Automatic stacking and loading device for industrial explosive products

A technology of industrial explosives and driving devices, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve problems such as low loading efficiency, unreasonable structure of the loading system, and unsustainable loading of explosives, so as to reduce friction and improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

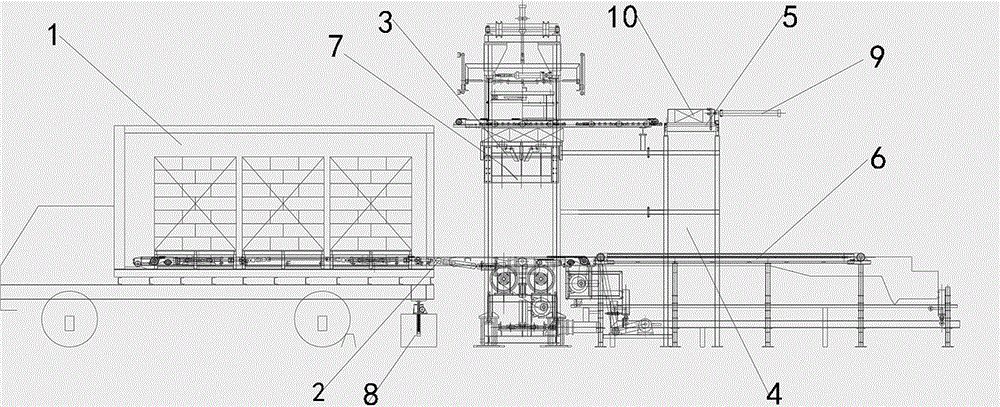

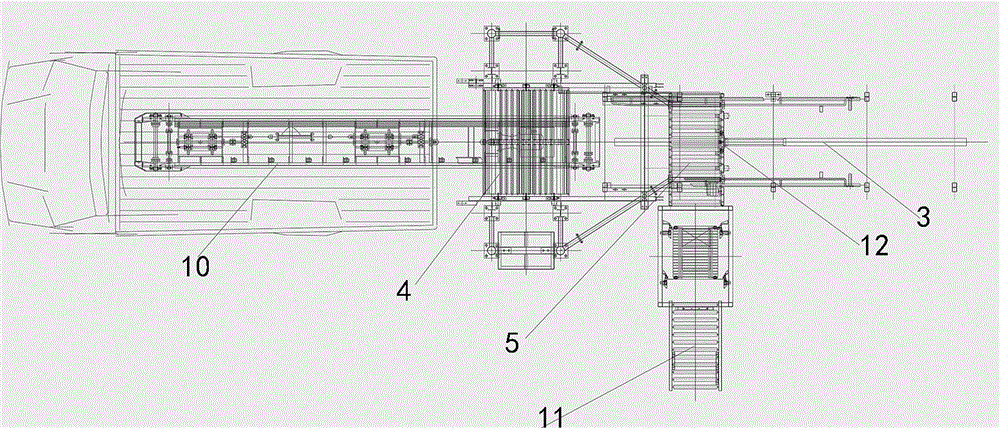

[0037] The automatic palletizing and loading device for industrial explosives products includes a loading vehicle. The carriage 2 of the loading vehicle is provided with a stacking pallet. The bottom of the stacking pallet is provided with a conveying device 2 and the rear end of the conveying device 2 is placed on a lifting frame; The device 2 is provided with a conveying line truss 6 next to it, a hoist 4 is provided above the portion of the conveying line truss 6 close to the conveying device 2, a driving device for driving the conveying line truss 6 is provided on the conveying line truss 6, and the lifting frame is provided with The pallet lifting drive device is provided with a pallet 3 above the pallet lifting drive device, and a plywood for regular goods is arranged around the pallet 3 respectively. The pushing device of the elevator 4 and the elevator are arranged next to each other. The pushing device includes a pushing layer and a Push drive device for driving the pus...

Embodiment 2

[0039] On the basis of Embodiment 1, an in-position sensing device 12 is provided on the truss of the conveying line.

Embodiment 3

[0041] On the basis of Embodiment 1 or 2, the conveying line truss 6 is matched with a guiding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com