Double seat valve

A double-seat valve and valve seat technology, which is applied in the direction of lifting valves, valve devices, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

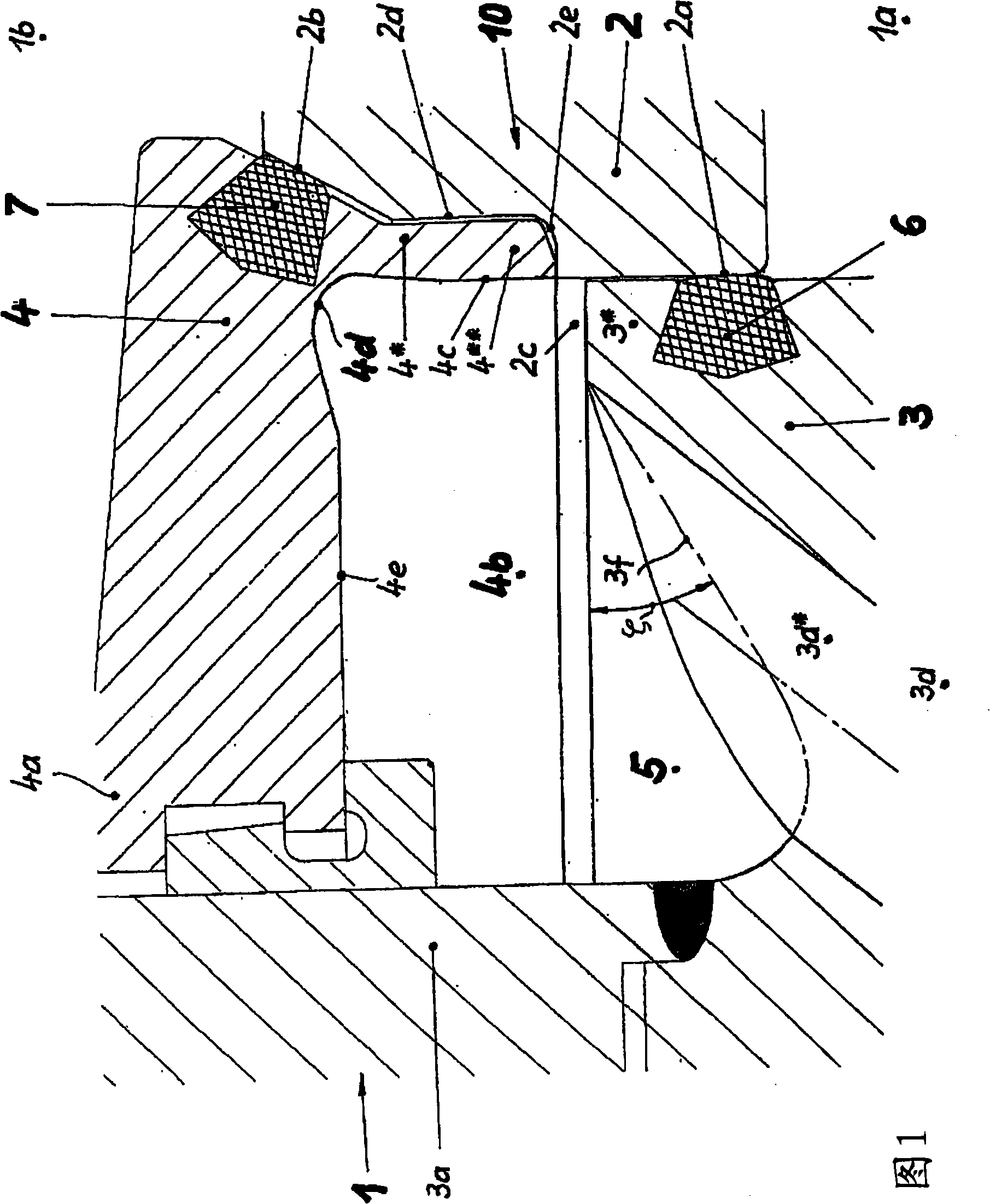

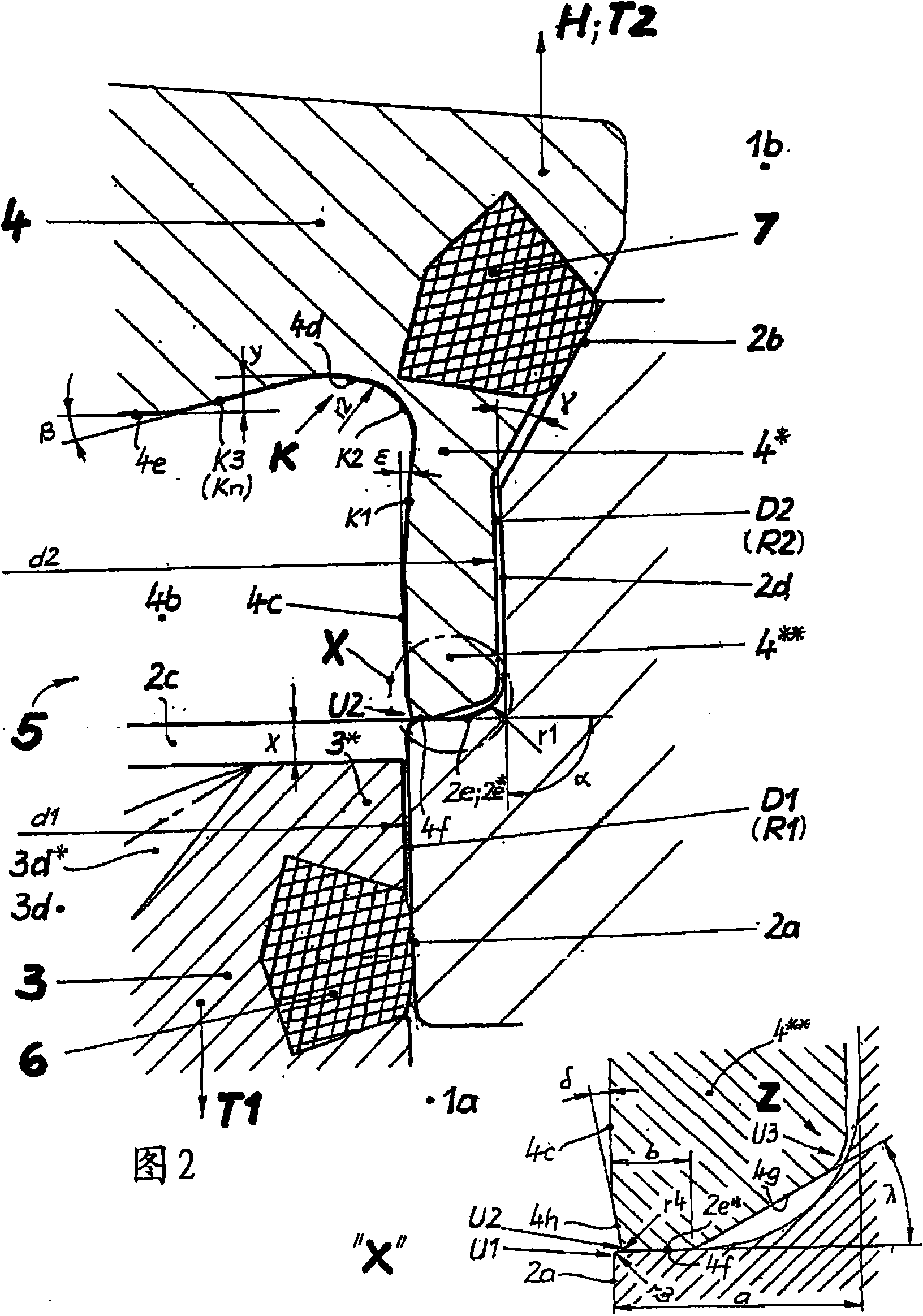

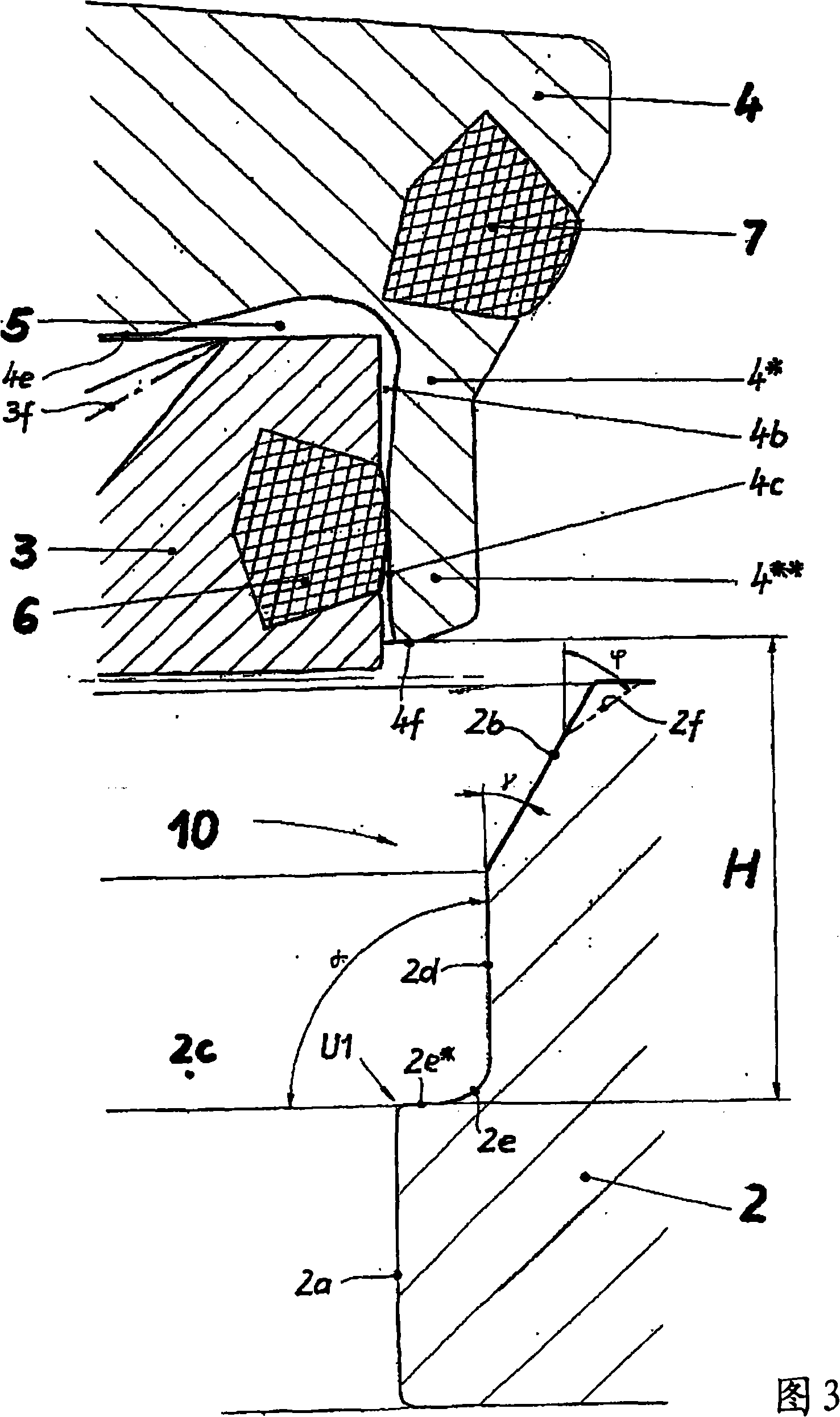

[0048] The double-seat valve 1 according to the invention (FIG. 1) basically comprises a valve chamber 10 with a first and a second valve chamber part 1a or 1b, two independently movable relative to each other with respectively assigned travel rods 3a or 4a The closing parts 3 and 4 and a valve seat ring 2, the valve seat ring establishes communication between the valve chamber parts 1a, 1b through a communication opening 2c on the inside.

[0049] In the closed position of the double-seat valve 1, the first closing part 3 (active closing part), which is designed as a sliding piston, is accommodated sealingly in a first seat surface 2a formed by the communication opening 2c, which is configured as Cylindrical seating surface. For this purpose, a first sealing ring 6 is arranged in the sliding piston 3 , which interacts with the first valve seat surface 2 a only by means of a radial offset (radial sealing ring in sliding engagement). In the closed position of the double-seat v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com