Wafer susceptor

A wafer carrying and wafer technology, which is applied in coating, gaseous chemical plating, metal material coating process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

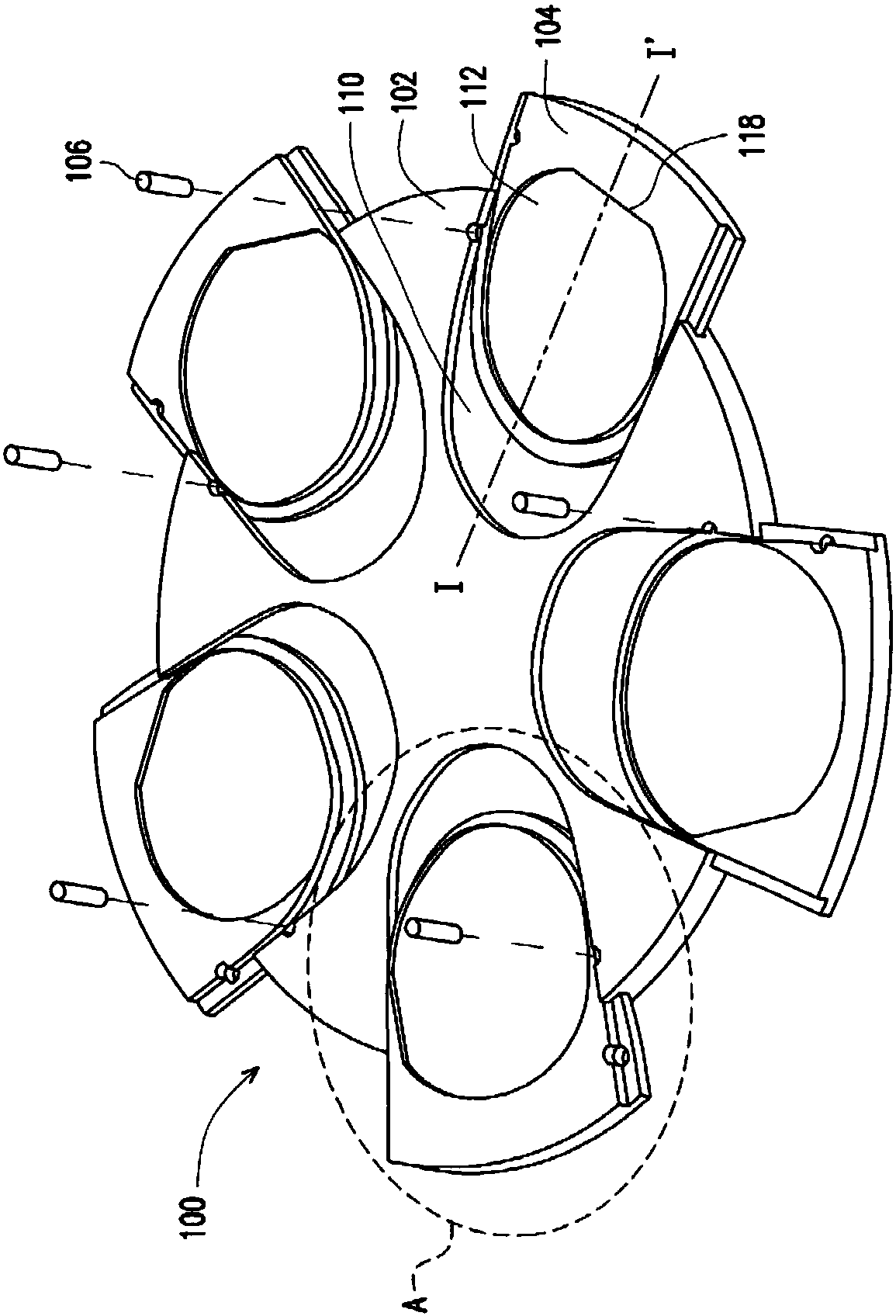

[0060] Figure 1A is a schematic diagram of a wafer carrier according to an embodiment of the present invention.

[0061] Please see first Figure 1A , the wafer susceptor 100 of the present invention includes a master plate 102 , several daughter plates 104 and several pins 106 . The wafer susceptor 100 can rotate clockwise or counterclockwise based on its center.

