Plastic color concentrates and intelligent preparation system and method of plastic color concentrates

A technology of intelligent preparation system and color masterbatch is applied in the field of plastic color masterbatch and its intelligent preparation system to achieve the effect of avoiding color doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

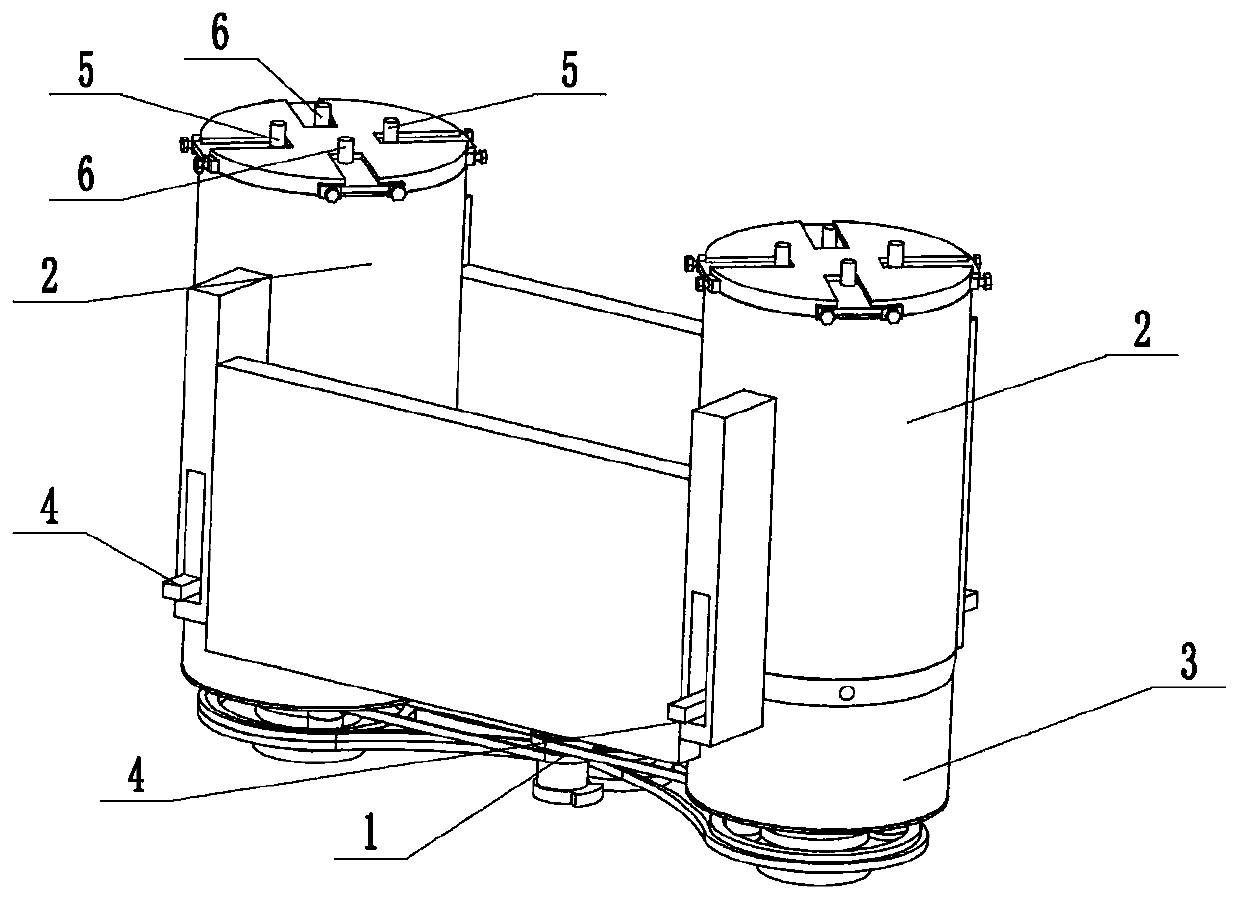

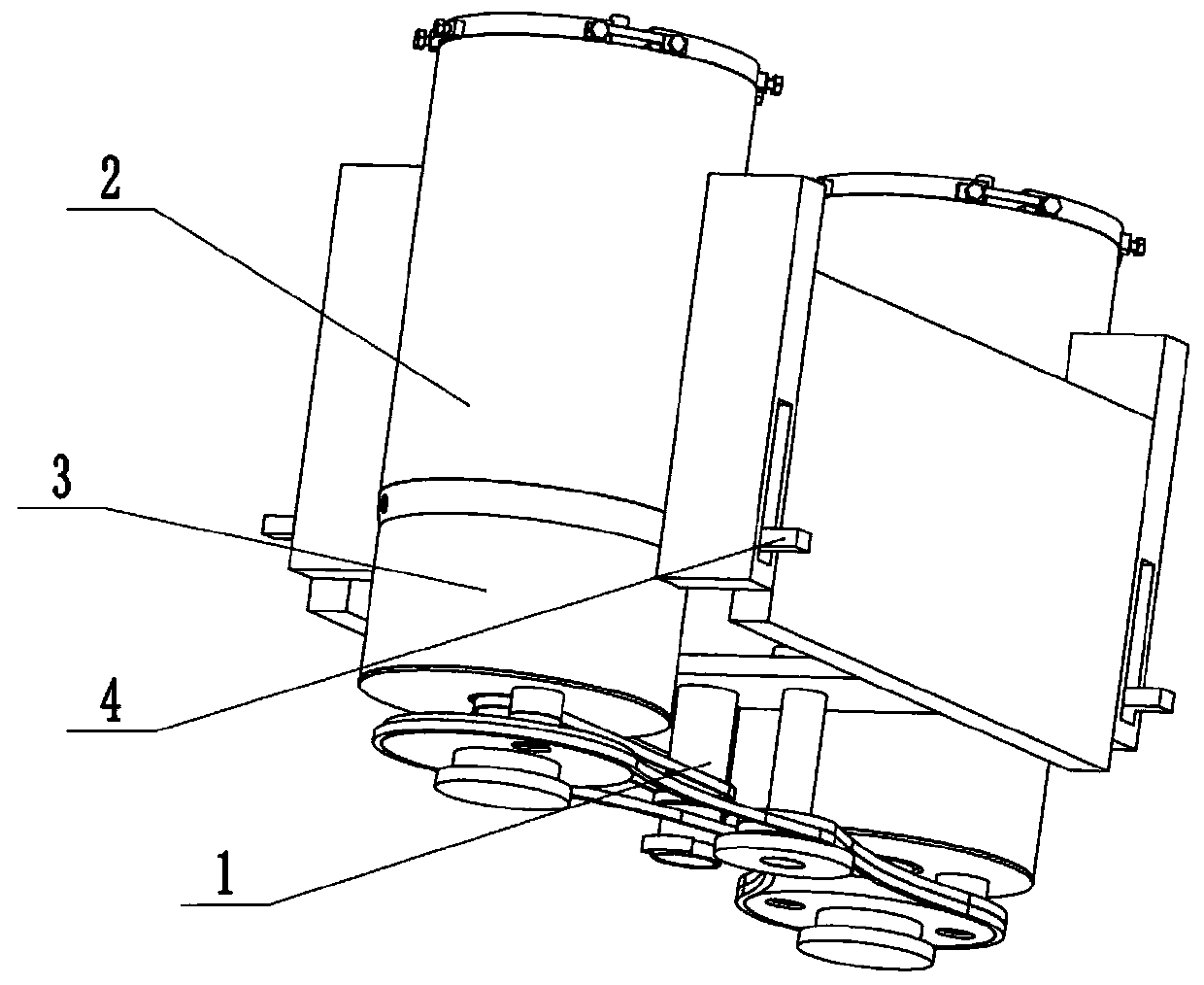

[0039] Such as Figure 1 to Figure 14 As shown, an intelligent preparation system for plastic color masterbatch includes a drive frame 1, two collection processing cylinders 2, two condensate tanks 3, four manual material guide valves 4, four mixing agitators 5 and four Combining the extruder 6, the drive frame 1 is fixedly connected between the two collection processing cylinders 2, the drive frame 1 is rotatably connected in the two collection processing cylinders 2, and the two condensed water tanks 3 are respectively fixedly connected in the The lower ends of the two collective processing cylinders 2 and the upper end of the collective processing cylinder 2 are slidingly connected to two hand-operated material guide valves 4, and the collective processing cylinder 2 is pinched and slidably connected to two mixing agitators 5 and two combined molding extruders 6, and combined molding The extruder 6 is clearance fit in the condensed water tank 3 . According to the raw mater...

