Patents

Literature

32results about How to "Avoid scrubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

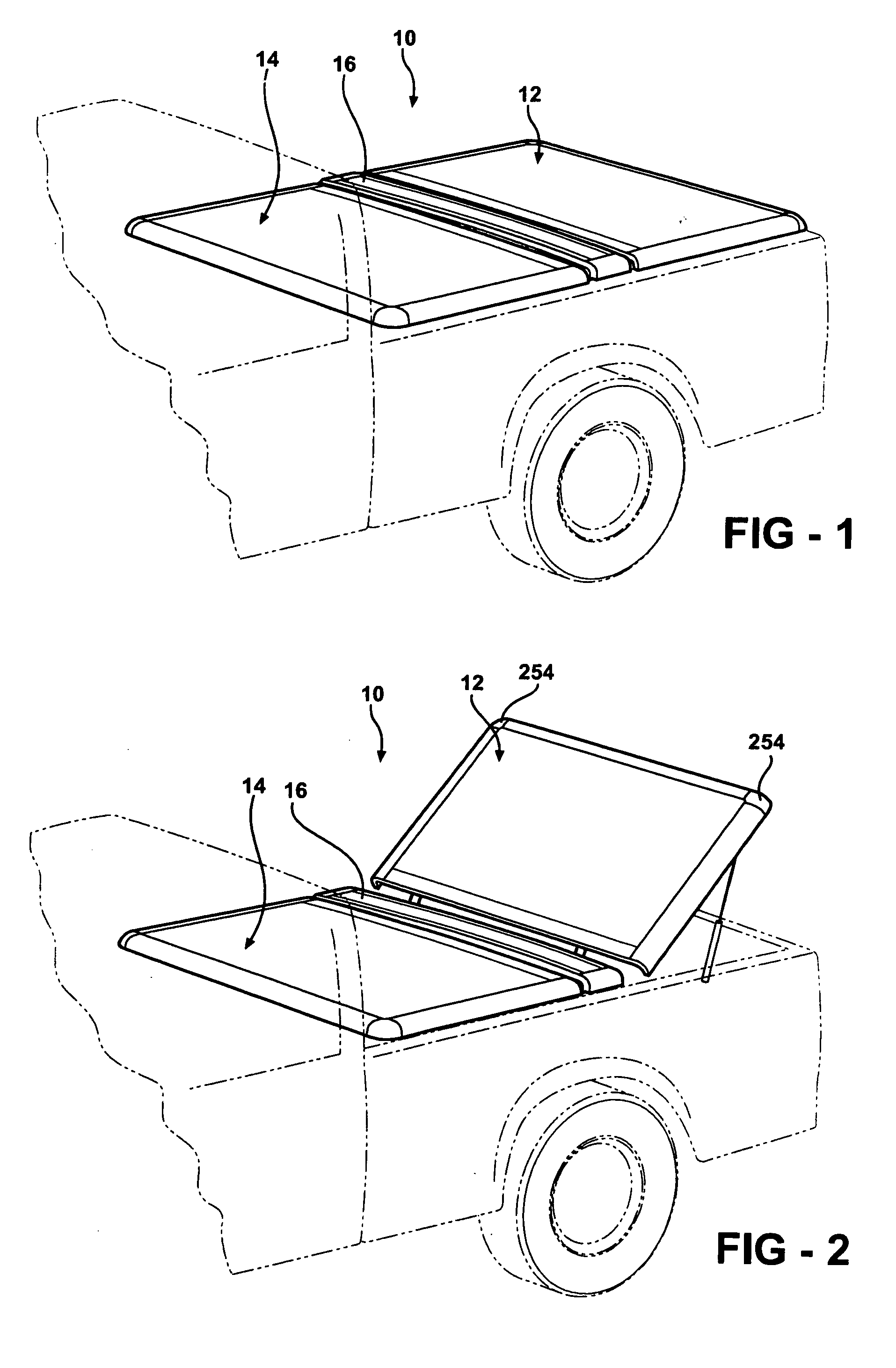

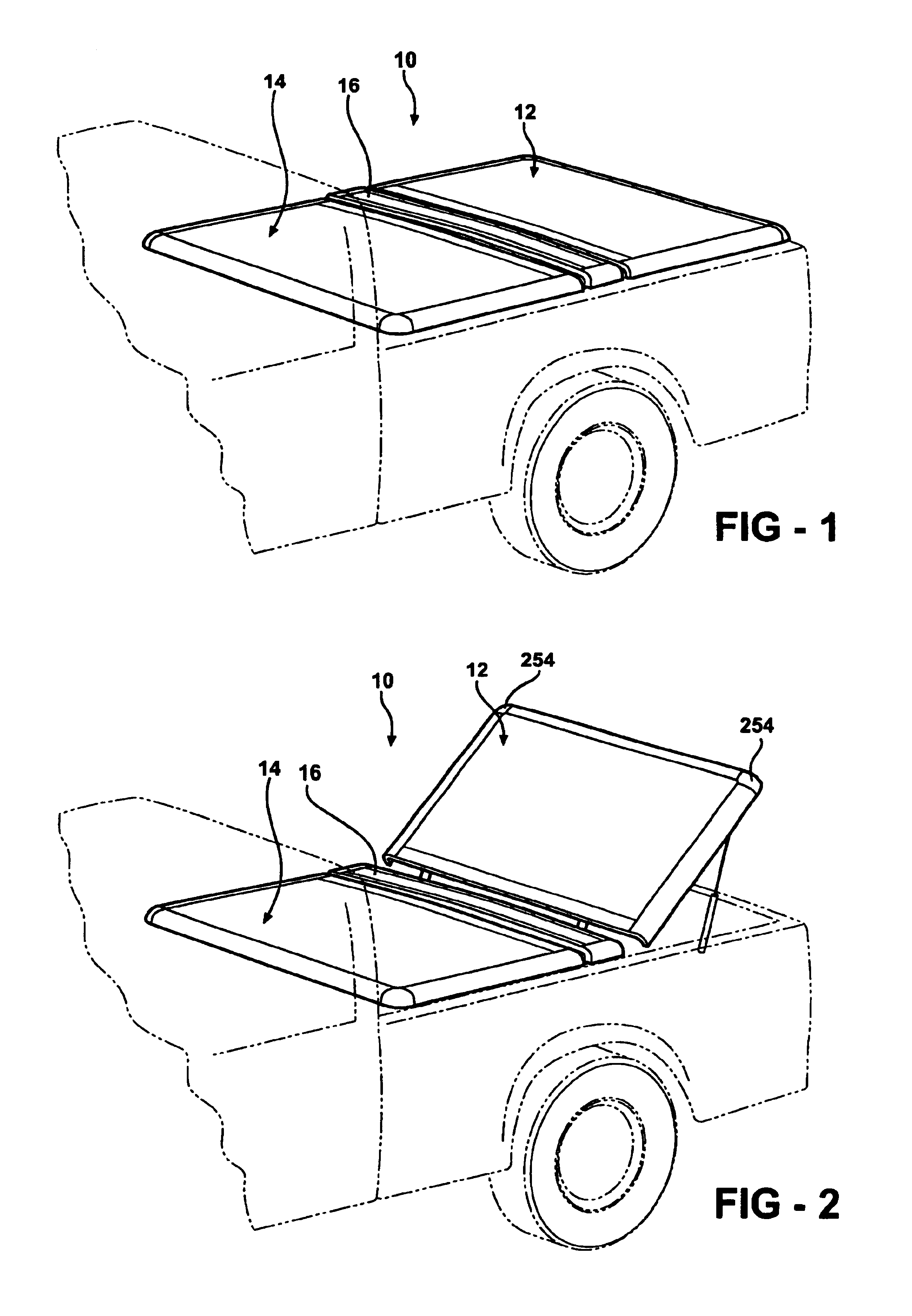

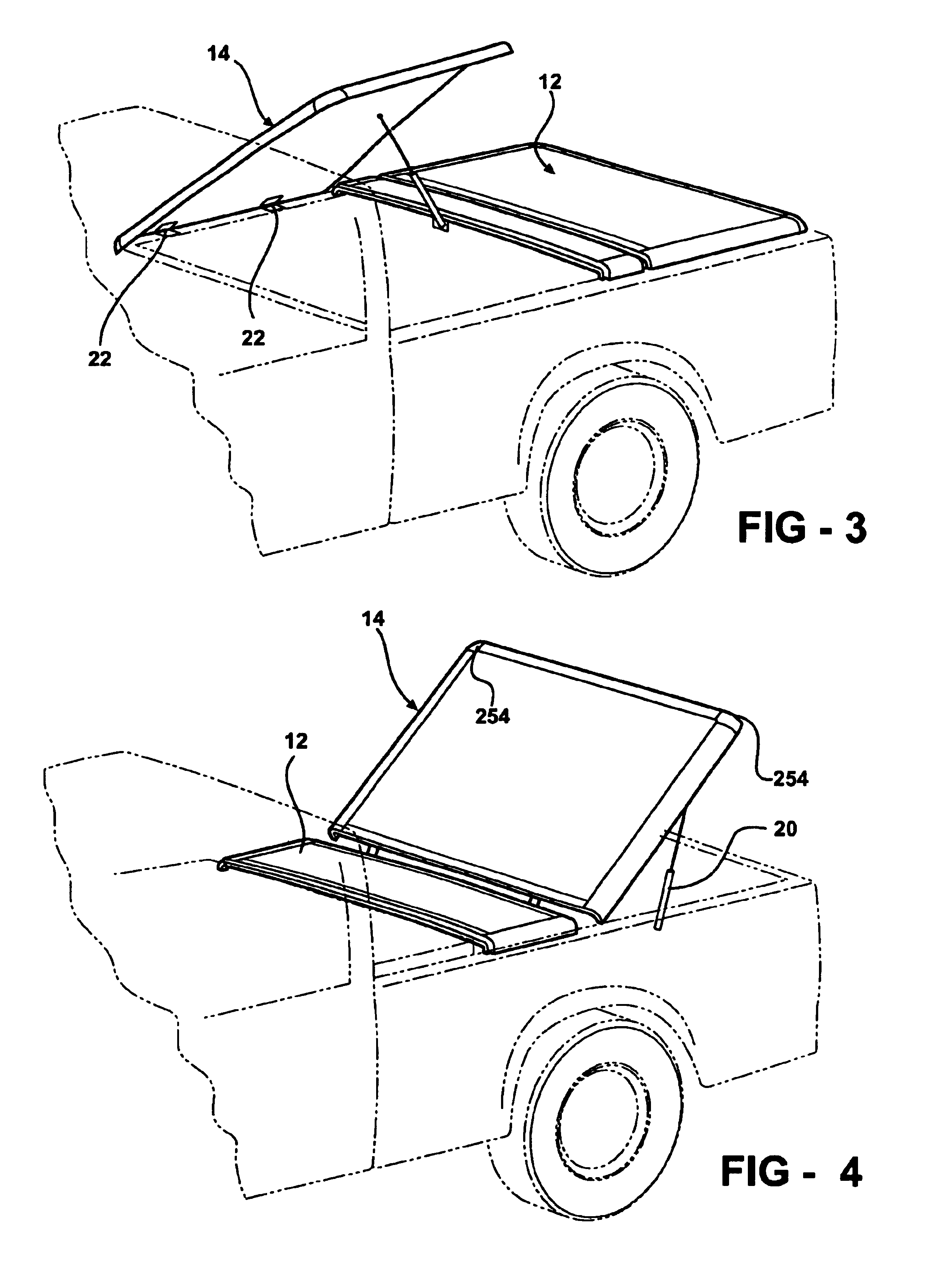

Hard tonneau cover

InactiveUS7252322B2Avoid enteringSufficiently compressibleLoad coveringRoofsPick-up truckEngineering

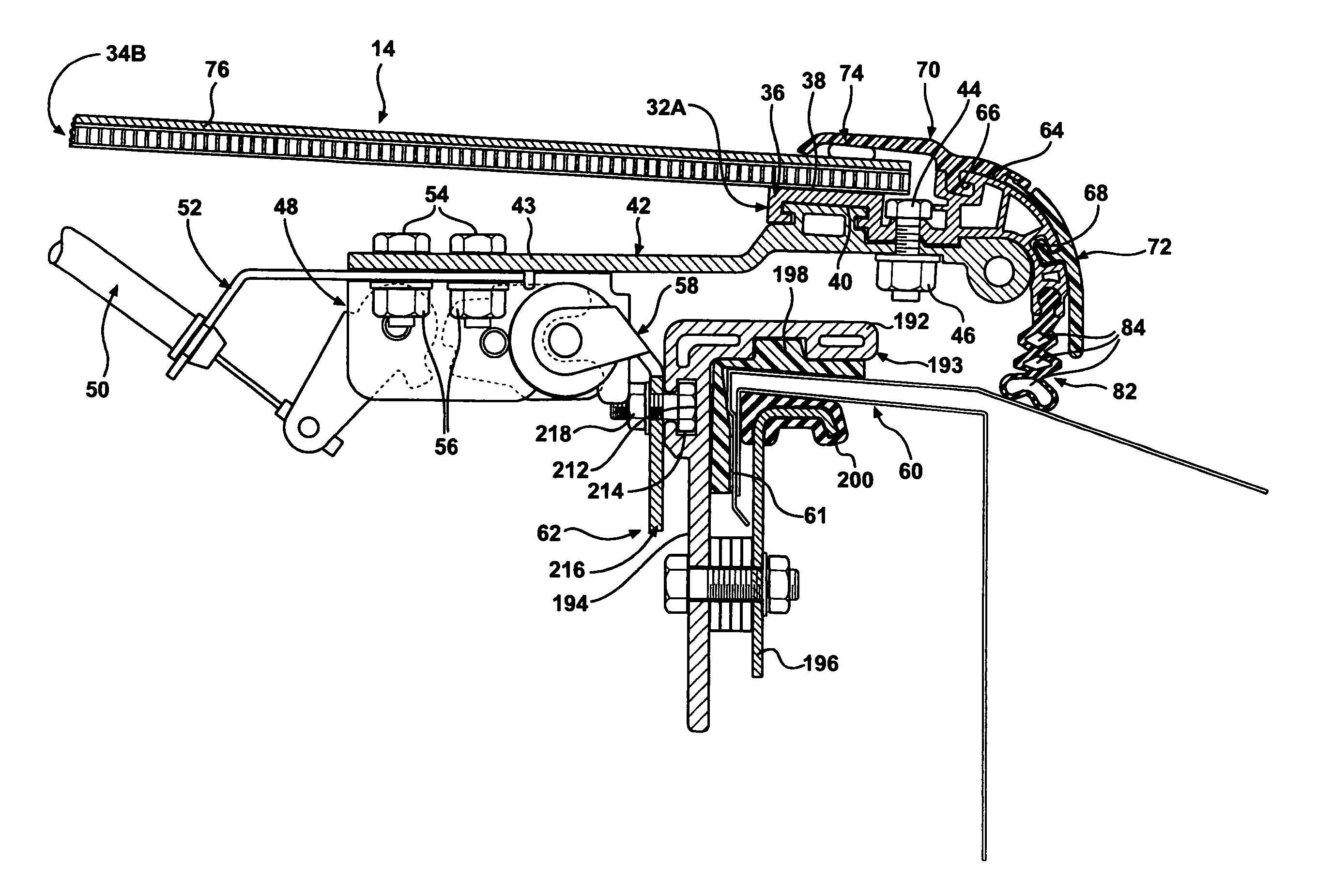

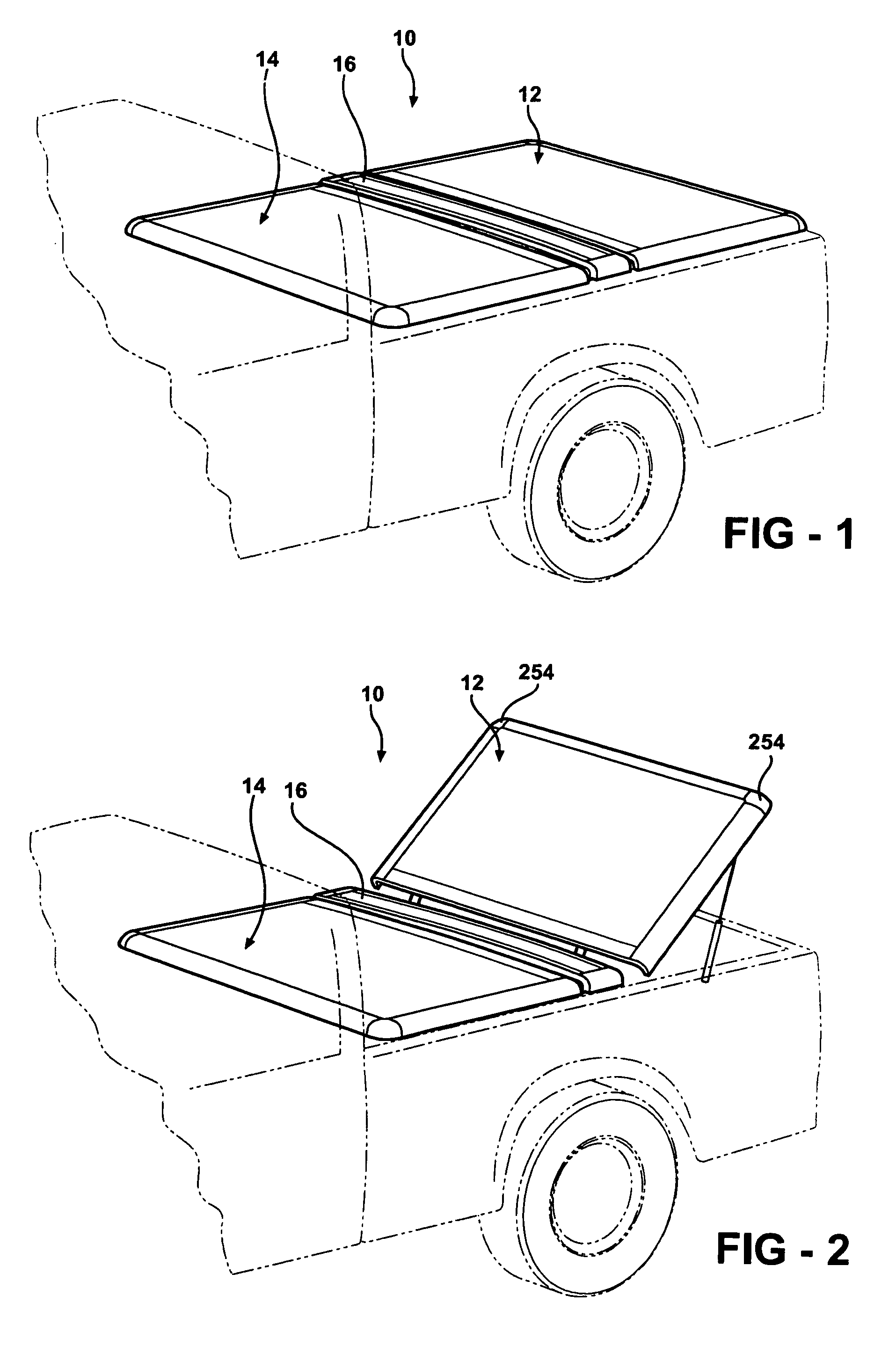

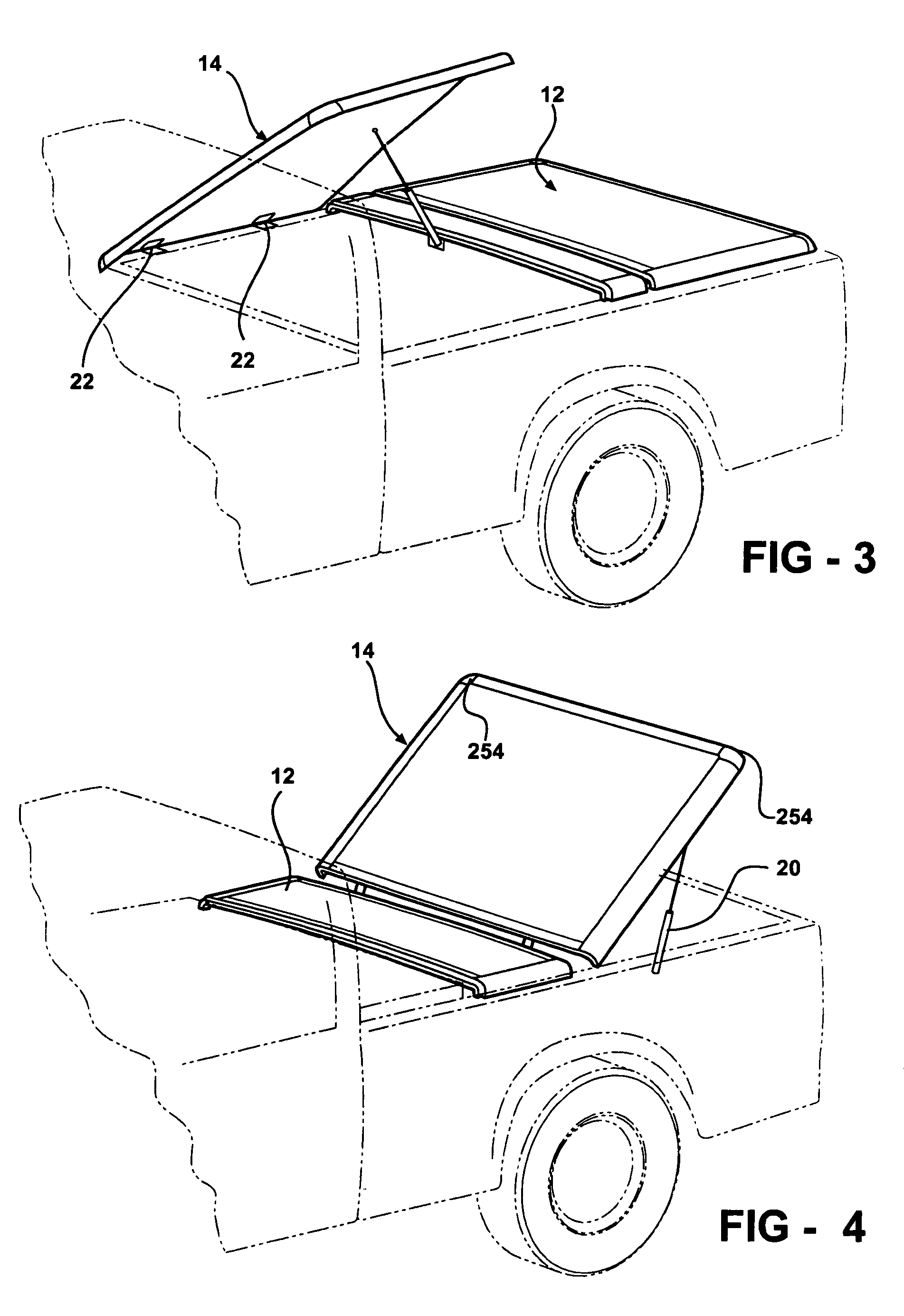

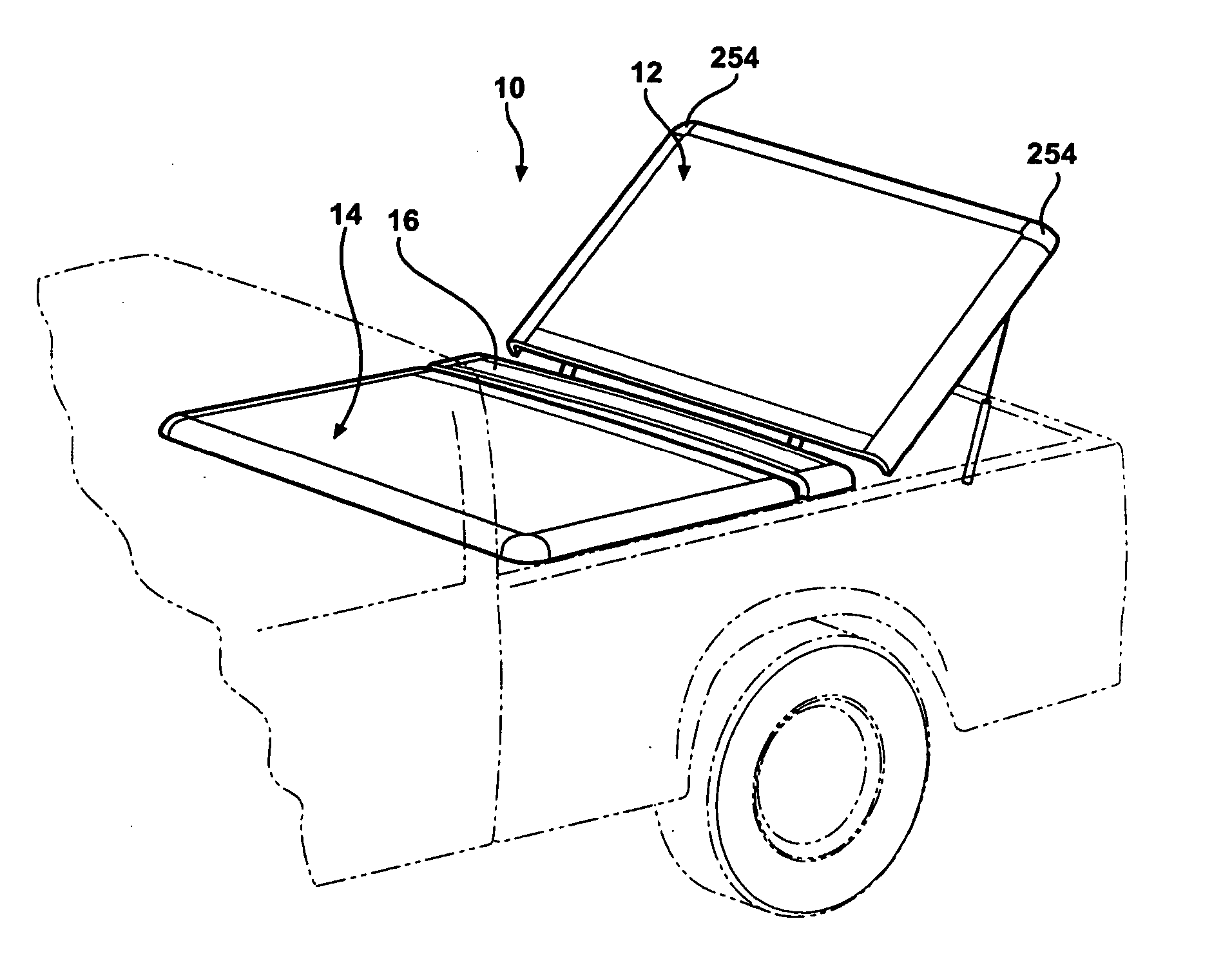

A hard tonneau cover having one or more sections is constructed of a framework of extruded rails with one or more section panels held by molded plastic trim strips installed on perimeter rails included in the framework. The cover is mounted above the cargo box of a pick-up truck by a plurality of striker-latch assemblies on one side of the cargo box, and hinge assemblies on the other side, each having components mounted to the cargo box side walls with universal clamp brackets. The panels are constructed of reinforced corrugated plastic which is covered by a color integrated film. A simplified connector plate is used to connect abutting ends of the rails in the framework. A peripheral seal extends down from the perimeter rails in which it is mounted to engage the top of the cargo box side walls and tailgate. Water drainage paths including drainage channels in the rails are provided to eliminate water from the panel surfaces.

Owner:RUSU WILLIAM

Hard tonneau cover

InactiveUS20070035151A1Avoid enteringSufficiently compressibleLoad coveringTransportation itemsPick-up truckEngineering

A hard tonneau cover having one or more sections is constructed of a framework of extruded rails with one or more section panels held by molded plastic trim strips installed on perimeter rails included in the framework. The cover is mounted above the cargo box of a pick-up truck by a plurality of striker-latch assemblies on one side of the cargo box, and hinge assemblies on the other side, each having components mounted to the cargo box side walls with universal clamp brackets. The panels are constructed of reinforced corrugated plastic which is covered by a color integrated film. A simplified connector plate is used to connect abutting ends of the rails in the framework. A peripheral seal extends down from the perimeter rails in which it is mounted to engage the top of the cargo box side walls and tailgate. Water drainage paths including drainage channels in the rails are provided to eliminate water from the panel surfaces.

