Connecting structure of lug and pole and connecting method

A connection structure and connection method technology, applied in the direction of connection, structural parts, electrical components, etc., to achieve the effect of improving battery energy density, improving production efficiency, improving yield and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

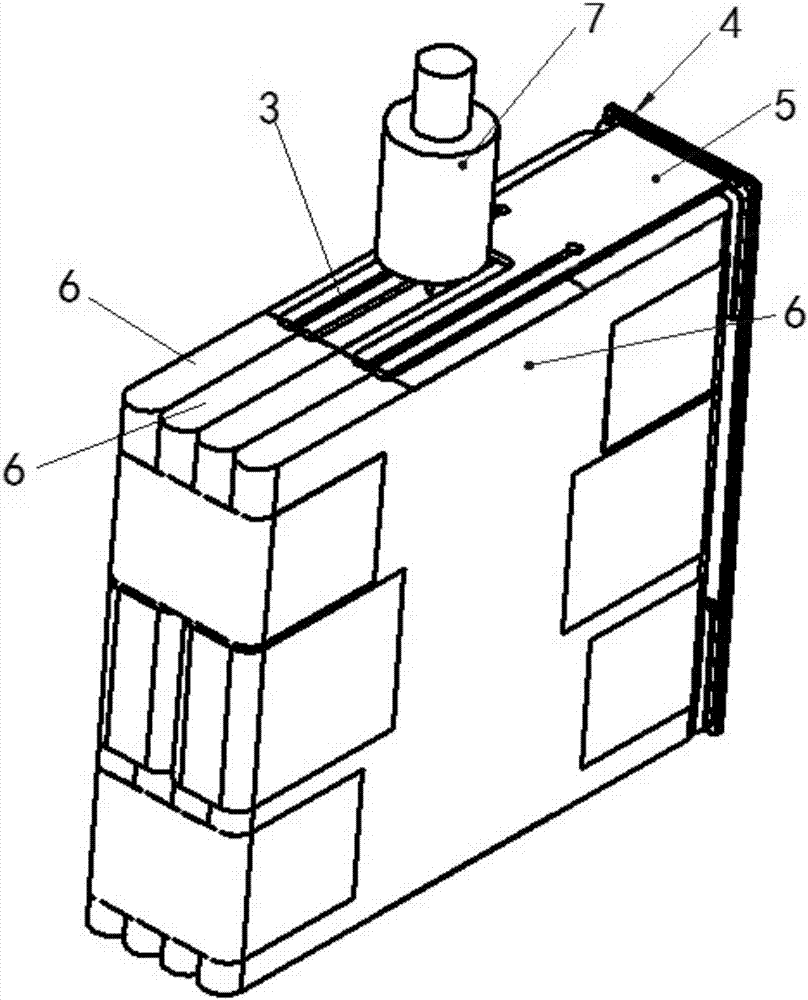

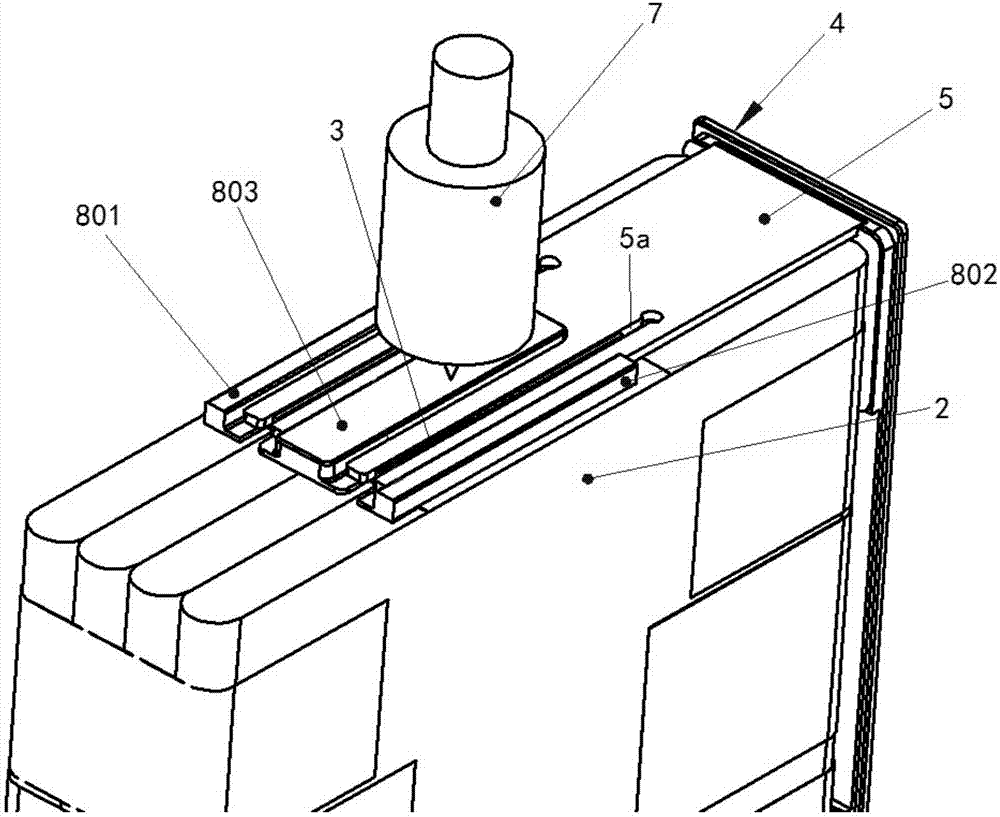

[0045] figure 1 and figure 2 It shows a specific application example of the connection structure of tabs and poles of this application in a lithium-ion battery in which the positive and negative electrodes are arranged on the same side (that is, the positive and negative electrodes of the battery are arranged on the same side of the battery). The same as the traditional battery, the lithium-ion battery also includes: a shell with an open structure at the upper end (in order to make it easier for readers to see the connection structure between the tab and the pole, the figure does not draw the shell structure), the bare cell 2 accommodated in the case, and the case cover 4 arranged at the openings at both ends of the case. Wherein, the left and right sides of the bare cell 2 are respectively provided with tabs 3 , and the left and right sides of the case cover 4 are provided with poles 5 . Wherein, the tab 3 on the left side of the bare cell 2 is a positive tab, and the tab ...