specific Embodiment approach 2

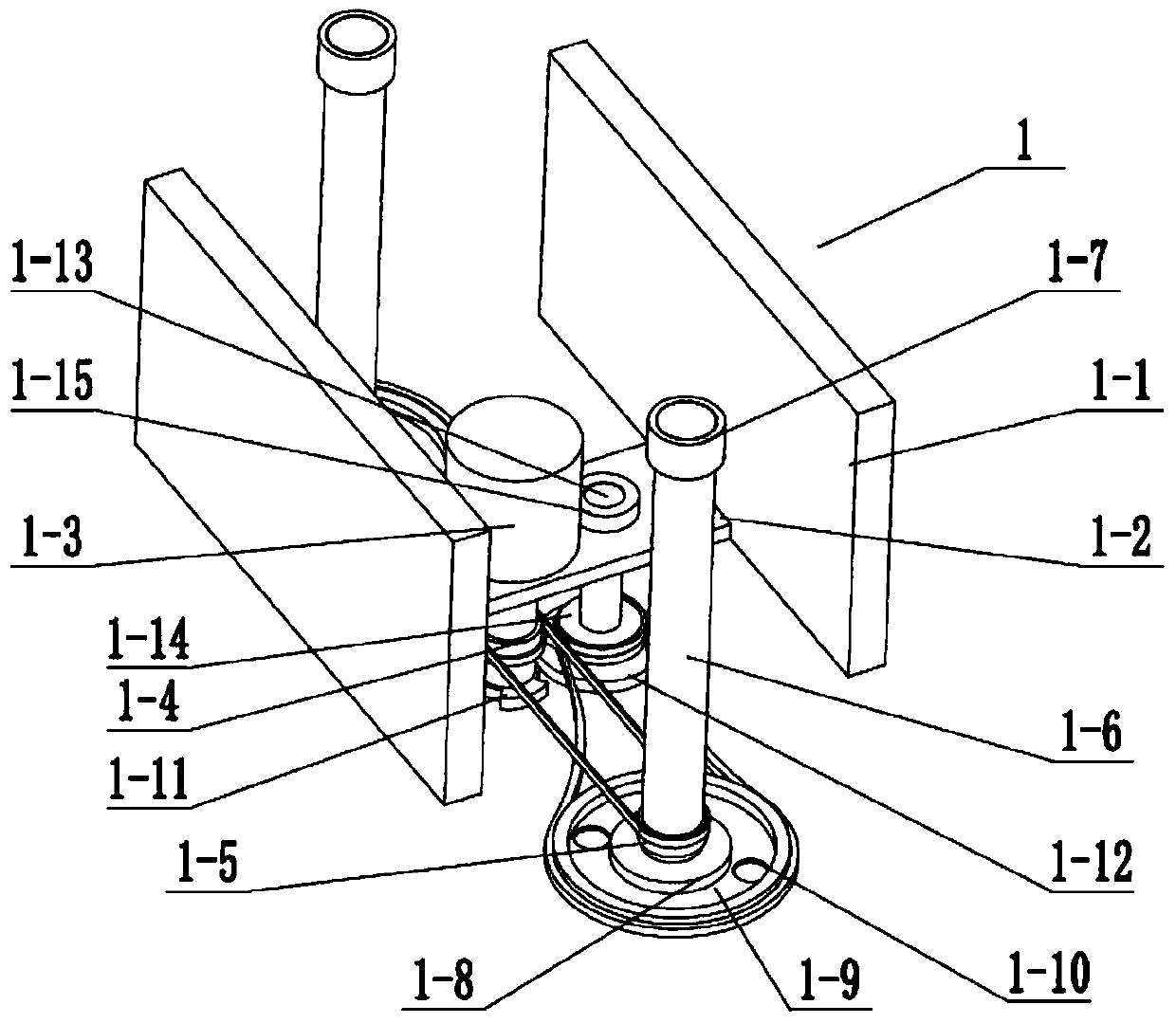

[0041] Such as Figure 1 to Figure 14 As shown, this embodiment will further explain Embodiment 1. The drive frame 1 includes two fixed connection frames 1-1, a motor fixing plate 1-2, a drive motor 1-3, and a double-layer drive pulley 1-4. , two slave pulleys 1-5, two central shafts 1-6, two central gears 1-7, two extruding wheels 1-8, inner ring grooves 1-9 and forming discharge holes 1-10, The two fixed connecting frames 1-1 are fixedly connected between the two assembly processing cylinders 2, the motor fixing plate 1-2 is fixedly connected between the two fixed connecting frames 1-1, and the drive motor 1-3 is fixedly connected to the motor On the fixed plate 1-2, the double-layer drive pulley 1-4 is fixedly connected on the drive shaft of the drive motor 1-3, and the double-layer drive pulley 1-4 is connected to two slave pulleys 1-5 by belt transmission, and two slave pulleys 1-5 are respectively fixedly connected to the two central rotating shafts 1-6, the two central...

specific Embodiment approach 3

[0044] Such as Figure 1 to Figure 14 As shown, this embodiment further explains the second embodiment. The collective processing cylinder 2 includes a processing cylinder 2-1, two operating tables 2-2, two operating sliding grooves 2-3, an upper end cover 2- 4. Four limit chutes 2-5, uniform four-space partition seat 2-6, four limit gear grooves 2-7, two lower limit slide plates 2-8, two lower limit chutes 2-9, The two hand-operated valves are connected to the sliding groove 2-10 and the central rotating circular groove 2-11, and the outer wall of the processing cylinder 2-1 is evenly and fixedly connected to the two operating tables 2-2, and the fixed connecting frame 1-1 is fixedly connected to the operating table 2-2, the outer walls of the two operating tables 2-2 are respectively provided with two operating sliding grooves 2-3, the upper end cover 2-4 is fixedly connected to the upper end of the processing cylinder 2-1, and the upper end cover 2-4 Four limit chutes 2-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com