Owner:RUSU WILLIAM

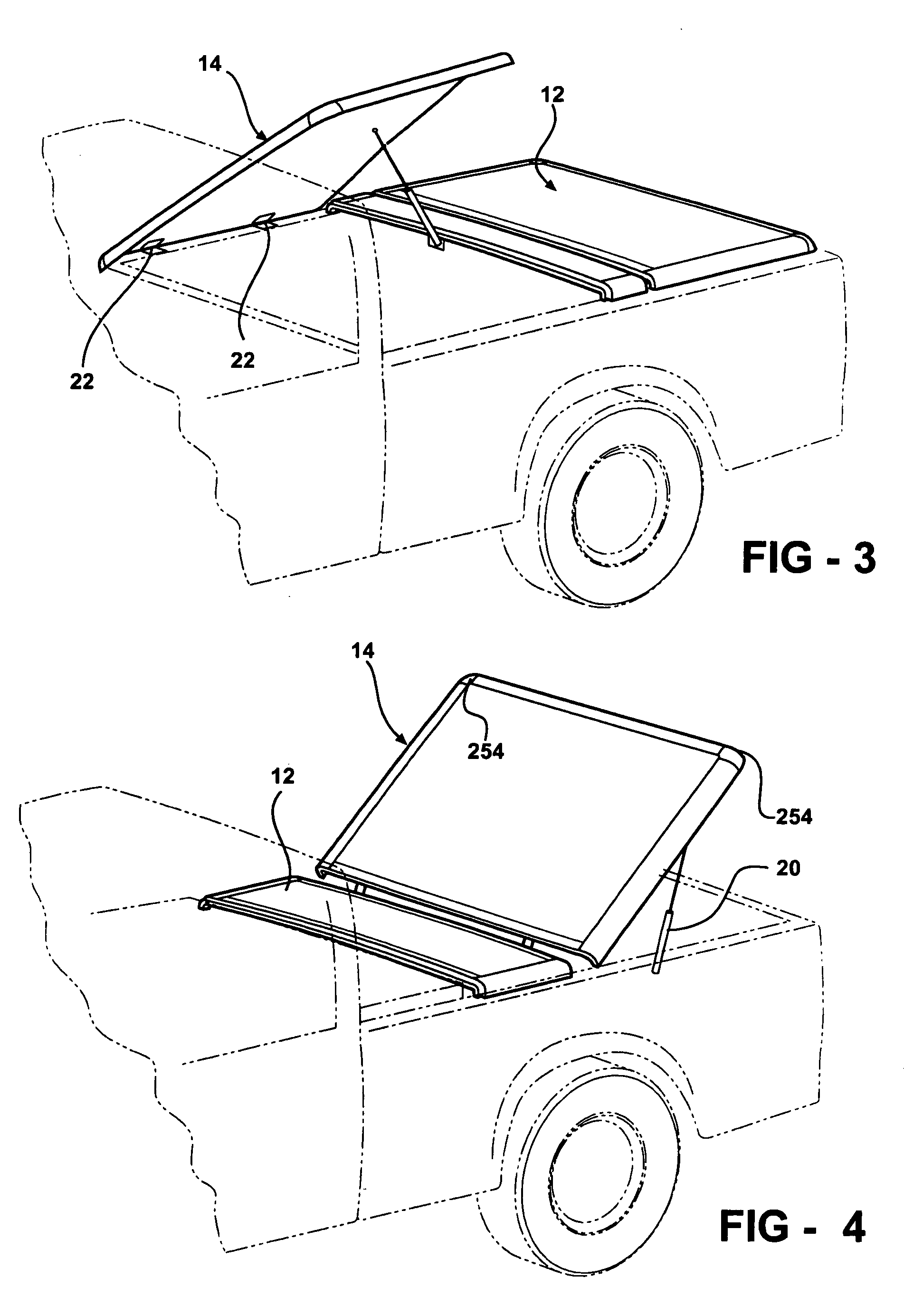

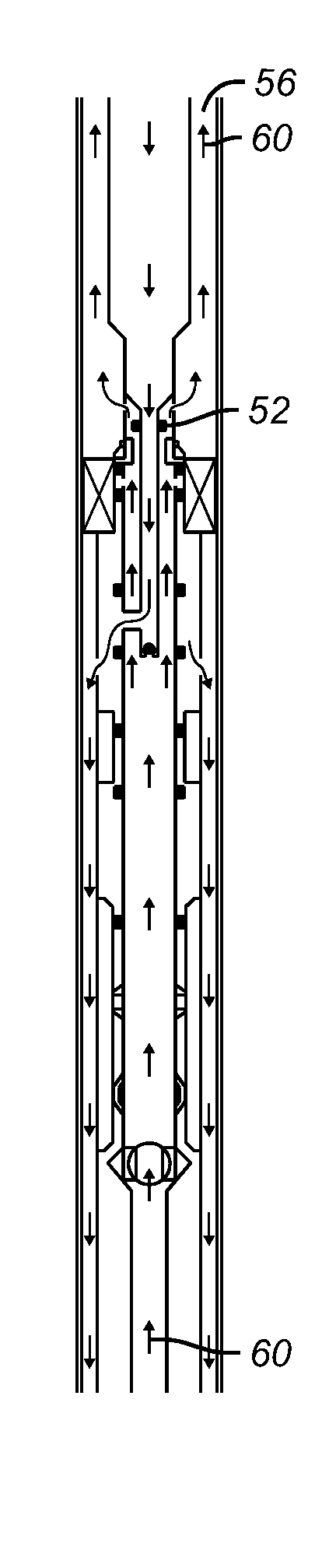

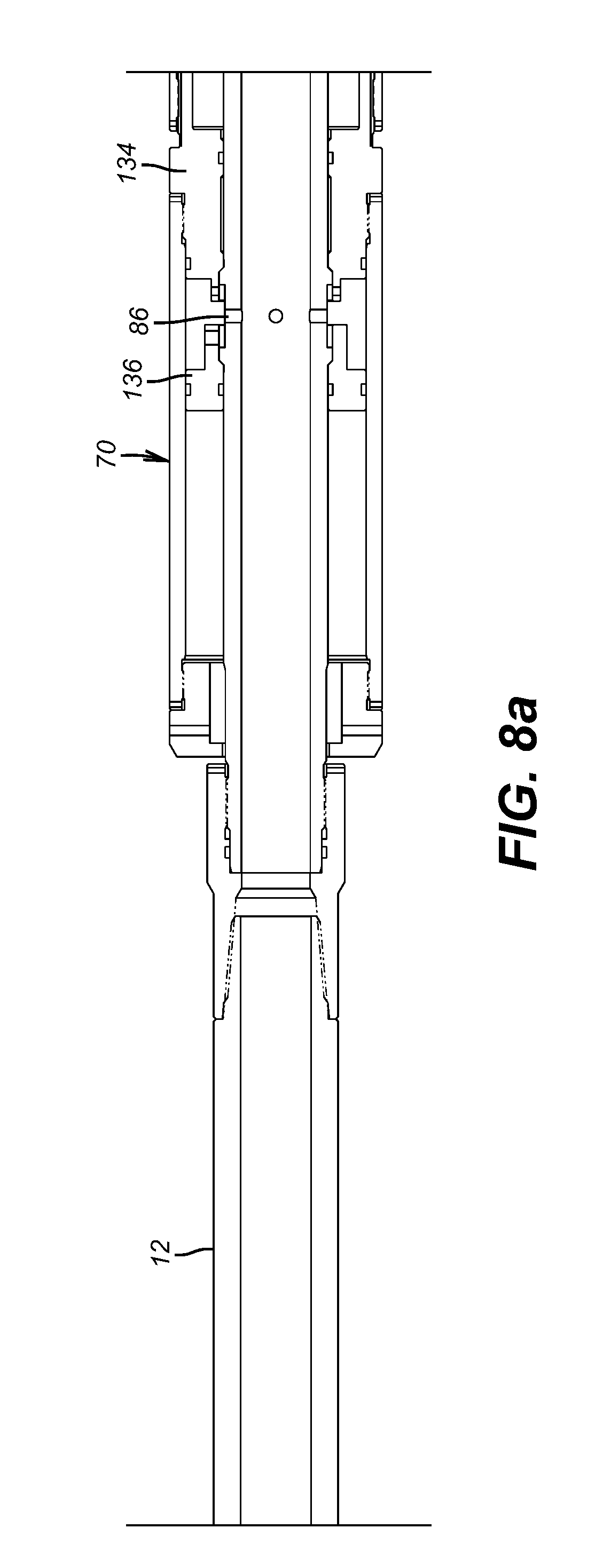

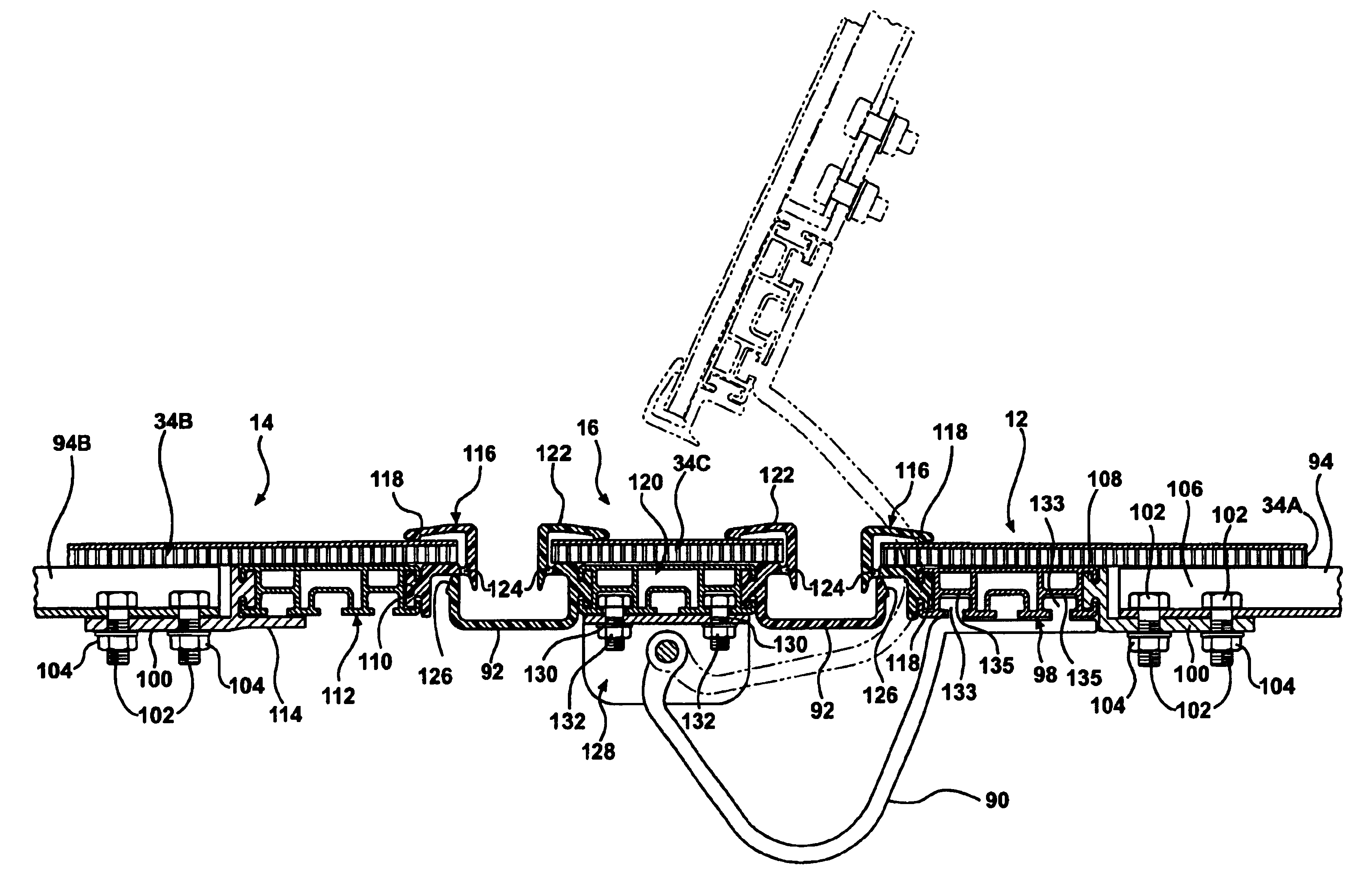

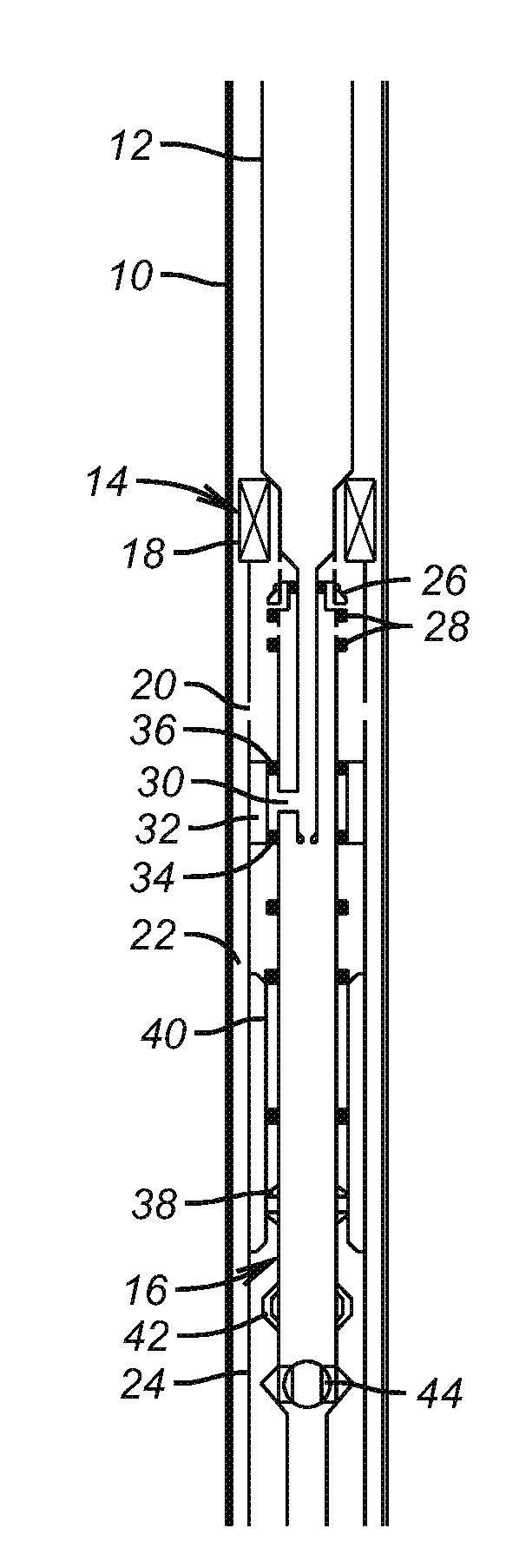

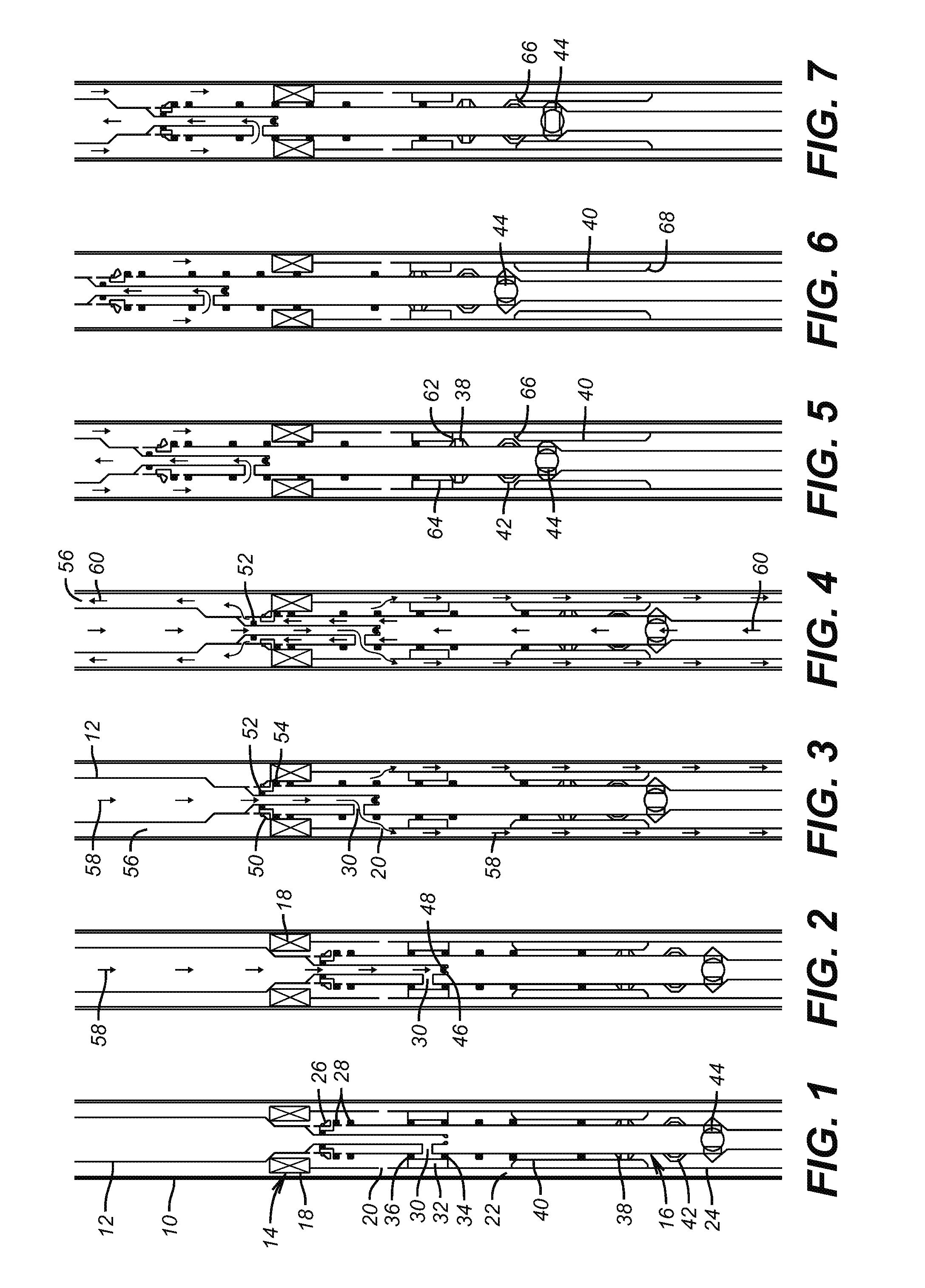

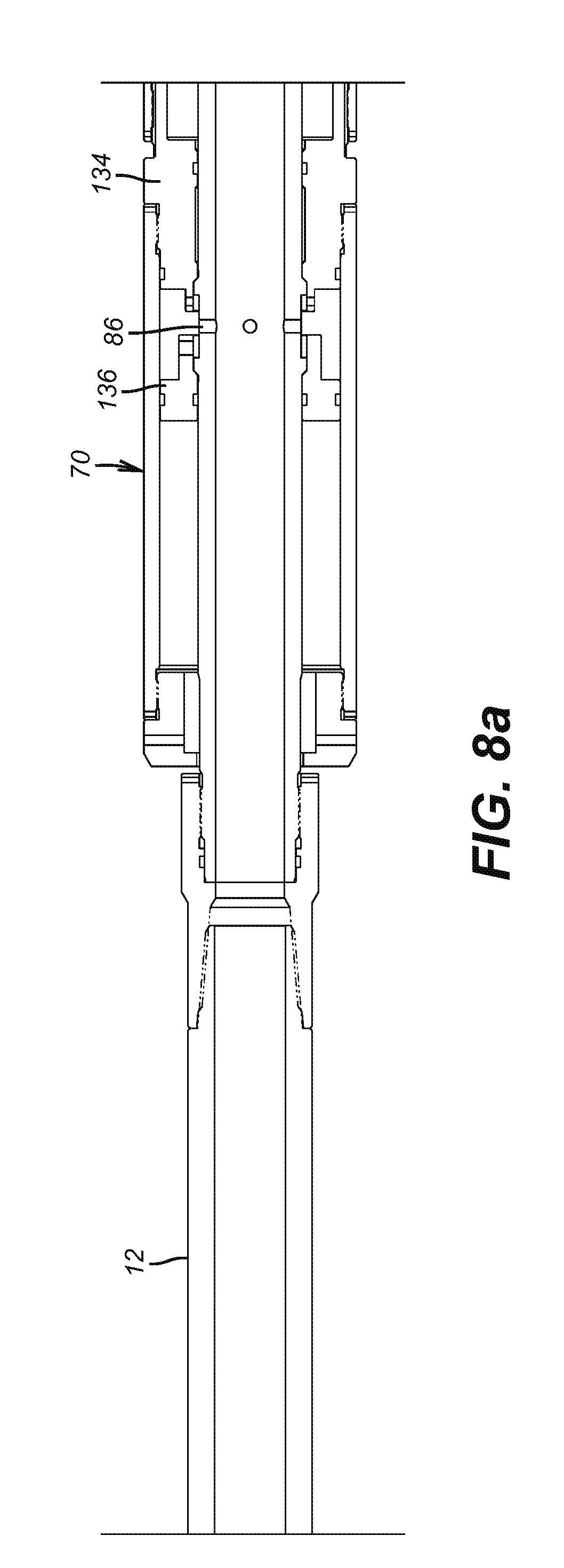

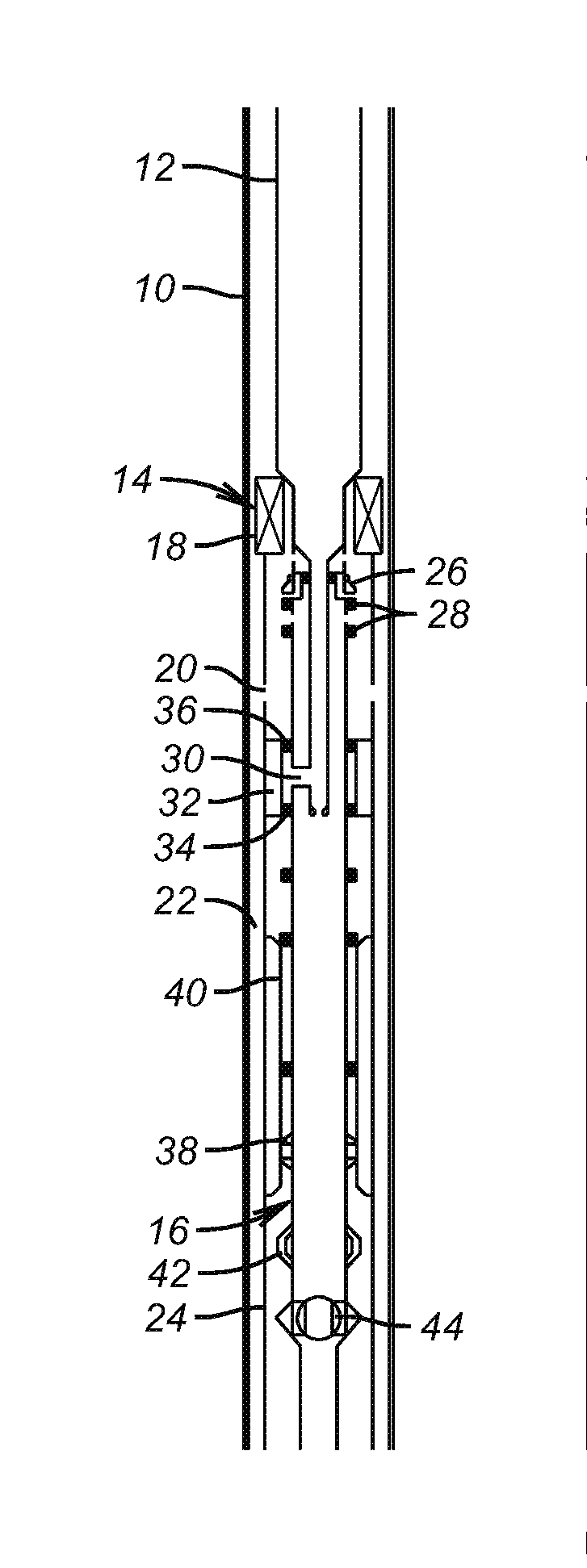

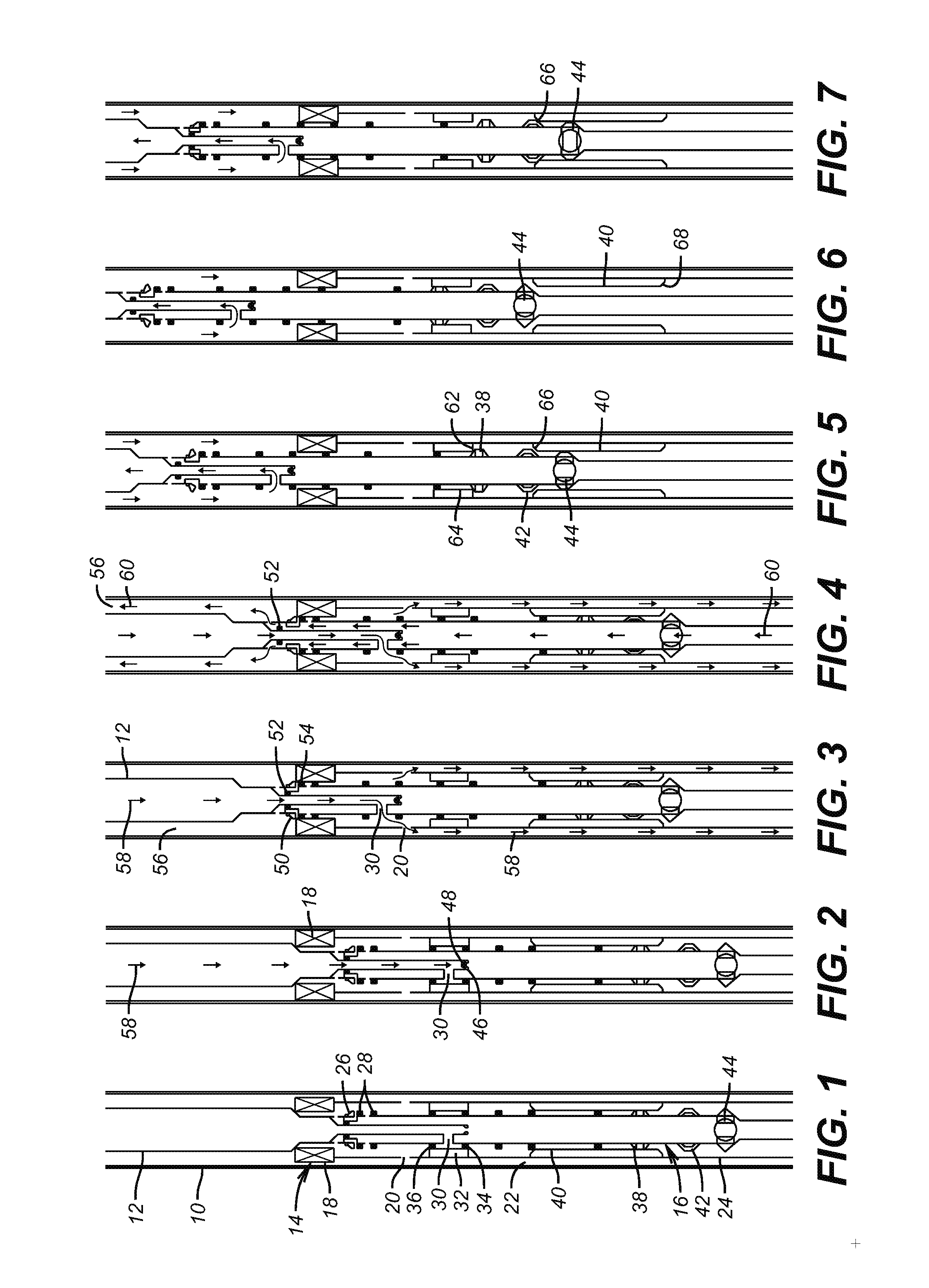

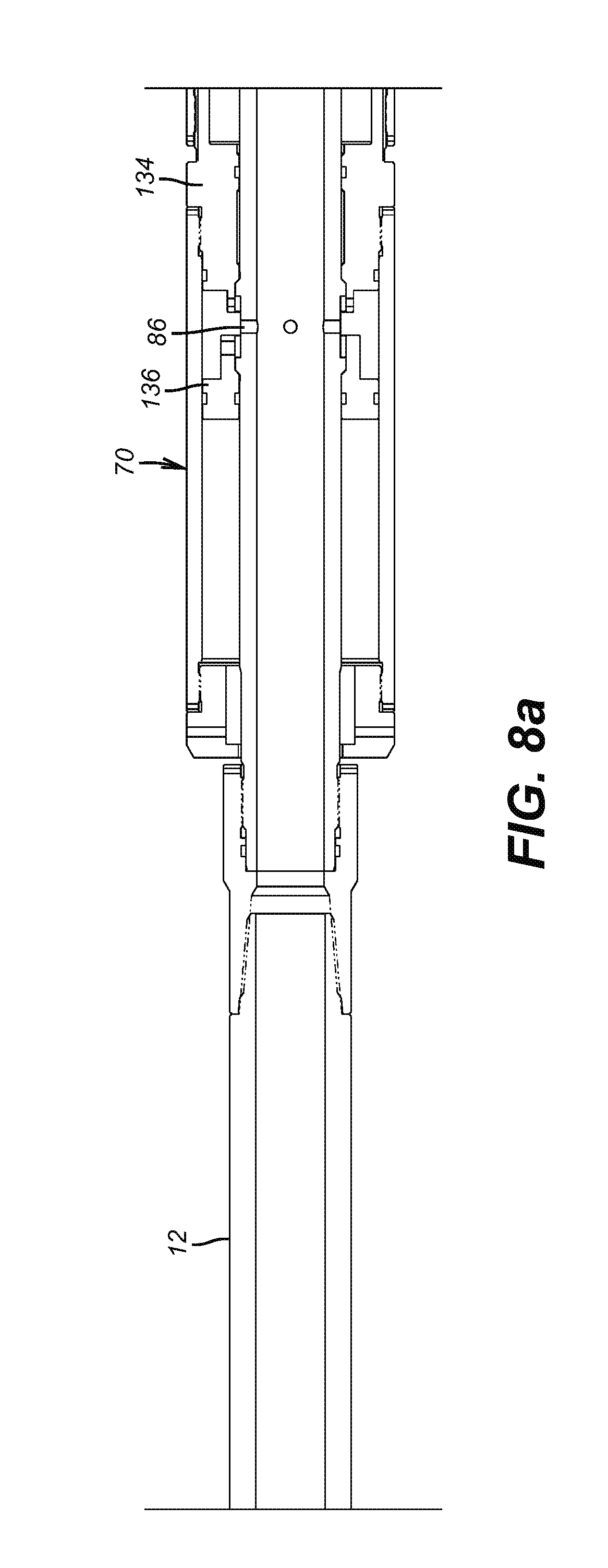

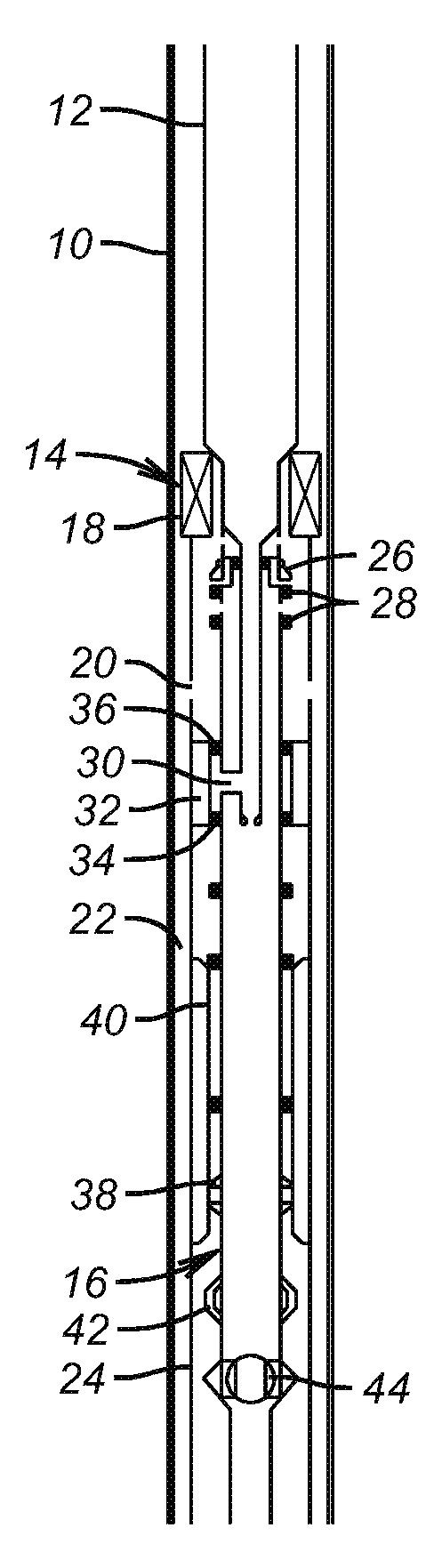

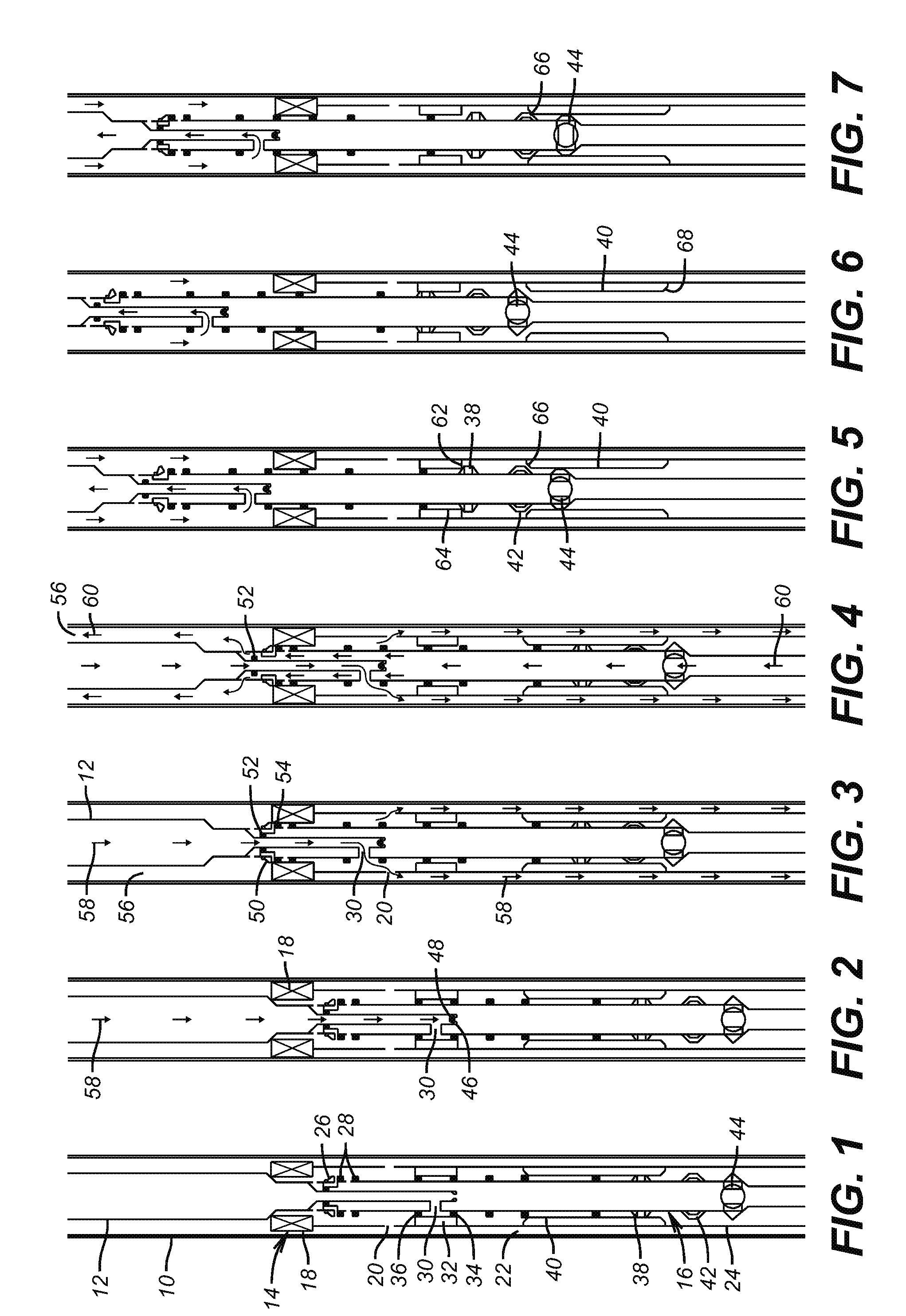

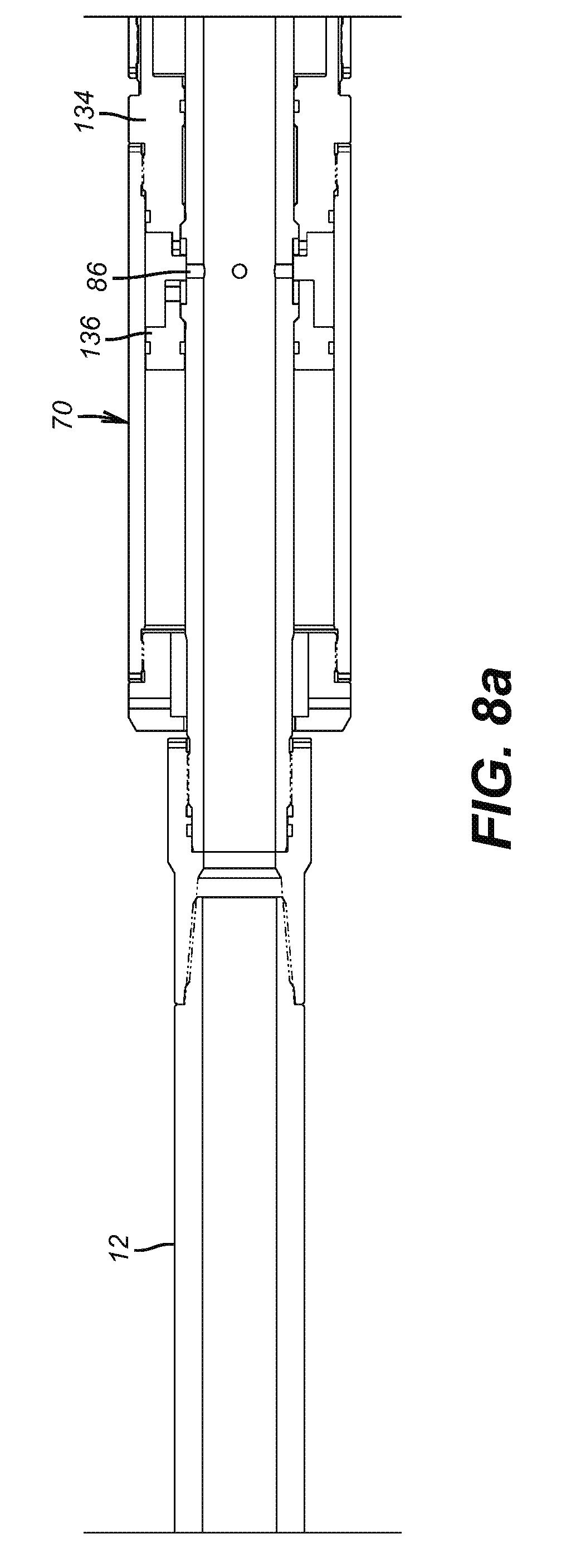

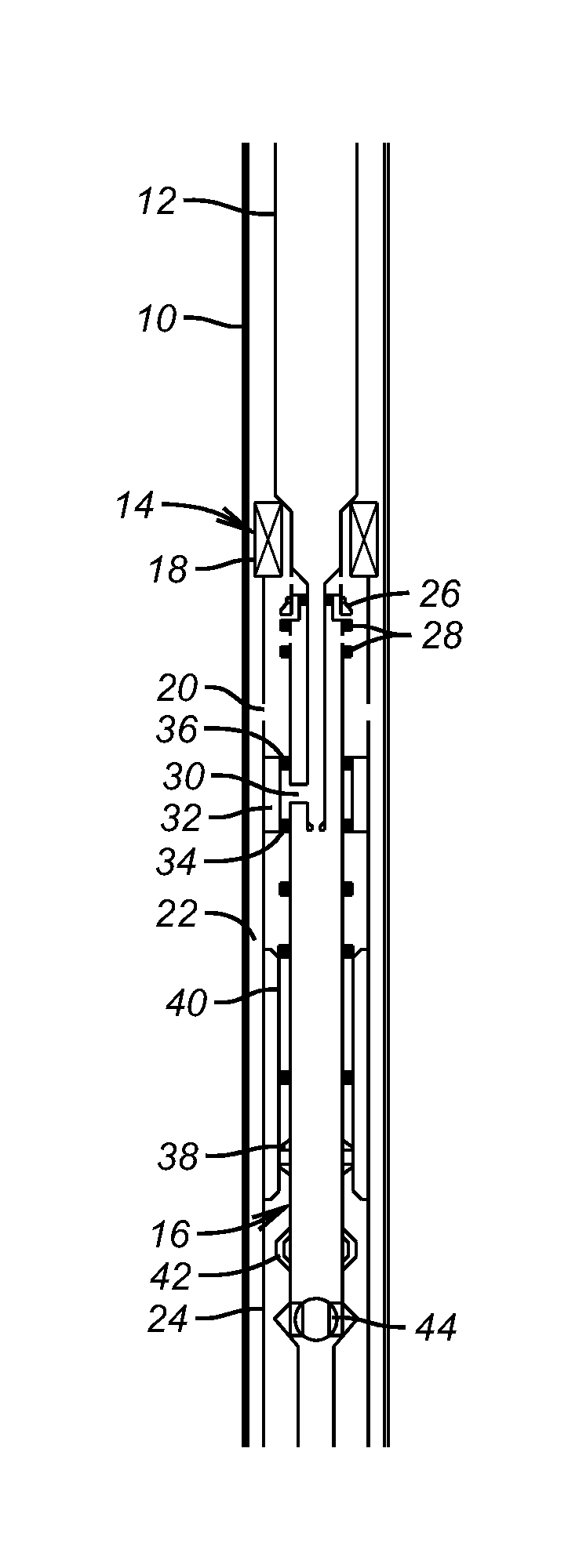

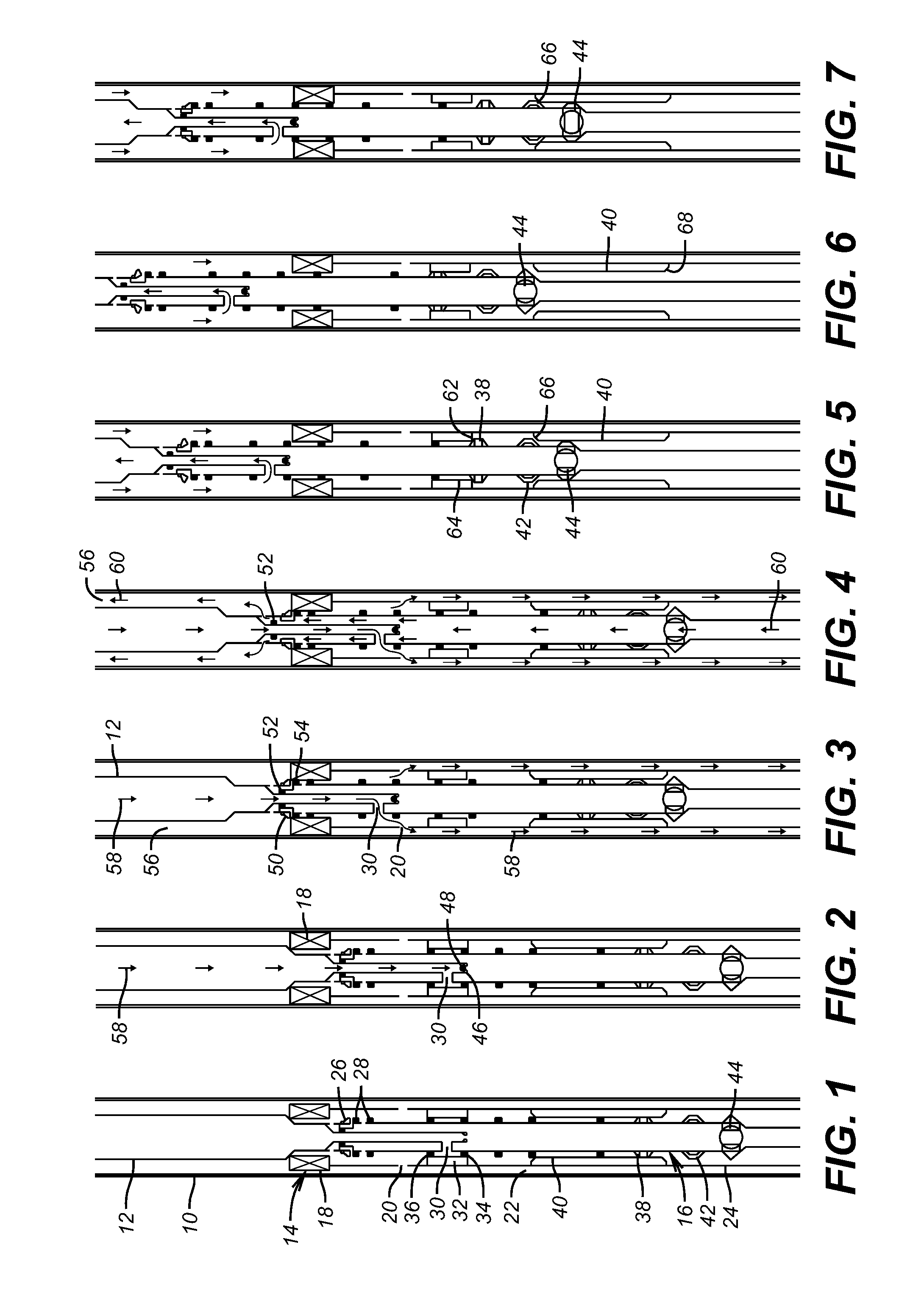

