Gearing drive unit comprising an electronics interface

一种驱动单元、电子接口的技术,应用在电气元件、电动组件、与控制/驱动电路相连等方向,能够解决电子插头有限的变化、插入模块结构体积限制等问题,达到降低工具成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

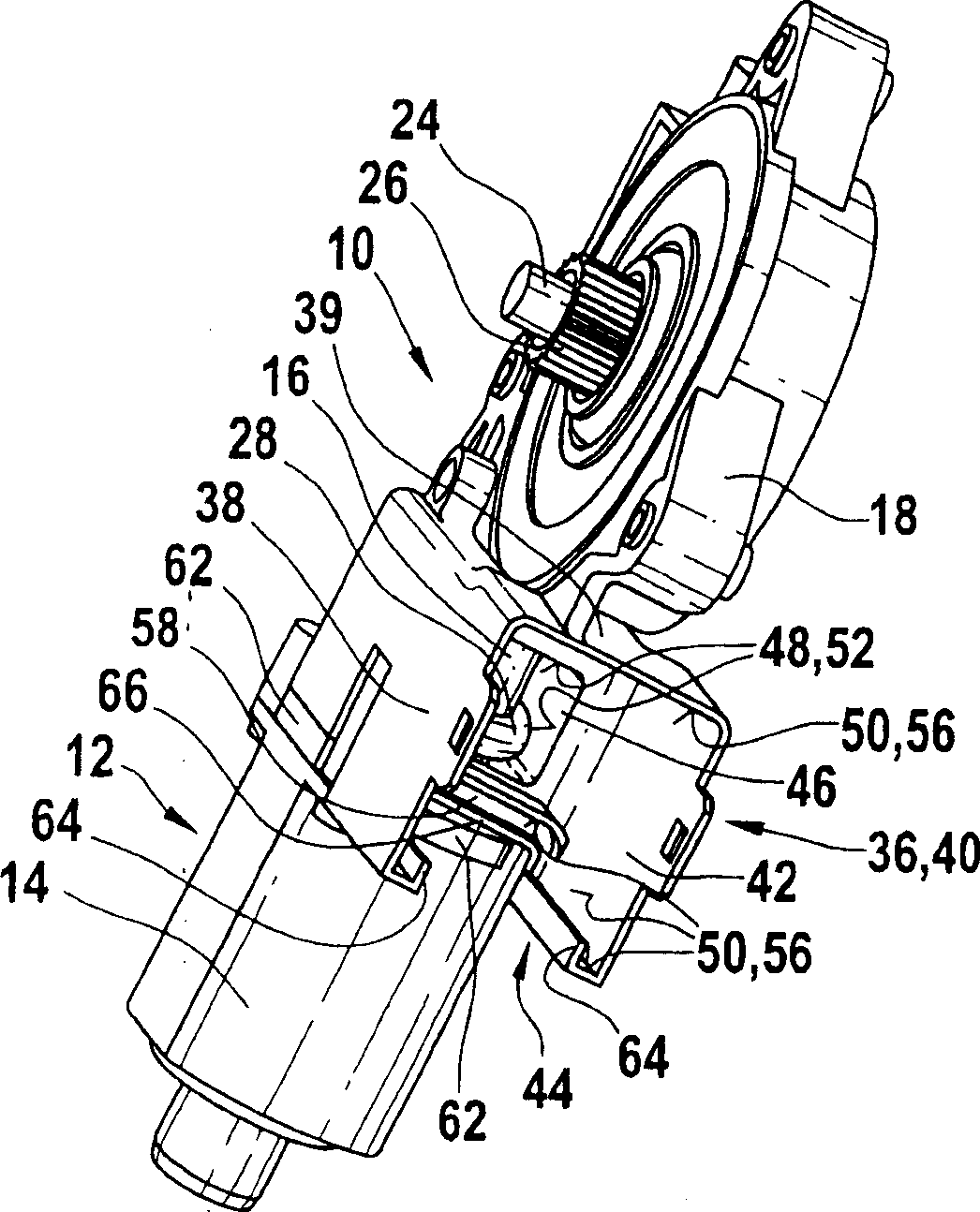

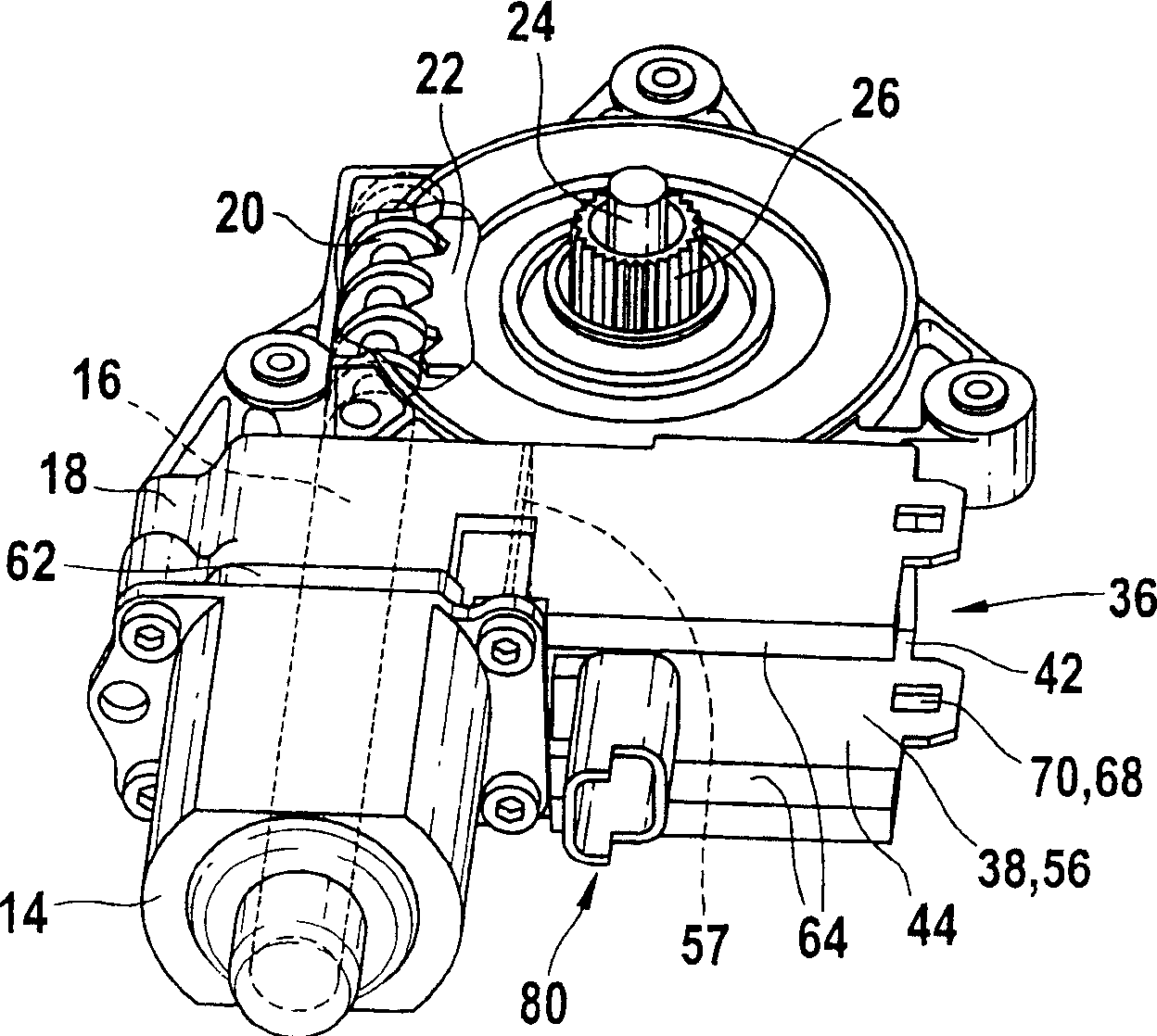

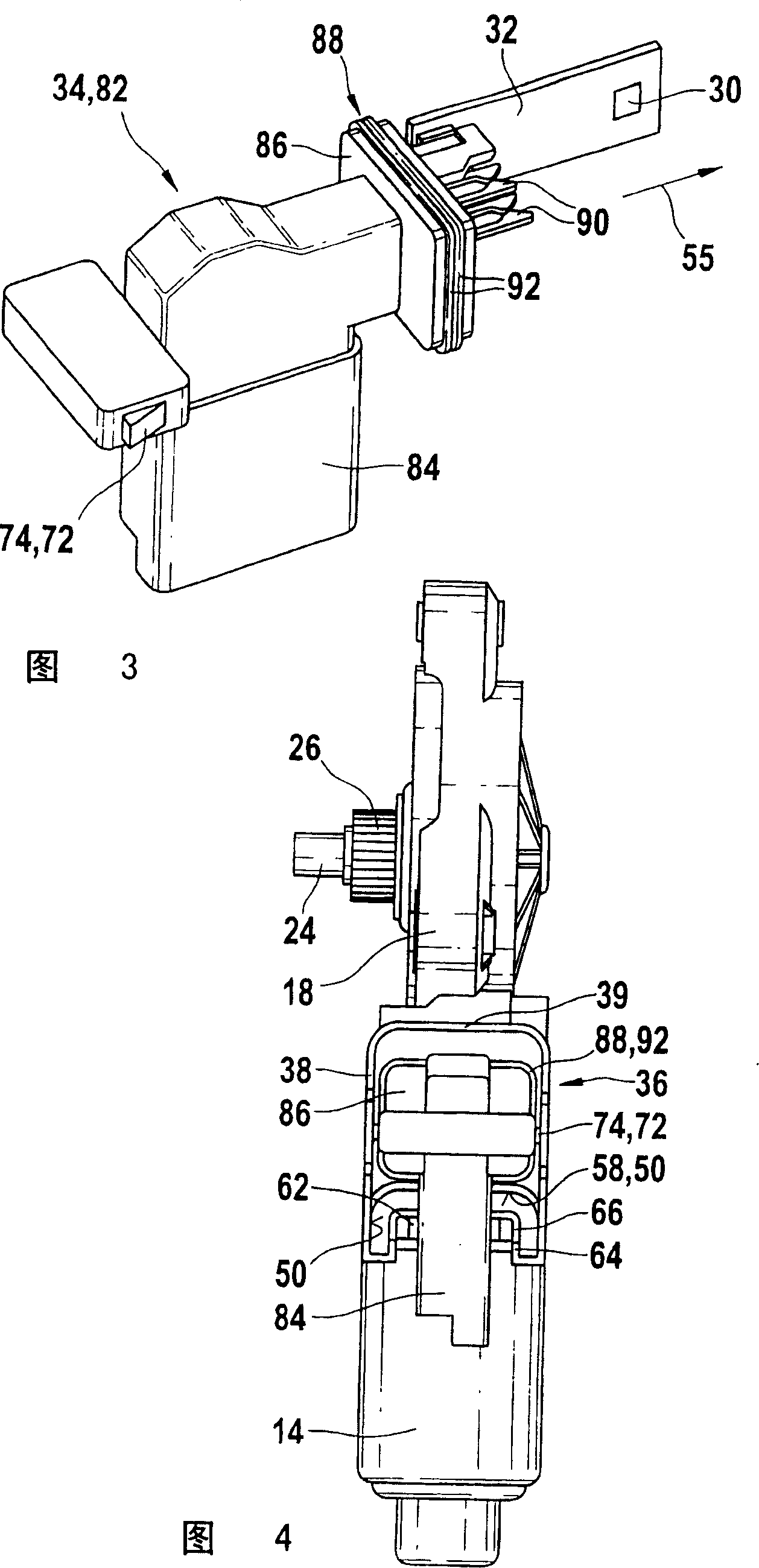

[0032] figure 1 It shows a speed reducer-drive unit 10 especially for a window regulator. The reducer-drive unit has an electric motor 12 housed in a pole shoe 14. The armature shaft 16 extends from the pole piece into the reducer case 18. A worm 20 is provided on the armature shaft 16, which meshes with the driven wheel 22, and transmits the force to an unshown window glass lifting mechanism through a transmission pinion 26 supported on the shaft 24 of the wheel . In order to detect the position of an adjustable part, a ring magnet 28 is provided, for example, on the armature shaft 16 in the area of the reduction gear box 18. The ring magnet interacts with the Hall sensor 30 arranged on a printed circuit board of an insert module 34, 82, 110. In order to insert the plug-in module 34, the reducer-drive unit 10 has an electronic interface 36 which is integrally formed with one of the casing parts 16, 18, in this case and a reducer case 18 by means of a die-casting method. The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com