Intelligent resin scrubbing endpoint detection device and method thereof

An endpoint detection and resin technology, applied in chemical instruments and methods, water treatment parameter control, special treatment targets, etc., can solve problems such as resin wear, increased resin purchases in power plants, and affecting unit safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

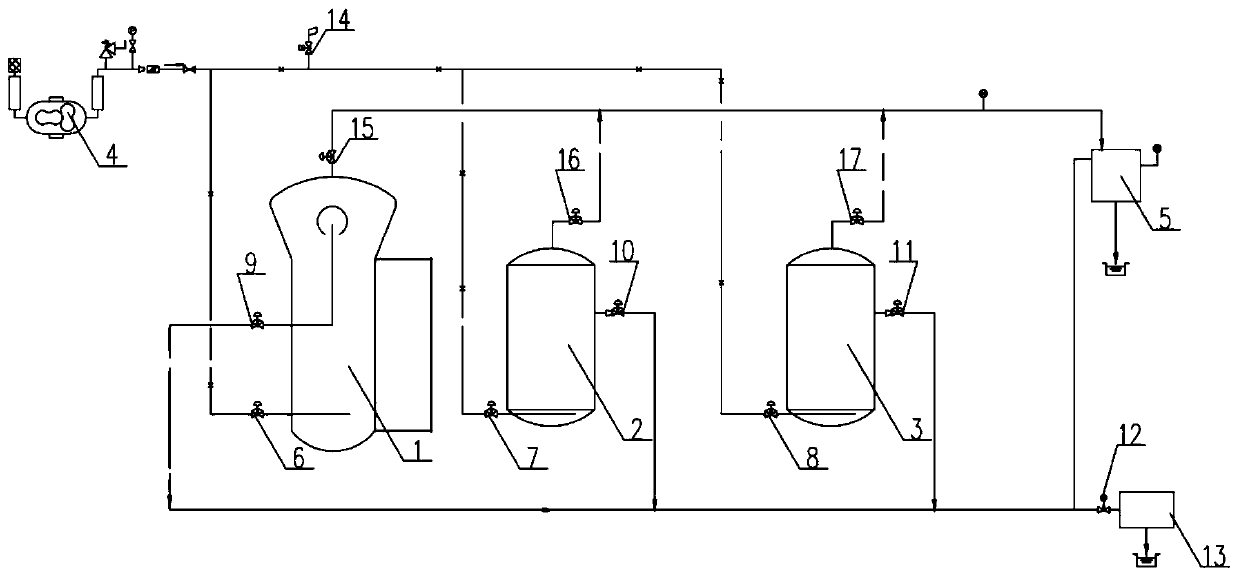

[0015] like figure 1 As shown, a kind of intelligent resin scrubbing terminal detection device of the present invention, in the resin separation tower 1, yin tower 2 and yang tower 3 middle part drainage main pipes in the resin separation tower 1, yin tower 2 and yang tower 3 in the power plant finishing treatment in vitro regeneration system, connect a special sampling pipe, in this A resin scrubbing endpoint detection device 13 is installed on the special sampling pipe, and an electromagnetic valve 12 interlocked with the power plant program control system is provided at the entrance of the resin scrubbing endpoint detection device 13 to control when the detection device 13 is put into use. The main function of the resin scrubbing endpoint detection device 13 is to detect the number of particles in the scrubbing waste liquid online, and transmit the switch information of the solenoid valve 12 and the detection results of the particle quantity of the scrubbing waste liquid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com