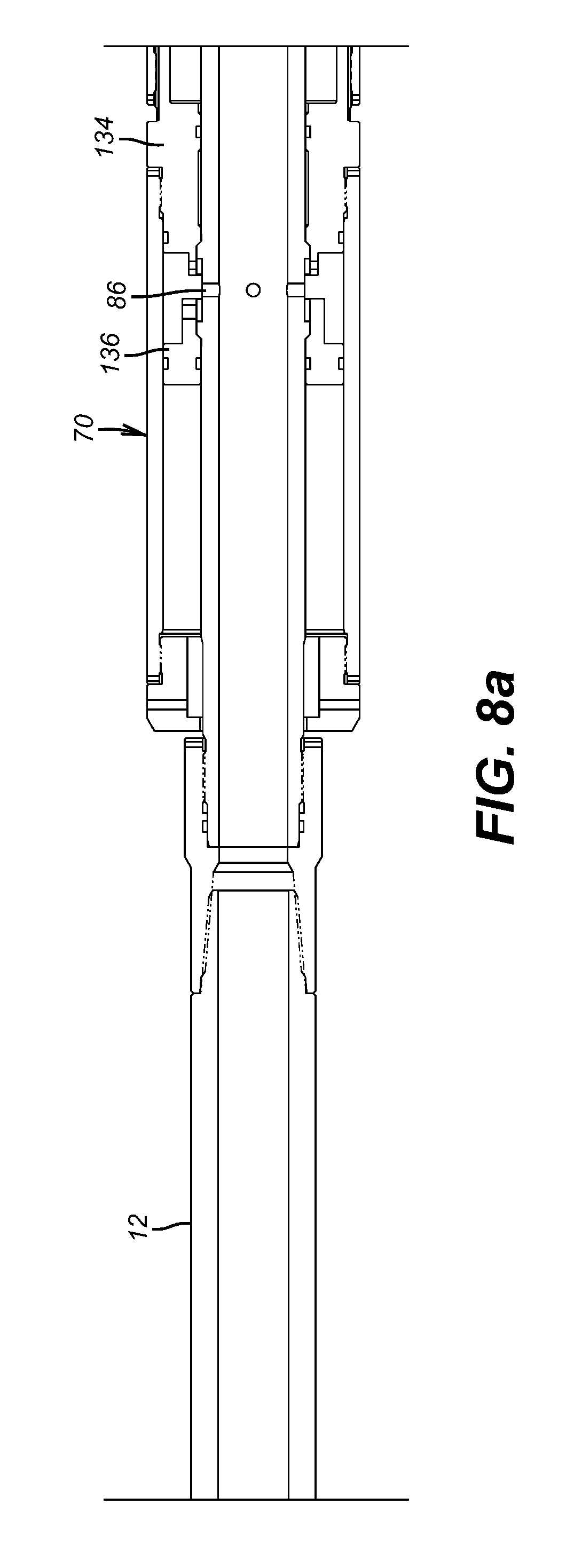

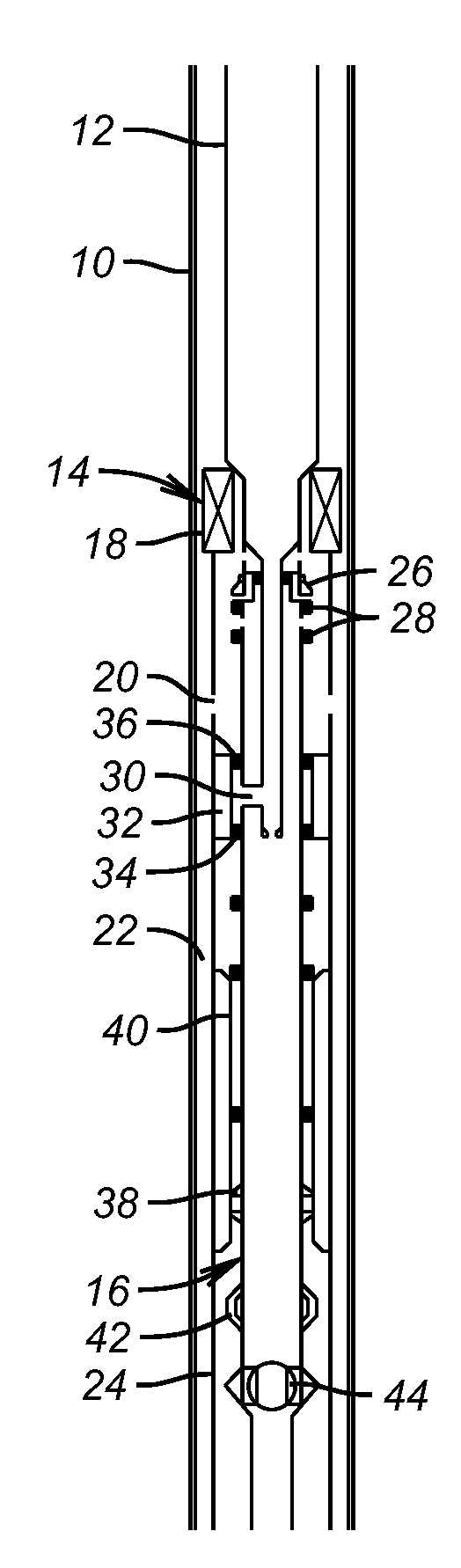

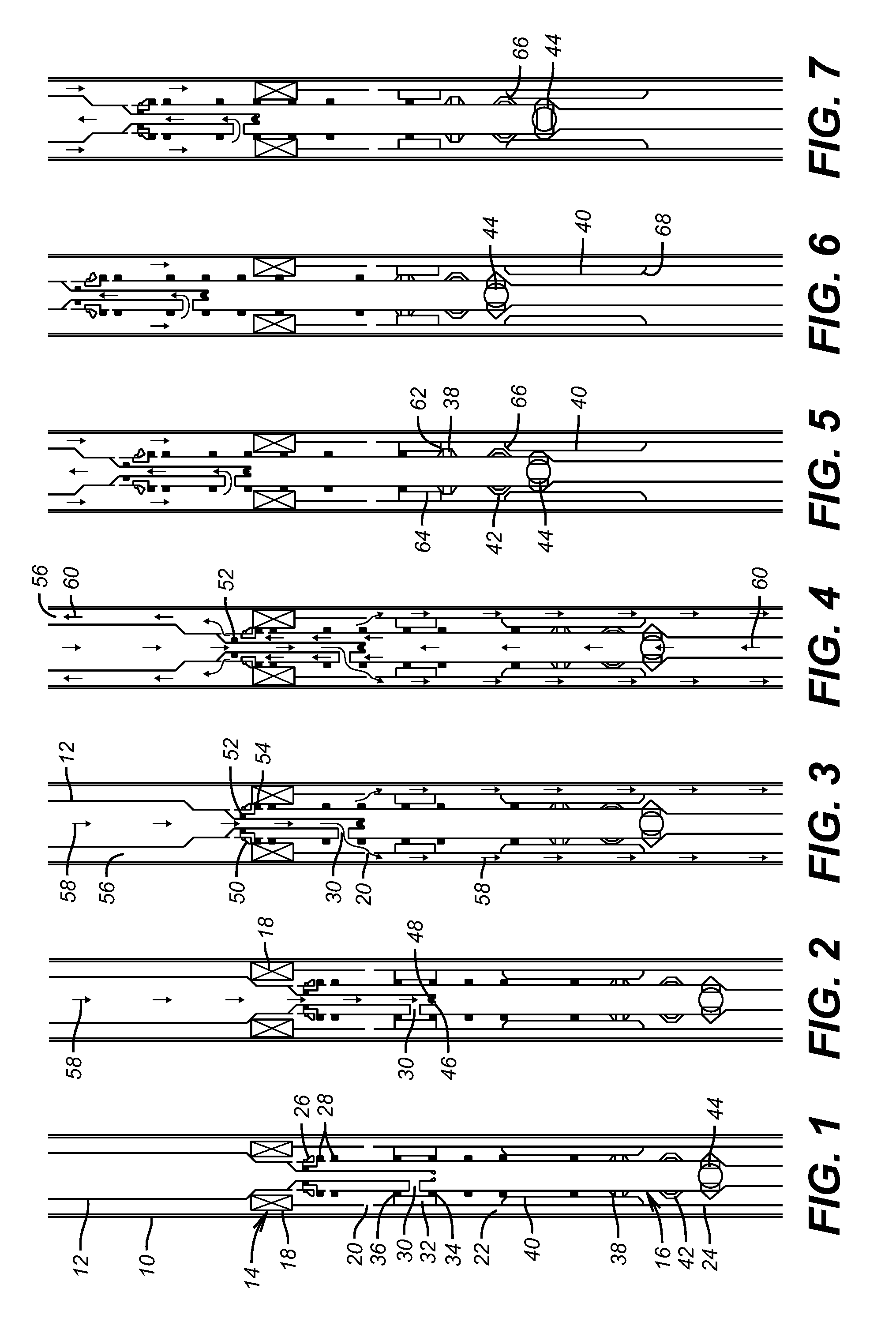

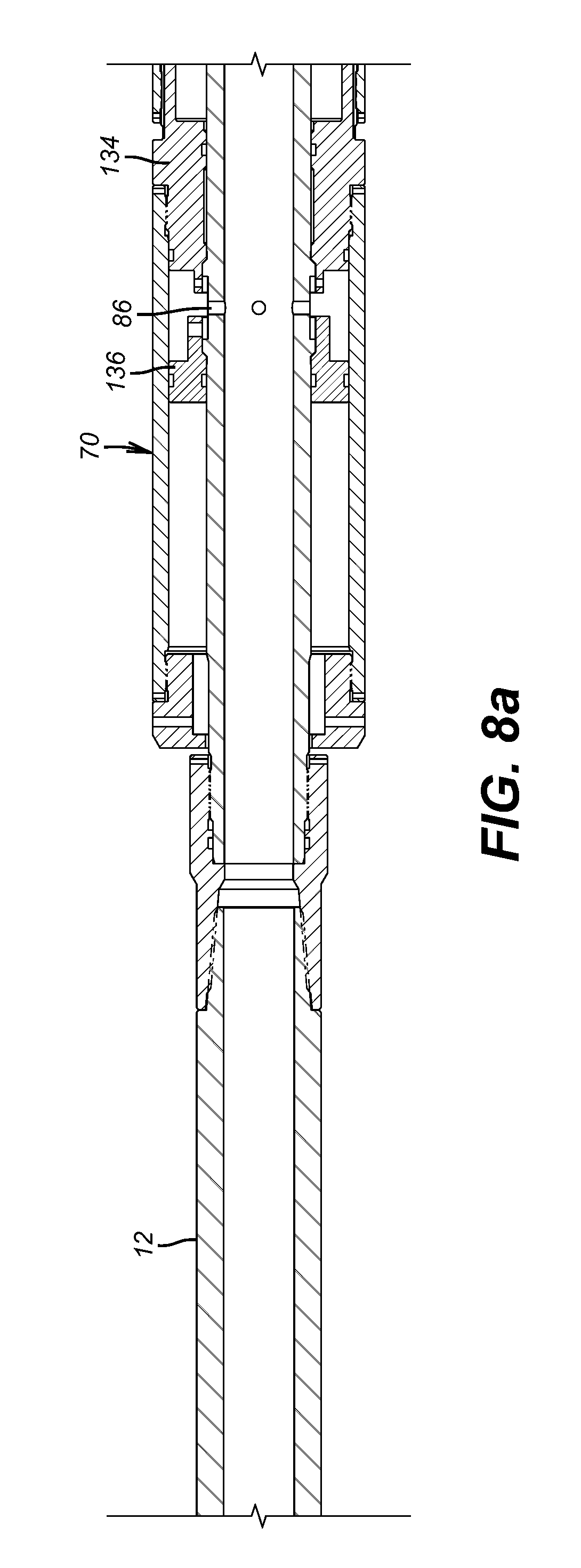

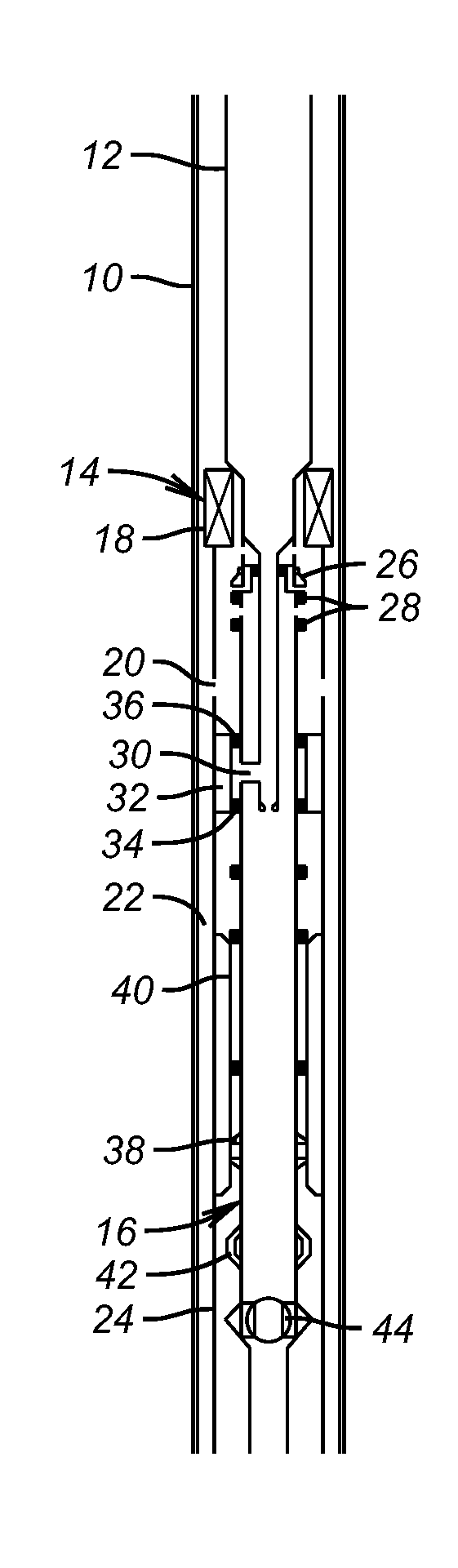

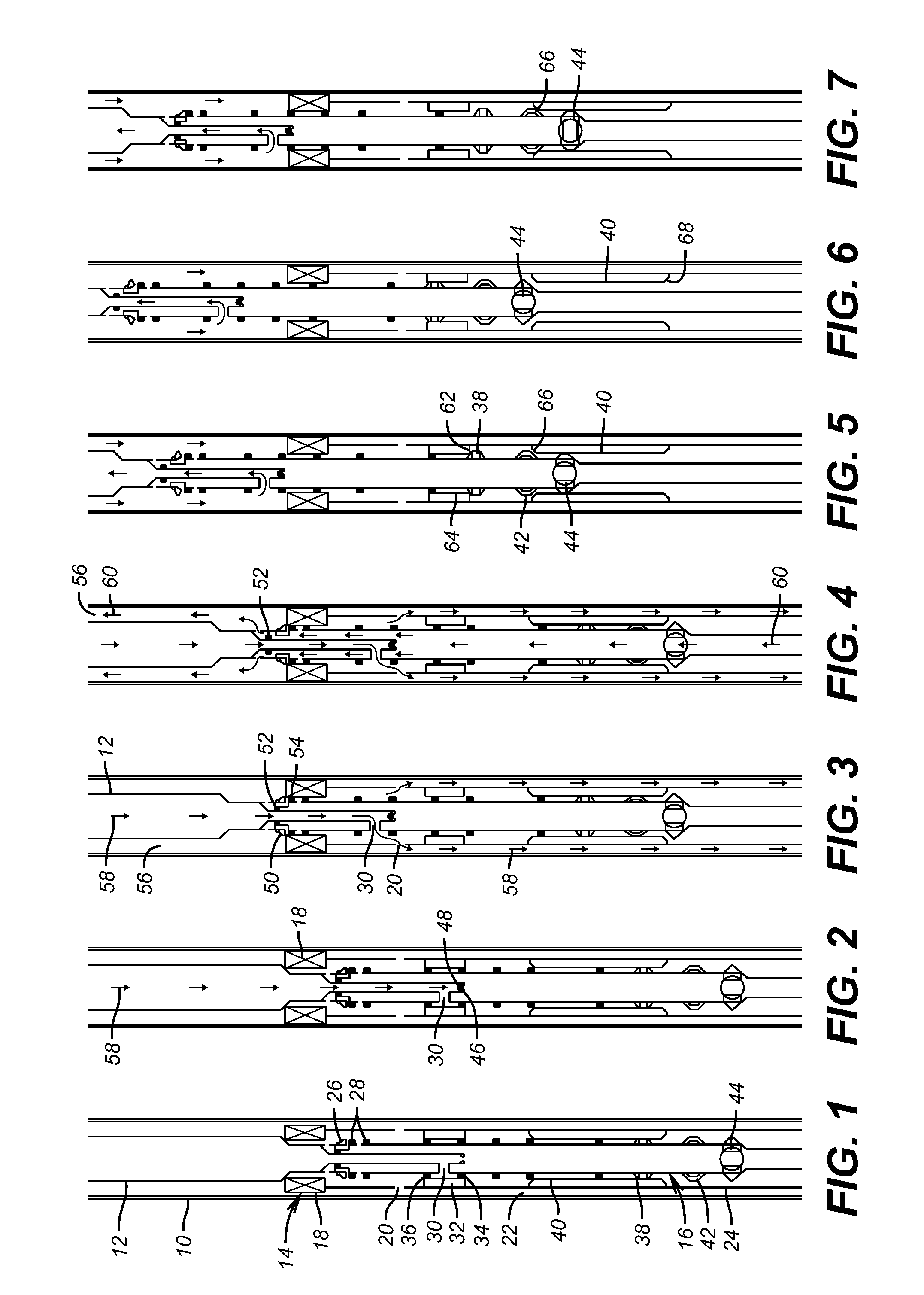

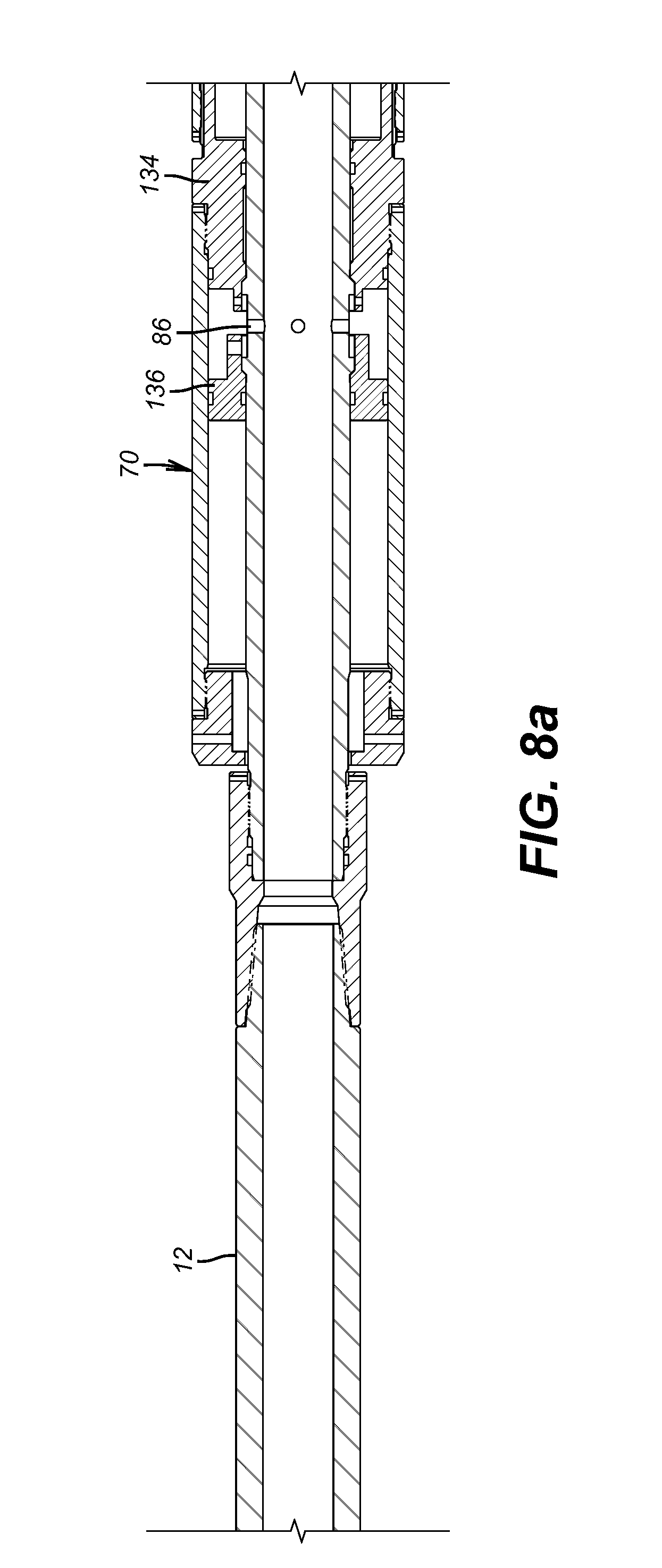

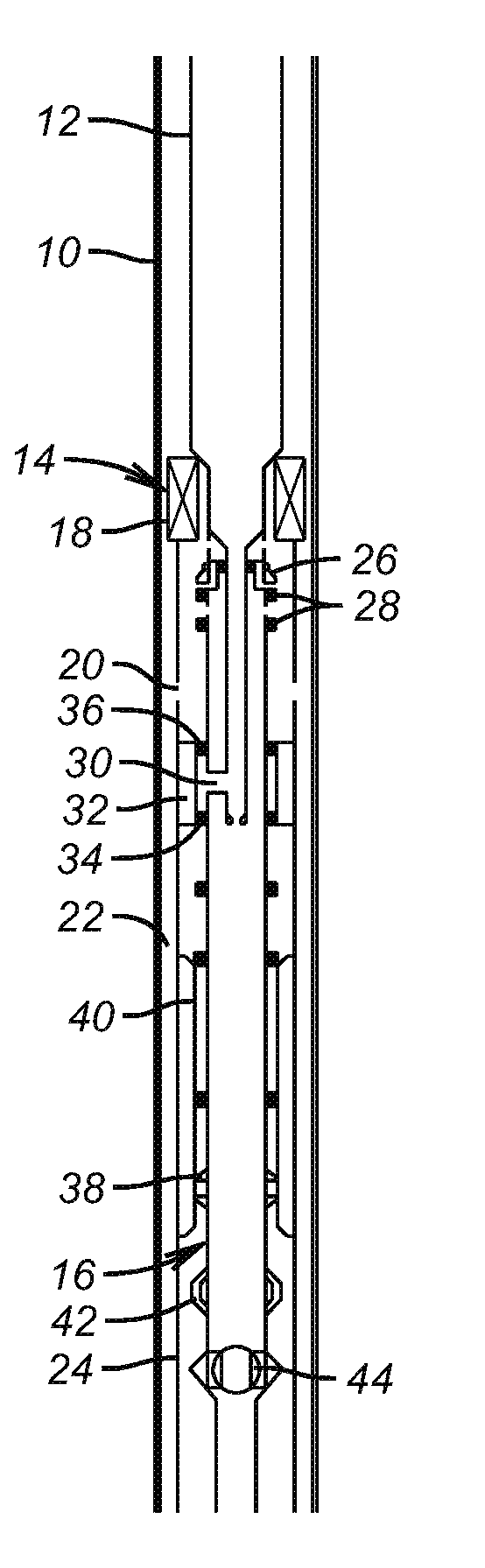

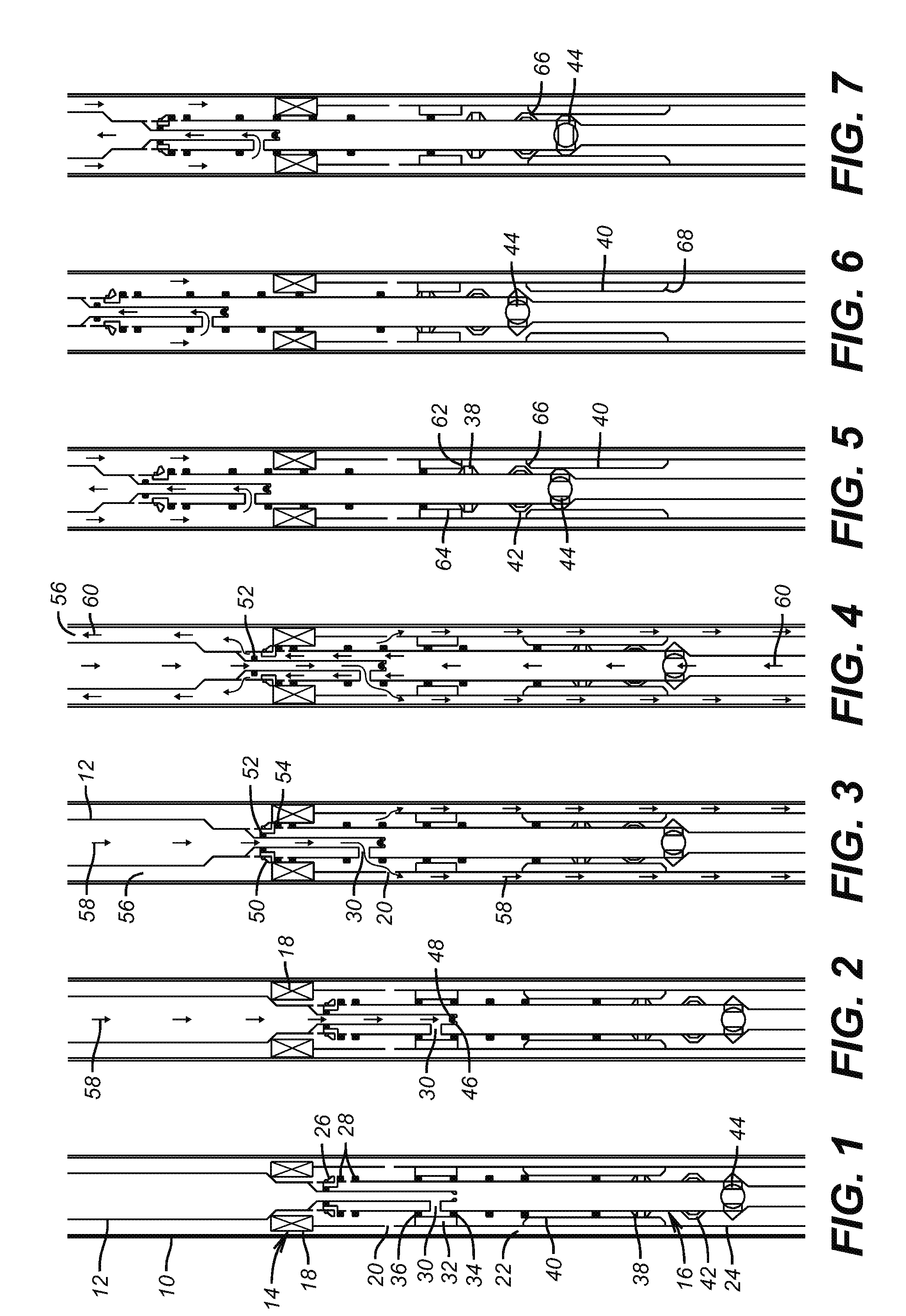

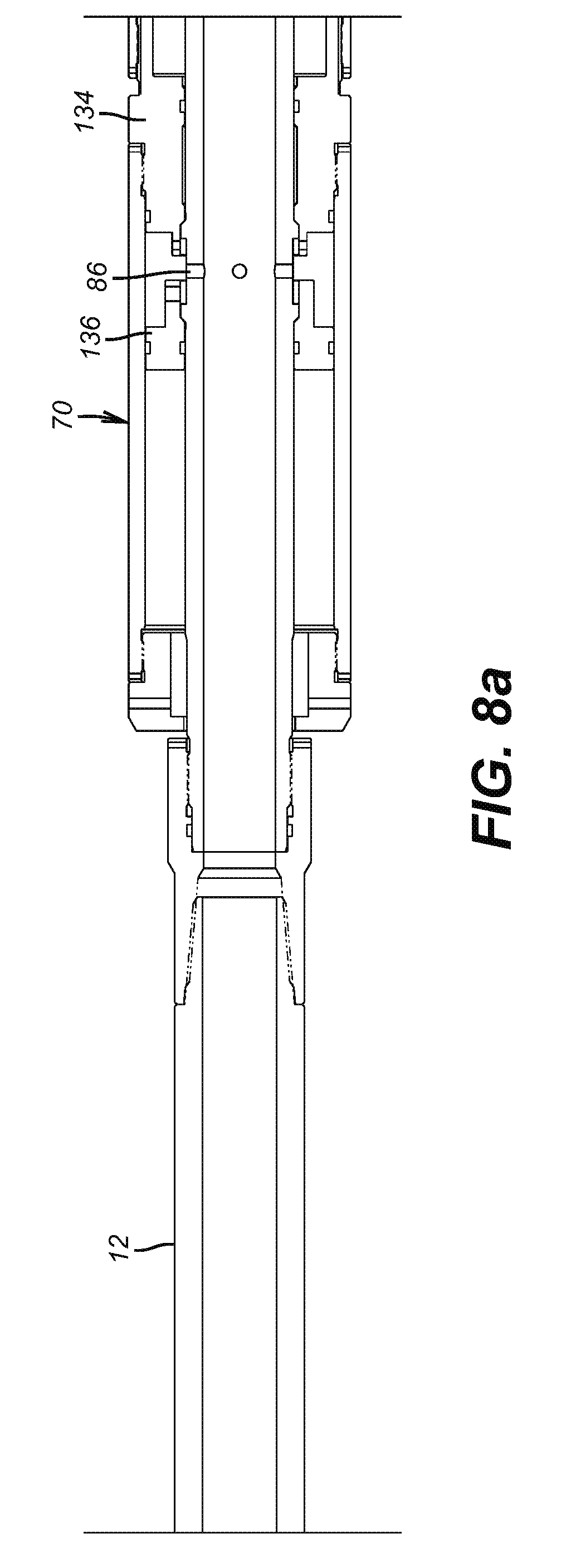

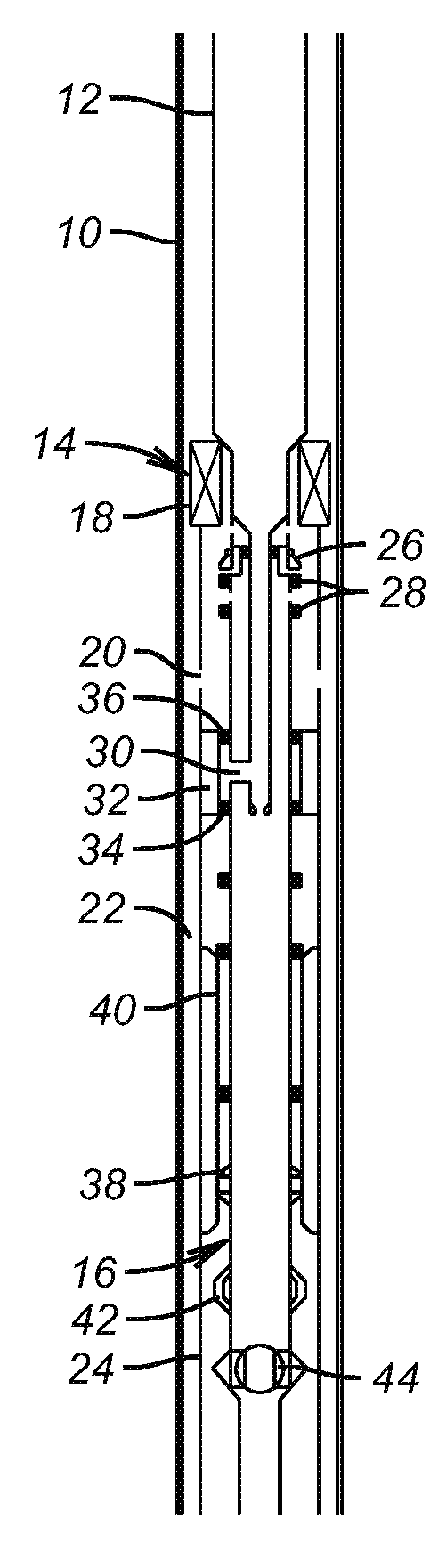

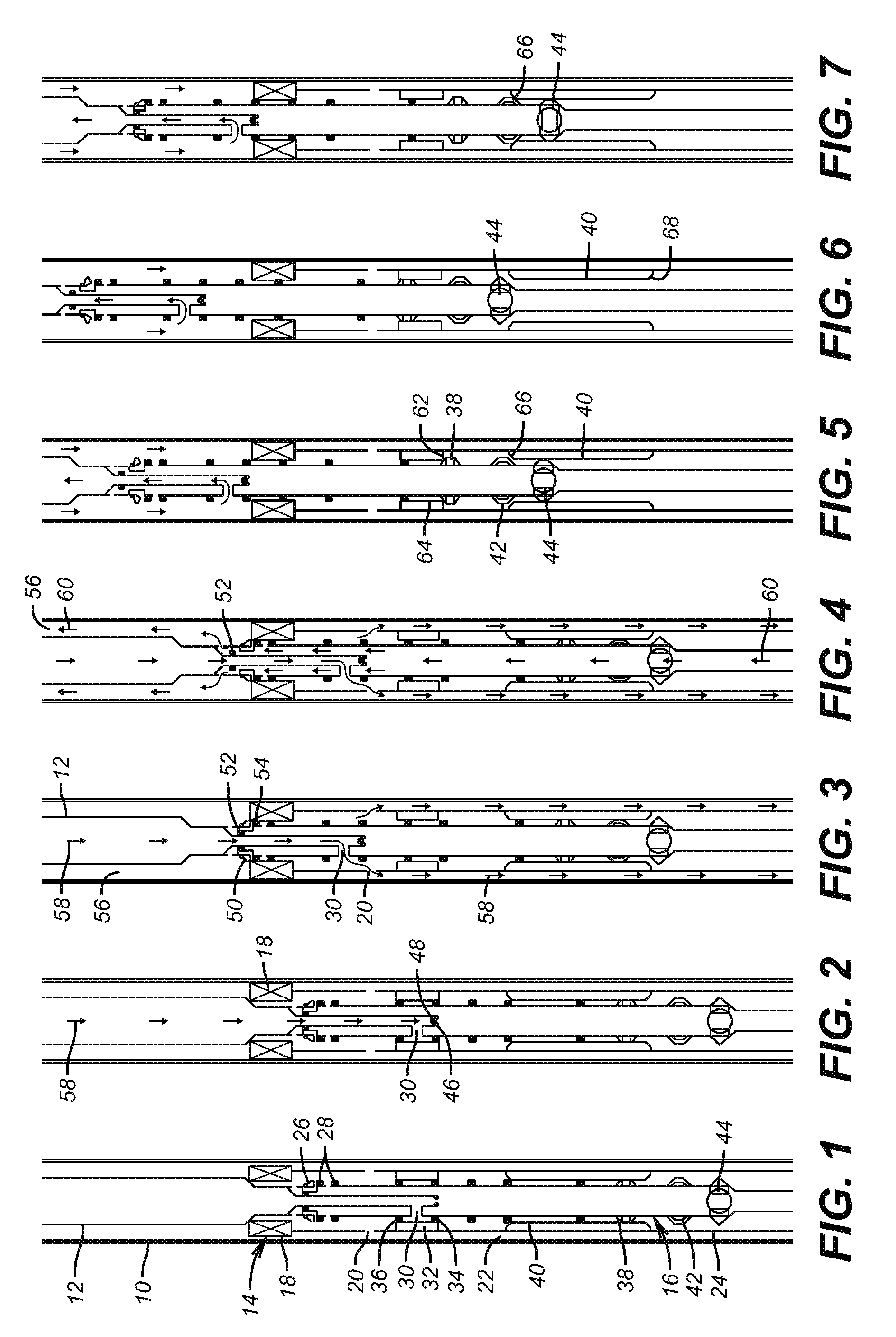

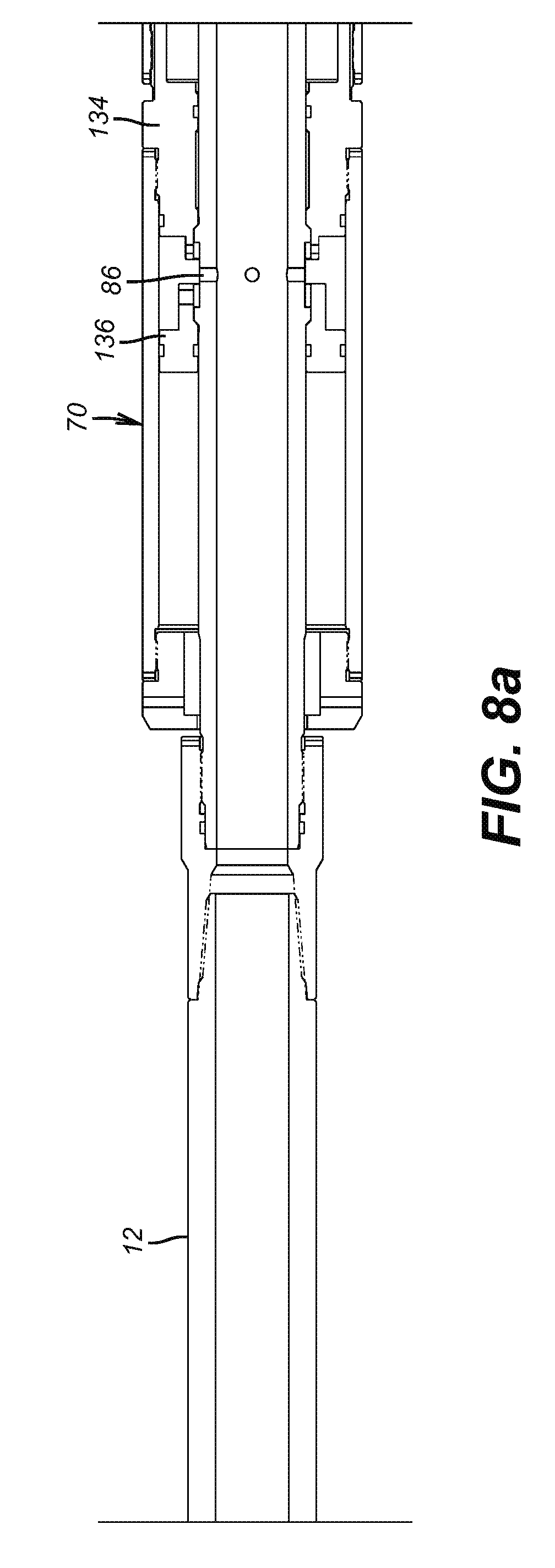

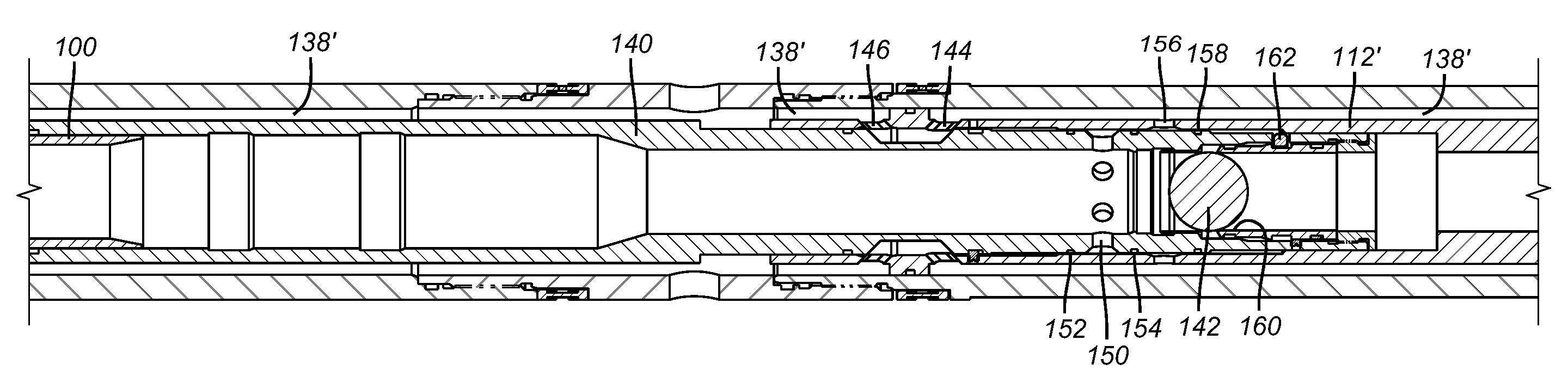

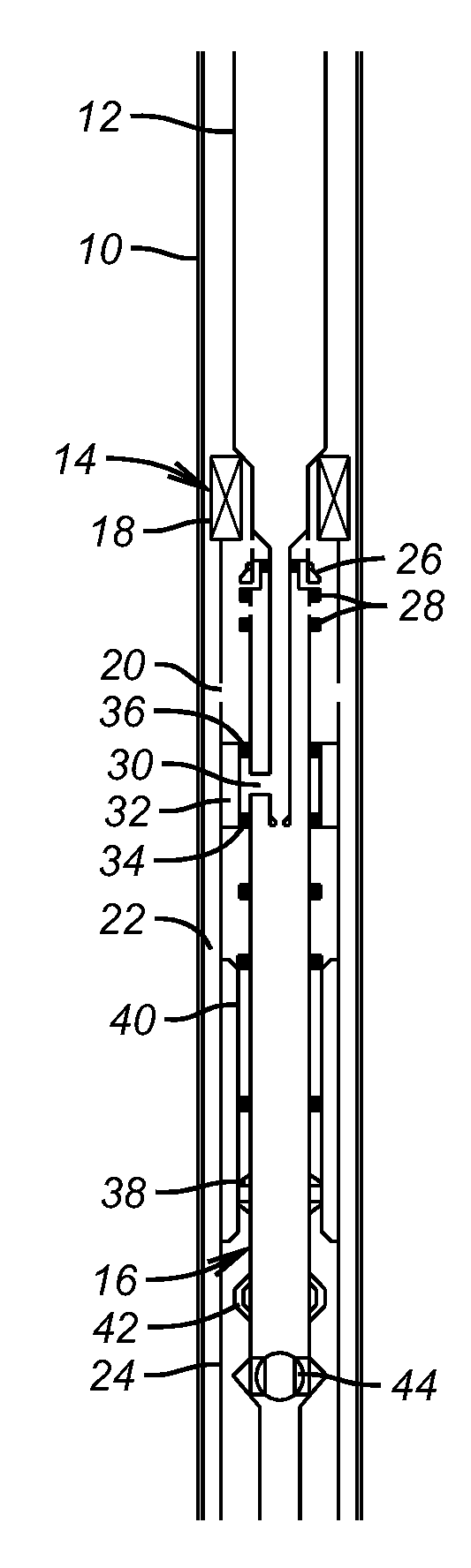

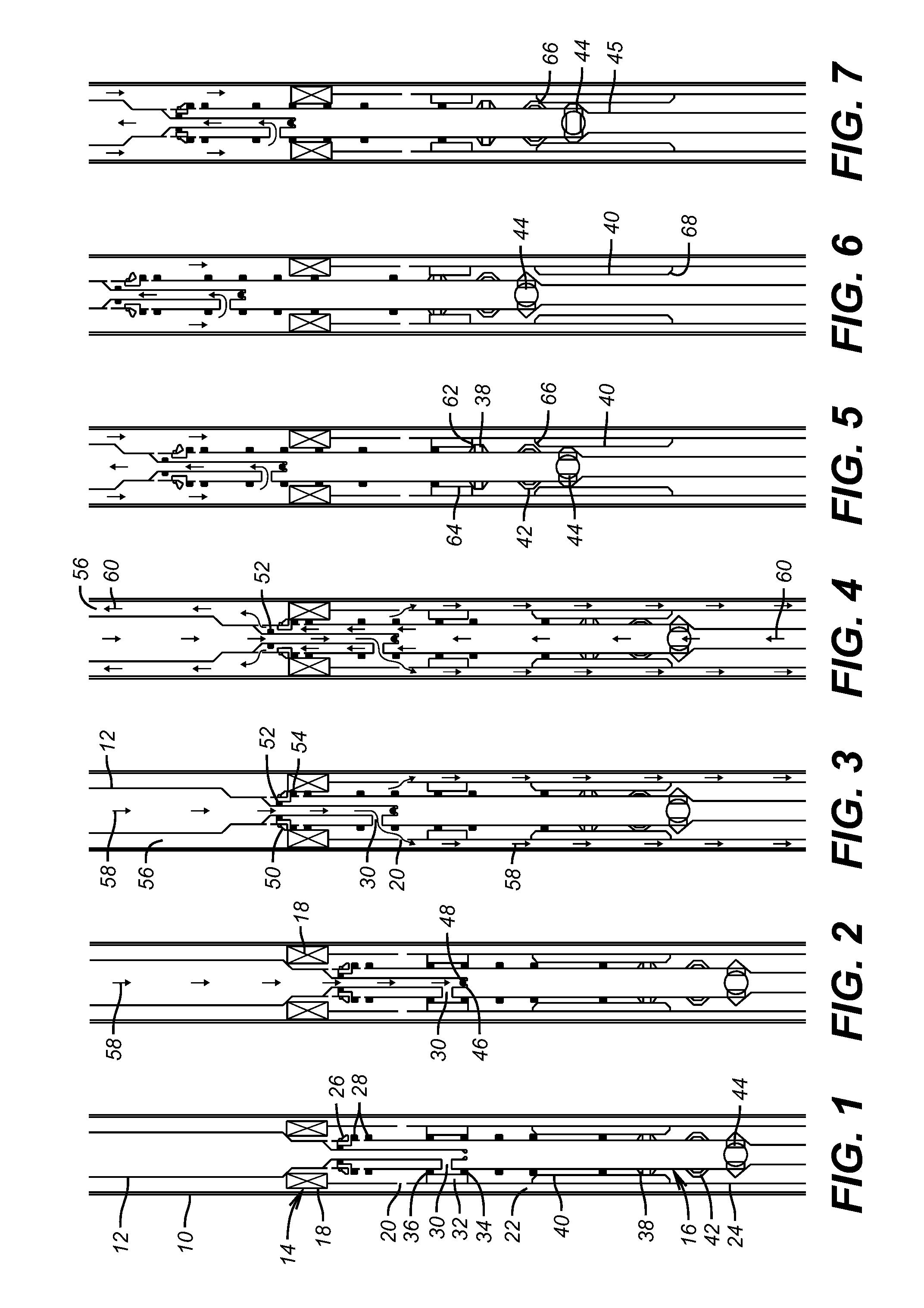

