Sheet material multistation stamping automated feeding feed equipment capable of being assembled in finite space

A technology of automatic feeding and limited space, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low production efficiency, large space occupation, poor specificity, etc., and achieve high work efficiency, rapid action, and fast response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

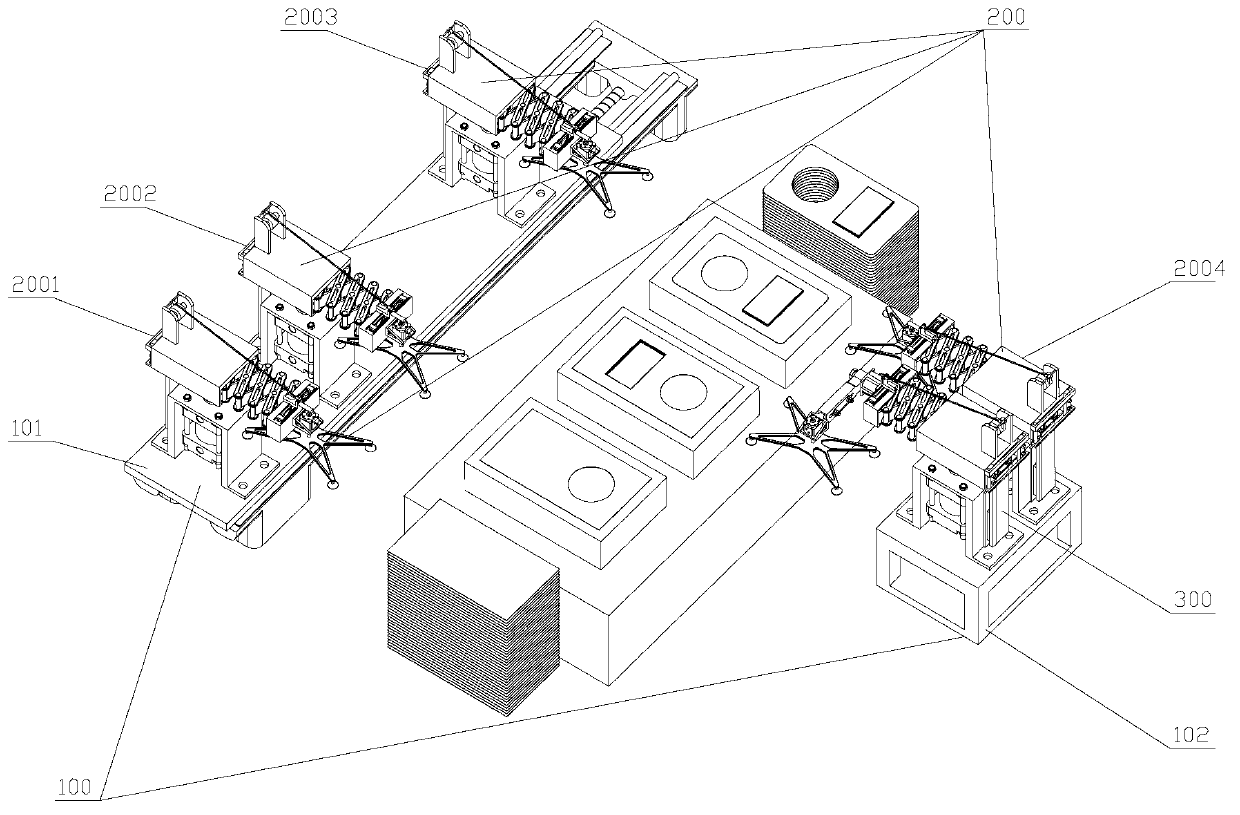

[0027] control figure 1 , can be assembled limited space sheet metal multi-station stamping automatic feeding feeding equipment, by the machine base 100, telescopic manipulator unit 200 and swing telescopic manipulator unit 300;

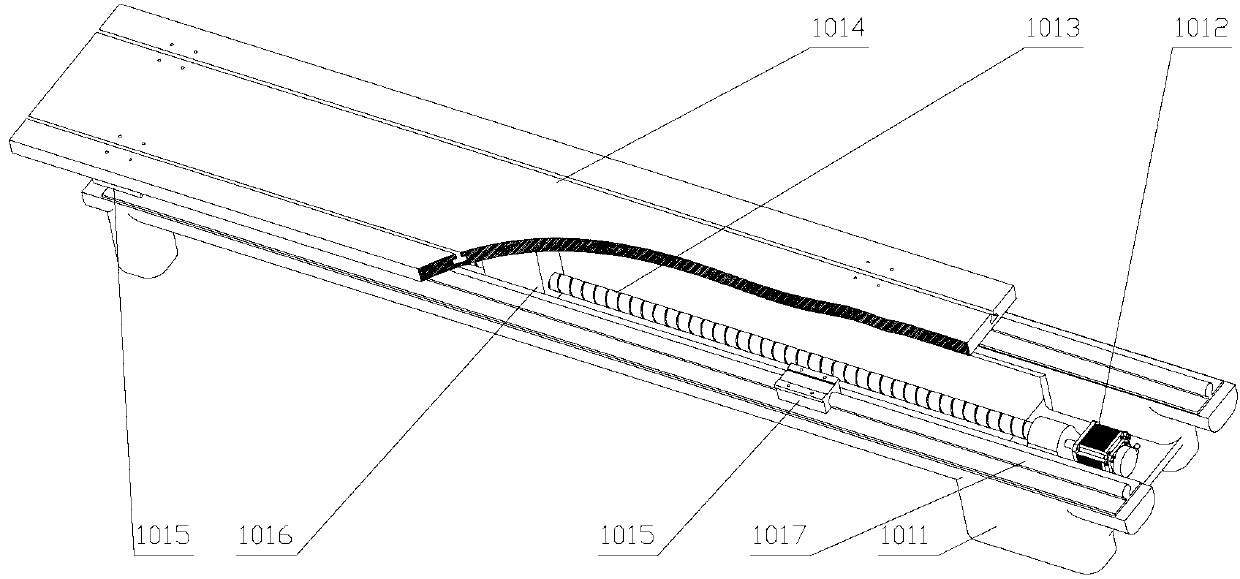

[0028] control image 3 , the feed base 101 adopts the screw feeding method, which consists of a bracket 1011, a motor 1012, a screw 1013, a screw slider 1016, a third linear guide rail 1017, four third linear guide rail sliders 1015 and a slider The motor 1012 transmits the torque to the lead screw 1013, and then through the cooperation of the lead screw 1013 and the lead screw slider 1016, the rotational motion of the lead screw 1013 is converted into the linear motion of the sliding table 1014, and the linear motion of the sliding table 1014 Guided by the third linear guide rail 1017 installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com