Rotary wheel mark scrubbing equipment on vacuum tube production equipment

A production equipment and rotary printing technology, applied in the field of vacuum tubes, can solve the problems of broken thorns stuck in the scratches of vacuum tubes, broken thorns of glass on the printing belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

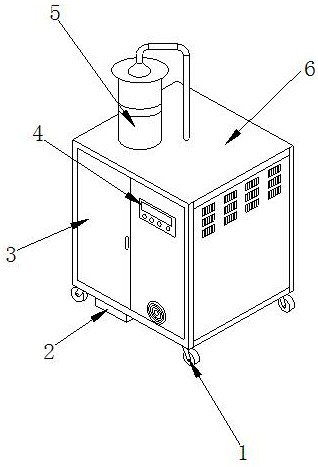

[0030] as attached figure 1 To attach Figure 6 Shown:

[0031] The invention provides a vacuum tube production equipment scrubbing wheel printing equipment, the structure of which includes a bottom wheel 1, an electric box 2, a placement door 3, a control panel 4, a water storage tank 5, and a working box 6. The upper end of the bottom wheel 1 is threaded Connected to the lower end of the working box 6, the upper end of the electric box 2 is connected to the lower end of the working box 6 by studs, the rear end of the placement door 3 is bolted to the front end of the working box 6, and the rear end of the control panel 4 is embedded and connected to the placement door 3 front end, the lower end of the water storage tank 5 is fixedly connected to the upper end of the working box 6.

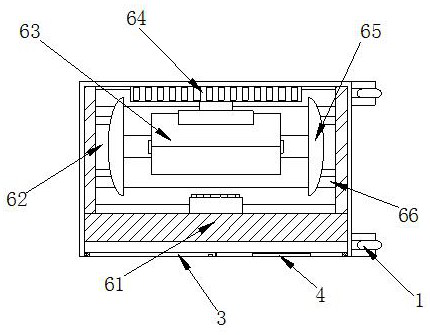

[0032] Wherein, the working box 6 is provided with a printing box 61, a rotating column 62, a scrubbing device 63, a slide rail 64, a vibrating device 65, and a chip removal groove 66, and the ...

Embodiment 2

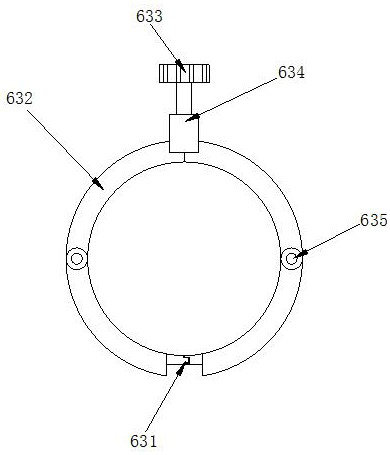

[0040] as attached Figure 7 To attach Figure 9 Shown:

[0041] The present invention provides a device for scrubbing the wheel marks on vacuum tube production equipment. The vibrating device 65 is provided with a vibrating plate 651, a bumper 652, a connecting plate 653, a guide port 654, and a push bar 655. The inner side of the vibrating plate 651 is embedded The connecting plate 653 is set between the vibrating plates 651 for supporting fit, the inner side of the guide port 654 fits with the outer side of the push bar 655, and the outer side of the push bar 655 is engaged with The inner side of the push block 652 is slidably fitted, and the outer side of the push bar 655 is provided with two pulleys, which are respectively stuck on the inner side of the collision block 652, so that when the vacuum tube is rotating, it will be slowly rotated and wiped with the sliding of the push bar 655 to prevent the vacuum tube from appearing on the outside. wear and tear.

[0042] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com