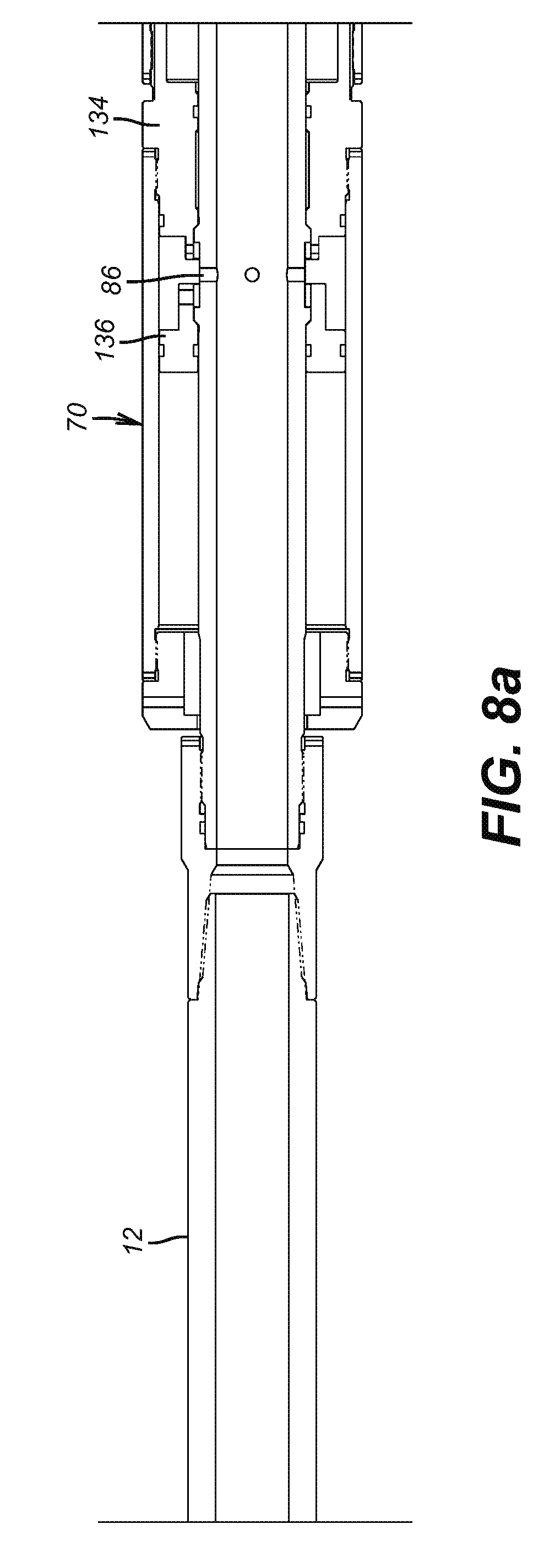

Multi-acting Circulation Valve

ActiveUS20110048723A1Prevent fluid lossAvoid scrubbingConstructionsFluid removalBottom hole pressureEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or multi-acting circulation valve allows switching between the squeeze and circulation positions without risk of closing the low bottom hole pressure ball valve. The multi-acting circulation valve can prevent fluid loss to the formation when being set down with the crossover tool supported or on the reciprocating set down device and the multi-acting circulation valve is closed without risk of closing the wash pipe valve.

