Automatic bending machining equipment for plate

A technology for bending processing and sheet metal, which is applied in the field of automatic sheet bending processing equipment, can solve problems such as unreasonable heating procedures, easy cracking of products, and low degree of automation, so as to save manual inspection and repeated positioning, improve stability, and degree of automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

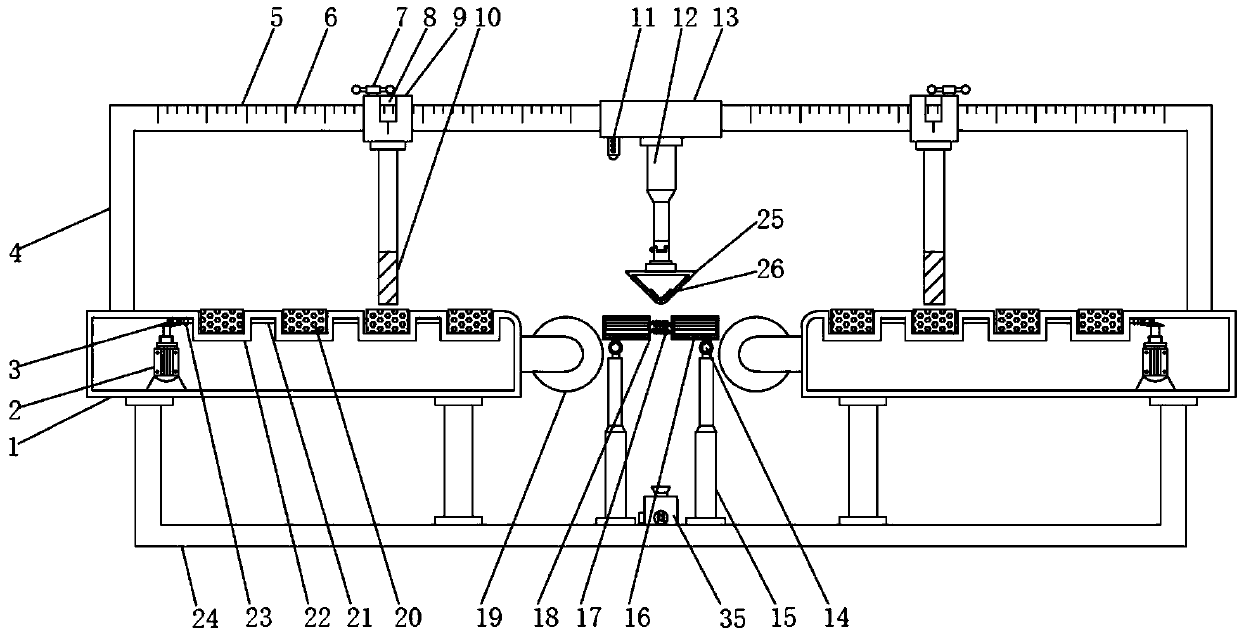

[0033] The technical solutions in the embodiments of the present invention are described in more detail below in conjunction with the accompanying drawings:

