Novel feeder

A feeder, a new type of technology, is applied in the direction of large containers, conveyor objects, containers, etc., and can solve problems such as inability to feed materials, blockage of the cone bucket, inaccurate positioning of the working hopper and the cone bucket, etc., to achieve the solution of blockage and easy dredging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

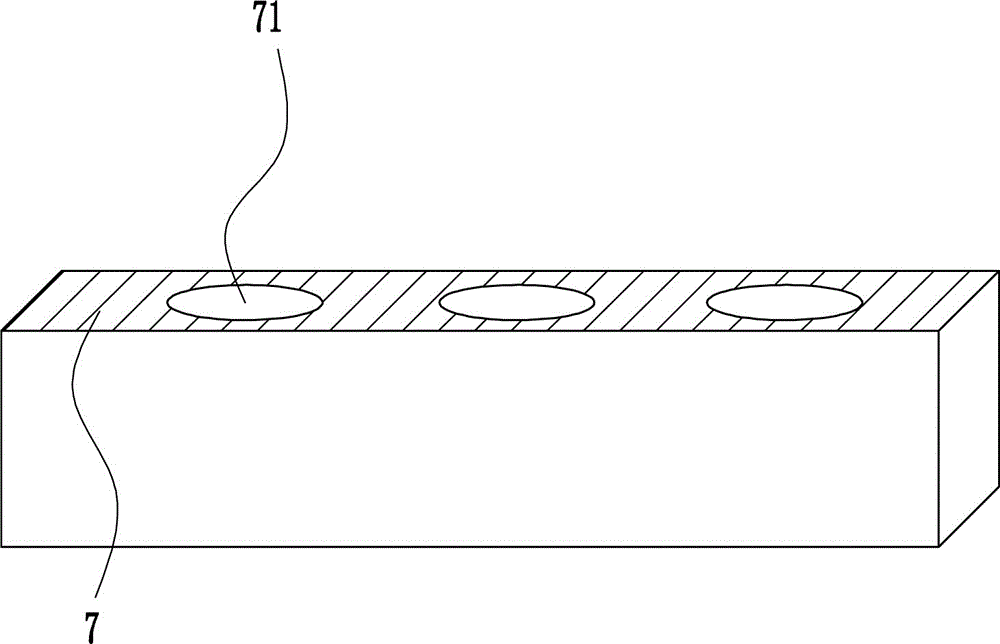

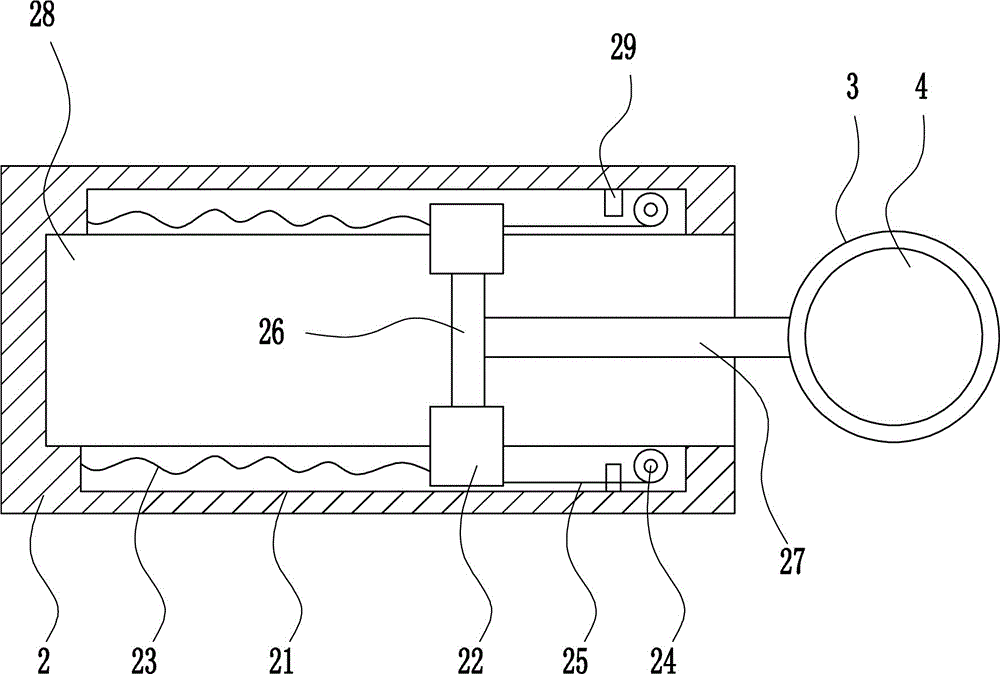

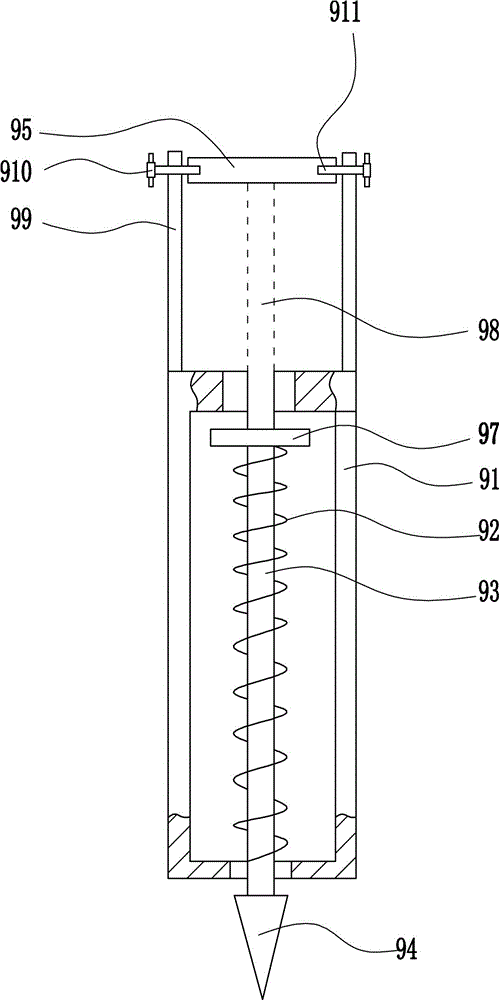

[0032] A new type of feeder, such as Figure 1-9 As shown, it includes a hopper lifting feeder 1, a mounting plate 2, a slide rail 21, a slider 22, a first spring 23, an electric wheel 24, a wire rope 25, a moving plate 26, a connecting rod 27, a travel switch 29, and a bucket 3 , working hopper 4, annular bump 41, roller 5, clamping device 6, first clamping plate 7, cone bucket 8, dredging device 9, pole 10 and discharge butterfly valve 11, the bottom of the hopper lifting feeder 1 is connected by bolts The mounting plate 2 is connected with the mounting plate 2, and a through hole 28 is opened on the mounting plate 2. Both the front and rear walls of the mounting plate 2 are connected with a slide rail 21 by means of bolt connection, and the right side of the inner wall of the slide rail 21 is connected by a screw connection. A travel switch 29 is connected, a slide block 22 is slidably connected on the slide rail 21, a first spring 23 is connected between the left wall of t...

Embodiment 2