Owner:BAKER HUGHES INC

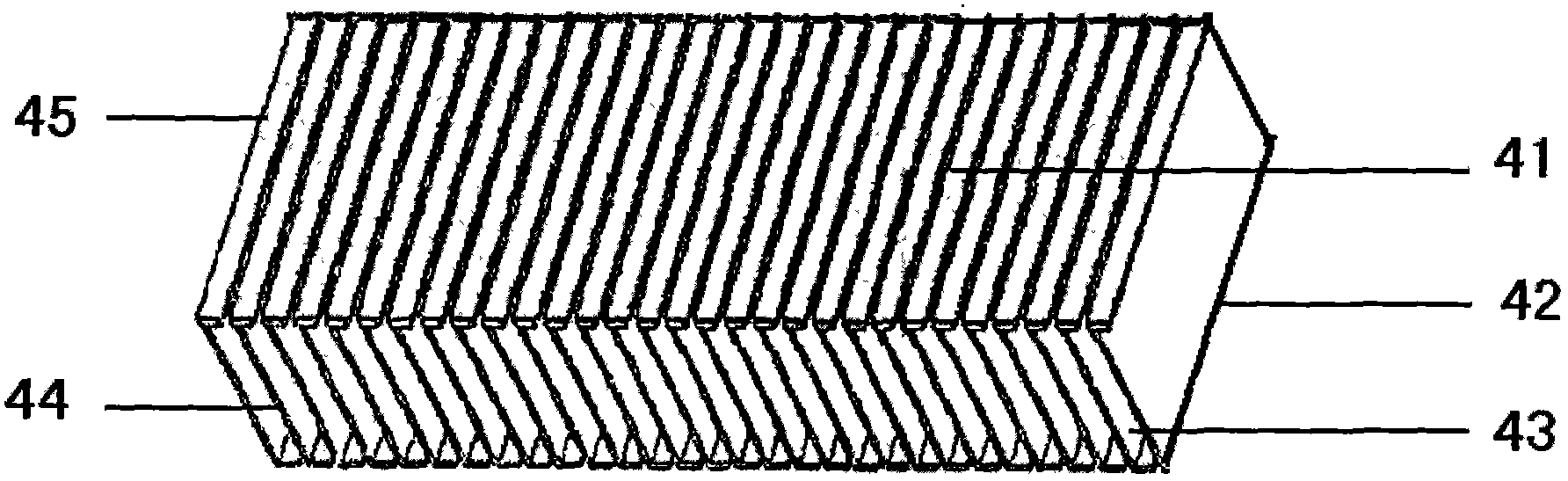

Hard tonneau cover

InactiveUS7093881B2Avoid enteringSufficiently compressibleTelemotorsSuperstructure subunitsCorrugated plasticSurface plate

A hard tonneau cover having one or more sections is constructed of a framework of extruded rails with one or more section panels held by molded plastic trim strips installed on perimeter rails included in the framework. The cover is mounted above the cargo box of a pick-up truck by a plurality of striker-latch assemblies on one side of the cargo box, and hinge assemblies on the other side, each having components mounted to the cargo box side walls with universal clamp brackets. The panels are constructed of reinforced corrugated plastic which is covered by a color integrated film. A simplified connector plate is used to connect abutting ends of the rails in the fiamework. A peripheral seal extends down from the perimeter rails in which it is mounted to engage the top of the cargo box side walls and tailgate. Water drainage paths including drainage channels in the rails are provided to eliminate water from the panel surfaces.

Owner:AMERITRENDZ

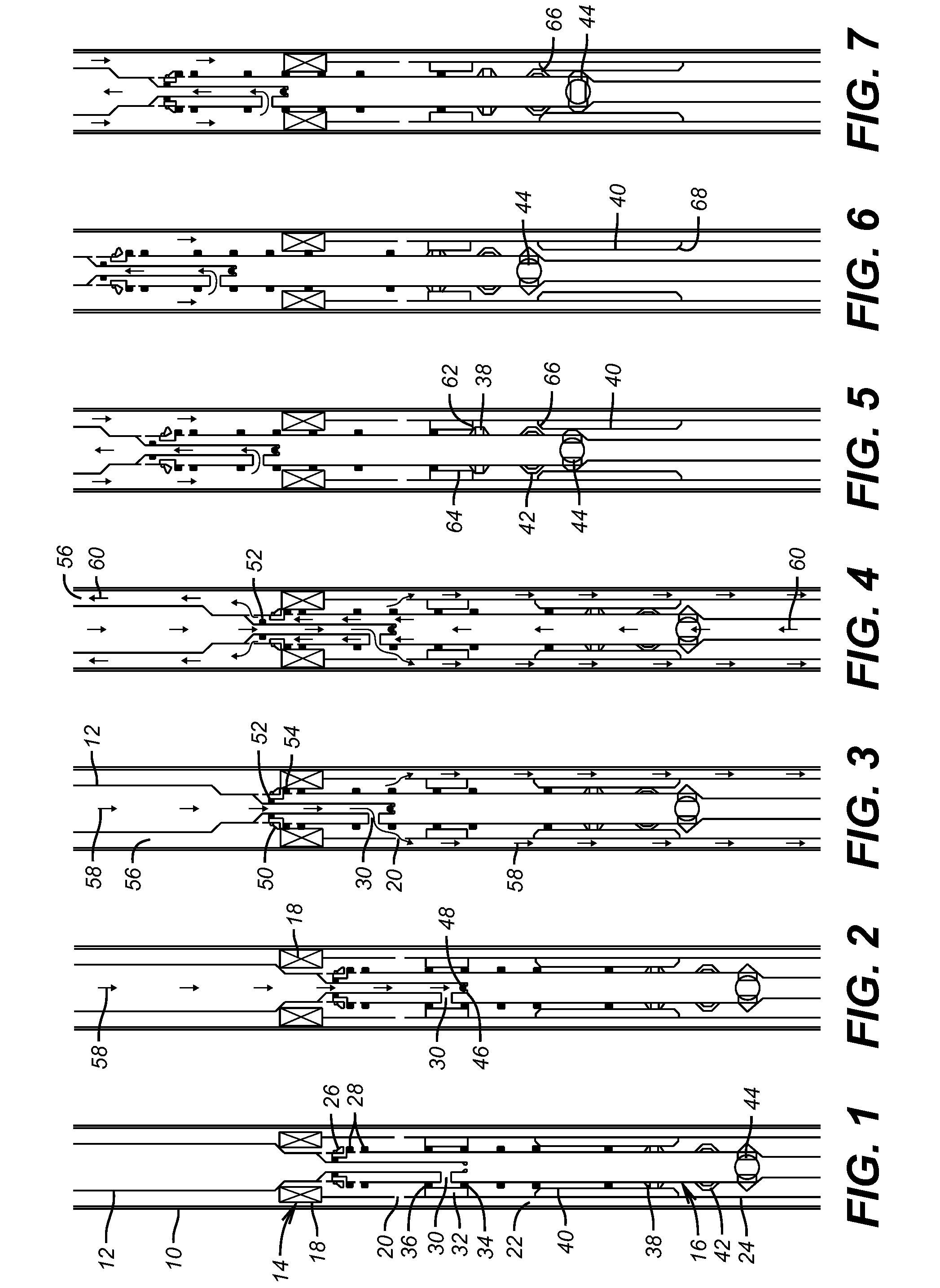

Fracturing and Gravel Packing Tool with Multi-position Lockable Sliding Sleeve

ActiveUS20110048706A1Prevent fluid lossAvoid scrubbingFluid removalWell/borehole valve arrangementsFinite timeEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

Fracturing and Gravel Packing Tool with Multi Movement Wash Pipe Valve

ActiveUS20110067862A1Avoid problemsPrevent fluid lossFluid removalWell/borehole valve arrangementsFinite timeEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