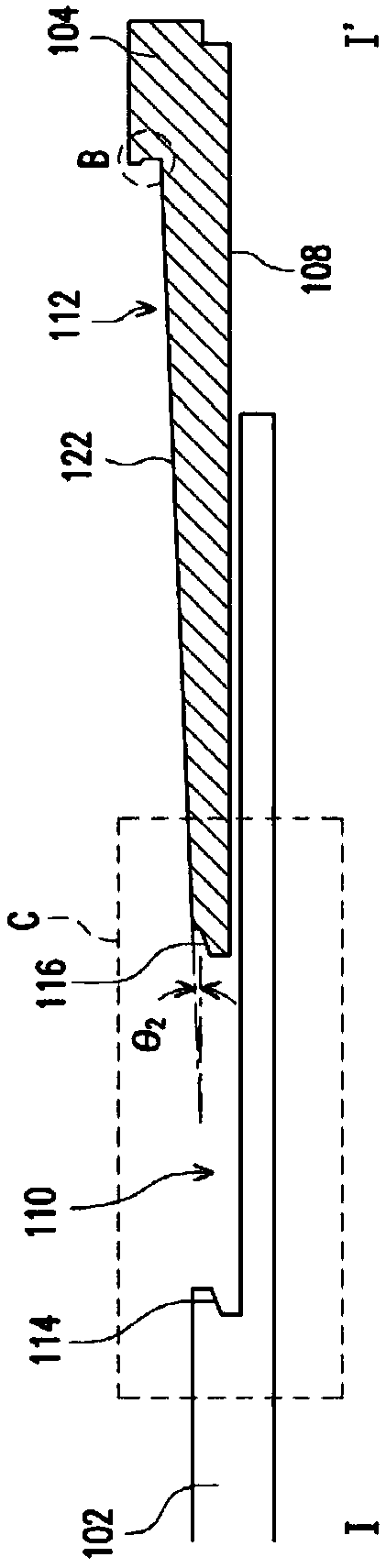

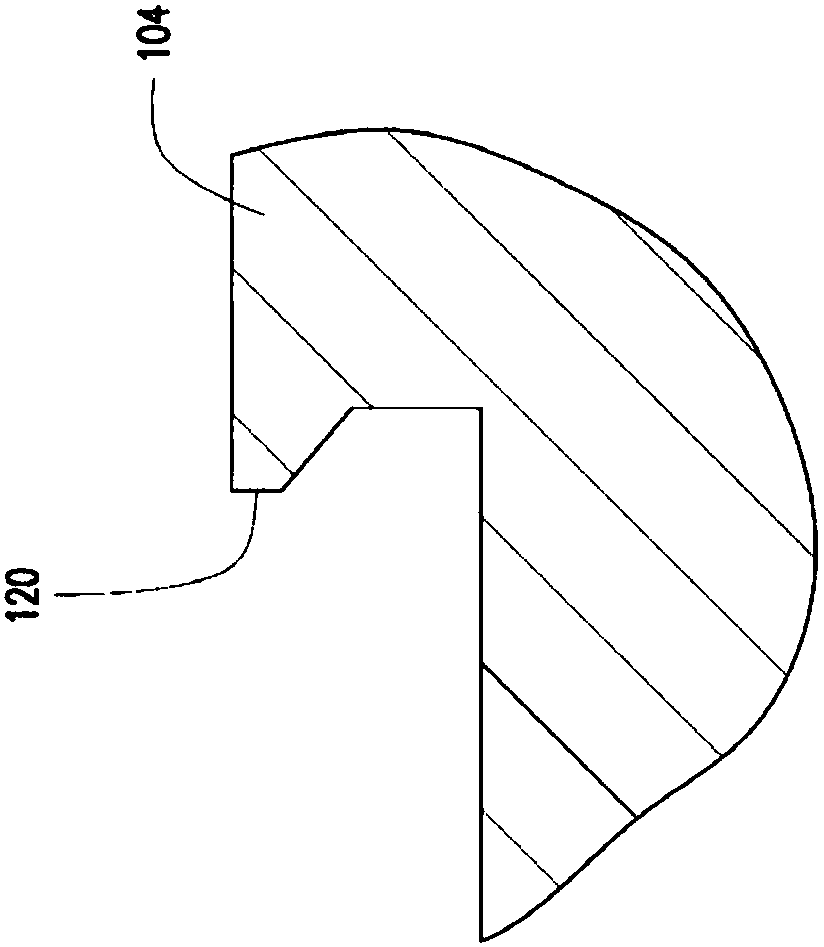

[0062] Figure 1B yes Figure 1A Sectional view along the line segment I-I'. Figure 1C yes Figure 1B Magnified view of region B of . Figure 1D yes Figure 1B Magnified view of region C. Figure 1E yes Figure 1A The enlarged view of the combination of the sub-disc and the master disc on which the wafer is placed in the area A of .

[0063]Please see Figure 1A and Figure 1B . The master disc 102 has a plurality of first grooves 110 . Several sub-discs 104 are respectively arranged in the first groove 110, and each sub-disc 104 has a second groove 112 for carrying wafers and a fitting slope 116 fitted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com