[0034] A new type of feeder, such as Figure 1-9 As shown, it includes a hopper lifting feeder 1, a mounting plate 2, a slide rail 21, a slider 22, a first spring 23, an electric wheel 24, a wire rope 25, a moving plate 26, a connecting rod 27, a travel switch 29, and a bucket 3 , working hopper 4, annular bump 41, roller 5, clamping device 6, first clamping plate 7, cone bucket 8, dredging device 9, pole 10 and discharge butterfly valve 11, the bottom of the hopper lifting feeder 1 is connected by bolts The mounting plate 2 is connected with the mounting plate 2, and a through hole 28 is opened on the mounting plate 2. Both the front and rear walls of the mounting plate 2 are connected with a slide rail 21 by means of bolt connection, and the right side of the inner wall of the slide rail 21 is connected by a screw connection. A travel switch 29 is connected, a slide block 22 is slidably connected on the slide rail 21, a first spring 23 is connected between the left wall of t...

Embodiment 3

[0037] A new type of feeder, such as Figure 1-9 As shown, it includes a hopper lifting feeder 1, a mounting plate 2, a slide rail 21, a slider 22, a first spring 23, an electric wheel 24, a wire rope 25, a moving plate 26, a connecting rod 27, a travel switch 29, and a bucket 3 , working hopper 4, annular bump 41, roller 5, clamping device 6, first clamping plate 7, cone bucket 8, dredging device 9, pole 10 and discharge butterfly valve 11, the bottom of the hopper lifting feeder 1 is connected by bolts The mounting plate 2 is connected with the mounting plate 2, and a through hole 28 is opened on the mounting plate 2. Both the front and rear walls of the mounting plate 2 are connected with a slide rail 21 by means of bolt connection, and the right side of the inner wall of the slide rail 21 is connected by a screw connection. A travel switch 29 is connected, a slide block 22 is slidably connected on the slide rail 21, a first spring 23 is connected between the left wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com