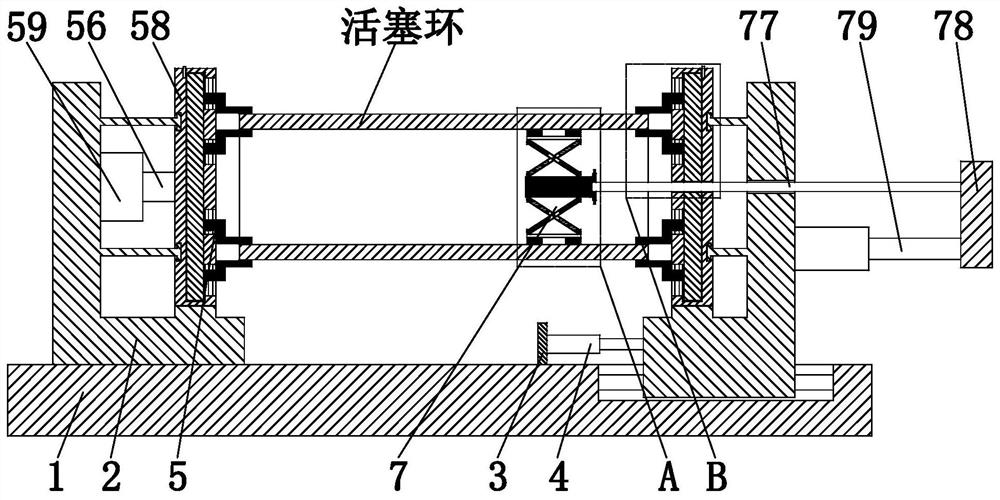

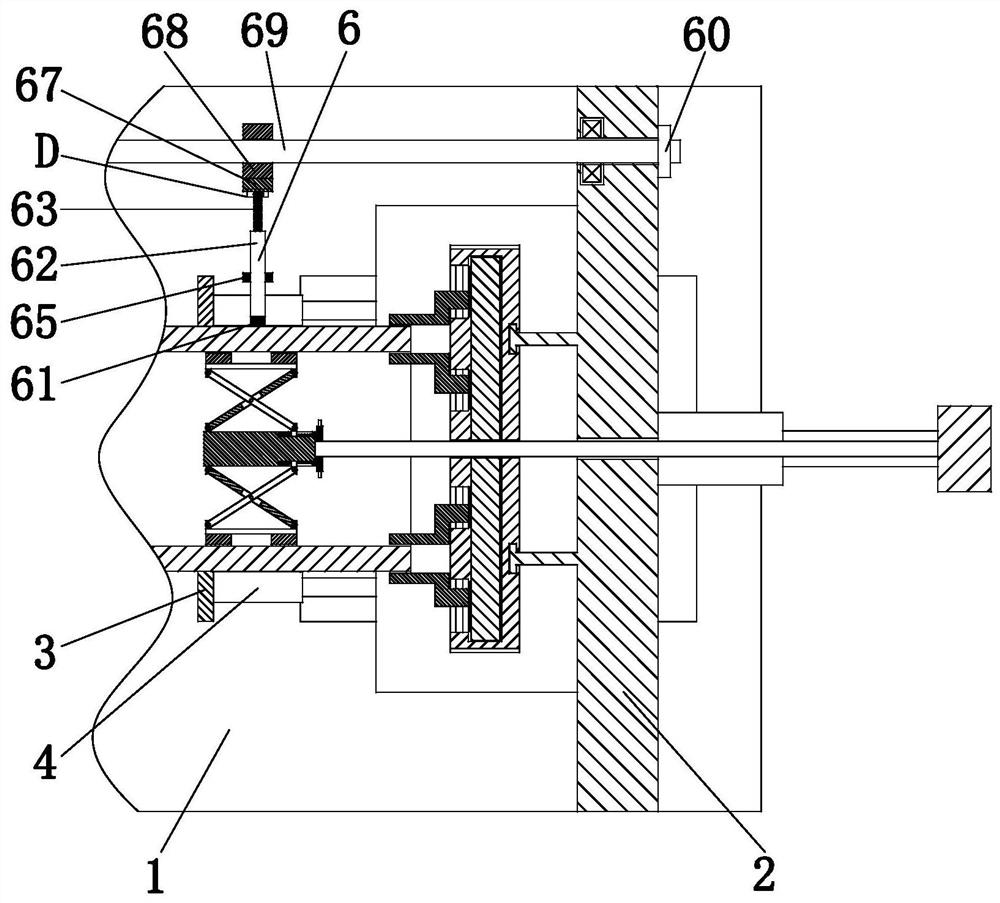

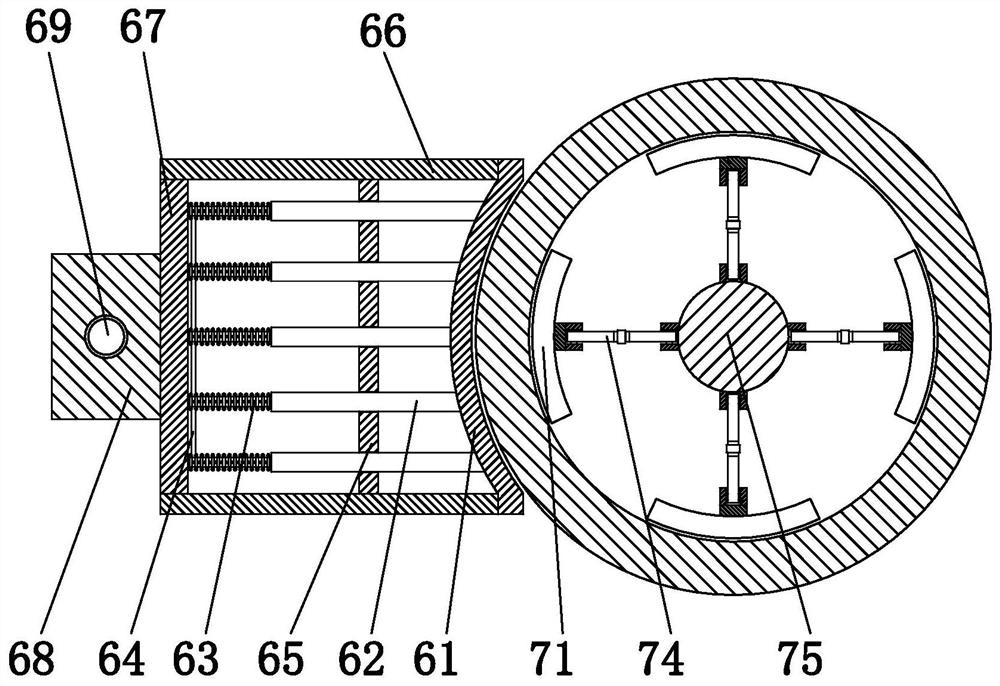

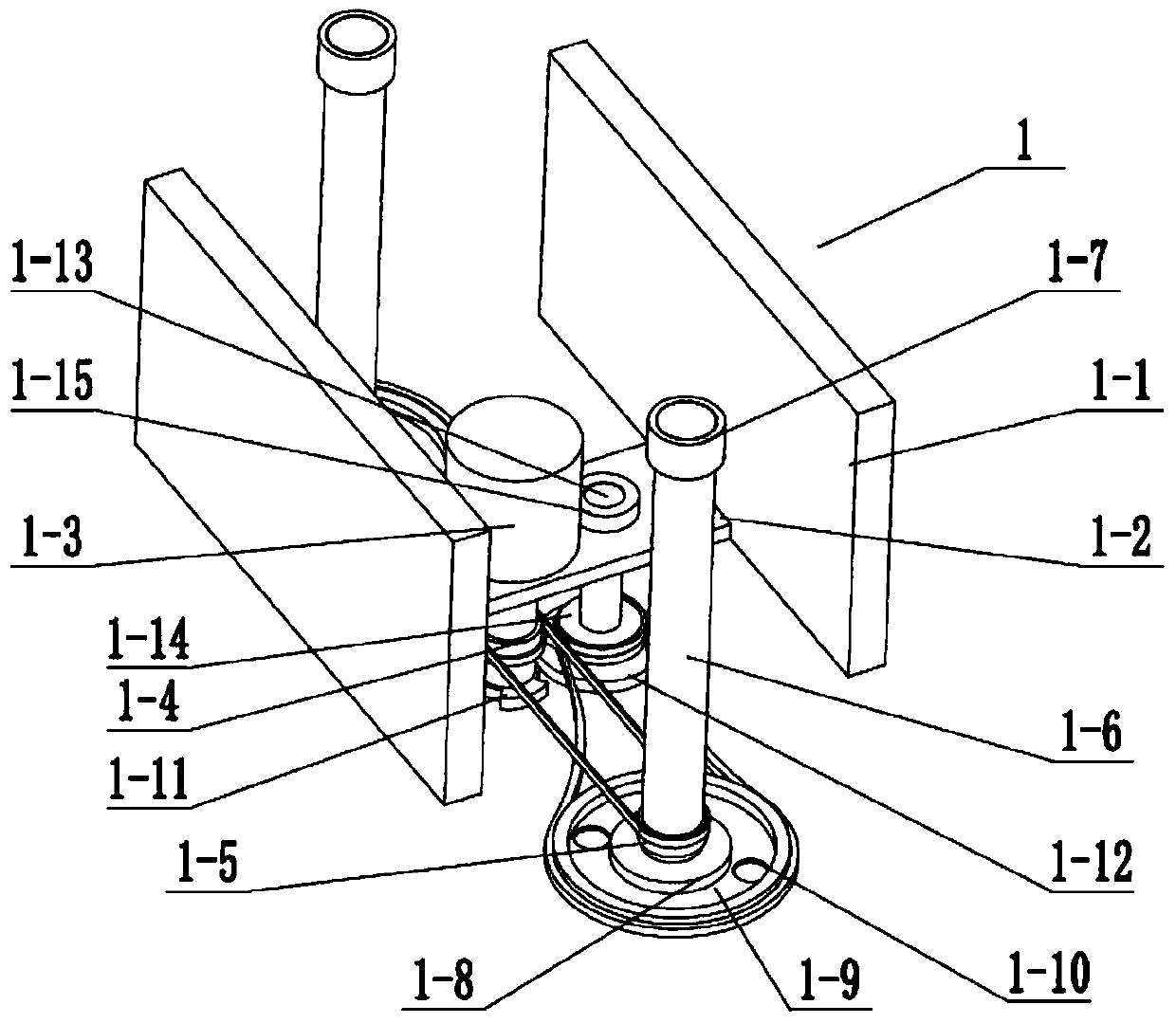

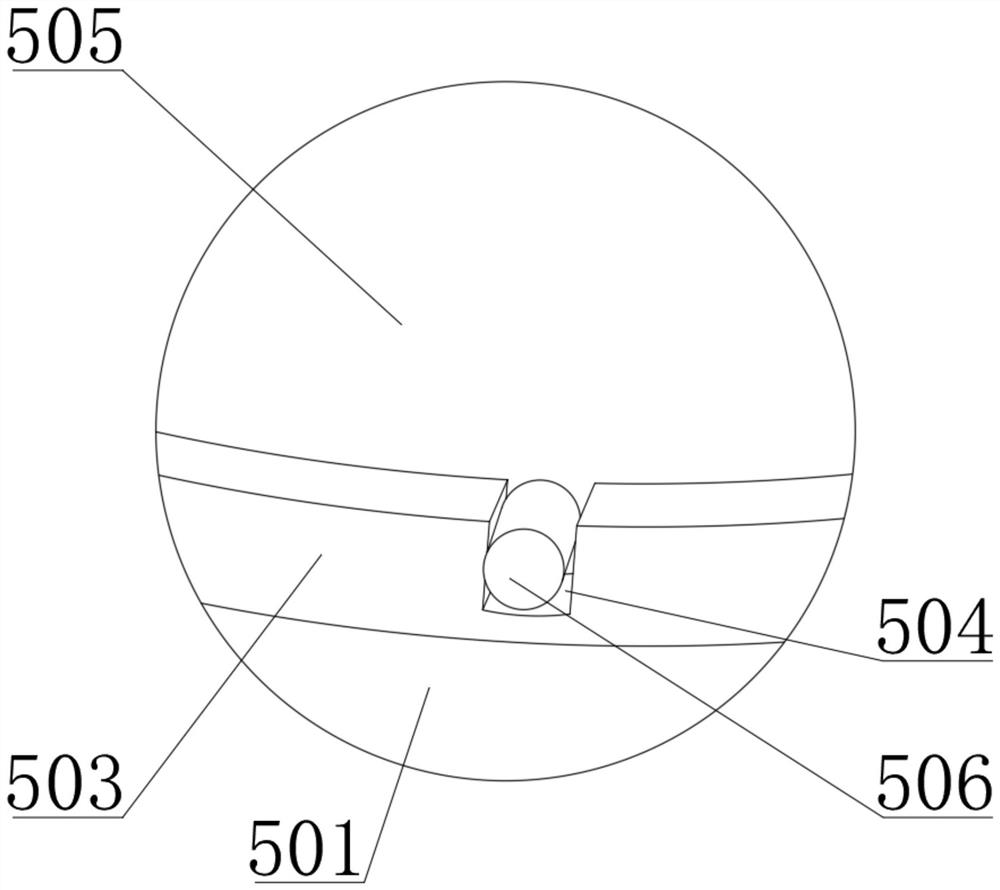

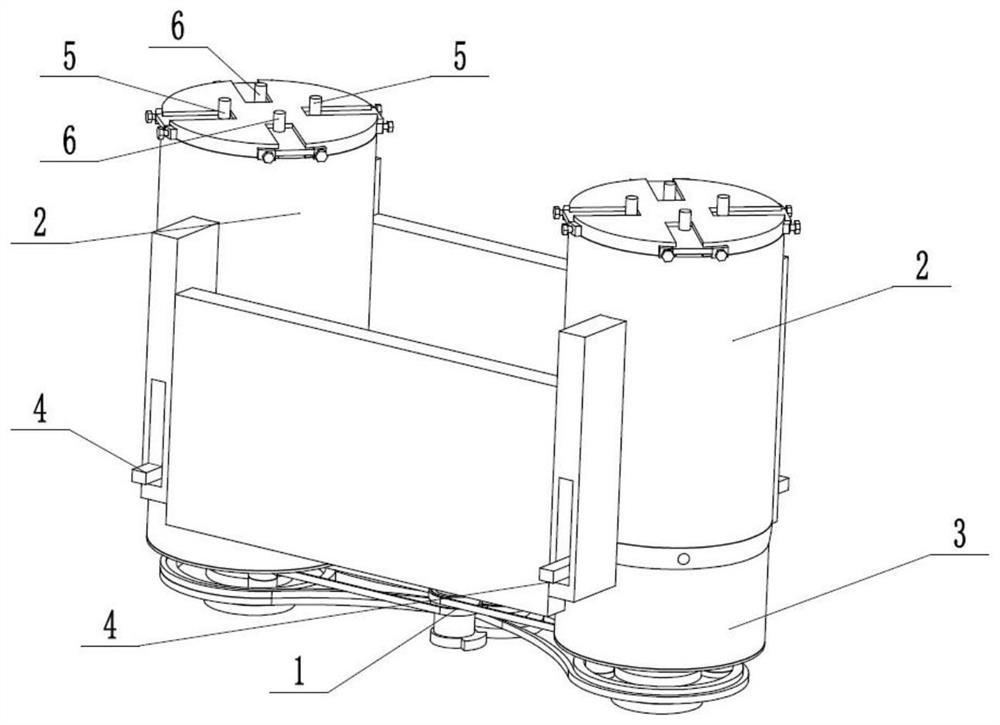

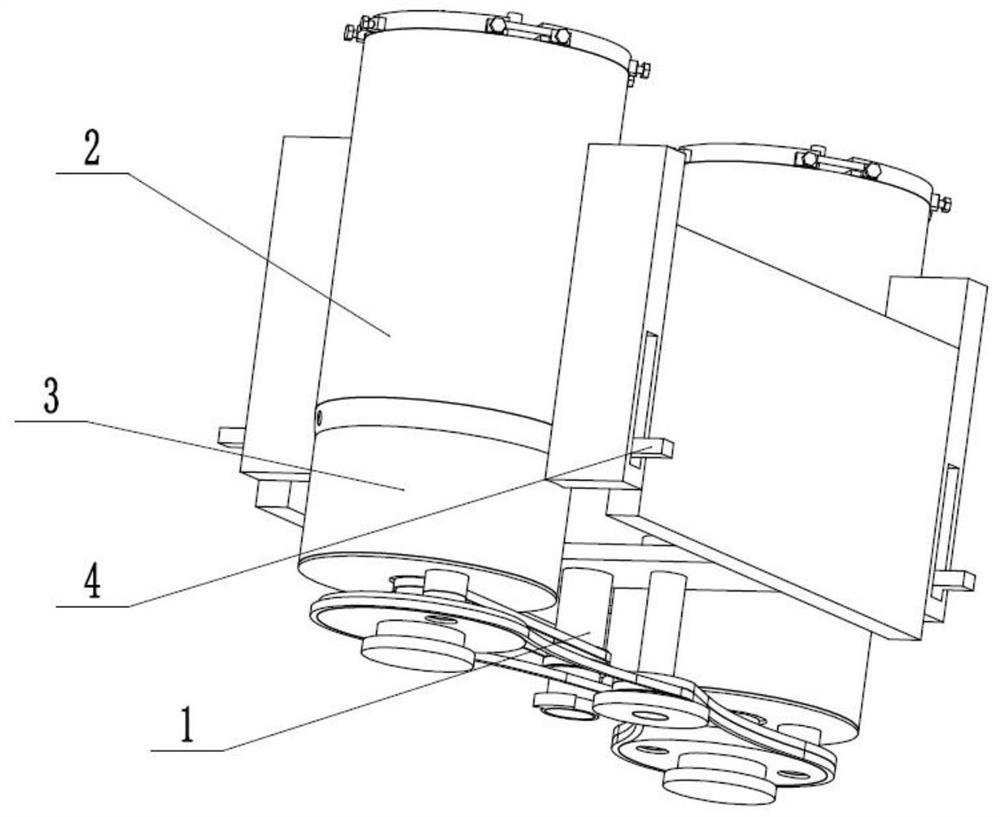

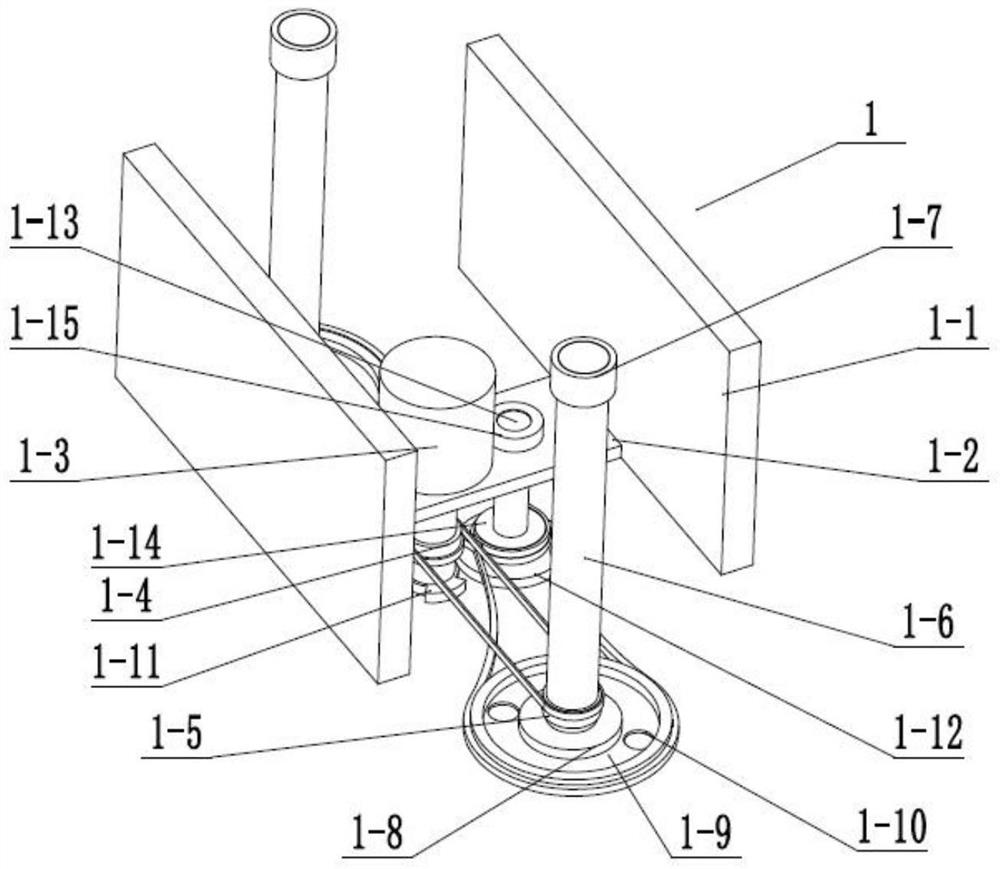

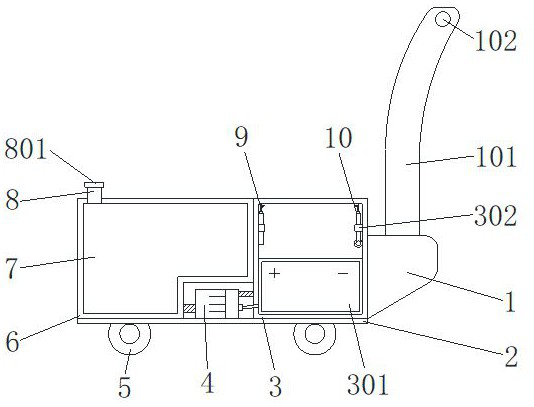

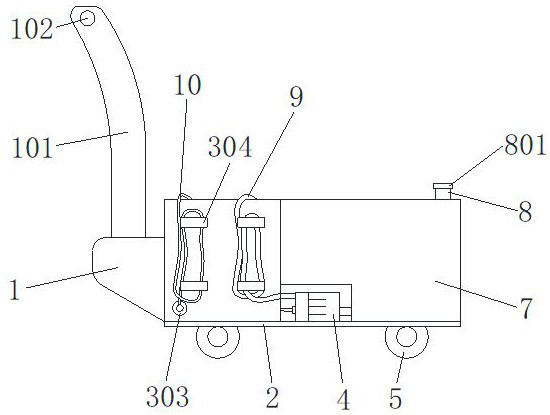

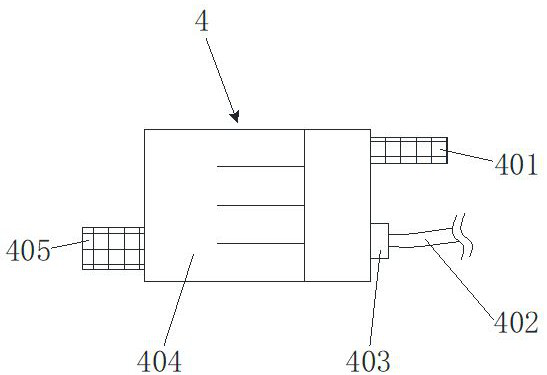

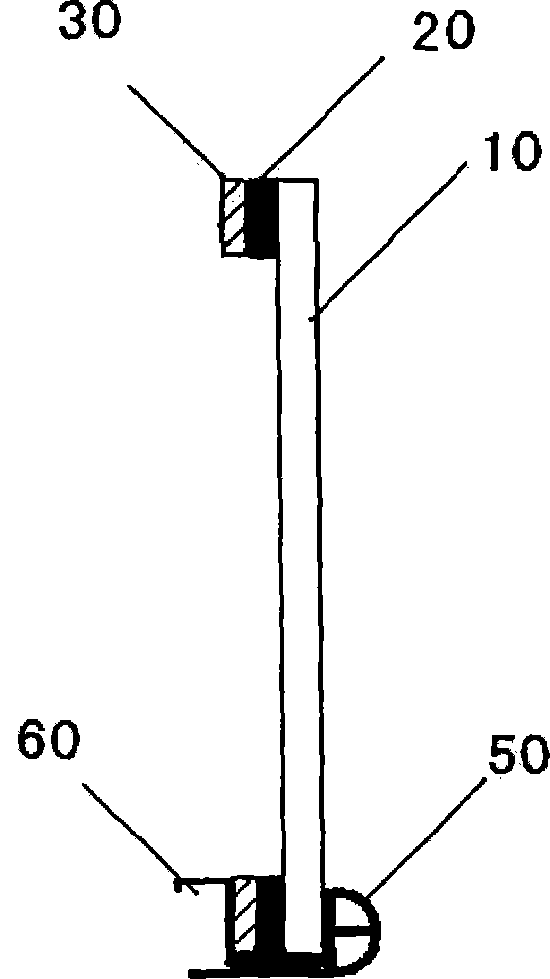

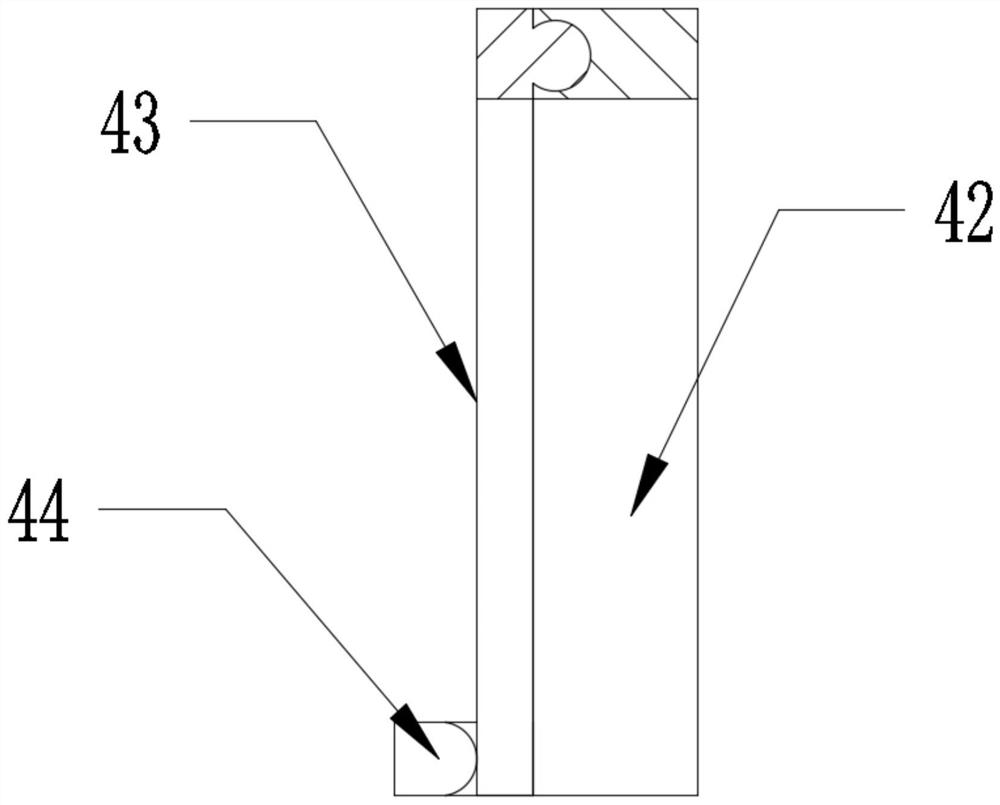

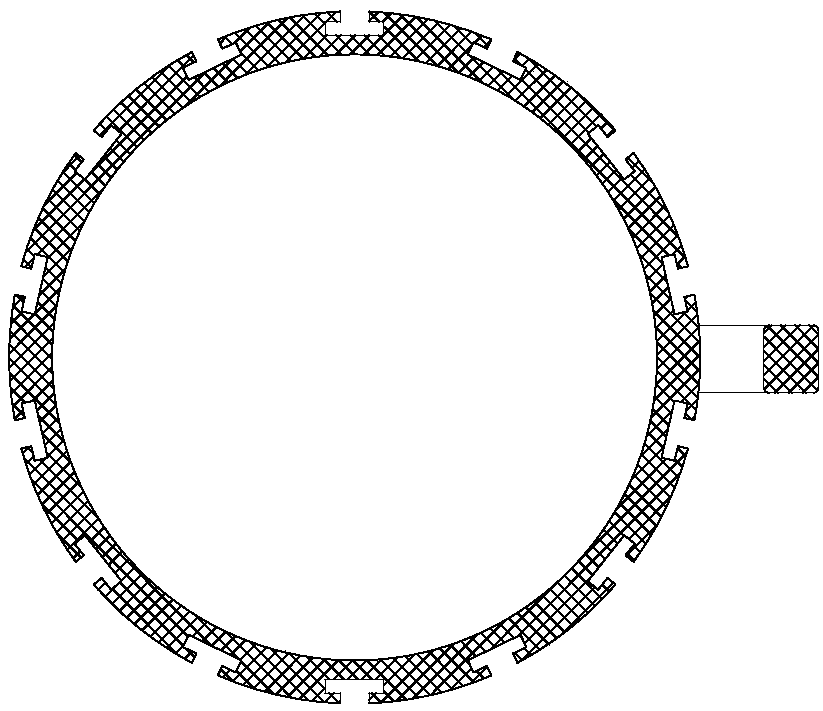

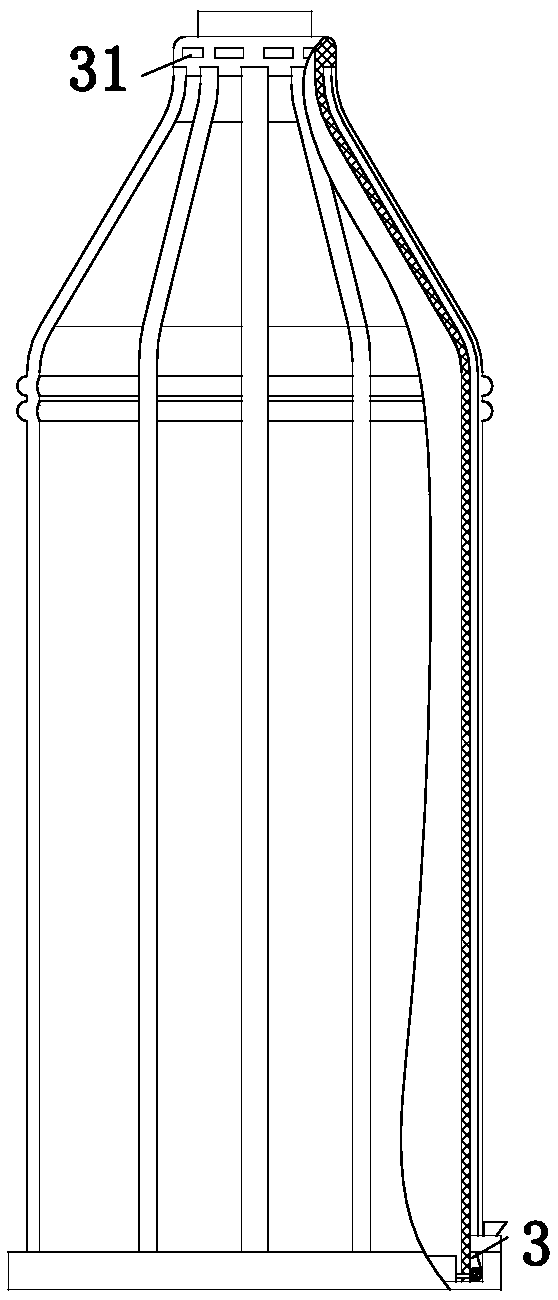

Sealing assembly piston ring casting molding machining machine and molding machining process

InactiveCN112059735ALow efficiencyAvoid scrubbingEdge grinding machinesRevolution surface grinding machinesMolding machinePiston ring

The invention provides a sealing assembly piston ring casting molding machining machine and a molding machining process. The sealing assembly piston ring casting molding machining machine comprises abase, a mounting plate, a baffle plate, a movable air cylinder, a clamping and rotating mechanism, an outer knock-out mechanism and an inner knock-out mechanism. The invention provides the sealing assembly piston ring casting molding machining machine which can solve the following problems existing in the piston ring casting molding process: a, when a piston ring is cast into a cylinder with a certain length, a plurality of sand grains can be generated on the inner and outer surfaces of the piston ring, the sand grains on the surfaces of the piston ring need to be removed, the sand grains on the surfaces of the piston ring are removed through grinding of abrasive paper according to a traditional manual mode, and the mode is time-consuming, labor-consuming and low in efficiency so as to beundesirable; and b, a traditional piston ring grinding device is single in function, generally can only grind piston rings of one specification and cannot be suitable for piston rings of different specifications, and the equipment is high in price, so that the price and the function effect cannot be equivalent.

Owner:王德忠

Fracturing and Gravel Packing Tool with Anti-Swabbing Feature

ActiveUS20110048705A1Avoid problemsPrevent fluid lossConstructionsFluid removalBottom hole pressureFinite time

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or multi-acting circulation valve allows switching between the squeeze and circulation positions without risk of closing the low bottom hole pressure ball valve. The low bottom hole pressure ball valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the low bottom hole pressure ball valve. The multi-acting circulation valve can prevent fluid loss to the formation when being set down with the crossover tool supported or on the reciprocating set down device and the multi-acting circulation valve is closed without risk of closing the wash pipe valve.

Owner:BAKER HUGHES INC

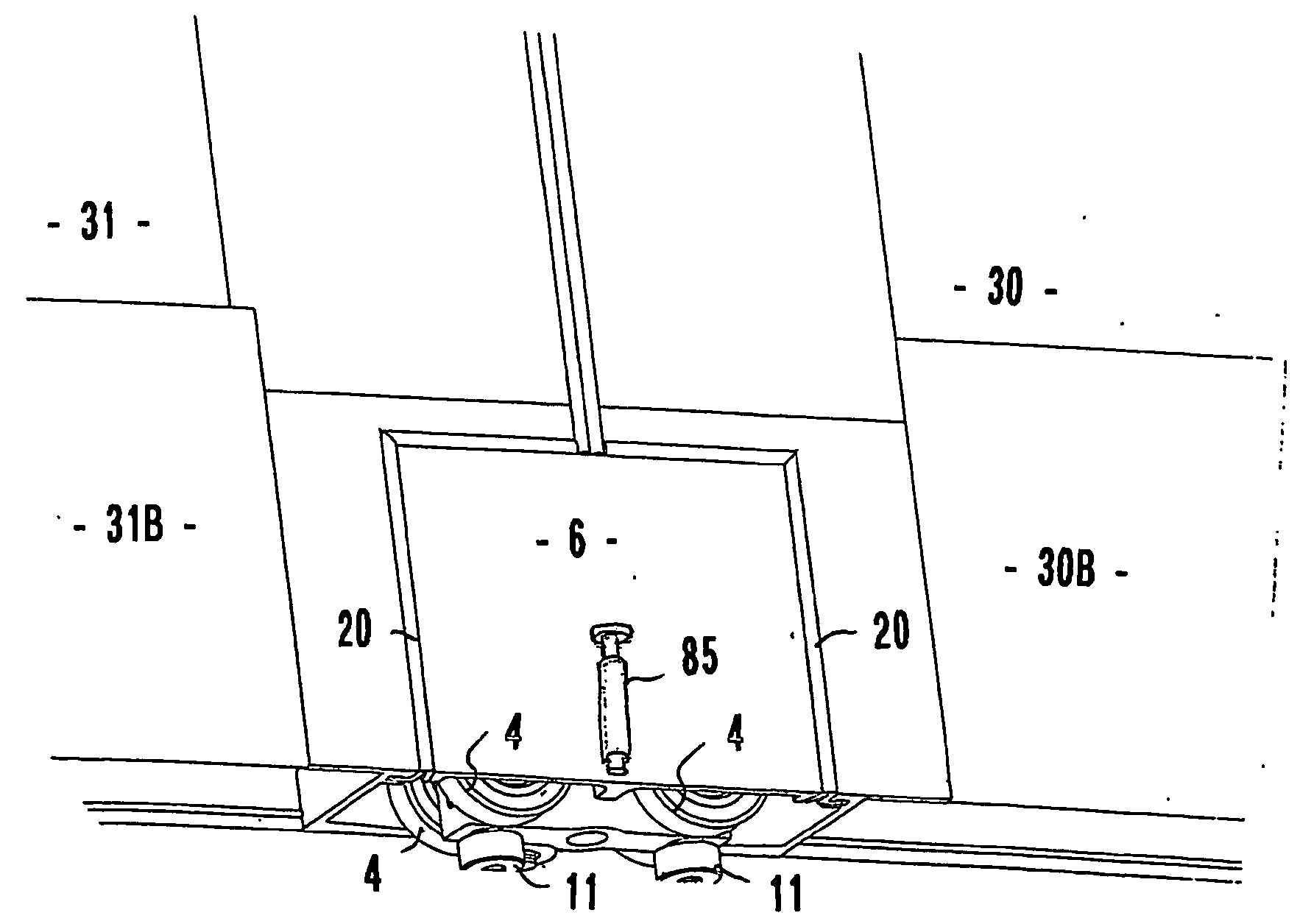

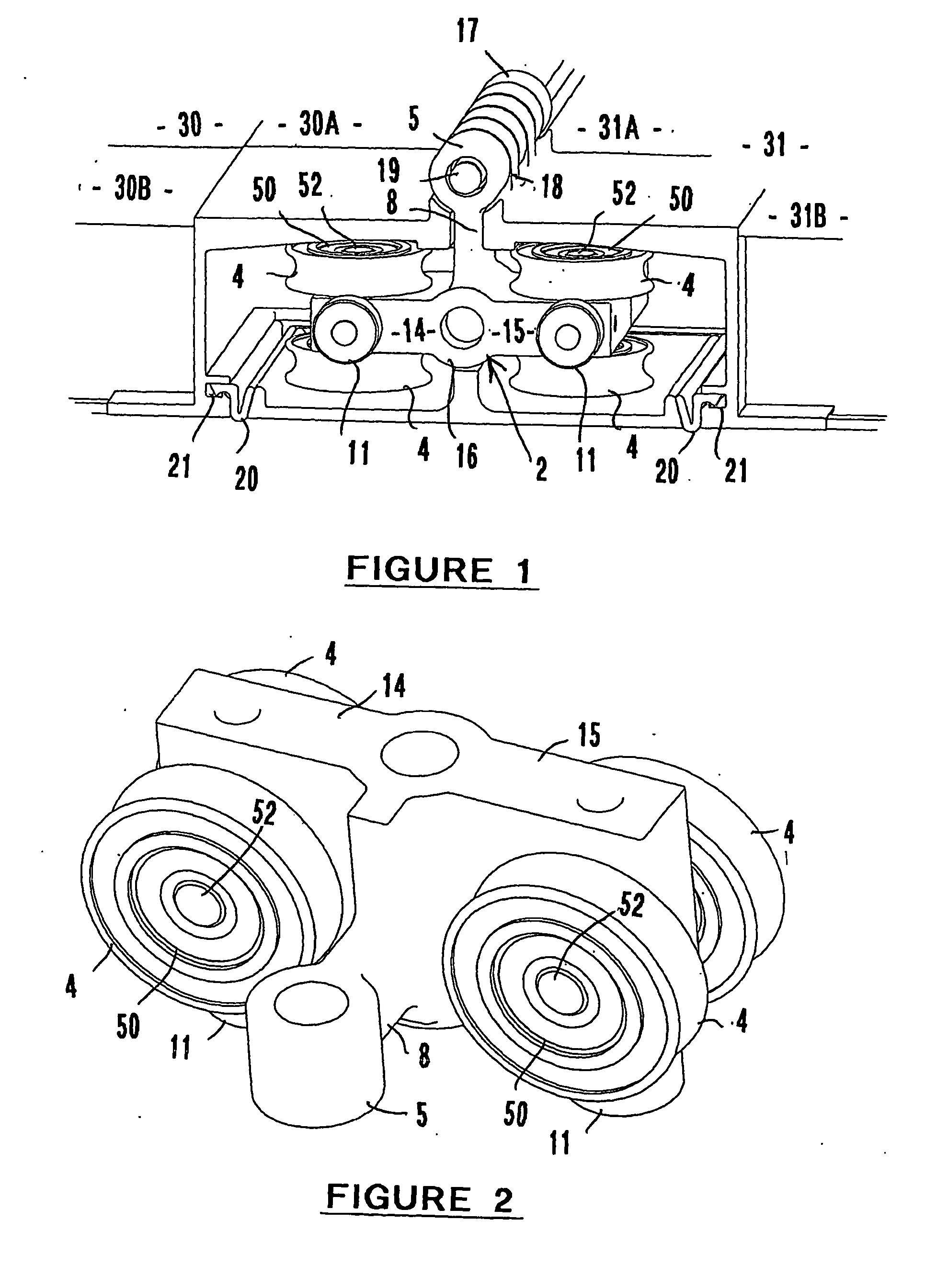

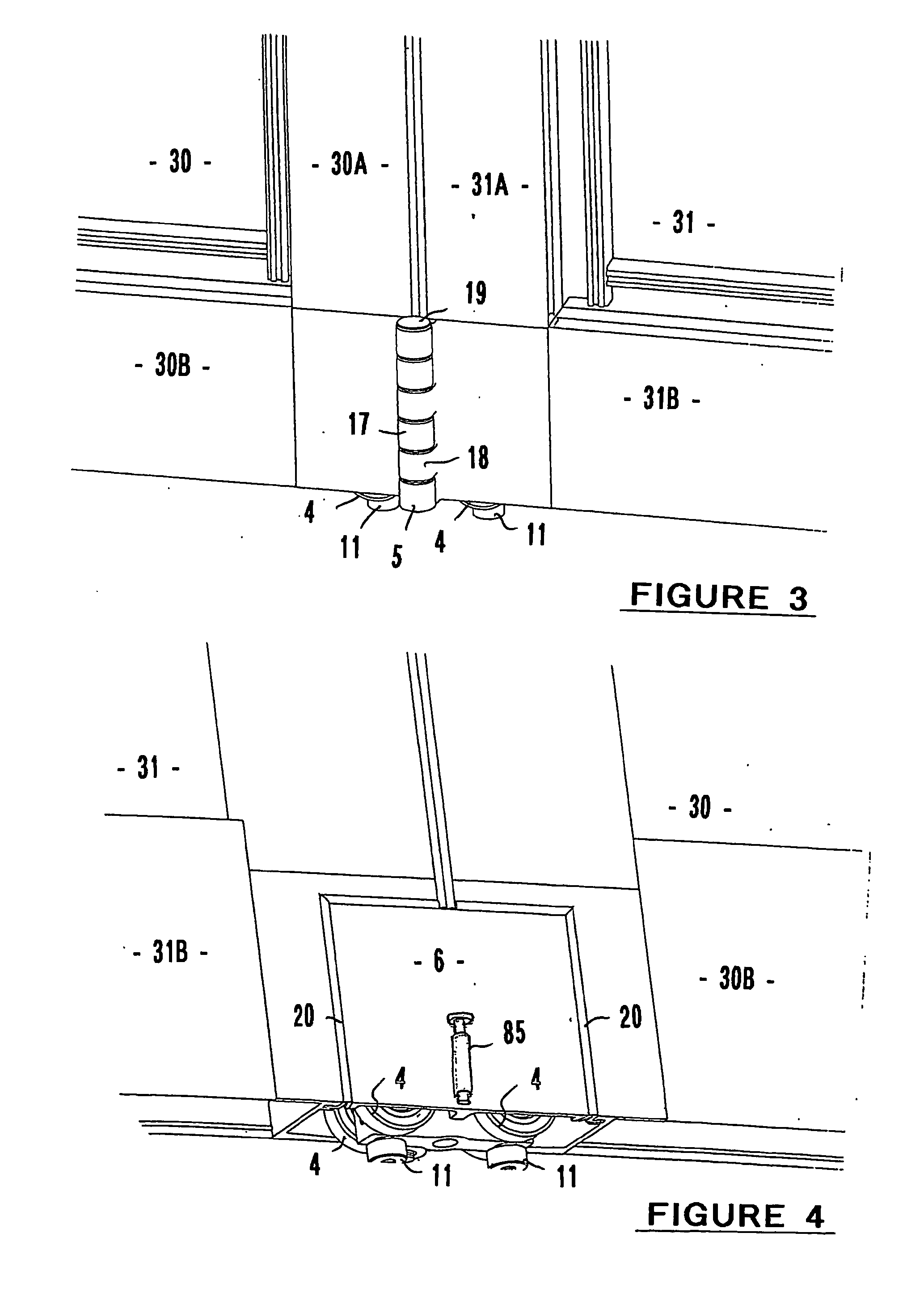

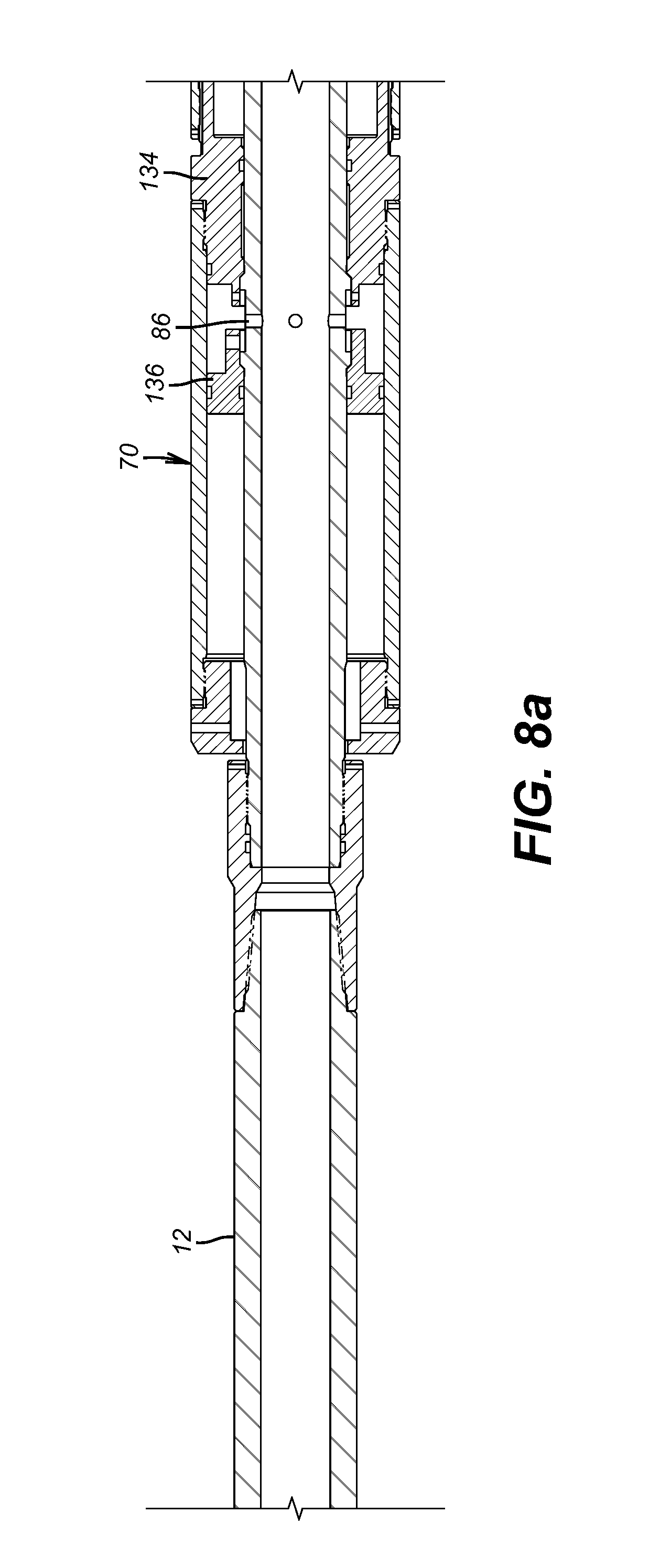

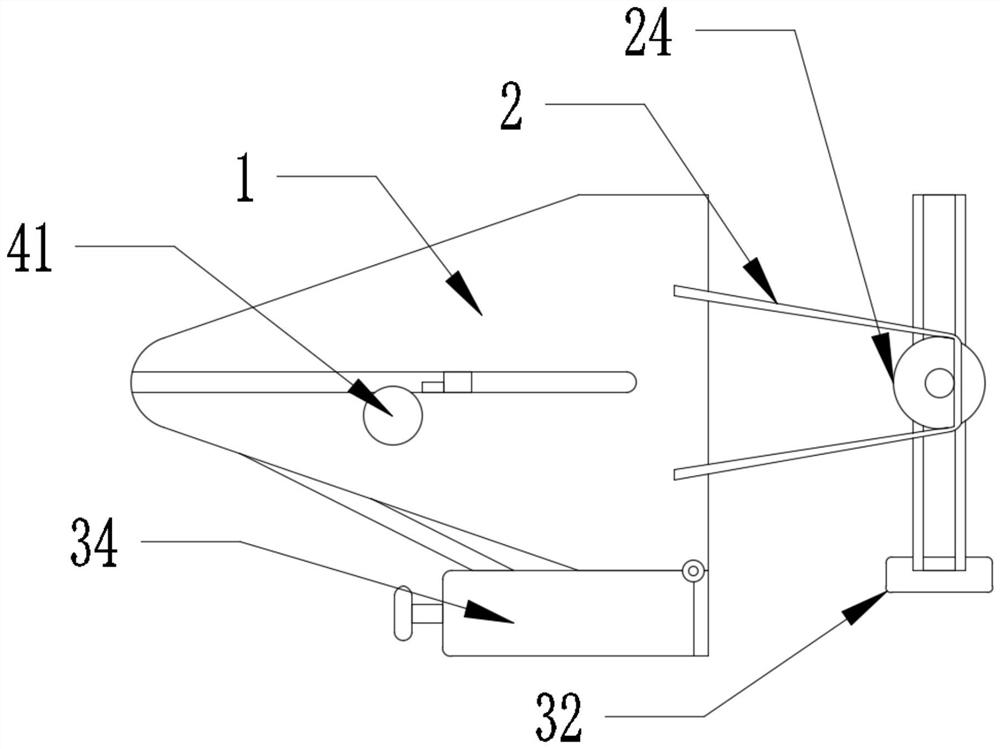

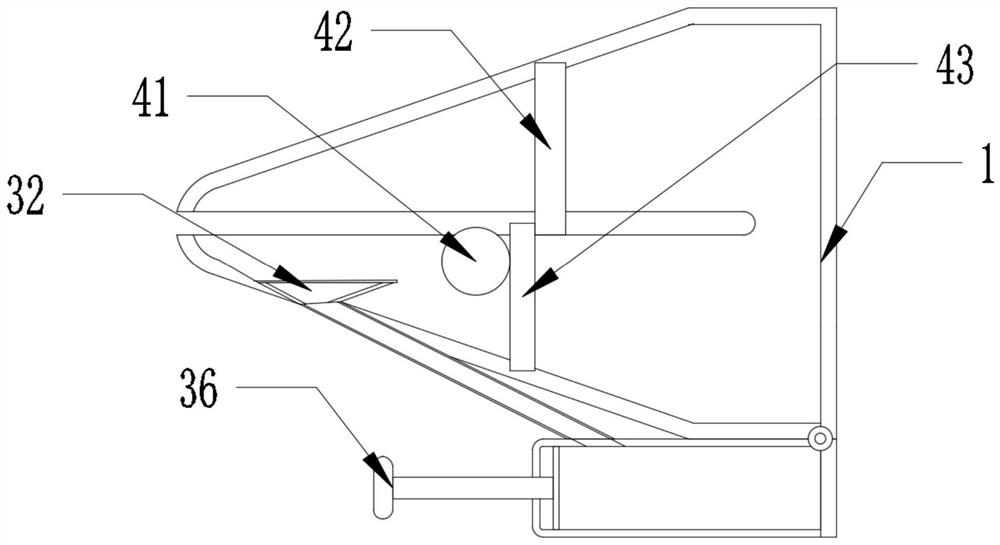

Multi-Fold Door and Window Assemblies

InactiveUS20070272372A1Prevent movementAvoid scrubbingHingesWing arrangementsEngineeringMechanical engineering

A multi-fold leaf (30,31) joinery assembly has a joinery bogey unit (2) that is pivotally connected to a joinery leaf. A seal (20) is provided on a moveable edge of the leaf adjacent to the bogey unit, the seal being adjacent to a frame seal (25) for a head or sill of a frame of the assembly when the at least one leaf is in a closed position. The pivot connection is off-set so that the seal moves away from the frame seal when the leaf is opened, thus avoiding scrubbing.

