Printed matter examination apparatus

A technology for inspecting devices and printed matter, which is applied to printing, printing machines, general parts of printing machinery, etc., and can solve problems such as vibration, increased cost of inspection devices, and inability to suppress paper vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

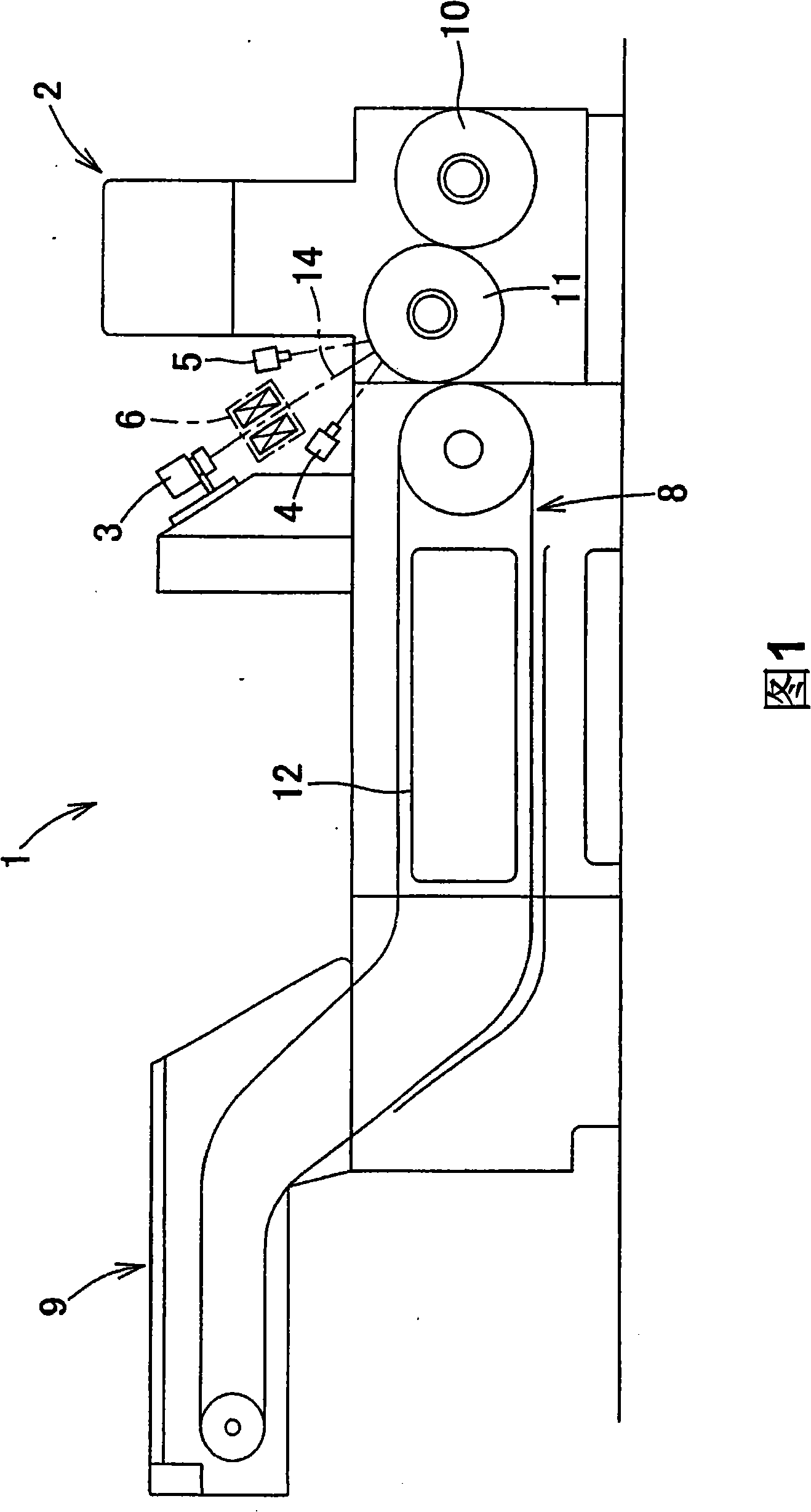

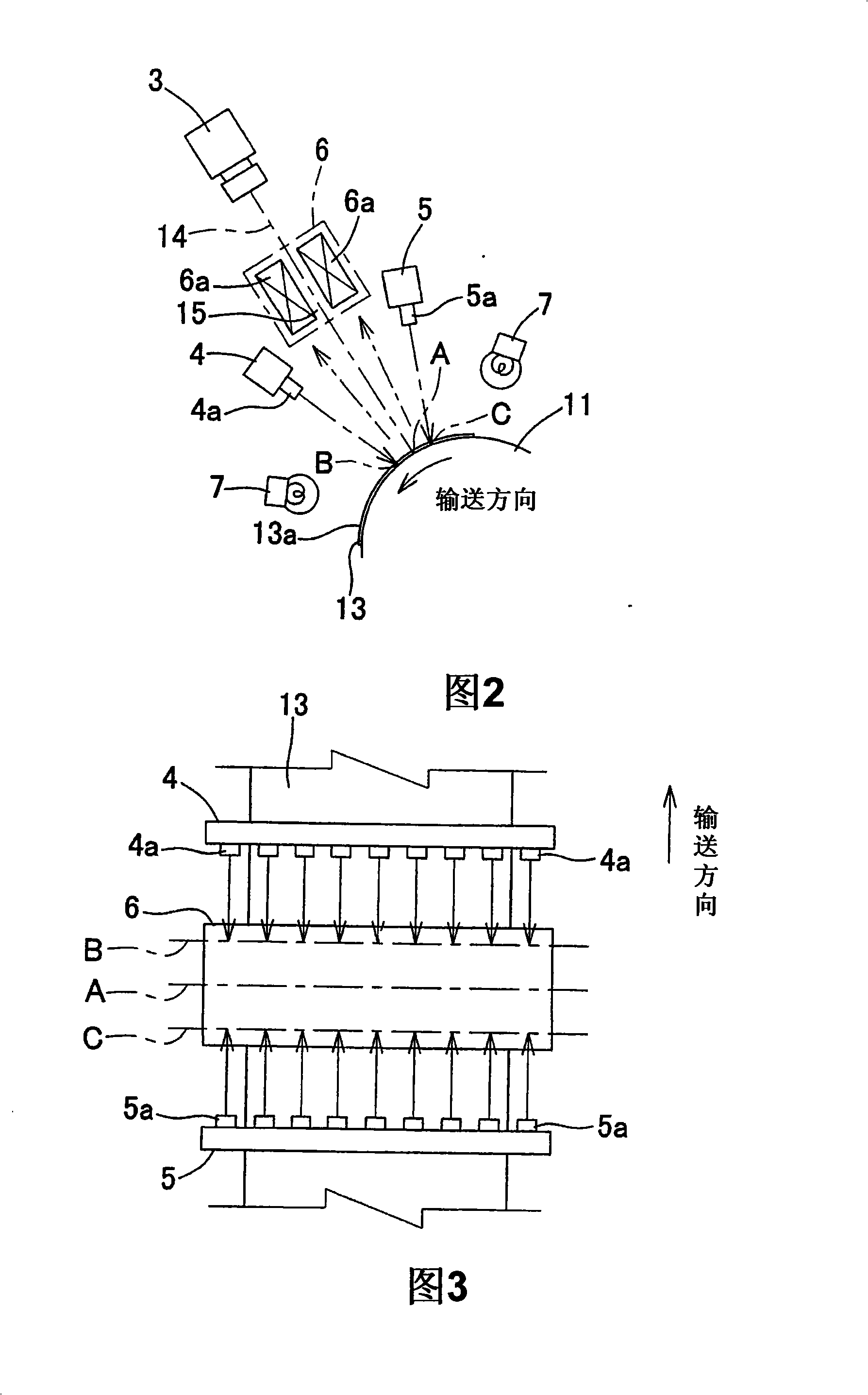

[0054] One embodiment of the printed matter inspection device according to the present invention will be described with reference to the drawings. As shown in FIG. 1 , the printed matter inspection device is arranged in a printing machine 1 for sheet-fed printing, and is an apparatus for inspecting printed matter printed by a final printing device 2 in the printing machine 1 . This printed matter inspection device is mainly composed of the following parts: a camera 3 constituting a photographing unit, a first air blowing unit 4 that blows air from the front obliquely above the conveying direction, The second air blowing unit 5 that blows air obliquely upward, the air suction unit 6 that sucks in the air discharged from the two air blowing units 4, 5, the lighting unit 7 (refer to FIG. The control unit 26 (refer to FIG. 8 ) of the two air blowing units 4 and 5 and the judging device 22 (refer to FIG. 8 ) for judging the printing state based on the image captured by the camera 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com