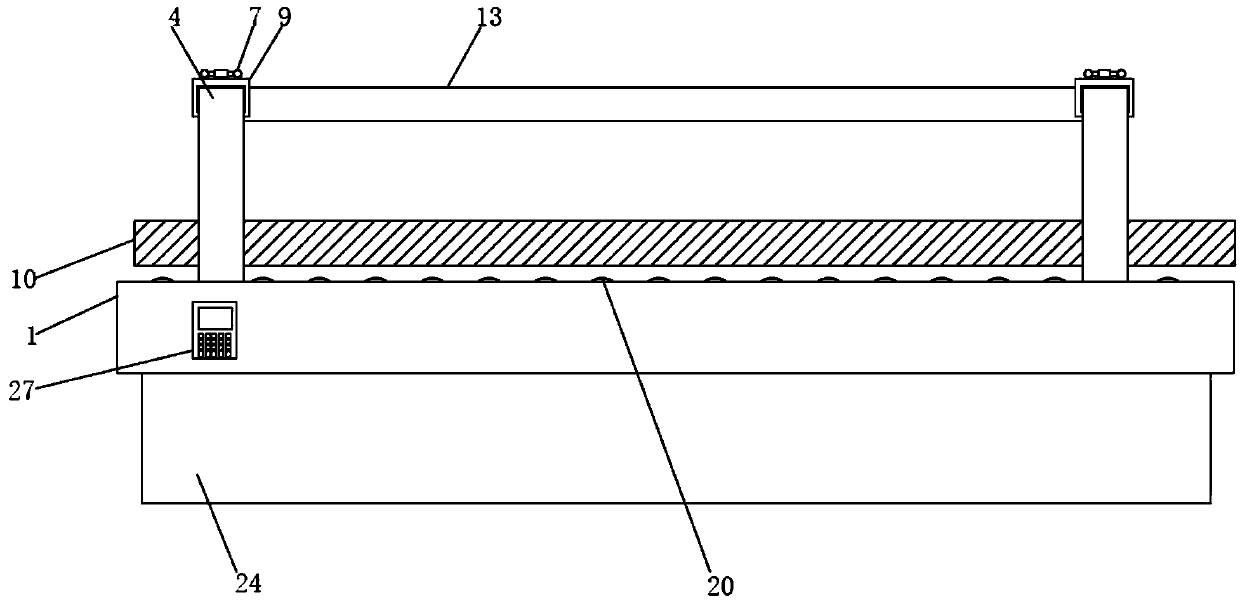

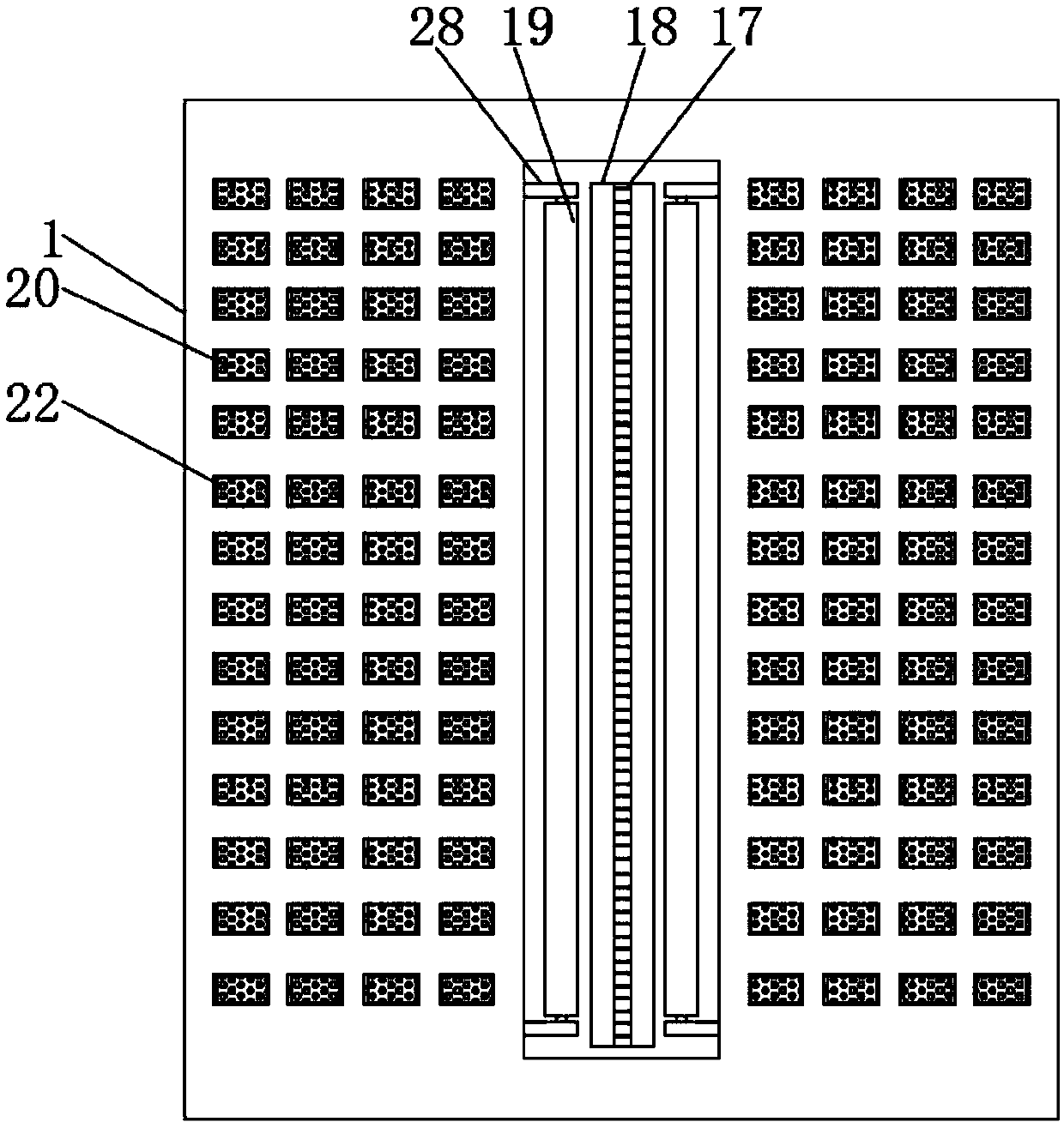

[0034] refer to figure 1 , a sheet material automatic bending processing equipment, including two transmission frames 1 arranged in parallel on the left and right, the bottom surface of the transmission frame 1 is welded with a base 24, and the top surface of the base 24 between the two transmission frames 1 is fixedly connected with a left and right parallel Two sets of lower telescopic rods 15, and the top surface of each group of lower telescopic rods 15 is hinged with a heating plate 18 through a rotating shaft 14, and the heating plates 18 on the left and right sides are connected by a spring 17, and a first heating assembly 16 is embedded inside the heating plate 18 .

[0035] The top surface of the transmission frame 1 is connected with the transverse connecting rod 5 through the bracket 4, and the transverse con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com