Owner:ARCHITECTURAL PROFILES

Fracturing and Gravel Packing Tool with Shifting Ability between Squeeze and Circulate while Supporting an Inner String Assembly in a Single Position

ActiveUS20110067861A1Avoid problemsPrevent fluid lossFluid removalWell/borehole valve arrangementsFinite timeEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

Method of fracturing and gravel packing with a tool with a multi-position lockable sliding sleeve

ActiveUS8235114B2Prevent fluid lossAvoid scrubbingFluid removalWell/borehole valve arrangementsEngineeringFinite time

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

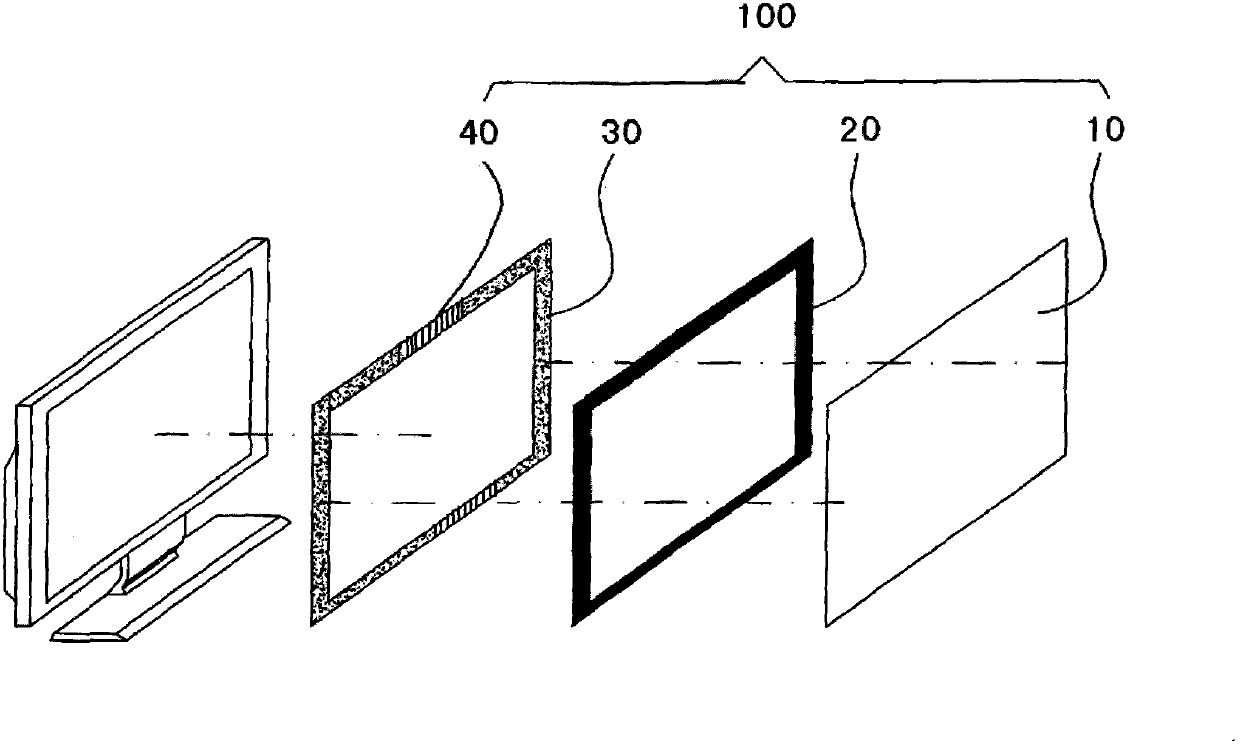

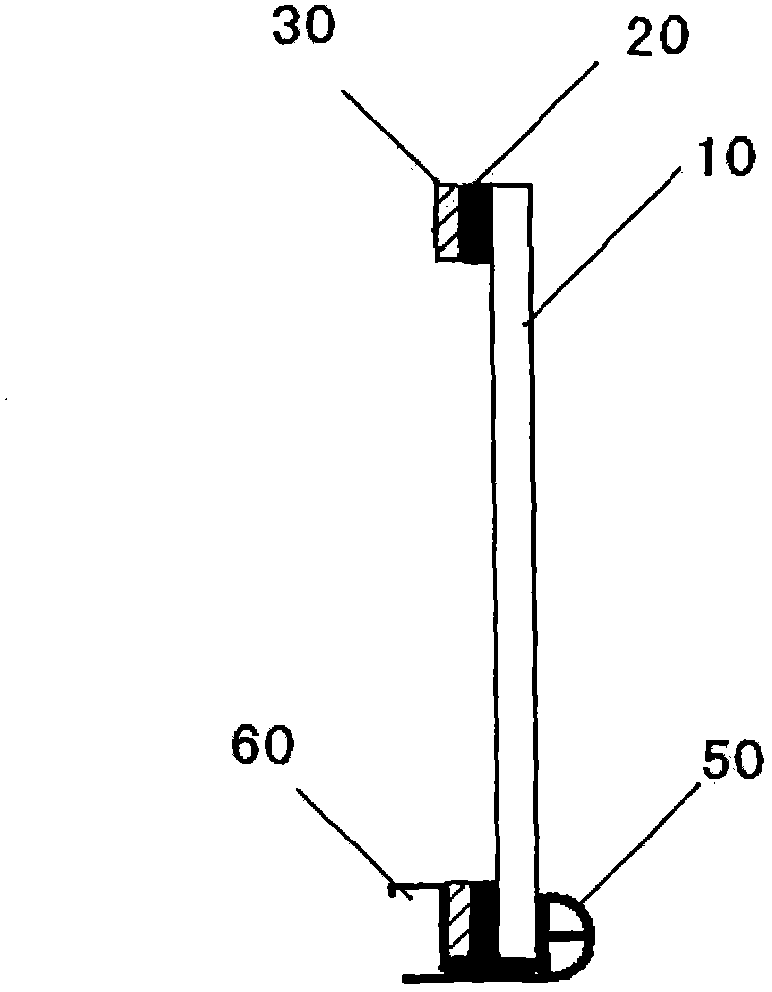

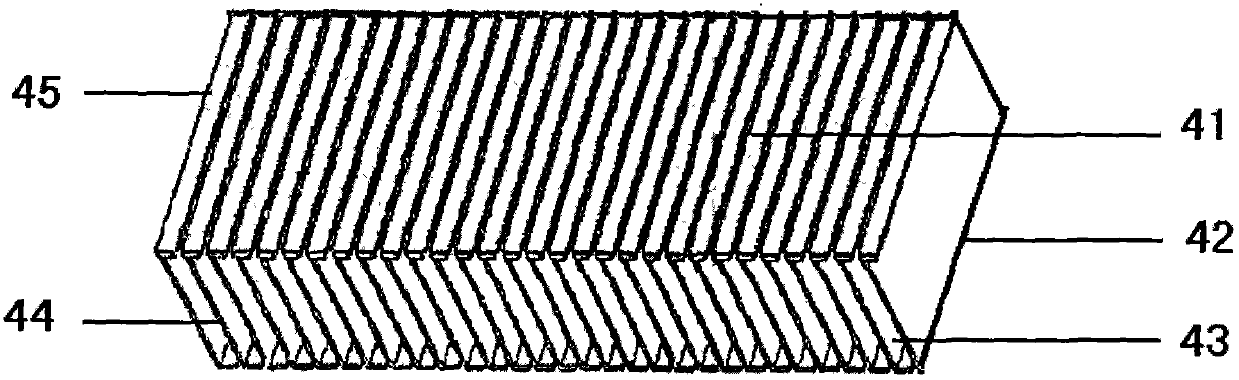

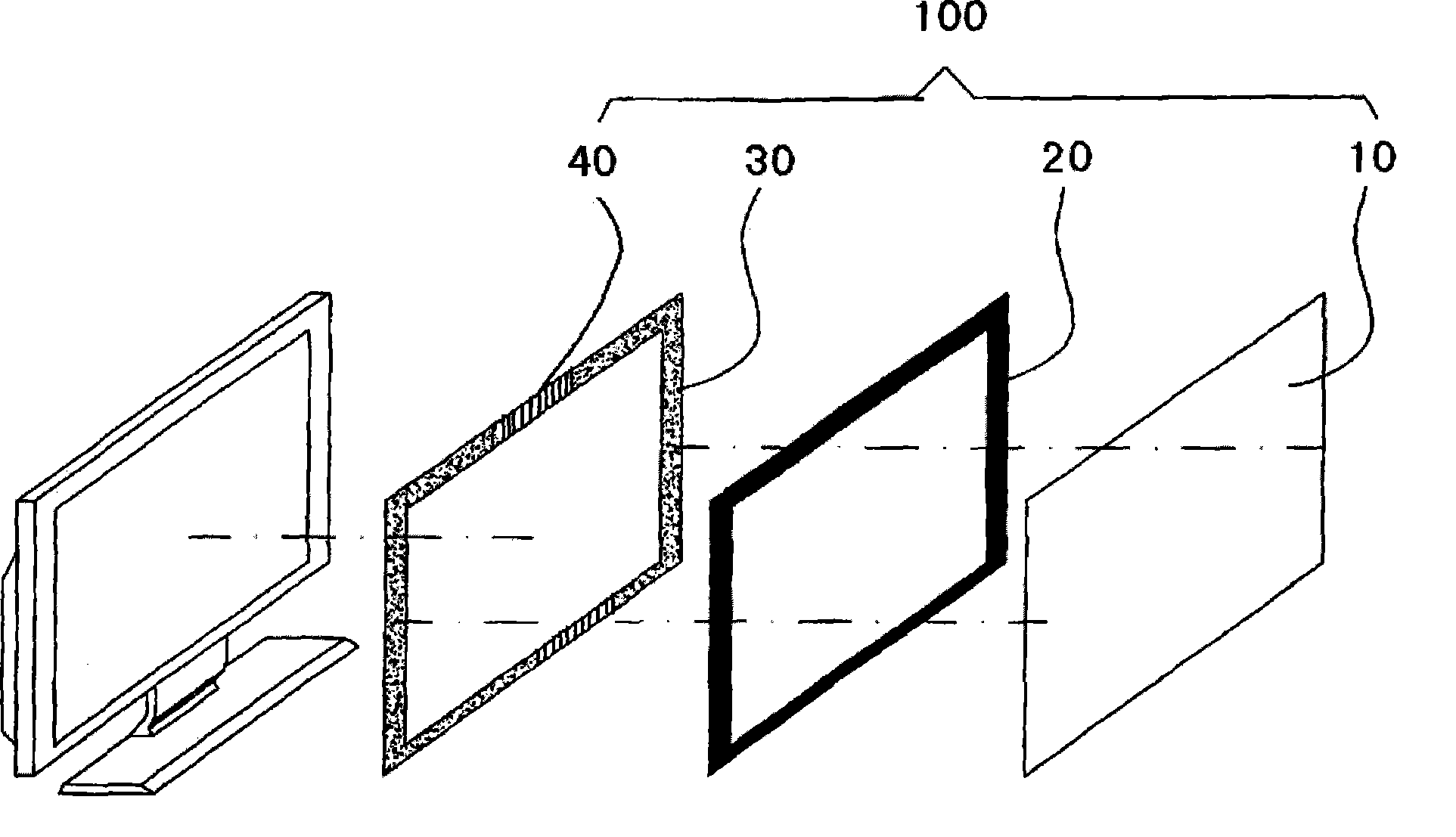

Flat-panel television protection screen

InactiveCN102685423AWill not affect the aesthetic effectAvoid influenceTelevision system detailsColor television detailsDisplay deviceEngineering

The invention relates to a flat-panel television protection screen, which comprises a transparent panel, a shading rim which is arranged on the peripheral edge of the transparent panel and a buffering layer which is adhered onto the shading rim, wherein at least one heat radiation device is arranged on the position corresponding to a flat-panel television frame, and the flat-panel television protection screen is characterized in that the heat radiation device comprises a first main contact surface which is contacted with the outer surface of the flat-panel television frame, a second main contact surface which is contacted with the inner surface of the shading frame and one or more heat radiation passages which extends in the length direction of the first main contact surface and the second main contact surface, wherein the first main contact surface is parallel to the second main contact surface, at least one of the two end surfaces formed by an port of one or more heat radiation passages is provided with a ventilation film. The flat-panel television protection screen is used for protecting a flat-panel television display device, simultaneously the heat radiation problem of the protection screen is also solved, and the influence of small particles such as dust, fogdrop and the like on the flat-panel television display device can be effectively avoided.

Owner:叶钧

Method of fracturing and gravel packing with multi movement wash pipe valve

ActiveUS8191631B2Prevent fluid lossAvoid scrubbingFluid removalWell/borehole valve arrangementsFinite timeEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

Fracturing and gravel packing tool with anti-swabbing feature

ActiveUS8528641B2Prevent fluid lossAvoid scrubbingConstructionsFluid removalBottom hole pressureEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or multi-acting circulation valve allows switching between the squeeze and circulation positions without risk of closing the low bottom hole pressure ball valve. The low bottom hole pressure ball valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the low bottom hole pressure ball valve. The multi-acting circulation valve can prevent fluid loss to the formation when being set down with the crossover tool supported or on the reciprocating set down device and the multi-acting circulation valve is closed without risk of closing the wash pipe valve.

Owner:BAKER HUGHES INC

Fracturing and Gravel Packing Tool with Upper Annulus Isolation in a Reverse Position without Closing a Wash Pipe Valve

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

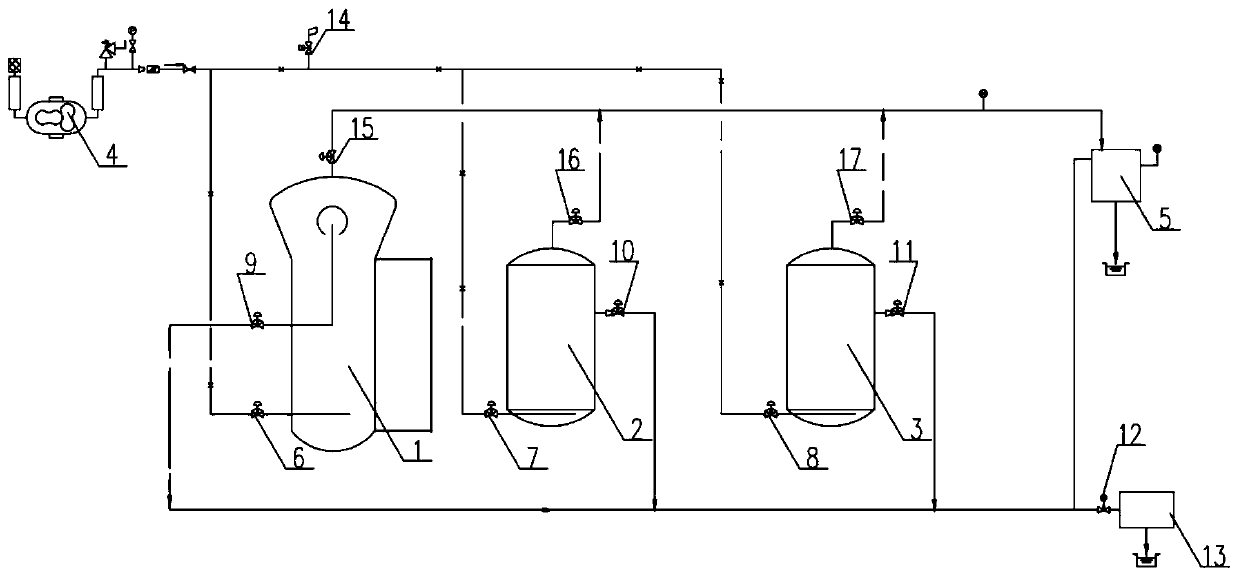

Intelligent resin scrubbing endpoint detection device and method thereof

InactiveCN110563085AReduce water consumption for regenerationExtend your lifeWater treatment parameter controlSpecific water treatment objectivesParticulatesWater discharge

The invention discloses an intelligent resin scrubbing endpoint detection device and a method thereof. A special sampling tube is connected to a water discharge main tube in the middle of a resin separation tower, an anion-exchange tower and a cation-exchange tower in the fine treatment in-vitro regeneration system of a power plant, the resin scrubbing endpoint detection device is mounted on the sampling tube, and an electromagnetic valve interlocked with the program control system of the power plant is arranged to control when the detection device is put into use. The resin scrubbing endpointdetection device online detects the quantity of particles in a scrubbing waste liquid, and transmits the switching information of the electromagnetic valve and the detection result of the quantity ofthe particles in the scrubbing waste liquid into the program control system of the power plant; a device performing resin scrubbing is determined through combining opening and closing conditions of an air inlet valve and a middle water discharge valve, and the endpoint of the resin scrubbing of the tower is determined by detecting the quantity of particles in the scrubbing waste liquid in order to determine the frequency required by tower resin scrubbing; and the device and the method have the advantages of energy saving, emission reduction, reduction of the water consumption in resin regeneration, prolongation of the periodic water production amount of a fine treatment mixed bed, and prolongation of the service life of the resin.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

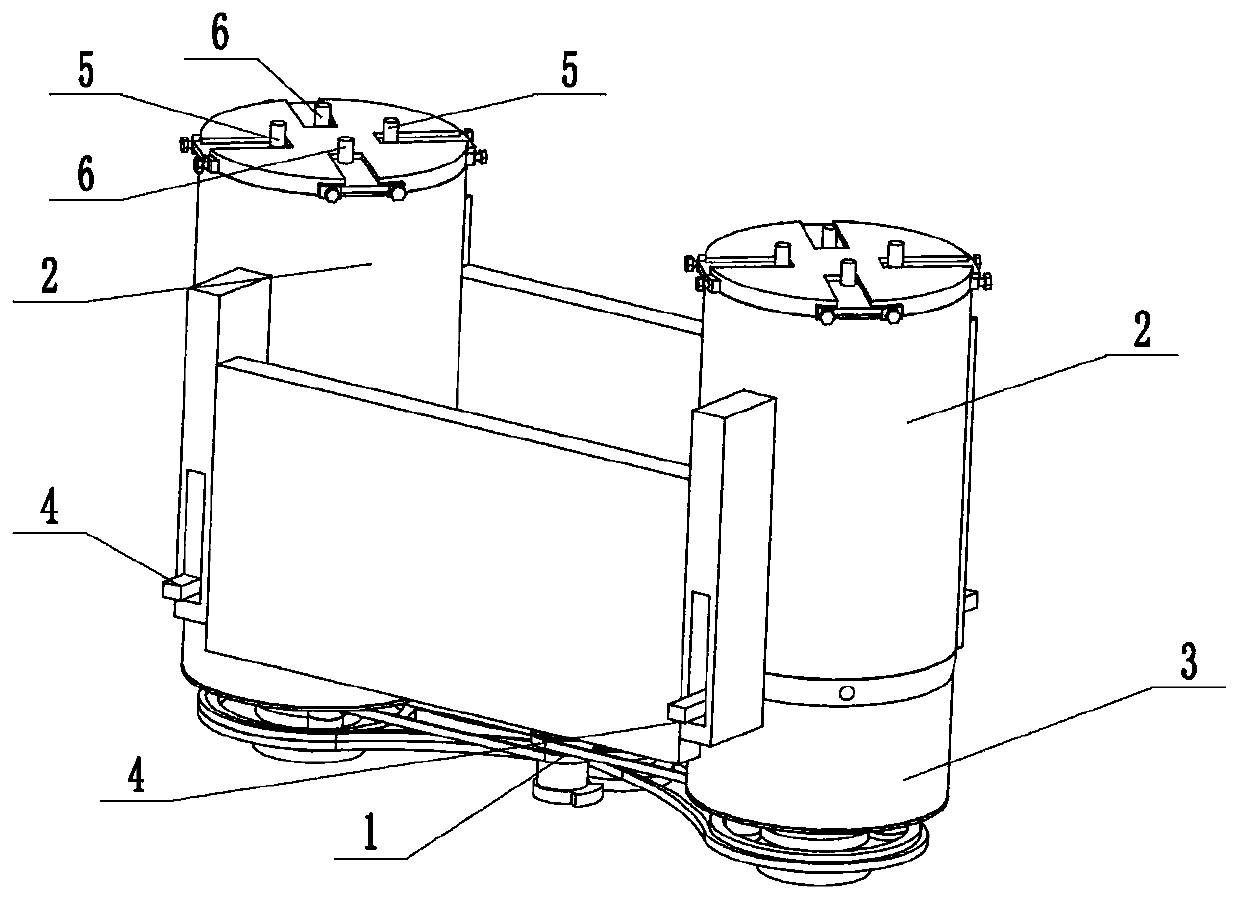

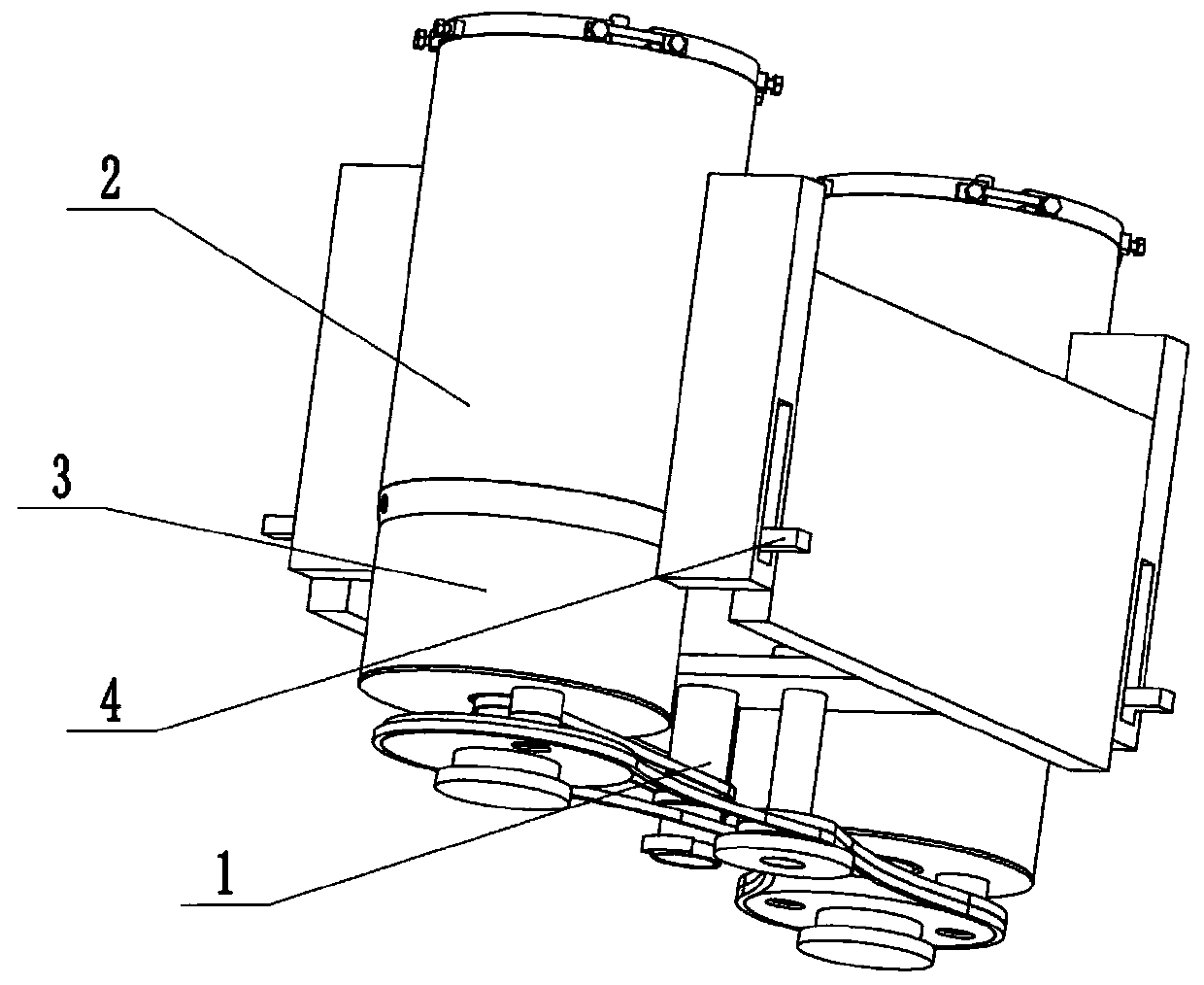

Plastic color concentrates and intelligent preparation system and method of plastic color concentrates

The invention relates to the field of color concentrate processing, in particular to plastic color concentrates and an intelligent preparation system and method of the plastic color concentrates. Theprocessing method includes the steps that liquid pigments, liquid dispersing auxiliaries and liquid resin are sequentially added into different stirring intervals of two gathering processing cylindersaccording to raw materials with different colors, and a driving machine frame is electrified to drive four mixing stirrers for mixing stirring; after even stirring, driving is stopped, specified mixed liquid is guided into different extrusion forming intervals of the two gathering processing cylinders through four manually-operated guide valves, the four manually-operated guide valves are closed,the driving machine frame is powered on to drive four combined forming extruders to continuously extrude mixed raw materials in two condensation water tanks; after multiple extrusion, the color concentrates after extrusion condensation forming are intermittently discharged through the driving machine frame; the color concentrates with different colors can be processed and formed at the same time;the materials include the pigments, the resin and polyethylene low molecule wax.

Owner:珠海巽丰特种塑料有限公司

Fracturing and gravel packing tool with shifting ability between squeeze and circulate while supporting an inner string assembly in a single position

ActiveUS8215395B2Prevent fluid lossAvoid scrubbingFluid removalWell/borehole valve arrangementsFinite timeEngineering

A fracturing and gravel packing tool has features that prevent well swabbing when the tool is picked up with respect to a set isolation packer. An upper or jet valve allows switching between the squeeze and circulation positions without risk of closing the wash pipe valve. The wash pipe valve can only be closed with multiple movements in opposed direction that occur after a predetermined force is held for a finite time to allow movement that arms the wash pipe valve. The jet valve can prevent fluid loss to the formation when being set down whether the crossover tool is supported on the packer or on the smart collet.

Owner:BAKER HUGHES INC

Fracturing and gravel packing tool with upper annulus isolation in a reverse position without closing a wash pipe valve

Owner:BAKER HUGHES INC

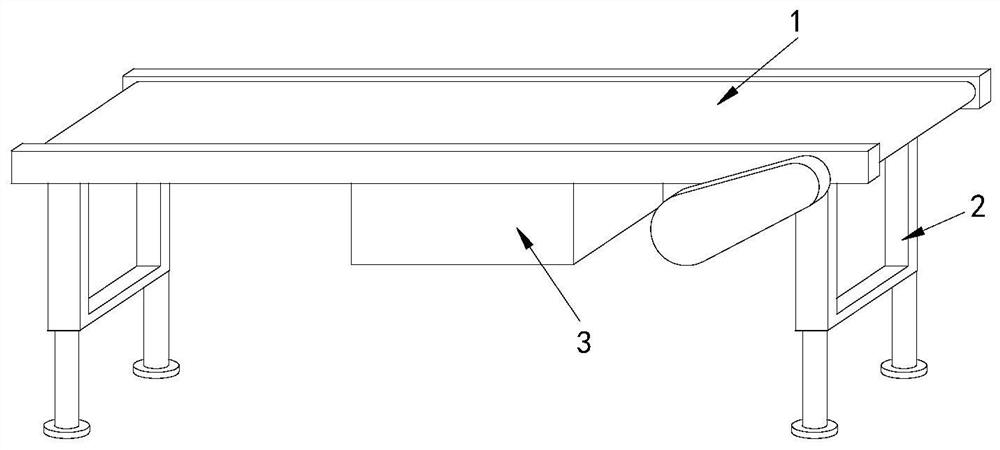

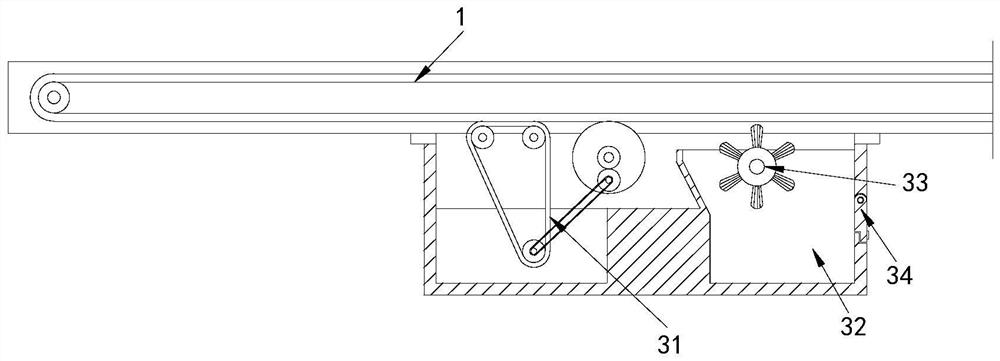

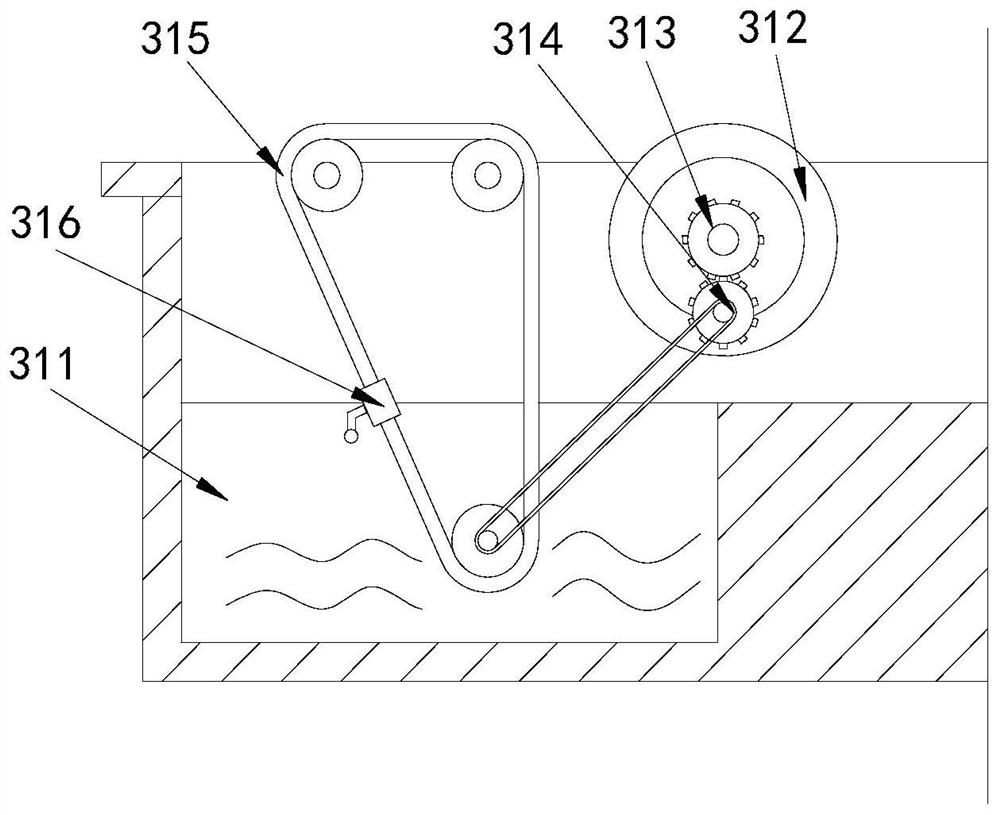

Paper box conveying equipment with powder removing device

The invention discloses paper box conveying equipment with a powder removing device. The paper box conveying equipment structurally comprises a conveying belt, two supporting legs and the powder removing device, the two supporting legs are transversely arranged, the powder removing device is installed in the middle of the bottom of the conveying belt, and the powder removing device comprises a cleaning device, a powder collecting groove, a cleaning brush and a box door. The cleaning device comprises a cleaning pool, a friction roller, a gear set, a belt, scrubbing cloth and a water removing device, the water removing device comprises a water removing block, a fixing block, a material guide block, a rewinding spring, a water scraping device and a cloth jacking device, the water scraping device comprises a water scraping block, a water through hole and a buffer pad, and the buffer pad comprises a buffer block, a rubber ring, an empty groove and a friction block. The friction roller makes contact with the bottom of the conveying belt to rotate, then the belt drives a rotating shaft to operate, the scrubbing cloth can be attached to the end face of the conveying belt for scrubbing, paper powder attached to the end face of the conveying belt is scrubbed cleanly, and the situation that the end face of the conveying belt is polluted is avoided.

