Multi-arc bottomed metalized magnetic core and preparation method thereof, and chip inductor

A technology of bottom metal and magnetic core, which is applied in the field of multi-arc bottom metallized magnetic core and its preparation, can solve the problems of good strength and solder resistance, high film density, good adhesion strength, etc., and achieve the reduction of metallization Cost, high quality, and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

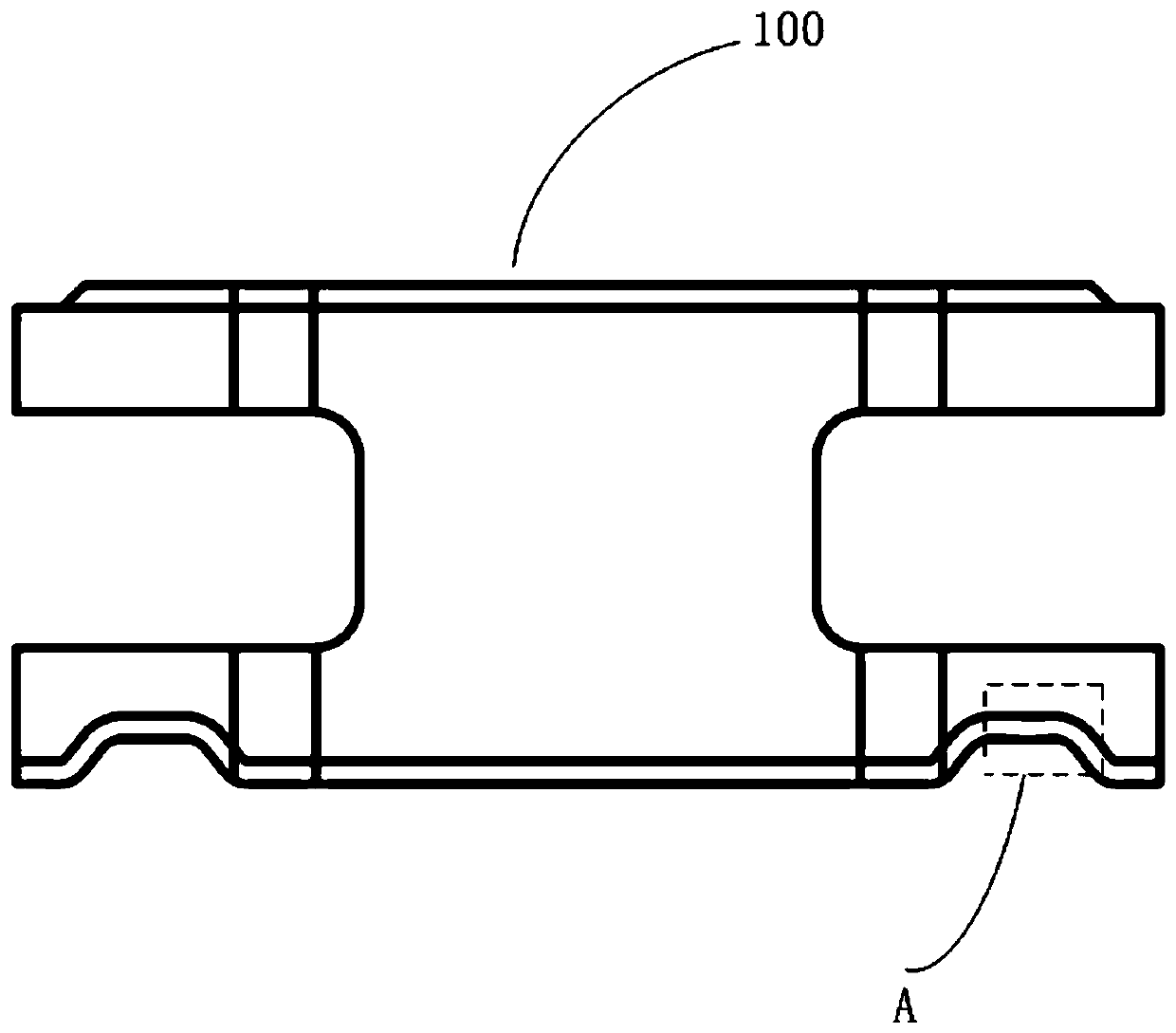

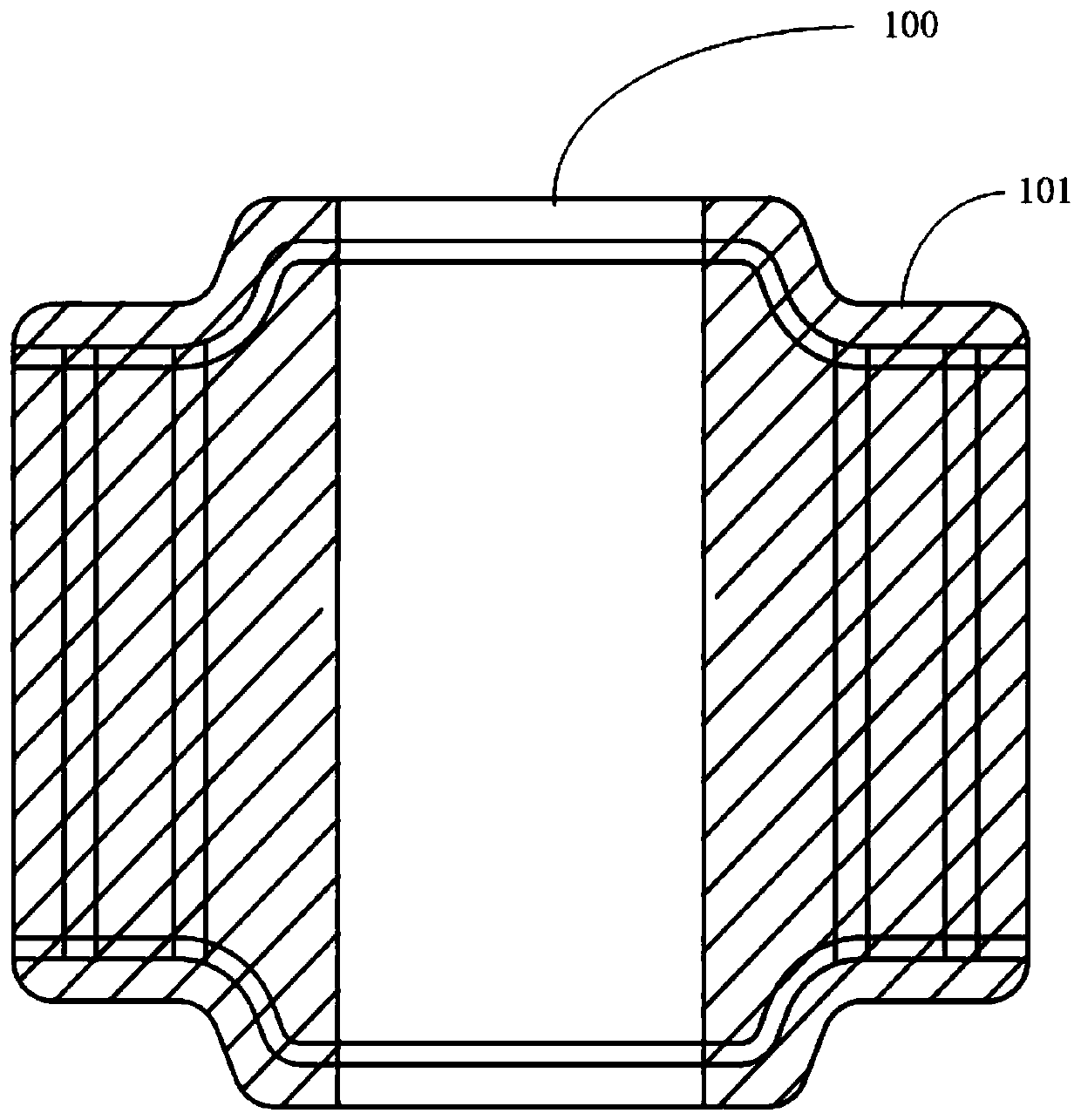

[0036] An embodiment of the present invention provides a method for preparing a multi-arc bottom metallized magnetic core, comprising the following steps:

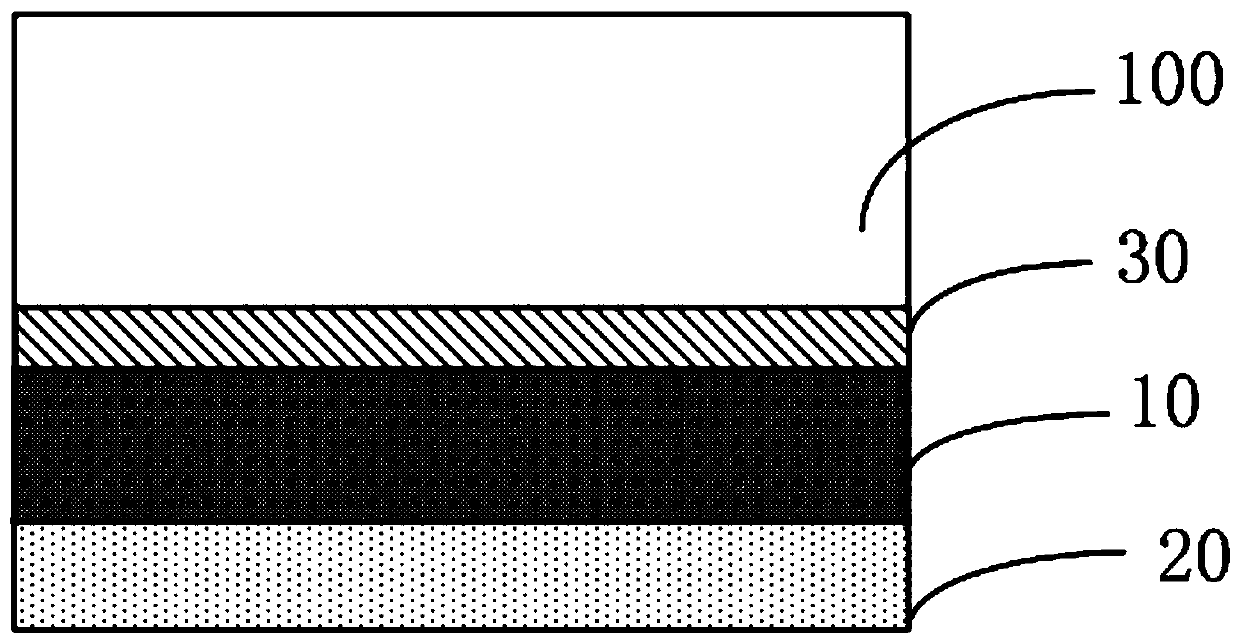

[0037] S10, take the magnetic core, the magnetic core is provided with an electrode area; adopt the mode of multi-arc ion plating to prepare a multi-arc primer layer on the surface of the electrode area, and the multi-arc primer layer is a titanium layer, a chromium layer, and an aluminum layer , zirconium layer or nickel-chromium alloy layer;

[0038] S20. Using magnetron sputtering to sequentially prepare a first coating layer and a second coating layer on the multi-arc primer layer to obtain a metal film layer, the first coating layer includes alternately arranged n layers of first metal layers and n- 1 second metal layer, the material of the first metal layer is one or more of nickel-copper alloy, nickel-vanadium alloy, silver, copper, and iron-nickel-copper alloy, and the material of the second metal layer is nickel ...

Embodiment 1

[0050] A method for preparing a multi-arc bottom metallized magnetic core, comprising the steps of:

[0051] (1) Take the ferrite core, and prepare a multi-arc primer layer on the surface of the electrode area by means of multi-arc ion plating. Specifically, arrange the magnetic cores and place them in a special jig, fix them, and only expose The electrode area is enough, then install the jig on the vacuum machine turntable, close the vacuum chamber for vacuuming, when the vacuum degree reaches 5×10 -3 Turn on the power supply of the chromium target, fill it with argon gas, and start sputtering. The current of the target is set to 70A, and the thickness of the chromium layer of the multi-arc primer layer is 0.2 microns;

[0052] (3) The first coating layer and the second coating layer are prepared on the multi-arc primer layer by magnetron sputtering to obtain a multi-arc primer metallized magnetic core, and the first coating layer includes 2 layers of nickel-copper alloy laye...

Embodiment 2

[0058] A method for preparing a multi-arc bottom metallized magnetic core, comprising the steps of:

[0059] (1) Take the ferrite core, and prepare a multi-arc primer layer on the surface of the electrode area by means of multi-arc ion plating. Specifically, arrange the magnetic cores and place them in a special jig, fix them, and only expose The electrode area is enough, then install the jig on the vacuum machine turntable, close the vacuum chamber for vacuuming, when the vacuum degree reaches 5×10 -3 At this time, turn on the power supply of the titanium target, fill it with argon gas, and start sputtering. The current of the target is set to 80A, and the thickness of the obtained multi-arc primer layer titanium layer is 0.6 microns;

[0060] (3) The first coating and the second coating are prepared on the multi-arc primer layer by magnetron sputtering to obtain a multi-arc primer metallized magnetic core, and the first coating layer includes 2 layers of nickel-vanadium allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com