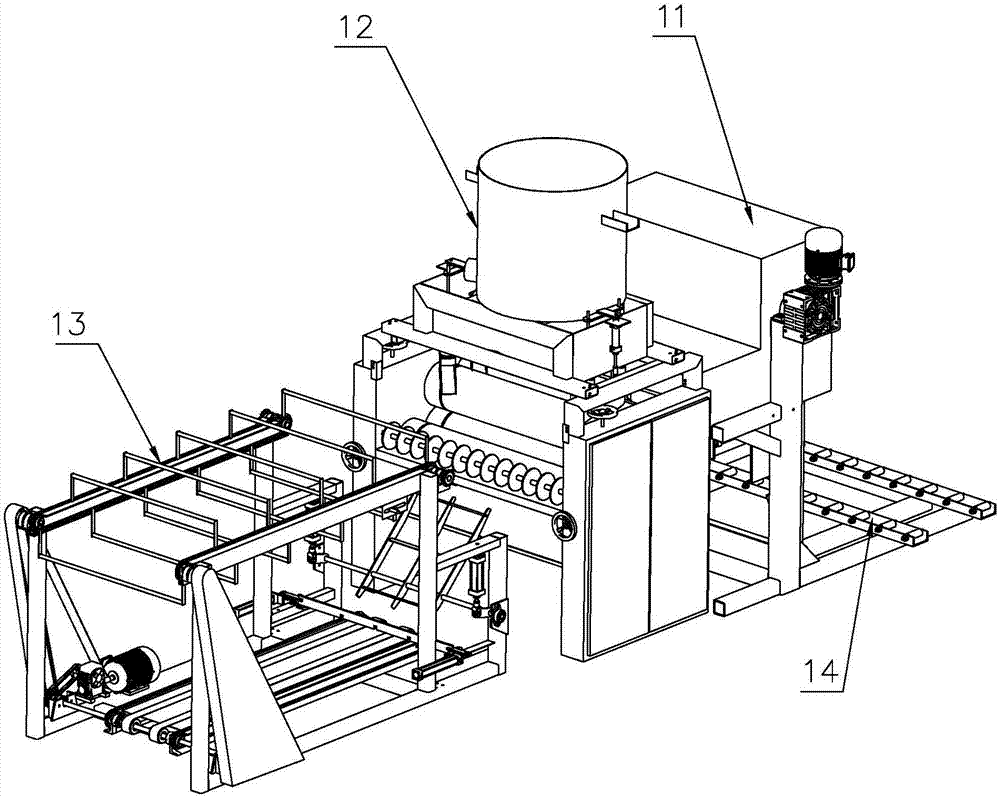

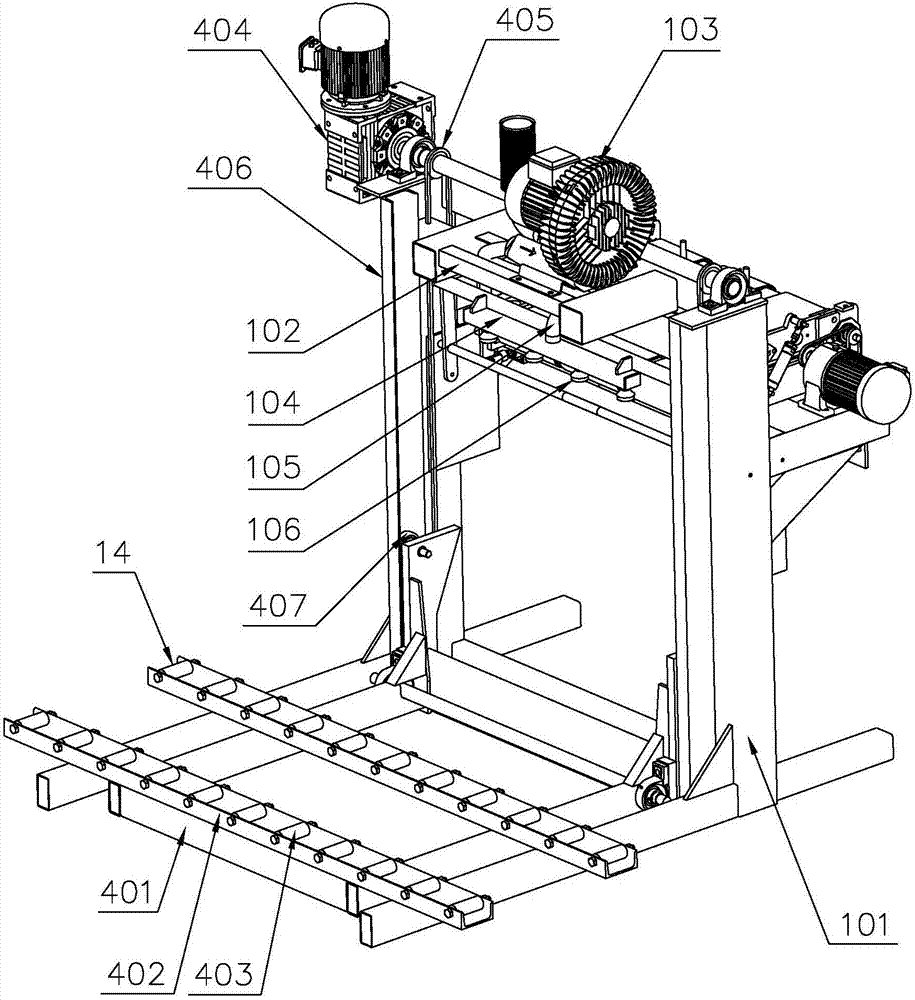

[0035] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-12 , to further specifically describe the technical solution of the present invention.

[0036] A fully automatic intelligent veneer gluing production line, comprising an adsorption transmission mechanism 11, a gluing mechanism 12, and a material receiving mechanism 13, a gluing mechanism 12 is provided on one side of the adsorption transmission mechanism 11, and a gluing mechanism 12 is provided on one side of the gluing mechanism 12. The receiving mechanism 13 and the adsorption conveying mechanism 11 quickly feed the veneer that has been rotary cut, and no lateral offset occurs during the veneer conveying process. After gluing, the veneer enters the material receiving mechanism 13 for automatic material receiving. The veneer processing efficiency is high, the working environment of the workers is improved, and the labor workload of the workers is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com