Embodiment 2

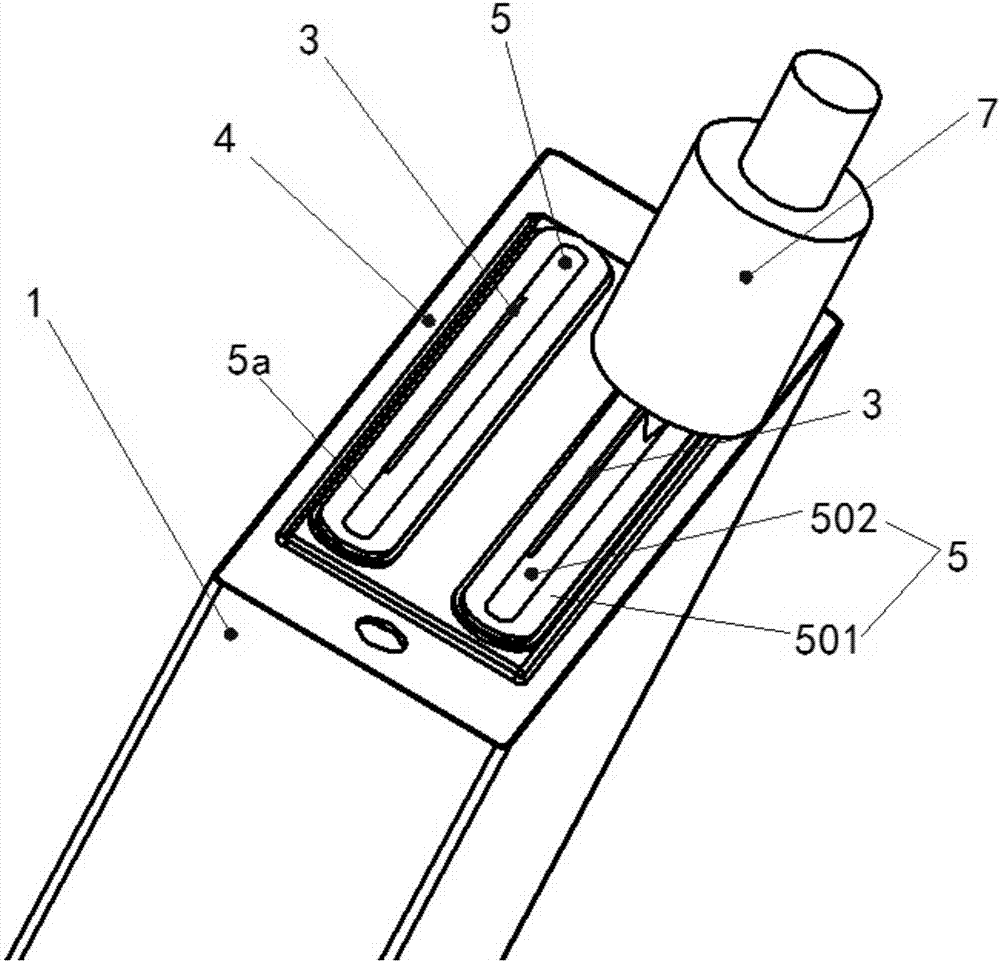

[0057] image 3 and Figure 4 It shows a specific application example of the lithium-ion battery in which the connection structure of tabs and poles of this application is arranged on both sides of the positive and negative electrodes (that is, the positive and negative electrodes of the battery are arranged on two opposite sides of the battery). The same as the traditional battery, the lithium-ion battery also includes: a casing 1 with open structures at both ends of the upper and lower ends, a bare battery cell 2 accommodated in the casing, and open cells respectively arranged at the upper and lower ends of the casing. Two shell covers at the mouth 4. The upper and lower ends of the bare cell 2 are respectively provided with tabs 3 , and each case cover 4 is provided with a pole 5 . The pole 5 on one of the shell covers 4 is a positive pole, and the pole 5 on the other shell 4 is a negative pole; The ear is the negative pole ear. Specifically, in image 3 Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com