Automatic ultrasonic cleaning process of feeding container

An automatic cleaning and ultrasonic technology, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of cleaning the feeding container, and achieve the effect of avoiding scrubbing or secondary cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] An ultrasonic automatic cleaning process for a feeding container of the present invention comprises the following steps:

[0020] Step 1. Put the crucible into the hydrochloric acid solution for pickling for 90-120 minutes;

[0021] Step 2, put the crucible pickled in step 1 into sodium hydroxide solution for alkali washing for 8-10 minutes;

[0022] Step 3. The crucible washed with alkali in Step 2 is washed with water for 8-10 minutes.

[0023] During the pickling in the first step and the alkali washing in the second step, ultrasonic waves with a certain power are passed into the acid solution and the alkali solution.

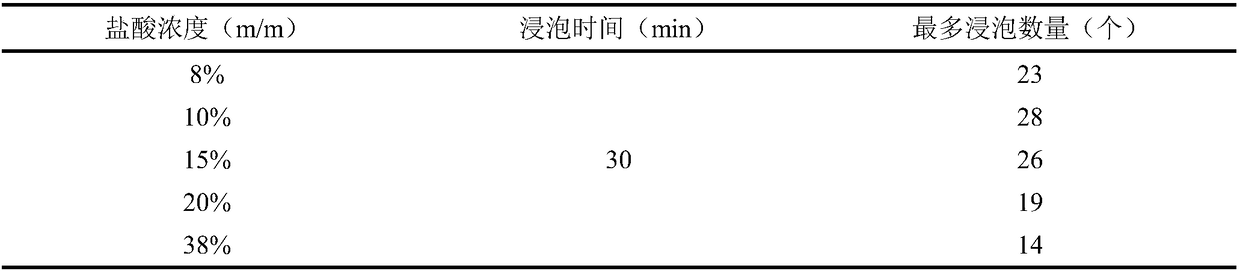

[0024] (1) Determination of ultrasonic power:

[0025] The ultrasonic power directly affects the cleaning effect. When the liquid level of the cleaning tank is lower than 400mm, the ultrasonic power density should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com