Owner:佛山市禅城区天华印业有限公司

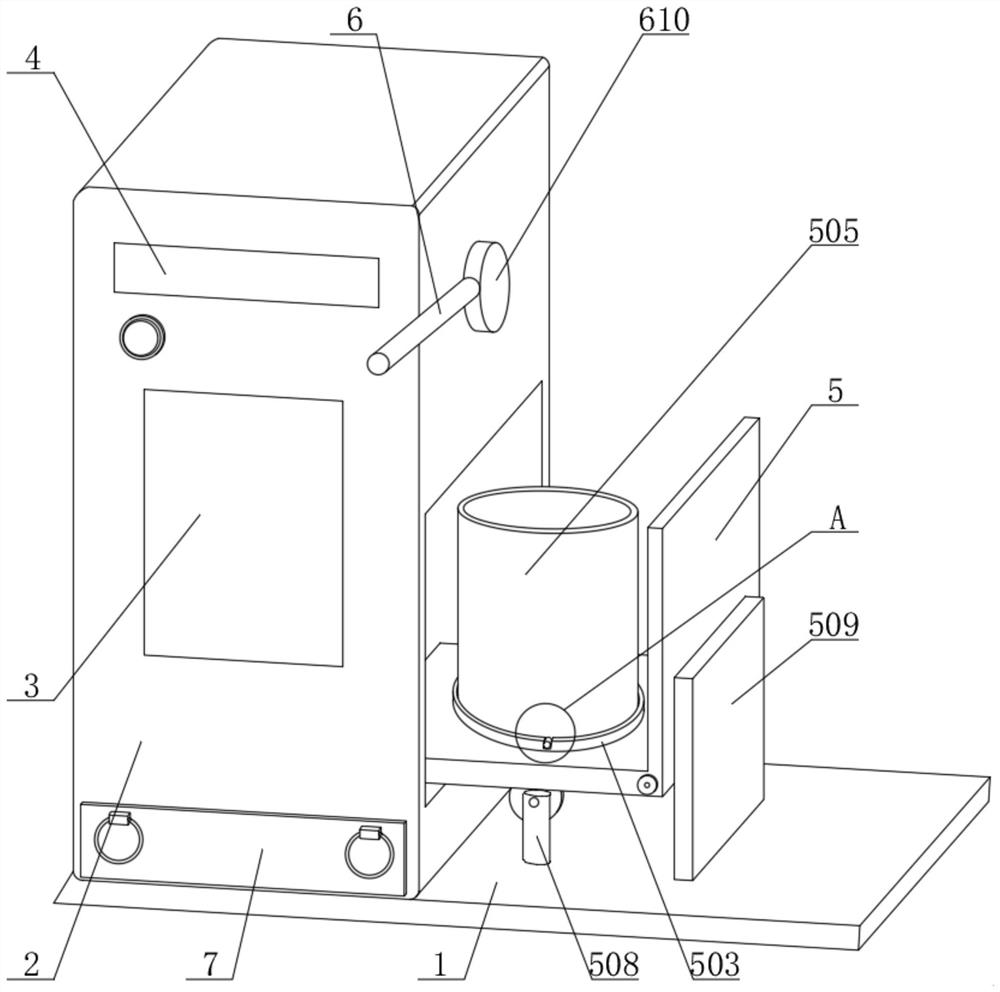

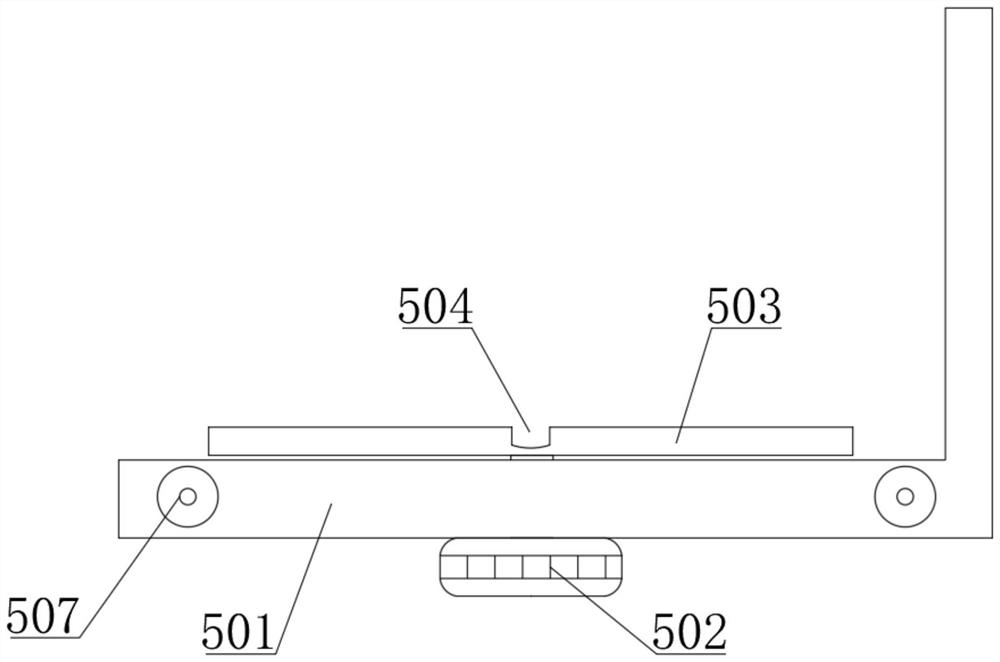

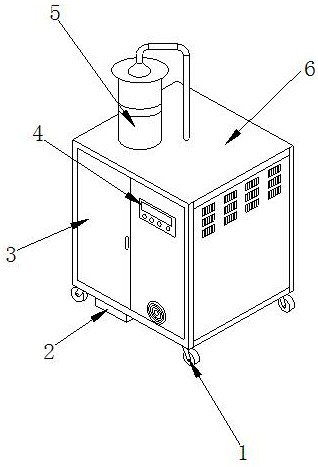

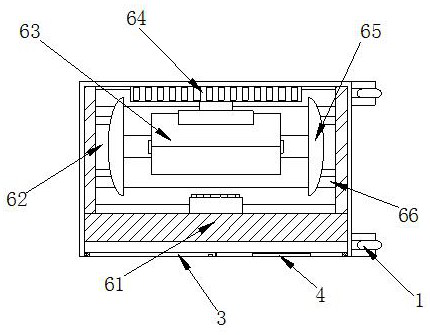

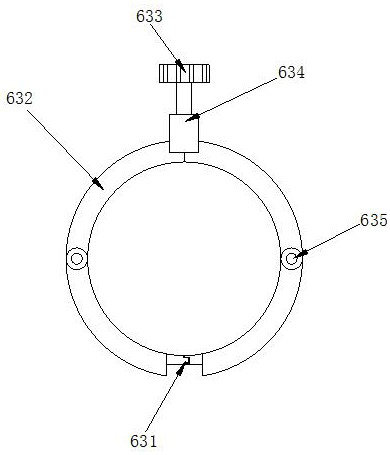

Flash extraction device capable of improving quality of coffee liquid and use method of flash extraction device

PendingCN114176406AReduce work intensitySpeed up flash extraction efficiencyBeverage vesselsElectric machineryEngineering

The invention relates to the technical field of coffee flash extraction, in particular to a flash extraction device capable of improving the quality of coffee liquid, which comprises a base and a refrigeration structure, the top end of the base is connected with a machine body, a transparent window is arranged in the middle of the front end of the machine body, and a control function area is arranged above the front end of the machine body; a positioning tray is arranged on one side of the machine body, a positioning structure is arranged on one side of the machine body, the positioning structure comprises a sliding plate frame, and a first motor is connected to the bottom end of the sliding plate frame. According to the arrangement, the sliding plate frame is fixedly connected with the first motor, the positioning tray is slidably connected with the flash extraction barrel, and the flash extraction barrel is fixedly connected with the positioning head, so that the flash extraction barrel is placed in the positioning tray, the positioning head on the outer side of the flash extraction barrel is clamped into the limiting groove, and the first motor can drive the positioning tray and the flash extraction barrel to quickly rotate; manual shaking is not needed, so that the flash extraction efficiency is improved, and the working intensity of workers is reduced.

Owner:昆明弘承食品科技有限公司

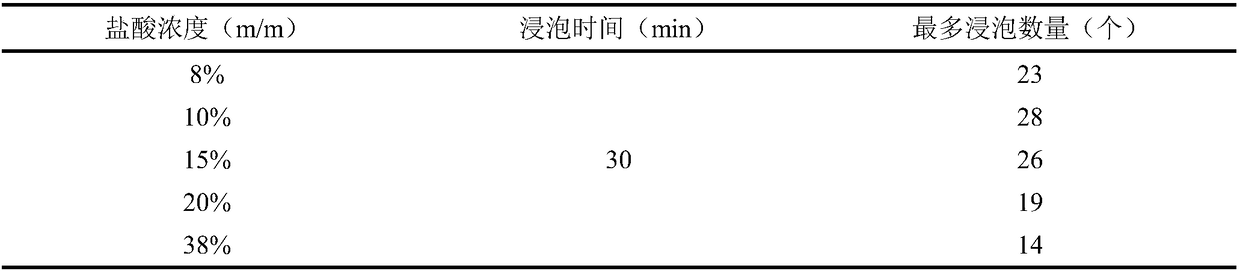

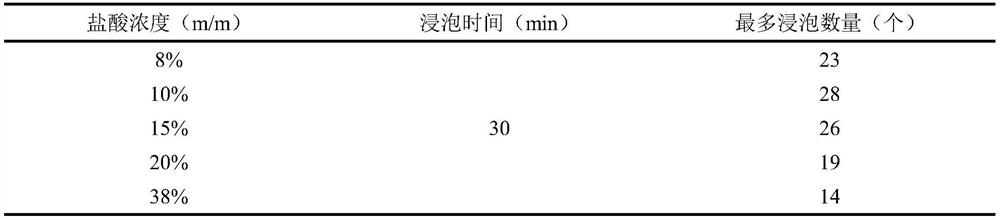

Automatic ultrasonic cleaning process of feeding container

ActiveCN108262302AAvoid scrubbingAvoid rewashingHollow article cleaningCleaning using liquidsCrucibleStrong acids

The invention relates to the technical field of cylindrical metal container surface pollution layer treatment, in particular to an automatic ultrasonic cleaning process of a feeding container. The process comprises the following steps of firstly, placing a crucible into a strong acid solution, and acid pickling for 90 to 120min; secondly, placing the crucible acid-pickled through the step I into an alkaline solution, and alkaline washing for 8 to 10min; and finally, water washing the crucible alkaline-washed through the step II for 8 to 10min, wherein during the step I acid pickling and step II alkaline washing processes, an ultrasonic wave with a certain power is fed into the acid solution and the alkaline solution. According to the automatic ultrasonic cleaning process of the feeding container provided by the invention, the one-time cleaning qualification rate exceeds 99 percent, and manual scrubbing or secondary washing is avoided.

Owner:CNNC JIANZHONG NUCLEAR FUEL

A plastic color masterbatch and its intelligent preparation system and method

The field of color masterbatch processing of the present invention is more specifically a plastic color masterbatch and its intelligent preparation system and method. The processing method is: according to the raw materials of different colors, they are sequentially transferred to different mixing intervals in the two collective processing cylinders. Add liquid pigments, liquid dispersion aids and liquid resins, drive the rack to drive four mixing agitators for mixing and stirring; after stirring evenly, stop the drive, and guide the specified mixed liquid into two In the different extrusion molding sections of the collective processing cylinder, close the four manual guide valves, drive the frame to connect the electricity to drive the four combined molding extruders to continuously extrude the mixed raw materials in the two condensate water tanks; multiple times After extrusion, intermittently drive the frame to discharge the color masterbatch after extrusion condensation molding; realize the processing and molding of different color masterbatches at the same time; the materials include pigments, resins and polyethylene low-molecular wax.

Owner:珠海巽丰特种塑料有限公司

An Ultrasonic Automatic Cleaning Process for Feeding Containers

The invention relates to the technical field of cylindrical metal container surface pollution layer treatment, in particular to an automatic ultrasonic cleaning process of a feeding container. The process comprises the following steps of firstly, placing a crucible into a strong acid solution, and acid pickling for 90 to 120min; secondly, placing the crucible acid-pickled through the step I into an alkaline solution, and alkaline washing for 8 to 10min; and finally, water washing the crucible alkaline-washed through the step II for 8 to 10min, wherein during the step I acid pickling and step II alkaline washing processes, an ultrasonic wave with a certain power is fed into the acid solution and the alkaline solution. According to the automatic ultrasonic cleaning process of the feeding container provided by the invention, the one-time cleaning qualification rate exceeds 99 percent, and manual scrubbing or secondary washing is avoided.

Owner:CNNC JIANZHONG NUCLEAR FUEL

Cooling box cleaning device for diamond cone numerical control lathe

PendingCN112453980AIncrease flexibility and usabilityReduce workloadAuxillary equipmentMaintainance and safety accessoriesPhysicsHandrail

The invention discloses a cooling box cleaning device for a diamond cone numerical control lathe, and relates to the technical field of mechanical equipment. The cooling box cleaning device comprisesa supporting plate, a first box body, a water pump, a water spraying assembly and a sweeping assembly; the center of the top of the supporting plate is fixedly connected with the water pump, one sideof the top of the supporting plate is fixedly connected with a second box body, the other side of the top of the supporting plate is fixedly connected with the first box body, and the side edge of thebottom of the supporting plate is fixedly connected with rolling wheels; the side faces of the supporting plate and the first box body are fixedly connected with one side of a handrail assembly, thetop of the handrail assembly is fixedly connected with the bottom of a first connecting piece, and the two sides of the upper portion of the first connecting piece are fixedly connected with first handles. Through the arrangement of the supporting plate, the first box body, the water pump, the water spraying assembly and the sweeping assembly, the effects that cleaning tools can be brought to a part needing to be cleaned at a time, and the inner wall of a cooling box can be rapidly cleaned through the water spraying assembly and the sweeping assembly are achieved.

Owner:苏州志纳精密科技有限公司

Flat-panel television protection screen

InactiveCN102685423BWill not affect the aesthetic effectSolve the cooling problemTelevision system detailsColor television detailsDisplay deviceEngineering

The invention relates to a flat-panel television protection screen, which comprises a transparent panel, a shading rim which is arranged on the peripheral edge of the transparent panel and a buffering layer which is adhered onto the shading rim, wherein at least one heat radiation device is arranged on the position corresponding to a flat-panel television frame, and the flat-panel television protection screen is characterized in that the heat radiation device comprises a first main contact surface which is contacted with the outer surface of the flat-panel television frame, a second main contact surface which is contacted with the inner surface of the shading frame and one or more heat radiation passages which extends in the length direction of the first main contact surface and the second main contact surface, wherein the first main contact surface is parallel to the second main contact surface, at least one of the two end surfaces formed by an port of one or more heat radiation passages is provided with a ventilation film. The flat-panel television protection screen is used for protecting a flat-panel television display device, simultaneously the heat radiation problem of the protection screen is also solved, and the influence of small particles such as dust, fogdrop and the like on the flat-panel television display device can be effectively avoided.

Owner:叶钧

Mask for preventing and controlling pet epidemic diseases

The invention relates to a mask for preventing and controlling pet epidemic diseases. The mask comprises an elastic band and a sealing cover, the elastic band is connected with the sealing cover, an adjusting mechanism is arranged on one side of the elastic band, the adjusting mechanism is connected with the elastic band, and a fixing mechanism is arranged in the sealing cover, and is connected with the sealing cover. A collecting mechanism is arranged on the outer side of the sealing cover, and is connected with the sealing cover. The adjusting mechanism comprises a fixing ring, an adjusting buckle, a sliding groove, an adjusting wheel, a limiting block, a rotating rod and a clamping groove, and the adjusting buckle is connected with the fixing ring. By means of the Compared with a common mask for pets, the mask has the advantages that the state of the mask can be switched and adjusted, the mask can be conveniently worn by the pets, saliva of the pets can be treated, and the like.

Owner:深圳市前沿新技术有限公司

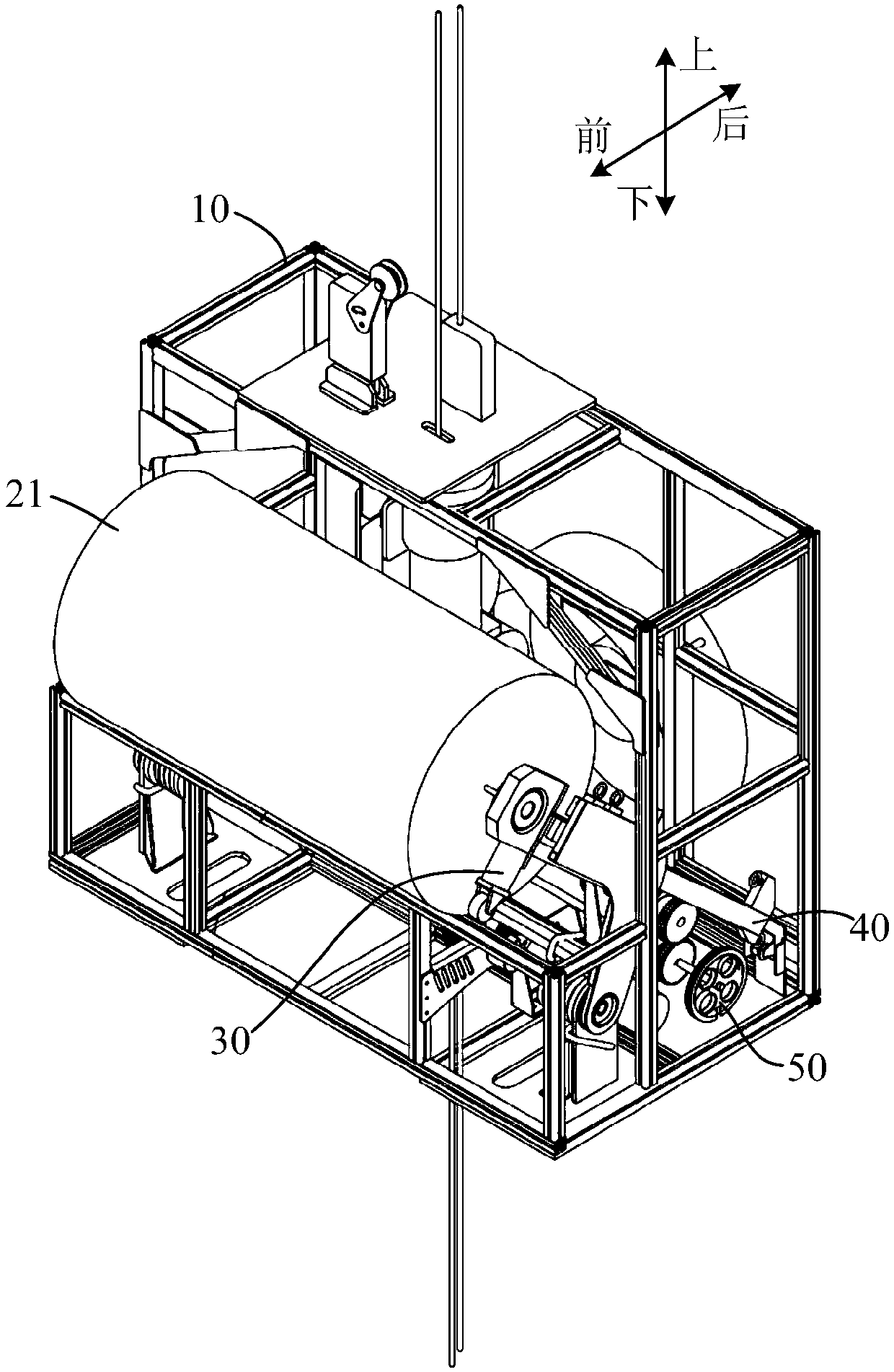

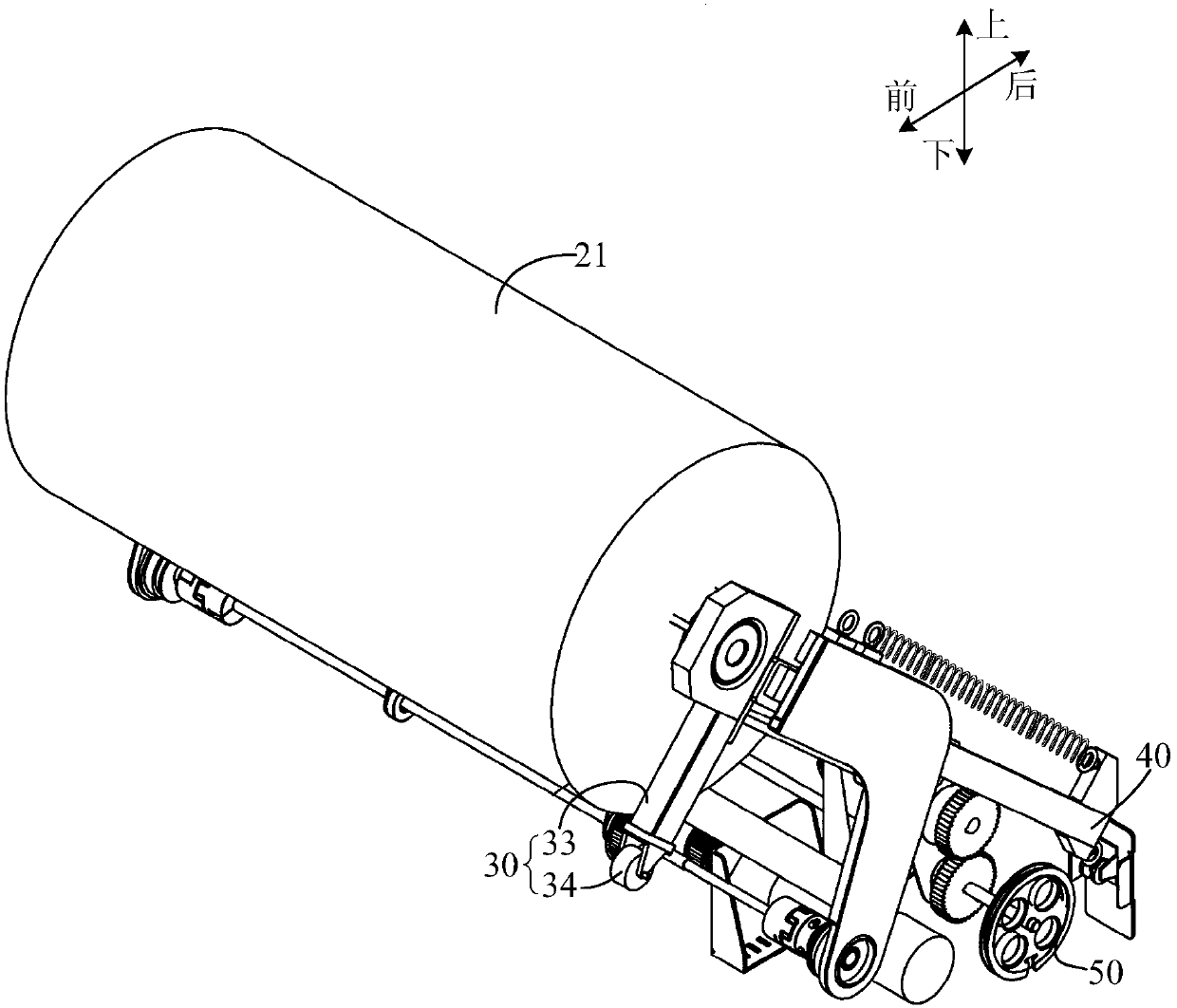

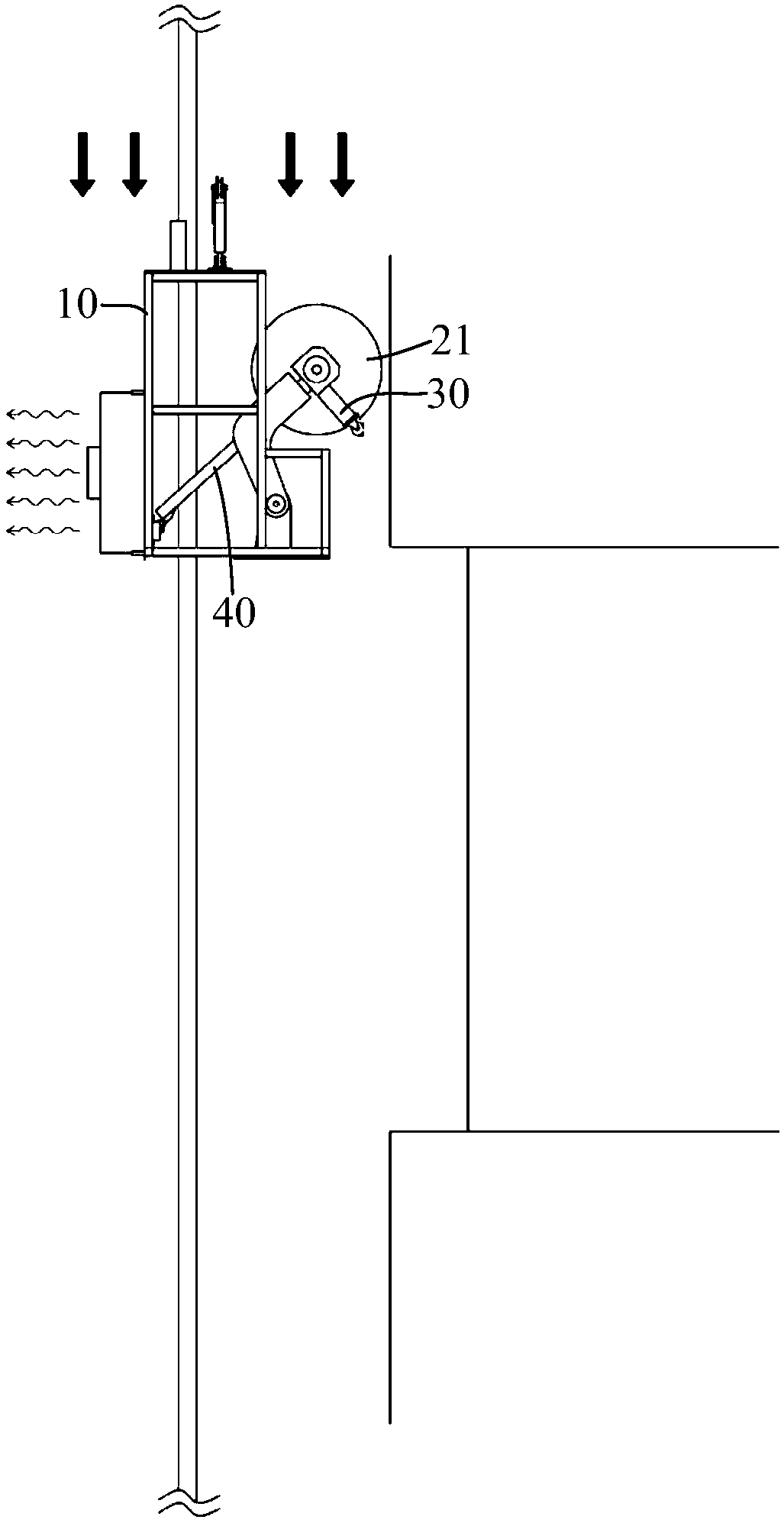

Rotary wheel mark scrubbing equipment on vacuum tube production equipment

The invention discloses rotary wheel mark scrubbing equipment on vacuum tube production equipment. The rotary wheel mark scrubbing equipment structurally comprises bottom wheels, an electric box, a placement door, a control panel, a water storage tank and a working box, wherein the upper ends of the bottom wheels are in threaded connection with the lower end of the working box, the upper end of the electric box is in stud connection with the lower end of the working box, the rear end of the placement door is in bolt connection with the front end of the working box, the rear end of the control panel is fixedly connected to the front end of the placement door in an embedded mode, and the lower end of the water storage tank is fixedly connected to the upper end of the working box. The equipment is powered on, the placement door is opened, a vacuum tube is placed in a vibration device and a scrubbing device, the control panel is controlled, a driving wheel in a rotating wheel drives a scrubbing plate to expand and be recycled, buckles are clamped to support the vibration tube, and the control panel is controlled, so that a rotating column drives the vacuum tube in the vibration device to rotate, pulleys in the scrubbing device continuously slide left and right in a sliding rail, the vacuum tube is scrubbed, and it is avoided that the outer edge face of the vacuum tube is pressed and covered, causing abrasion of broken thorns, scratches left on the outer surface, and damage to a printing belt.

Owner:广州斑超电子科技有限公司

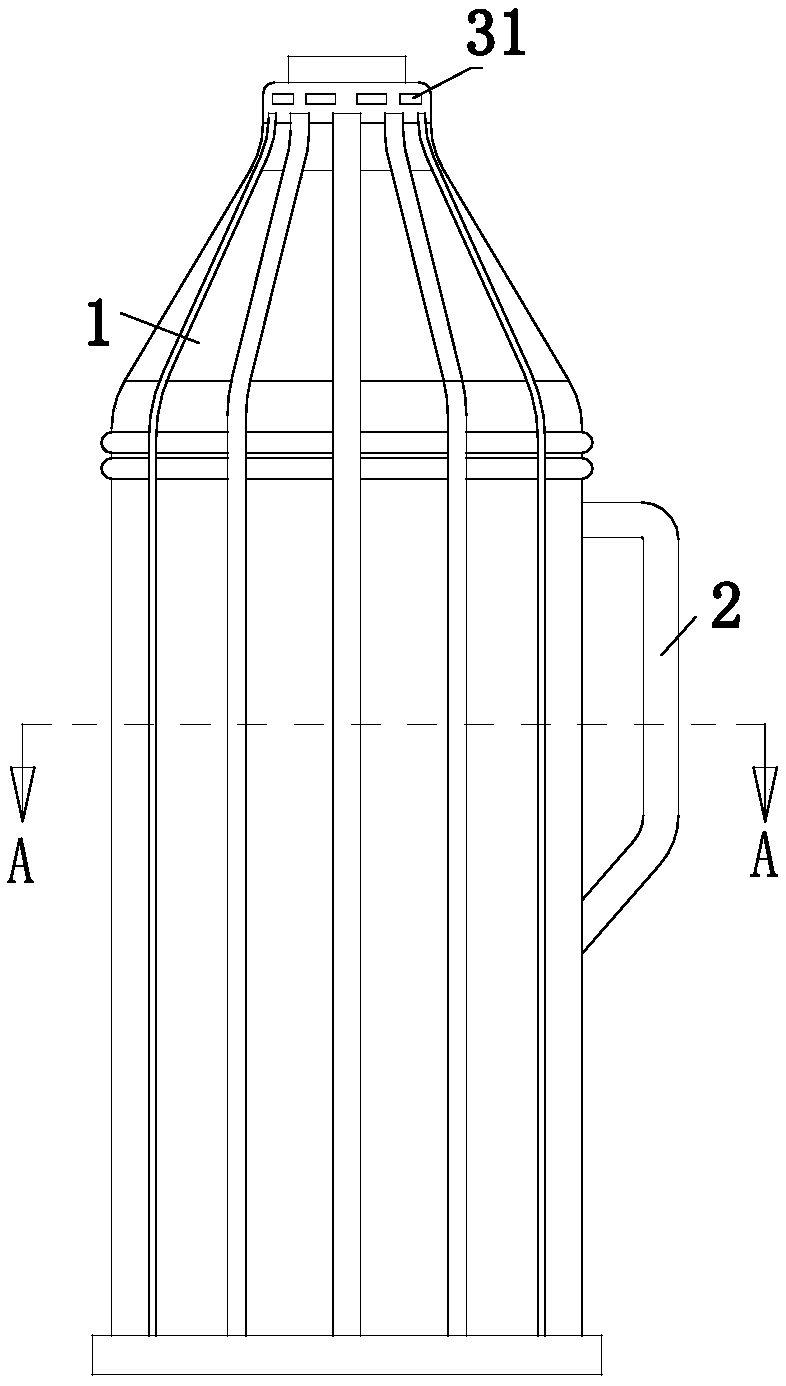

Automatic wall surface cleaning device

PendingCN109674394AAvoid obstructionAvoid obstructing bristle scrubbingCarpet cleanersFloor cleanersBristleSurface cleaning

The invention discloses an automatic wall surface cleaning device. The automatic wall surface cleaning device comprises a stander, a roll brush assembly and a breakage-proof rod, wherein the stander can move relative to a to-be-cleaned wall surface; the roll brush assembly is mounted at the stander and comprises a roller and bristles connected to the circumferential wall surface of the roller; andthe breakage-proof rod is connected to the roller, a free end of the breakage-proof rod protrudes out of the circumferential wall surface of the roller, and the tail ends of the bristles protrude outof the free end of the breakage-proof rod, and the free end of the breakage-proof rod props against the to-be-cleaned wall surface. According to the automatic wall surface cleaning device, the breakage-proof rod is arranged on the roller, the free end of the breakage-proof rod protrudes out of the circumferential wall surface of the roller and does not protrude out of the tail ends of the bristles, so that the situation that the brushing of a hairbrush to the wall surface is impeded by the breakage-proof rod can be avoided, the contact between the circumferential wall surface of the roller, and the wall surface can be prevented, the roller is effectively protected, and the stability of the automatic wall surface cleaning device is improved.

Owner:深圳截明电子科技有限公司

A household smart kettle

The invention relates to the field of thermal pots and specifically relates to a home-use intelligent thermal pot. The pot comprises a pot shell, a handle and a cleaning device, wherein the pot shell comprises a hollow rotation body structure and is used to store a liner filled with water, a brush cleaning groove with a T-shaped cross section is formed uniformly along the vertical direction on the outer wall of the pot shell, and a controller used to control automatic operations of the cleaning device is installed in the pot shell; the handle is disposed at the middle part of the outer side of the pot shell and used to lift the pot; the cleaning device is installed on the bottom of the pot shell; the cleaning device comprises a humidity sensor, a No.1 scrubbing unit, a No.2 scrubbing unit, an air pump, an electromagnetic valve, an electric rope and a No.2 sponge; and the No.1 scrubbing unit and the No.2 scrubbing unit comprise a slide block with a T-shaped cross section, a water collection cabin, a sponge clamping sleeve, a No.1 sponge, a buffer spring, a rolling spring and an airbag respectively. According to the invention, water dirt splashed out from the spot shell can be absorbed automatically, and water stains and dust on the pot shell can be scrubbed automatically.

Owner:盐城中咏投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com