LED (Light Emitting Diode) lamp bulb light strip connecting portion structure and LED lamp bulb light strip and conducting wire connection method

A technology of LED light bulbs and connection methods, which is applied in the field of electric light sources, can solve problems such as poor welding of connecting parts and guide wires, and achieve the effects of solving poor welding problems, reducing difficulty, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

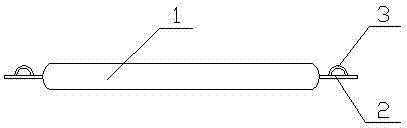

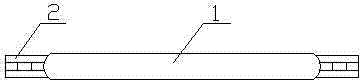

[0019] Embodiment 1: as figure 1 and image 3 As shown, the structure of the connecting part of a LED light bulb light bar, the light bar is composed of a light emitting area 1 in the middle and connecting parts 2 at both ends, the connecting parts 2 at both ends of the light bar are used to connect with the guide wire, and the connecting part 2 is provided with The semi-circular bayonet 3 that holds the guide wire.

Embodiment 2

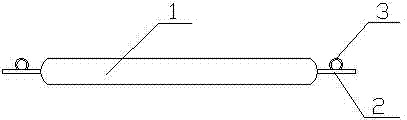

[0020] Embodiment 2: as figure 2 and image 3 As shown, the structure of the connecting part of another LED light bulb light bar, the light bar is composed of the light-emitting area 1 in the middle and the connecting part 2 at both ends, the connecting parts 2 at both ends of the light bar are used to connect with the guide wire, and the connecting part 2 There is an annular bayonet 3 for holding the guide wire.

Embodiment 3

[0021] Embodiment 3: as Figure 4 and Figure 5 As shown, there is another structure of the connecting part of the LED bulb light bar. The light bar is composed of a light-emitting area 1 in the middle and connecting parts 2 at both ends. The connecting parts 2 at both ends of the light bar are used to connect with the guide wire. There is a fork-shaped bayonet 3 for holding the guide wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com