Device for testing compression resistance of aluminum ice solid propellant

A technology of solid propellant and compression resistance, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve problems such as grain fracture, broken, engine failure, explosion, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

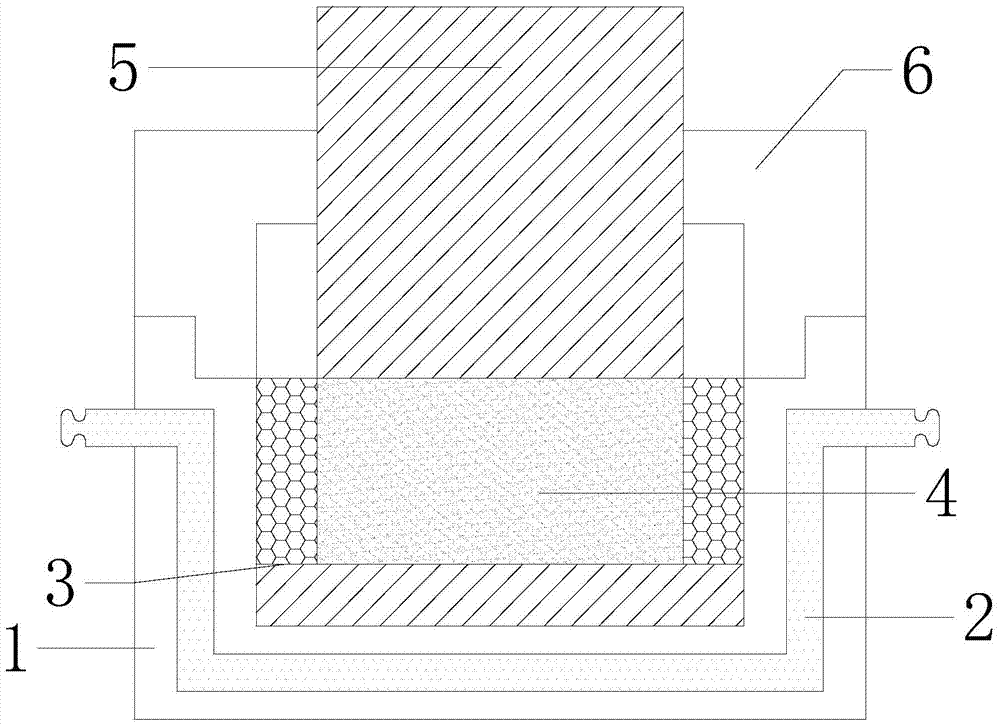

[0016] combine figure 1 , the aluminum ice solid propellant compression performance testing device of the present invention includes a base 1 , a cooling pipeline 2 , a drug tank 3 , a bearing rod 5 and a stopper 6 . Before the test, coolant is passed through the cooling pipeline 2 to ensure that the base 2 and other parts are all in a low temperature state. After the raw materials such as aluminum powder and water are mixed, they are directly loaded into the medicine tank 3 to make the aluminum ice solid propellant test block 4 . During the test, open the limiter 6, take out the load-bearing rod 5, put the medicine tank 3 into the base 1, cover the limiter 6 and put the load-bearing rod 5 into the device. The whole device is put into the material testing machine, and the pressure of the material testing machine is transmitted to the surface of the aluminum ice solid prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com